Alum Heads & Alum Intake - valley pan question.

#1736997

Alum Heads & Alum Intake - valley pan question.

#1736997

01/23/15 06:23 PM

01/23/15 06:23 PM

|

Joined: Sep 2009

Posts: 1,377

Tennessee

WyleECoyote

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Sep 2009

Posts: 1,377

Tennessee

|

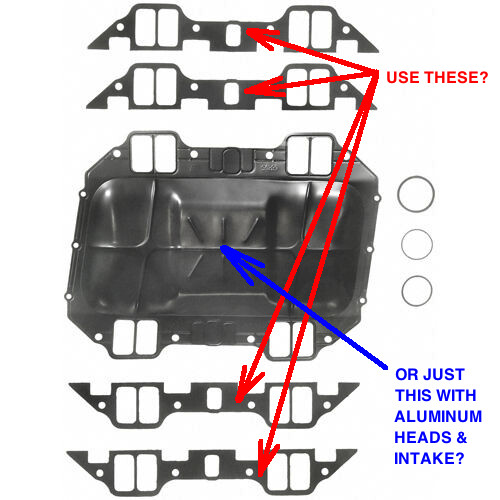

I'm helping a young (21 yr old) enthusiast new to the hobby with some engