|

Engine Build Philosophy: Port Size vs Application

#2415380

Engine Build Philosophy: Port Size vs Application

#2415380

12/08/17 07:52 PM

12/08/17 07:52 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

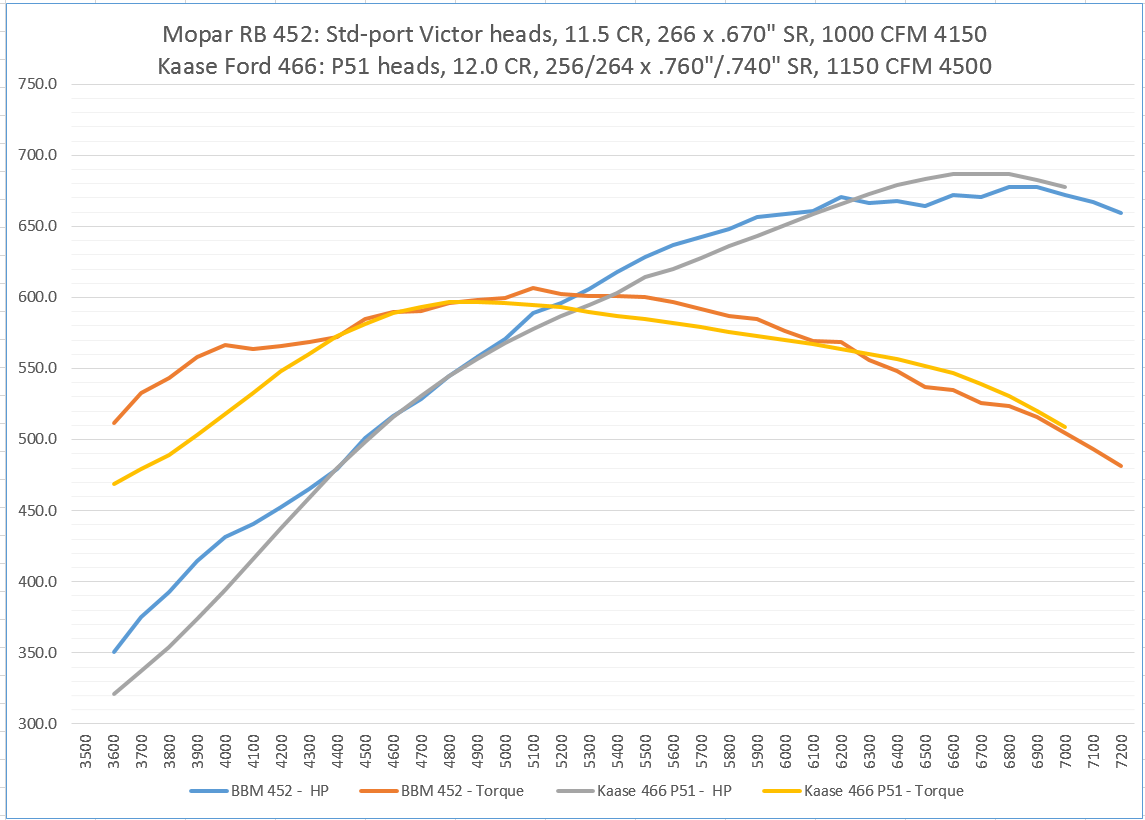

>> OK, THIS IS WHAT HAPPENS WHEN WORK IS REALLY SLOW AND I HAVE TOO MANY STOOPID IDEAS RUNNING THRU MY HEAD << Let's suspend reality for the moment and proceed under the assumption that the dyno results from three (3) different dynos referenced below can be compared without needing to apply "fudge factors". What I'm trying to cover here is not intended to be based on the absolute #s, but point out the trends and findings that I believe can be gleaned from the information. Also, it's NOT a way to bad-mouth OR praise one selection of parts over another, but to highlight the design implications of certain of parts choices. So, what's going thru my mind here? 1. Lower flowing heads with better velocity can peform as well as -- or better than -- higher flowing heads with less velocity... IF used with the appropriate application 2. Impressive flow #s won't help as much for limited-displacement applications that aren't able to take full advantage of the head's potential 3. It's a balancing act of optimizing what you have (or are required to use) and minimizing the compromises that go along with it 4. Be careful what you wish for 5. The numbers on the dyno may not translate to the numbers on the ET slip... or, at least, not the way you were expecting them to What got me thinking about this? 1. The recent dyno session of my new combination, which is a 452 RB w/ standard-port E Victor heads and my first time using a solid roller w/ a street/strip car 2. My review & analysis of the 2008 Mopar Muscle Engine Challenge where the engines were limited to stock-stroke 440-based builds, required to use Indy SR heads, and run on Rockett-brand 93 octane fuel. There was a wide range of outcomes as far as final parts combinations and dyno results, but I saw some of the same performance characteristics with almost all the builds. - http://www.hotrod.com/articles/mopp-0910-2008-amsoil-mopar-muscle-engine-challenge-wrapup and the invdividual articles that were written about each entry 3. An article I read about the Kaase P51 BBF heads for the 429-460 platform when these heads were introduced around 2007. That test used OOB P51 heads on a basic 460 performance rebuild w/ an aggressive -- although not especially big duration -- solid roller, and made close to 700 HP on pump gas and about 600 torque. - http://www.hotrod.com/articles/0707phr-p51-cylinder-heads/Keep in mind that my understanding is that all of these builds, irrespective of brand, were "supposed" to be targeted to what I'll call "real-world serious street/strip applications" that were expected to get by on pump fuel if required, although a blend of race fuel might be needed on track day. >> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415381

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415381

12/08/17 07:55 PM

12/08/17 07:55 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

General observations & opinions from 2008 Mopar Muscle Engine Challenge:

1. All the legit competitors in the 2008 Mopar Muscle Engine Challenge used MW-sized ported versions of the spec Indy SR head. Some started out using ICH's 295 CNC program and at least one used MCH's CNC program. It's probably fair to say those were at least 355+ CFM heads, depending upon any additional work done. Most used MW-sized single-plane intakes (ICH RB and Edelbrock Super Victor) and two entries used ICH's tunnel ram intake. The cams, when the specs were provided, ranged from 260 to 276+ at .050" and most builders used 1.7 rockers to get the lift well over .700".

2. The dyno tests were run from 3000 to 7000 RPM and, not unexpectedly IMO, every one of those MW-head 440s had a big freakin' dip in the torque curve around 4000 RPM. The engine with the smallest cam listed that also used one of the tunnel ram setups actually had one of the biggest holes in the torque curve. None of them hit their torque peaks below 5500+, and only one actually got close to, or exceeded, 600 lbs-ft. That was the 750+ HP ICH build with the offset heads, custom T&D rocker setup, and a 276/280 at .050" cam. Yeah, it was the HP and torque King, but peak torque was almost 6000 RPM and it probably hadn't even maxed out on HP at the 7000 limit from the look of the dyno chart (still climbing).

3. One of the single-plane Dominator combinations made about 735 HP at 7000, 585 torque at 5500 and, oh yeah, they didn't provide their cam specs. Im' guessing... pretty bleepin' big. A more "mild" single-plane Dominator combination made almost 700 HP, but only 560-something torque at around 5600, and used a 270/280-ish at .050" cam.

Anybody see the obvious (to me, at least) pattern?

- 450-ish cubes

- Octane-limited CR

- MW ports

- Big dips in the torque curves right at the bottom of the range of where I'd expect a typical street/strip 440 needs the converter to stall

- Big HP at high RPM at the expense of the rest of the torque curve

>> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415384

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415384

12/08/17 07:58 PM

12/08/17 07:58 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

What about the Kaase P51 466?

IMO, P51s are way better heads than any of the Indy-headed combinations in the MM Challenge: Kaase claims almost 400 CFM OOB, has a more oval-shaped intake port that is better for the velocity gradient in the port and results in less fuel drop-out, definitely has a better chamber design w/ canted valves, and the chamber's more centrally-located over the bore to reduce shrouding. This design is also more detonation-resistent, since the P51 build has 12.0:1 CR and was still able to pull solid #s on "real" pump gas.

Kaase stuffed an aggressive (not really "streetable" lobes IMO) 256/262 at 0.050" x 0.761"/0.743" roller in it and put an Edelbrock Victor with an 1150 CFM 4500-series carb on it. The cool stuff is that it made almost the same HP and torque on pump swill as it did on 100 oct race fuel, and it made 597 lbs-ft at only 4900 RPM and 687 HP at 6700 RPM on pump. And there was no "hole" in the torque curve across the 3000 to 7000 RPM dyno pull.

Sooo... going back to my opening statement "Let's suspend reality for the moment and proceed under the assumption that the dyno results from three (3) different dynos... can be compared", then consider why my 11.5:1, "small-block sized" standard-port 350 CFM head, 266 at .050" x .670" endurance-type solid roller, 4150-carbed RB 452:

- Had a broader torque curve than everything above except the Kaase 466, and out-grunted the Kaase 466 below 4000

- Made more torque than everything except the insane ICH 750+ HP combination

- Had a torque peak at a lower RPM than everthing except the Kaase 466, about 500 RPM lower than any MW-head combination in the MM Engine Challenge

- Made comparable HP to the Kaase 466 when used w/ the 2" spacer, and was less than 10 HP down with a 1" spacer... and this was testing 1.52" v downleg and 1.59" v annular 4150 carbs, rather than a Dominator

- Actually idles well at 1200 RPM and won't eat valve springs in the first 1000 miles on the street

- Can get away with a dual-purpose 4500-stall converter, even though it would probably 60-ft better with a 5000+ stall

FWIW, the Kaase 466 was tested at Westech in CA, the MM Engine Challenge was held at COMP Cams in TN, and my results came from dyno testing w/ Porter Racing Heads in VT. I know that the results from that dyno in Vermont correlate quite accurately to the in-car results, so I have faith in at least one of them.

>> NEXT >>

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415390

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415390

12/08/17 08:13 PM

12/08/17 08:13 PM

|

Joined: Feb 2005

Posts: 20,160

PA.

pittsburghracer

"Little"John

|

"Little"John

Joined: Feb 2005

Posts: 20,160

PA.

|

I have nothing to add. Lol

1970 Duster

Edelbrock headed 408

5.984@112.52

422 Indy headed small block

5.982@112.56 mph

9.42@138.27

Livin and lovin life one day at a time

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2415435

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2415435

12/08/17 09:48 PM

12/08/17 09:48 PM

|

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

|

As Andy pointed out, engine dyno tests are not always a good indication on how those motors will perform in the car  The torque converter, exhaust system and every other part on the car contributes to the in car feelings  One of my old pump gas Duster(that I traded to 9second Phil) with a mild 360 motor and 4 speed ran mid 14.40 at LACR with 3.55 gears and slicks, we swap the third member to a set of 4.89 and the car felt way faster on the street, at the track it might have pickup .2 ET and maybe 1/2 MPH   My other bracket Duster picked up .8 ET and 7 MPH by changing the carb. from 600 DP on a Eddy TM7 intake to a 1050 Holley Dominator carb. and Mopar M1 4500 single plane intake manifold with no other changes  Theory is one thing , real world results are different  I should add, put that motor in the car and go drive it and flog that rascal a bunch   Have fun

Last edited by Cab_Burge; 12/08/17 09:49 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415645

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415645

12/09/17 10:57 AM

12/09/17 10:57 AM

|

Joined: Jan 2003

Posts: 9,986

Frostbitefalls MN (Rocky&Bullw...

gregsdart

master

|

master

Joined: Jan 2003

Posts: 9,986

Frostbitefalls MN (Rocky&Bullw...

|

Picking a cylinder head based on the rpm range of the lower half of each gear makes the most sense to me, which falls right in line with what you are pointing to, Brad. Once another car has a length on you out of the gate, it takes a big top end charge to overcome it, if you even can!

8..603 156 mph best, 2905 lbs 549, indy 572-13, alky

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415697

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415697

12/09/17 01:06 PM

12/09/17 01:06 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

[quote=BradH So, what's going thru my mind here? 1. Lower flowing heads with better velocity can peform as well as -- or better than -- higher flowing heads with less velocity... IF used with the appropriate application Here's where you can get tripped up---higher flow equals higher velocity. You need to look at discharge co-efficient for a better view.2. Impressive flow #s won't help as much for limited-displacement applications that aren't able to take full advantage of the head's potential Of course not. A more accurate statement would be RPM limited3. It's a balancing act of optimizing what you have (or are required to use) and minimizing the compromises that go along with it 100% agree4. Be careful what you wish for Don't fall into the bigger is better trap5. The numbers on the dyno may not translate to the numbers on the ET slip... or, at least, not the way you were expecting them to See #4What got me thinking about this? 1. The recent dyno session of my new combination, which is a 452 RB w/ standard-port E Victor heads and my first time using a solid roller w/ a street/strip car 2. My review & analysis of the 2008 Mopar Muscle Engine Challenge where the engines were limited to stock-stroke 440-based builds, required to use Indy SR heads, and run on Rockett-brand 93 octane fuel. There was a wide range of outcomes as far as final parts combinations and dyno results, but I saw some of the same performance characteristics with almost all the builds. - http://www.hotrod.com/articles/mopp-0910-2008-amsoil-mopar-muscle-engine-challenge-wrapup and the invdividual articles that were written about each entry 3. An article I read about the Kaase P51 BBF heads for the 429-460 platform when these heads were introduced around 2007. That test used OOB P51 heads on a basic 460 performance rebuild w/ an aggressive -- although not especially big duration -- solid roller, and made close to 700 HP on pump gas and about 600 torque. - http://www.hotrod.com/articles/0707phr-p51-cylinder-heads/Keep in mind that my understanding is that all of these builds, irrespective of brand, were "supposed" to be targeted to what I'll call "real-world serious street/strip applications" that were expected to get by on pump fuel if required, although a blend of race fuel might be needed on track day. >> NEXT >> J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415702

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415702

12/09/17 01:17 PM

12/09/17 01:17 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

A few of my own thoughts.

Kaase's P51 heads are excellent and not just because of the flow. They don't flow anywhere near 400 unless you test @ 10" and convert up. However the flow @ .400" is remarkable--I believe 325-330 cfm IIRC. It is the chamber and how it is positioned (which you pointed out) which belies its true flow capability. What is baffling about them is the massive stall they suffer from @ .550" and up. I've tested 3 different sets and they all exhibit the same trend. Is there something more to this?

Those curves you put up are all indicative of a large port volume AND the wrong header design. My 2013 466 Pro-comp Victor deal had the same trend until we added something like 24" of collector with a .5" reduction in diameter along the way. This knocked out most of that dip. However this is pretty much a Band-Aid to a high flow port that is too large for the application. Min CSA of these heads were exactly 3.125" as calculated by Solidworks.

Learning from this I used a 2.85" CSA on my 2014 EMC 439.9 ci (440) effort. These Victors were dowel shifted, angle milled, guides moved in X and Y and angle changed. Flow was 353 cf. with a 2.19" valve. Torque was impressive 535 tq @ 3000, off the brake zero dip was observed and a peak of 630 was observed. If I could do it again I would make the port even smaller. That engine was easily 100pts better than my 2013 effort. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415708

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2415708

12/09/17 01:43 PM

12/09/17 01:43 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

After my 2016 EMC build 469 ci SPEC build using RPM heads I have determined some eye opening results. The SPEC rules that year mandated the use of Edelbrocks RPM heads and no welding or epoxy whatsoever was allowed so this limited us to a stock offset rocker. We were also required to use the stem size and head diameter of the valves that Edelbrock states. This meant 2.14/1.81" and that was it. The cylinder heads were ported hastily and a peak of 298-299 cfm was my first and last result--meaning I didn't agonize at all--they were what they were and that is all. I made a best of 592 ft/lbs @ 3500 rpm ZERO dip and 653 ft/lbs @ 4800 rpm with 680 hp @ 6100-6300 rpm IIRC. This build really makes me question the Victors when used with a standard port opening, I mean if you are required to use a big .650" offset rocker then why the heck would you NOT open the port to gain more CSA?

What this means to me is--On your engine Brad, the Victors are a waste. You could have gotten where you are with regular old RPM,s. I've said it before and I'll say it again--I don't know why Edelbrock would even offer them in a standard port. IMO selecting standard port Victors and not targeting BIG power--800-900HP is a dichotomy. Victors should be used only by masochists and those that are hoping for well into the 800+hp range. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415721

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2415721

12/09/17 02:21 PM

12/09/17 02:21 PM

|

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

|

IMO, if you replaced Brads Victor heads with a set of 300cfm RPM heads, milled for equal compression, and left everything else the same, the motor would have made way less power.

Additionally, in "engine contest" trim, there would certainly be some more power available from that combo.

More aggressive cam, more rigid rocker arms, ported intake manifold, gas ported pistons, lower tension ring pack, 4500 carb on an HVH SS/adapter...... It easily would have made solidly over 700hp.

When the RPM heads first came out I built a 448 that was very comparable to Brads 452(same cr, similar cam).

I ported the heads to flow in the 300cfm range, and tested them on the motor with a few different intake and carb combos.

At that point, the best intake/carb combo i tried was the Weiand TR with 2 x 650 Demon carbs on it. That made around 595tq and not quite 640hp.

The next closest single carb test was around 625hp, with a similar drop in tq.

Brads Victor combo made 684hp/605tq with an old school HP950 Holley on it(1.375 venturi), which resulted in the motor using 20cfm less air than when the bigger carbs were being run.

Had the bigger carbs been better optimized for the motor, I have to believe some benefit could have been gleaned from that extra 20cfm of air.

With the current crop of std port offerings available, for me the real litmus test would be how much difference in power there would be if you pulled the Victors off Brads motor and plopped a set of ootb TF240's on it.

If it made within 10-15hp of the Victors, then that would be a good argument against the viability of the std port version of those heads, at least at that power level.

It would be a fun test.

The nuts and bolts of this particular test is that Brad replaced his ported std port Stage 6's and flat tappet cam with the std port Victors and a roller cam and picked up 20ft/lbs and 60hp.

There are a few things I don't really care for in how the Victors are made, but I'd say the biggest "problem" with the std port version for me is the they are cast with the bowls .300 smaller in diameter than they should be.

If they had the bowls sized correctly to begin with(sort of like the original version was), then I would feel better about recommending them for the hot street applications where a high flowing std port head can work.

As they are now though, they're too labor intensive to be cost effective.

I wouldn't mind doing a "low effort" type job with some Pro Comp "Victors" at some point though(since those don't have the ridiculously undersized bowls).

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: mopar dave]

#2415742

Re: Engine Build Philosophy: Port Size vs Application

[Re: mopar dave]

#2415742

12/09/17 03:04 PM

12/09/17 03:04 PM

|

Joined: Jul 2004

Posts: 19,317

State of confusion

Thumperdart

I Live Here

|

I Live Here

Joined: Jul 2004

Posts: 19,317

State of confusion

|

I agree on the velocity thing 100%. Hughes Engines used to advertise their head porting that way yrs back. Dom uses ported Rpm heads on a 470 and i use E MW heads on a 511. Doms engine makes more power than my 511. Compression is not much different between the 2. I think my 511 combo may make more power with RPM heads. Mine may be considered max ported base on Pettis and George Koopals opinions but no flow #`s since I was in a hurry to assemble and the flow bench was tied up. I know that on a chassis dyno years ago it was still makin power to 7000 where I stopped and went home and on the street, it's a beast to me anyhow w/a new best hopefully very soon..........I plan on a max wedge build next year and a bigger cam..............

72 Dart 470 n/a BB stroker street car `THUMPER`...Check me out on FB Dominic Thumper for videos and lots of carb pics......760-900-3895.....

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2415756

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2415756

12/09/17 03:51 PM

12/09/17 03:51 PM

|

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

|

My first 400 block stroker motor made 612 HP at 5500 RPM and 644 Ft. lbs. torque at 4500 RPM, that was with 9.25 to 1 compression using a set of mildly ported 906 heads (flowed 266 at 28.0 inches at .700 lift on Pettis 600 Super flow bench) with 2.14 intake and 1.81 ex. valves. Comp Cams solid roller custom ground for Benschoff racing (SP?) in WI. the testing was done on Vrbansic Bros. (Ontario, CA) DTS engine dyno in 2003 or 2004, CRS  We tested three different sets of six pack carbs and multiple air cleaners combination. the best results are posted where with the stock air cleaner base with no air cleaner and a set of the Holley mechanical carbs with stock jetting, the worst results where with a set of replacement Holley 1971 440 automatic carbs with stock jetting that bogged horribly when open but still made 605 HP at 5400 RPM  I put the motor in my Duster and took it to Woodburn drag strip in October of 2005 after we moved to Oregon, it ran a best of 10.69 at 124. MPH. I swapped the heads that winter to a set of MCH CNC ported Eddy RPM heads that flowed 319 CFM at .700 on MCH flow bench and flowed 310 CFM on Pettis bench at .700 lift with 28 inches of water on his Super Flow bench  Both sets of heads had 84 CC so the motor ended up having the same compression ratio and a different set of 1.6 rockers, I took the CAT 1.6 ratio rockers off(they where wearing the shafts out nmaking metal  ) and put a set of Harland sharp 1.65 ratio on the Eddy heads, those two changes ended up making the car go 10.49 at 126 MPH  I ended up changing a lot of other things on the motor including the cranks shaft increasing the stroke .050 to make the same pistons and rods end up with 10.29 to 1 compression ratio and increased the C.I. from 511 to 517, that change made the car go 10.30s ET at 127.+ MPH  The last change was going to a set of Indy SR M.W. size ports not CNC ported with a Indy 400-3 intake with a Wilson manifold 1.5 inch reversion spacer with a 19x3.0 inch air cleaner instead of the stock type six pack air cleaner with two K&N six pack elements on it. I ended up using several different Holley 1050 CFM Dominator carbs on the motor that ended up with a best ET of 9.993 at 134.+ MPH through the 3.0 inch exhaust with the 16x3.0 inch tall paper air cleaner element on using 91 octane non ethanol pump swill, the car weighed 3450 Lbs. with me in it. I had a lot of fun and learned a bunch from that car and different engine combinations  I did try a set of 440-1 heads with 2.25 intake valves that where CNC ported by MCH, on the DTS engine dyno in Klamath Falls OR they made 50 HP more on my Duster motor with the same compression ratio, those heads flowed 30 CFM more at .700 (370 CFM)than the SR heads did on the same bench  I would of loved to try a set of B1 heads that flowed over 400 CFM with that short block making less than 11.0 to 1 compression   My message is results on the dyno compared to at the track may or may not make what you think it should, go test that motor Brad in the car

Last edited by Cab_Burge; 12/09/17 03:55 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: jwb123]

#2415964

Re: Engine Build Philosophy: Port Size vs Application

[Re: jwb123]

#2415964

12/09/17 11:34 PM

12/09/17 11:34 PM

|

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

|

Where drivability (I define as off idle to <WOT) throttle torque is important (and for most dual purpose cars it's way more important than most will admit) having a slightly undersized higher velocity port will be more responsive and fun to drive. At the track and with the optimal gearing (critically important) a larger port will et quicker, though driving it around on the street it will feel more sluggish or will be far more dependent on stall/flash....which means pretty inefficient if only in terms of how it's mainly going to be used.

Brad do you have Steve Dulcich's hp/tq graph from his 2003 EM 470/Chapman or our own EM Stage VI high velocity/epoxied MW entry? I don't think those had much if/any perceivable dip, but 470's hit a little quicker and harder on a dyno than a 440 of the same peak power. I think a big part of the strategy for EM is the fixed rate of acceleration in 100R's/sec against WOT standardized testing. I think guys like Kaase and Bischoff figured out very early that tight lobe centers combined with early ICL's get the motors a harder dyno "hit" and perhaps help the combo carry momentum...like 'pedaling downhill' of sorts. in other words the gains in torque below the peak more than offset perhaps losing a couple up top, the motors are obviously much more "lift dependant" from peak torque to peak power because the durations have to be kept relatively short to achieve mid range velocity at the slower RPM/piston speeds.

On the street or at the strip with a high stall converter or a clutch that 3500-4000 won't have much bearing with the right converter, but velocity has a TON to do with responsiveness. My approach has always been on a big 500" motor it shouldn't need to be so converter dependent to get to the sweet spot, so I'm a huge fan of velocity. But of course my philosophy for dual purpose cars is more likened to a road-race shortblock with killer heads for the best (or near best) of both worlds. My 517 Chapman design was based a lot on what I learned from Steve's 470 motor and discussions with Dwayne and Dan Costello....and it's the flattest/broadest torque and fastest revving wedge I've ever built...by a mile.

Last edited by Streetwize; 12/11/17 11:52 PM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416054

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416054

12/10/17 03:19 AM

12/10/17 03:19 AM

|

Joined: Jun 2005

Posts: 793

Utah

topbrent

super stock

|

super stock

Joined: Jun 2005

Posts: 793

Utah

|

do you have Steve Dulcich's hp/tq graph from his 2003 EM 470/Chapman

... My 517 Chapman design was based a lot on what I learned from Steve's 470 motor and discussions with Dyanne and Dan Costello....and it's the flattest/broadest torque and fastest revving wedge I've ever built...by a mile. No dyno graph, but for those who are interested, here are some of the details of Steve's 470. Lots of clever techniques involved and some smart planning. Peak HP: 752@ 6,500 rpm Peak TQ: 641.9@ 5,500 rpm Avg. HP: 547 Avg. TQ: 598.8 Dulcich 470" 2003 Engine Masters info link a Dulcich 470 Engine Masters info link b .034-inch quench clearance, 12.7:1 Ohio Crankshaft forged steel 3.90-inch stroke TCI Rattler balancer 7.2" diameter Manley connecting rods Ross Pistons Harland Sharp 1.7 rockers Comp MM lobe Solid flat tappet cam 259@.050 single pattern 108 LSA - 102.5 intake centerline Indy 383-13 intake Tapered 4150-4500 HVH spacer adapter Barry Grant King Demon RS carb TTI 2"-2-1/8" step headers Chapman CNC Victor Heads, 285cc INTAKE VALVE EXHAUST VALVE 0.050 -36 cfm - 0.050 -30 cfm 0.100 -73 cfm - 0.100 -60 cfm 0.200 -148 cfm - 0.200 -107 cfm 0.300 -214 cfm - 0.300 -158 cfm 0.400 -270 cfm - 0.400 -210 cfm 0.500 -308 cfm - 0.500 -232 cfm 0.600 -332 cfm - 0.600 -250 cfm 0.700 -350 cfm - 0.700 -265 cfm 0.800 -385 cfm - 0.800 -278 cfm

Last edited by topbrent; 12/10/17 04:37 AM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: topbrent]

#2416124

Re: Engine Build Philosophy: Port Size vs Application

[Re: topbrent]

#2416124

12/10/17 12:34 PM

12/10/17 12:34 PM

|

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

|

Thanks Brent,

I see the flow numbers on the intakes are POST Tear-down for his EM 285CC heads, which are lower than his as new bench set in the magazine.

The Chapman 285s from Steves bench (Mopar Muscle May 2004 Issue) were:

.100---77

.200---151

.300---220

.400---283

.500---330

.600---364

.700---375

Dwayne (Fast68Plymouth) flowed my actual set of 285s for Moparts and they were pretty close to this, If I remember right (at the time ) he only used a 10" flowbench so the bigger (>.600 lifts) were maybe a little low compared to being measured on a 28". Here they are from the tech archives:

Lift" I/E

.100 72.5/58.2

.200 153.7/118.6

.300 224.3/178.2

.400 285.2/218.2

.500 329.6/232.8

.600 361.9/245.1

.650 368.1/249.9

.700 364/253.1

.750 364/254.7

.800 364/256.3

At the time we were commenting that although they flowed very close to a well ported set of -1's, they do so with a far smaller CC intake port, so they acheive the flows with much higher velocity (which for a street car equates to responsivenness and torque)

Last edited by Streetwize; 12/10/17 12:50 PM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2416126

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2416126

12/10/17 12:41 PM

12/10/17 12:41 PM

|

Joined: Jan 2003

Posts: 1,807

Mopar Country, Mi

ccdave

The Ultimate

|

The Ultimate

Joined: Jan 2003

Posts: 1,807

Mopar Country, Mi

|

After my 2016 EMC build 469 ci SPEC build using RPM heads I have determined some eye opening results. The SPEC rules that year mandated the use of Edelbrocks RPM heads and no welding or epoxy whatsoever was allowed so this limited us to a stock offset rocker. We were also required to use the stem size and head diameter of the valves that Edelbrock states. This meant 2.14/1.81" and that was it. The cylinder heads were ported hastily and a peak of 298-299 cfm was my first and last result--meaning I didn't agonize at all--they were what they were and that is all. I made a best of 592 ft/lbs @ 3500 rpm ZERO dip and 653 ft/lbs @ 4800 rpm with 680 hp @ 6100-6300 rpm IIRC. This build really makes me question the Victors when used with a standard port opening, I mean if you are required to use a big .650" offset rocker then why the heck would you NOT open the port to gain more CSA?

What this means to me is--On your engine Brad, the Victors are a waste. You could have gotten where you are with regular old RPM,s. I've said it before and I'll say it again--I don't know why Edelbrock would even offer them in a standard port. IMO selecting standard port Victors and not targeting BIG power--800-900HP is a dichotomy. Victors should be used only by masochists and those that are hoping for well into the 800+hp range. J.Rob I would not have used those springs with those rockers on that 2016 EMC build.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416131

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416131

12/10/17 12:53 PM

12/10/17 12:53 PM

|

crabman173

Unregistered

|

crabman173

Unregistered

|

In general most folks always opt for biggest port--highest flow numbers they can find and afford

That is exactly why AFR sells so many sets of ( chevy and ford )heads for about the highest price on the market Biggest valves--highest flow numbers

yet many engines that are built with them would be far better drivers and much more fun with smaller port runner volume

Folks always want a street car that runs like a dragster

They sell fake boobs but not man parts because guys would all have to push a wheel barrow to walk around

Head sales people know this simple fact and profit greatly from it

My conclusion is an easy to build cheapo 500CI big block with almost any head will make 570 HP easy as pie and be the most awesome fun most have ever had and often when combined with the right gear. converter/ intake/ carb combo out run many that sport much more HP and if it does not--WHO CARES? Because no matter how much HP you have or how much $$$ you throw at it thirty other guys can wax your behind so ??????????

If you want to go fast attend one of the dragster or funny car deals--pay a couple thou and on day two make a 200 MPH pass--then you are done for least amount possible

Last edited by crabman173; 12/10/17 03:23 PM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2416134

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2416134

12/10/17 12:56 PM

12/10/17 12:56 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

IMO, if you replaced Brads Victor heads with a set of 300cfm RPM heads, milled for equal compression, and left everything else the same, the motor would have made way less power. I don't think it would be much, but even if it was 40hp less than are the Victors really worth the ROI?

Additionally, in "engine contest" trim, there would certainly be some more power available from that combo.

More aggressive cam, more rigid rocker arms, ported intake manifold, gas ported pistons, lower tension ring pack, 4500 carb on an HVH SS/adapter...... It easily would have made solidly over 700hp. You bring up some good points here but using my 2016 469 I had 1.5 Comp rockers, no spacer, Holley 950 XP 4150, standard tension rings albeit .043" 3mm Total Seal AP's. Had I been allowed to use a spacer then yes I observed 696HP w 1 1/2" Wilson 4 hole, A 4500 would have undoubtedly yielded even more. Again I would ask just how much power are the Victors worth? 40, 50 hp?

When the RPM heads first came out I built a 448 that was very comparable to Brads 452(same cr, similar cam).

I ported the heads to flow in the 300cfm range, and tested them on the motor with a few different intake and carb combos.

At that point, the best intake/carb combo i tried was the Weiand TR with 2 x 650 Demon carbs on it. That made around 595tq and not quite 640hp.

The next closest single carb test was around 625hp, with a similar drop in tq.

Brads Victor combo made 684hp/605tq with an old school HP950 Holley on it(1.375 venturi), which resulted in the motor using 20cfm less air than when the bigger carbs were being run.

Had the bigger carbs been better optimized for the motor, I have to believe some benefit could have been gleaned from that extra 20cfm of air. You know yourself that moving more air but not making power with it is inefficiency. This is telling you that that carb is simply a better fuel mixer. I doubt you could ever turn that extra 20 cfm into power--there no way to trap it without getting into the cam timing events.

With the current crop of std port offerings available, for me the real litmus test would be how much difference in power there would be if you pulled the Victors off Brads motor and plopped a set of ootb TF240's on it.

If it made within 10-15hp of the Victors, then that would be a good argument against the viability of the std port version of those heads, at least at that power level.

It would be a fun test. It would be a cool test and I'm glad you brought up the TF240's. To me there are nothing more than a fully CNC'd RPM with a slightly nicer chamber. I will have an opportunity to work with them soon. Again--I will reiterate, The TF's cannot be any better than an RPM with the stock valve placement and stock rocker offset.

The nuts and bolts of this particular test is that Brad replaced his ported std port Stage 6's and flat tappet cam with the std port Victors and a roller cam and picked up 20ft/lbs and 60hp. I agree but this can easily be attributed to the roller cam swap. I have seen a 50+ gain with my own eyes, same engine/ same dyno 2 days. Also the Stage 6's could have easily been inferior to Victors that you and Brad ported with the knowledge you have gained over the years.

There are a few things I don't really care for in how the Victors are made, but I'd say the biggest "problem" with the std port version for me is the they are cast with the bowls .300 smaller in diameter than they should be.

If they had the bowls sized correctly to begin with(sort of like the original version was), then I would feel better about recommending them for the hot street applications where a high flowing std port head can work. Totally with you on this

As they are now though, they're too labor intensive to be cost effective. Nailed it again

Dwayne I think you and I are on the same page almost all of the time, however I don't think you realize just how underperforming the Victors really are. I don't want to de-rail this thread further with more of their shortcomings (install height, etc....) In short I view the RPM's especially the 75cc version, and TF 240 as the same in power potential. The only difference is the TF's come fully CNC'd. If Edelbrock was smart they would offer their 75cc version fully CNC'c with a GOOD design at the same price point as TF and with their marketing and distribution TF probably would not sell too many. Edelbrock could then market their NOW JUNK Victor line with revised valve locations and angles with only a large port version CNC'd for serious efforts and probably demolish Indy's sales. Sorry Brad, not meaning to derail your thread, the question you posed is a very viable one. A large port in this style of head CAN be crutched with headers, aggressive cam, increased static comp, wrong timing curve, etc..... However when these are missed a giant hole in the power curve often shows up. To sum up: How much more power are the standard port Victors worth over another standard port RPM or TF240? 100hp? nope, 75hp? nope, 50hp? probably not even. ROI @ less than 50hp? Not there for me. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: ccdave]

#2416135

Re: Engine Build Philosophy: Port Size vs Application

[Re: ccdave]

#2416135

12/10/17 12:57 PM

12/10/17 12:57 PM

|

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

|

I remember several years ago talking to David Vizard (who lives here in Charlotte) and one thing we both agree on is that Velocity AND Flow are critical to maximizing torque and horsepower, particularly when you consider the slight 'supercharging' or "packing' force that occurs when the intake valve is still open while the piston is coming back up the cylinder after passing BDC. If you still fill the hole as the swept volume is Decreasing...well that my friends is where the magic really happens in terms of high RPM power output. Too small or too low a velocity ports can't achieve this.

To me the ultimate street/strip BBW head might be the Chapman MW ports combined with the TF chamber and plug placement.

And of course "real world" torque is also as much dependent on intake flow as it is the port itself, To me looking at just the port is kinda moot, you have to consider the whole intake tract from the plenum to the valve, again too big is a low/mid torque/response killer, too small is a high RPM HP killer (choke point). But the intake alone has a huge impact on how a motor is going to hit on the dyno or on the street. The intake has to outflow the port or really the flowbench numbers for the port itself are kinda moot. And lets not even go into how the fuel mass in suspension passes through the port. at 12.5 A/F ratio on a 360 cfm port flow you are flowing roughly (air and fuel obviously have different flow cooefficients) a rate of 28.8 CFM of solid fuel (which displaces/subtracts from the same volume of bench Air flow). To me port flow in a poppet valve engine needs to be viewed as a Window (opening and shutting over a fixed time) which is the average sum/mean flow from all the effective lift points....peak flow is only one point of measure.

Sorry guys...my second cup of coffe was kicking in, don't mean to ramble!

Last edited by Streetwize; 12/10/17 01:28 PM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2416182

Re: Engine Build Philosophy: Port Size vs Application

[Re: AndyF]

#2416182

12/10/17 02:21 PM

12/10/17 02:21 PM

|

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

|

Sorry guys, I was just going by the thread title, I didn't think the discussion was limited to the merits of the Victor, or TF, or Chapmans or whatever...I didn't think anything I was saying or bringing up for consideration would be considered going "off topic"...was I???  Finding the neal ideal balance of flow (for power) and Velocity (for torque and drivability...at least in a dual purpose street/strip application) for a given displacement and weight/gearing....well that should always be the goal...right? for Drag racing it gets at least a bit simpler. BTW, Dom's 470 is definately one of the most impressive Eddy RPM combos I've ever seen or heard about, and he's probably getting about as much out of a set of them as there is to have for sure. Actually I was thinking (and judging from the caliber of respected participants) that this was one of the more interesting threads in the past several months.

Last edited by Streetwize; 12/10/17 02:51 PM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416238

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416238

12/10/17 03:31 PM

12/10/17 03:31 PM

|

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

|

Jesse, I guess we look at the Victors through different eyes. It seems like unless you take them “to the max”, and bolt them onto a similar type of short block, to get every last possible hp out of them, then they aren’t worth using. I see them differently. Again, “if” they had the bowls sized correctly(or using the Pro Comp head)it wouldn’t take any more time for me to port them into the 340cfm range than it would to port an RPM to 300. They aren’t that much more money, you get away from the valley pan gasket, and the chambers are better. If you bought TF240’s and used the recommended HS rockers for the TF heads, or something like T&D’s......then the cost difference of the rockers is diminished considerably. Like I said previously, the big hurdle in using them for me is the way the bowls are cast. One thing I do like about them is they are a true std port head. Not a MW head with a reduced port opening at the flange. If, in your words, flow is velocity......then at 350cfm from a true std port head.......they should be pretty good. IMO, if they made 30hp more than a set of CNC RPM heads on the same motor, same cam, same compression.......I’d be fine with that. I don’t feel like I need to make 800hp out of them to have them be worthwhile. With regards to Brads combo, there is no way the two cams used in his motor would be 50hp apart......with either set of heads. Maybe 1/2 that. As for whether or not his stage 6’s could have been improved today......that wasn’t really part of your original argument. You said your 298-299cfm RPM heads would have made the same power as the Victors. If that’s the case, then the Stage 6’s would also be just as good, since they flowed a little more than 300, and have a better chamber(although those heads required way more work to be made usable than the Victors). Also, at 350cfm @.700 Victors have a better discharge coefficient than the RPM’s at 300, or the TF’s at 325(what they flow on my bench). A 251cc MCH CNC ported RPM flows 315@.700 on my bench. If the flow doesn’t matter, and the c/d doesn’t make any difference........we might as well stop testing heads, since the numbers must not have any bearing on power output. Until someone does “the test”, it’s all just speculation. It’s easy.......don’t like ‘em? Don’t use ‘em.........plenty of other choices. As for the carbs.......couldn’t disagree more. I tried my HP950 on his motor as a point of reference to gauge how well the other carbs were doing their job. It’s by no means my best carb, yet was basically as good as the others we tried. I doubt you could ever turn that extra 20 cfm into power--there no way to trap it without getting into the cam timing events. You totally lost me here. By that logic I guess I could have put a 650 on it and made the same power with even less flow through the motor. I’m confident that had I run the motor with my ported annular 850(which flows about 40cfm more than the HP950) it would have made 8-10 more HP........and picked up most of the lost 20cfm.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416289

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416289

12/10/17 04:34 PM

12/10/17 04:34 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

Actually I was thinking (and judging from the caliber of respected participants) that this was one of the more interesting threads in the past several months. I feel the same way and because I have firsthand experience with this build numerous times I was sharing my thoughts on the whys and hows. Nothing more, nothing less. J.rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2416301

Re: Engine Build Philosophy: Port Size vs Application

[Re: fast68plymouth]

#2416301

12/10/17 04:52 PM

12/10/17 04:52 PM

|

Joined: Feb 2006

Posts: 1,051

The Great White North

RAMM

super stock

|

super stock

Joined: Feb 2006

Posts: 1,051

The Great White North

|

Jesse, I guess we look at the Victors through different eyes. It seems like unless you take them “to the max”, and bolt them onto a similar type of short block, to get every last possible hp out of them, then they aren’t worth using. AgreedI see them differently. Again, “if” they had the bowls sized correctly(or using the Pro Comp head)it wouldn’t take any more time for me to port them into the 340cfm range than it would to port an RPM to 300. But they aren't sized correctly so its another check mark in the Con column.They aren’t that much more money, you get away from the valley pan gasket, and the chambers are better. Chambers are no better. They still make best power @ 35-36 total timing. What makes you say this?If you bought TF240’s and used the recommended HS rockers for the TF heads, or something like T&D’s......then the cost difference of the rockers is diminished considerably. Like I said previously, the big hurdle in using them for me is the way the bowls are cast. One thing I do like about them is they are a true std port head. Not a MW head with a reduced port opening at the flange. If, in your words, flow is velocity......then at 350cfm from a true std port head.......they should be pretty good. IMO, if they made 30hp more than a set of CNC RPM heads on the same motor, same cam, same compression.......I’d be fine with that. I don’t feel like I need to make 800hp out of them to have them be worthwhile. If I can make 700hp from a far cheaper RPM casting then why would I expect the same power from a "better" cyl head?With regards to Brads combo, there is no way the two cams used in his motor would be 50hp apart......with either set of heads. Maybe 1/2 that. As for whether or not his stage 6’s could have been improved today......that wasn’t really part of your original argument. You said your 298-299cfm RPM heads would have made the same power as the Victors. I'm saying they couldIf that’s the case, then the Stage 6’s would also be just as good, since they flowed a little more than 300, and have a better chamber(although those heads required way more work to be made usable than the Victors). I have no input on the previous Stage 6's. What I was implying is that you would no doubt improve them if you were to use them again.Also, at 350cfm @.700 Victors have a better discharge coefficient than the RPM’s at 300, or the TF’s at 325(what they flow on my bench). A 251cc MCH CNC ported RPM flows 315@.700 on my bench. If the flow doesn’t matter, and the c/d doesn’t make any difference........we might as well stop testing heads, since the numbers must not have any bearing on power output. Never said anything of the sort.Until someone does “the test”, it’s all just speculation. It’s easy.......don’t like ‘em? Don’t use ‘em.........plenty of other choices. I won'tAs for the carbs.......couldn’t disagree more. I tried my HP950 on his motor as a point of reference to gauge how well the other carbs were doing their job. It’s by no means my best carb, yet was basically as good as the others we tried. I doubt you could ever turn that extra 20 cfm into power--there no way to trap it without getting into the cam timing events. You totally lost me here. By that logic I guess I could have put a 650 on it and made the same power with even less flow through the motor. You're putting words in my mouth and jumping to conclusions. I test a lot of DIRT 358's that mandate a 650 and everytime we try a larger carb it doesn't hardly ever yield more power--maybe 5 hp more with a big jump in CFM through the hat-these are on 570-580hp engines too. I look at manifold vacuum closely and see best results when 1.5-1.7 " hg is observed. I’m confident that had I run the motor with my ported annular 850(which flows about 40cfm more than the HP950) it would have made 8-10 more HP........and picked up most of the lost 20cfm. Dry flow on the bench doesn't mean a whole lot but perhaps you are right-wish you would have tried it. J.Rob

2009 PHR\EMC Competitor

2010 PHR\EMC Competitor

2011 PHR\EMC Competitor

2012 PHR\EMC Competitor

2013 PHR\EMC Competitor

2014 HotRod/EMC Competitor

2015 HotRod/EMC NoShow

2016 HotRod/EMC 3rd place SPEC Bigblock

2018 HotRod/EMC 7th place G3

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416309

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416309

12/10/17 05:01 PM

12/10/17 05:01 PM

|

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

|

I’ll only add this..... Brads motor made the most HP of any std port motor I’ve tested. It wasn’t the biggest, didn’t have the biggest cam, or the most compression.......but it did have the highest flowing heads. I’m confident that had I run the motor with my ported annular 850(which flows about 40cfm more than the HP950) it would have made 8-10 more HP........and picked up most of the lost 20cfm. Dry flow on the bench doesn't mean a whole lot but perhaps you are right-wish you would have tried it. That’s exactly what happened when we did it with the stage 6 heads.

If I can make 700hp from a far cheaper RPM casting then why would I expect the same power from a "better" cyl head?

You mean the $54 per head?

If the flow doesn’t matter, and the c/d doesn’t make any difference........we might as well stop testing heads, since the numbers must not have any bearing on power output. Never said anything of the sort.

Well......IMO, you did indirectly. Your position is that your 299cfm heads that flow 50cfm less than the ported Victors, that also have a lower c/d.......would make the same power on Brads short block. That certainly seems like you’re saying to disregard the c/d and fairly substantial flow differential. Maybe it’s my lack of knowledge of the platform for the low expectations of what I was looking for out of the Victor heads.........but they performed as I thought they would on Brads motor. The best stock stroke RPM headed motor I’ve tested(which as it turns out had 300cfm intake ports) was an RB 451 with a tall filled block, Ross dome pistons(13:1cr), aluminum rods, ported Victor intake with a blended HVH SS 4500/4150 spacer/adapter, Pro Systems 1050 Dominator, 272@.050 flat tappet cam, .650 lift with 1.6 rockers, big box style pan.......and that motor made 652hp and about 570tq........and I was pretty happy with that too.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: 451Mopar]

#2416530

Re: Engine Build Philosophy: Port Size vs Application

[Re: 451Mopar]

#2416530

12/10/17 11:55 PM

12/10/17 11:55 PM

|

Joined: Oct 2009

Posts: 1,267

North, Alabama

D-50

pro stock

|

pro stock

Joined: Oct 2009

Posts: 1,267

North, Alabama

|

My motor is a old Engine Masters motor and I have never used anything but 93 octane pump gas in it. Has run fine for 5 years.

1.33 60 ft,6.21 at 110.59 in the 1/8, pump gas small block,2950lbs,drag radials,mufflers and driven to track ...

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416755

Re: Engine Build Philosophy: Port Size vs Application

[Re: Streetwize]

#2416755

12/11/17 02:02 PM

12/11/17 02:02 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

Sorry guys, I was just going by the thread title, I didn't think the discussion was limited to the merits of the Victor, or TF, or Chapmans or whatever...I didn't think anything I was saying or bringing up for consideration would be considered going "off topic"...was I???  No problem. It was NOT intended to be a brand-specific promo or bash thread, as I did state originally. That it took on that sort of flavor... well, it is what it is. Hey, "Let it roll..." Actually I was thinking (and judging from the caliber of respected participants) that this was one of the more interesting threads in the past several months. Thanks. I was really hoping it would generate some interest and add some value, given what I believe this forum is intended primarily to be.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416819

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416819

12/11/17 04:31 PM

12/11/17 04:31 PM

|

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

HotRodDave

I Live Here

|

I Live Here

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

|

It seems to me that a too big of port thing is not as important as it seems at first glance, a stone stock 392 CID GEN III hemi runs great at 2000 RPM with huge ports, next time you drive one with a 6spd try lugging it at low RPM, seems to run just fine, as a matter of fact the eagle 5.7 has almost as big of ports with even less displacement and make plenty of TQ down low and has great throttle response once the DBW crap is tuned right.

Wet flow dynamics is more than just high velocity. These modern engines work so well because the engineers work on improving all aspects like flow, swirl, velocity, cam timing, runner length, ex flow, chamber shape, spark plug placement (find a way to get the plug in the richest mixture part of the chamber), cool intake air (hint... the manifold is a lot more important in keeping the charge cool before entering the chamber than the part the air filter is hiding in).

Bottom line is you can still make big TQ with big efficent ports but you can not make big HP with little ports no matter how "efficent" they are. I got a set of modern cylinder head CNC 302 casting heads and velocity is incredible but even jeff said he had a hard time making 500 hp with em but TQ was great. You just got to find a balance that works for you.

I am not causing global warming, I am just trying to hold off a impending Ice Age!

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2416869

Re: Engine Build Philosophy: Port Size vs Application

[Re: RAMM]

#2416869

12/11/17 05:56 PM

12/11/17 05:56 PM

|

Joined: Jun 2006

Posts: 5,161

CT

GTX MATT

master

|

master

Joined: Jun 2006

Posts: 5,161

CT

|

Victors should be used only by masochists Do you follow Brad's posts on here?

Now I need to pin those needles, got to feel that heat

Hear my motor screamin while I'm tearin up the street

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: GTX MATT]

#2416882

Re: Engine Build Philosophy: Port Size vs Application

[Re: GTX MATT]

#2416882

12/11/17 06:20 PM

12/11/17 06:20 PM

|

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

fast68plymouth

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 14,492

So. Burlington, Vt.

|

Victors should be used only by masochists Do you follow Brad's posts on here? Brads Victors were less work than his stage 6's(well, pretty much any non-Chapman stage 6's)......and no more time or labor intensive than a set of 280cfm 906's.

68 Satellite, 383 with stock 906’s, 3550lbs, 11.18@123

Dealer for Comp Cams/Indy Heads

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2416922

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2416922

12/11/17 07:35 PM

12/11/17 07:35 PM

|

Joined: Jun 2003

Posts: 52,972

Romeo MI

MR_P_BODY

Master

|

Master

Joined: Jun 2003

Posts: 52,972

Romeo MI

|

It seems to me that a too big of port thing is not as important as it seems at first glance, a stone stock 392 CID GEN III hemi runs great at 2000 RPM with huge ports, next time you drive one with a 6spd try lugging it at low RPM, seems to run just fine, as a matter of fact the eagle 5.7 has almost as big of ports with even less displacement and make plenty of TQ down low and has great throttle response once the DBW crap is tuned right.

Wet flow dynamics is more than just high velocity. These modern engines work so well because the engineers work on improving all aspects like flow, swirl, velocity, cam timing, runner length, ex flow, chamber shape, spark plug placement (find a way to get the plug in the richest mixture part of the chamber), cool intake air (hint... the manifold is a lot more important in keeping the charge cool before entering the chamber than the part the air filter is hiding in).

Bottom line is you can still make big TQ with big efficent ports but you can not make big HP with little ports no matter how "efficent" they are. I got a set of modern cylinder head CNC 302 casting heads and velocity is incredible but even jeff said he had a hard time making 500 hp with em but TQ was great. You just got to find a balance that works for you. Your talking dry flow VS wet.. 2 different worlds I love the power in my 416 W2.. its injected with multi port injection.. it was less power with the carb on the street.. but I did make some changes so its not 100% the same... I did go with a smaller cam for one thing

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416923

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2416923

12/11/17 07:37 PM

12/11/17 07:37 PM

|

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

HotRodDave

I Live Here

|

I Live Here

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

|

HRD - I don't think that's an apples-to-apples comparison. How's a 426 N/A Drag Pak with a 270+ at .050" cam pull at 2000 RPM under a load? And how would it behave if it was also retro-fitted with a carb and old-tech mechanical-advance ignition? The original question was port size vs aplication, this is a very exagerated example of really big ports in both size and flow for the CID but still makes plenty of TQ in the aplication and velocity will be really low at lower RPM yet it works. If you heard of someone putting heavily ported W2s (similar flow to an eagle but smaller cross section) but on a stock 340 short block you would think they were crazy and going to kill there streetability but the Gen III engine seems to defy old school logic. All I am saying is you can not just say you need velocity more than flow, there is a lot more to it and some of the old hard fast theory no longer seems to hold up. Now we have a 485 hp SAE Net 392 with plenty of low end TQ.

I am not causing global warming, I am just trying to hold off a impending Ice Age!

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2416953

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2416953

12/11/17 08:35 PM

12/11/17 08:35 PM

|

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

BradH

OP

OP

Taking time off to work on my car

|

OP

OP

Taking time off to work on my car

Joined: Jan 2003

Posts: 15,439

Val-haul-ass... eventually

|

HRD - I don't think that's an apples-to-apples comparison. How's a 426 N/A Drag Pak with a 270+ at .050" cam pull at 2000 RPM under a load? And how would it behave if it was also retro-fitted with a carb and old-tech mechanical-advance ignition? The original question was port size vs aplication, this is a very exagerated example of really big ports in both size and flow for the CID but still makes plenty of TQ in the aplication... Now we have a 485 hp SAE Net 392 with plenty of low end TQ. True, as it is w/ the GM LS7 "stuff". But what works using current tech doesn't always apply -- much less retro-fit -- to the old sh!t most of us are building on here.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417043

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417043

12/11/17 10:56 PM

12/11/17 10:56 PM

|

Joined: Nov 2010

Posts: 3,696

jersey

Spaceman Spiff

master

|

master

Joined: Nov 2010

Posts: 3,696

jersey

|

It seems to me that a too big of port thing is not as important as it seems at first glance, a stone stock 392 CID GEN III hemi runs great at 2000 RPM with huge ports, next time you drive one with a 6spd try lugging it at low RPM, seems to run just fine, as a matter of fact the eagle 5.7 has almost as big of ports with even less displacement and make plenty of TQ down low and has great throttle response once the DBW crap is tuned right.

Wet flow dynamics is more than just high velocity. These modern engines work so well because the engineers work on improving all aspects like flow, swirl, velocity, cam timing, runner length, ex flow, chamber shape, spark plug placement (find a way to get the plug in the richest mixture part of the chamber), cool intake air (hint... the manifold is a lot more important in keeping the charge cool before entering the chamber than the part the air filter is hiding in).

Bottom line is you can still make big TQ with big efficent ports but you can not make big HP with little ports no matter how "efficent" they are. I got a set of modern cylinder head CNC 302 casting heads and velocity is incredible but even jeff said he had a hard time making 500 hp with em but TQ was great. You just got to find a balance that works for you. What do you consider " big HP?" Modified eliminator guys were running in the 9's, under 300 cubic inches, and with stock head castings. and that was 40 years ago.

526 cubes of angry wedge, pushbutton shifted, 9 passenger killer!

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Spaceman Spiff]

#2417177

Re: Engine Build Philosophy: Port Size vs Application

[Re: Spaceman Spiff]

#2417177

12/12/17 03:15 AM

12/12/17 03:15 AM

|

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

|

When you discuss the old days in Modified eliminator you have to remember that all those drivers let the clutch out at 8000 + RPM with either 6.17, 5.86 or maybe as tall as 5.57 with a 3.25 low gear and shifted them between 8500 up to 9800 RPM, NO torque what so dang ever  They idle at 1500 + RPM, those motors flat scream from when the top bulb came on until they let off on the other end, none of those motors ran in gear below 2500 RPM until they stuck the clutch in to reverse directions or were shutting the motor off

Last edited by Cab_Burge; 12/12/17 03:16 AM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Cab_Burge]

#2417227

Re: Engine Build Philosophy: Port Size vs Application

[Re: Cab_Burge]

#2417227

12/12/17 09:30 AM

12/12/17 09:30 AM

|

Joined: Nov 2010

Posts: 3,696

jersey

Spaceman Spiff

master

|

master

Joined: Nov 2010

Posts: 3,696

jersey

|

When you discuss the old days in Modified eliminator you have to remember that all those drivers let the clutch out at 8000 + RPM with either 6.17, 5.86 or maybe as tall as 5.57 with a 3.25 low gear and shifted them between 8500 up to 9800 RPM, NO torque what so dang ever  They idle at 1500 + RPM, those motors flat scream from when the top bulb came on until they let off on the other end, none of those motors ran in gear below 2500 RPM until they stuck the clutch in to reverse directions or were shutting the motor off  That was my point. Those cars made big HP, from little cubes, and a production head, with not very large ports( compared to what is available in the aftermarket today).

526 cubes of angry wedge, pushbutton shifted, 9 passenger killer!

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Spaceman Spiff]

#2417392

Re: Engine Build Philosophy: Port Size vs Application

[Re: Spaceman Spiff]

#2417392

12/12/17 03:42 PM

12/12/17 03:42 PM

|

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

Cab_Burge

I Win

|

I Win

Joined: Aug 2003

Posts: 43,127

Bend,OR USA

|

The smaller the motor the more sensitive it is to port size at WOT below peak torque RPM  Did you ever drive a 351 Cleveland powered Mustang or Torino? Talk about port size being over sized for the application   They where dogs to me below 5000 RPM

Last edited by Cab_Burge; 12/12/17 03:44 PM.

Mr.Cab Racing and winning with Mopars since 1964. (Old F--t, Huh)

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417505

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417505

12/12/17 06:51 PM

12/12/17 06:51 PM

|

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

HotRodDave

I Live Here

|

I Live Here

Joined: Jan 2005

Posts: 12,419

Kalispell Mt.

|

Glad the cleavland was brought up, it is about 2.9 square inch and the eagle 5.7 is about 3.0 sq inch. One is good at making TQ and one sucks both are good at making HP but one is better.

I am not causing global warming, I am just trying to hold off a impending Ice Age!

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417578

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417578

12/12/17 08:56 PM

12/12/17 08:56 PM

|

Joined: Jan 2003

Posts: 17,840

S.E. Michigan

ZIPPY

I Live Here

|

I Live Here

Joined: Jan 2003

Posts: 17,840

S.E. Michigan

|

Nice analysis and research, good reading and food for thought as ever.

Is there a timeframe for the ol' E body to come back out with the new bullet in it?

Any changes anticipated to better accommodate the motor?

Rich H.

Esse Quam Videri

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417716

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417716

12/13/17 01:02 AM

12/13/17 01:02 AM

|

Joined: May 2003

Posts: 6,560

Downtown Roebuck Ont

Twostick

Still wishing...

|

Still wishing...

Joined: May 2003

Posts: 6,560

Downtown Roebuck Ont

|

Glad the cleavland was brought up, it is about 2.9 square inch and the eagle 5.7 is about 3.0 sq inch. One is good at making TQ and one sucks both are good at making HP but one is better. Put port injection and a fast burn chamber that only needs 25 degrees of timing on the Cleveland and I think the torque gap disappears. Kevin

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: Twostick]

#2417718

Re: Engine Build Philosophy: Port Size vs Application

[Re: Twostick]

#2417718

12/13/17 01:06 AM

12/13/17 01:06 AM

|

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

Streetwize

master

|

master

Joined: Jan 2003

Posts: 9,872

Weddington, N.C.

|

Comparing old to new is a bit moot, New motors have either port or dirct chamber fuel injection, the manifold and port only have to move AIR and not carry fuel in suspension. Put a carb manifold on a modern hemi in a 4400 pound car nd watch the torque plummet at low/medium piston speeds.

The cleveland in smaller 2V form still needed a long skinny intake manifold runner just ot make decent torque, and the 4V was a bit soft on the bottom end unless you had steep gears, you basically had a smallblock with a 427 Chevy size intake port , they used to sell port stuffer sheetmetal plates to pick up the velocity in the Cleveland heads which blocked the lower third of the port....but Clevelands still make really stout 408+ " short rod stroker motors.

Last edited by Streetwize; 12/13/17 01:12 AM.

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417763

Re: Engine Build Philosophy: Port Size vs Application

[Re: BradH]

#2417763

12/13/17 02:16 AM

12/13/17 02:16 AM

|

Joined: Aug 2011

Posts: 2,853

Pattison Texas

CSK

master

|

master

Joined: Aug 2011

Posts: 2,853

Pattison Texas

|

Newer engines also have variable runner length intake manifolds, this is an OLD Harley engine I built, this is a 94 inch Harley, very old design with heads I ported on the large side for cid, it is also EFI, the blue run on the dyno is with a 8 inch long individual runner length, very gutless down low, the red line is with 22 inch runners, everything else is the same, tie both these power bands together with a Variable runner set up & you will have something that has power all over the place with a HUGE intake port on the cyl head. this is only for a 2 cyl, X the results by 4 for an 8 cyl

Last edited by csk; 12/13/17 02:25 AM.

1968 Charger COLD A/C Hilborn EFI

512ci 9.7 compression, Stealth heads, 4.10 gear A518 ODtrans 4100lb,10.93 full street car trim

2020 T/A 392 Stock 11.79 @ 114.5

|

|

|

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417852

Re: Engine Build Philosophy: Port Size vs Application

[Re: HotRodDave]

#2417852

12/13/17 12:04 PM

12/13/17 12:04 PM

|

Joined: Jun 2006

Posts: 5,161

CT

GTX MATT

master

|

master

Joined: Jun 2006

Posts: 5,161

CT

|

Glad the cleavland was brought up, it is about 2.9 square inch and the eagle 5.7 is about 3.0 sq inch. One is good at making TQ and one sucks both are good at making HP but one is better. Look at the flow out of the box though, the Hemi head flows ~50 CFM more at .300 (190 vs 240) and ~60 CFM more at .600. (270 vs 330).

Now I need to pin those needles, got to feel that heat

Hear my motor screamin while I'm tearin up the street

|

|

|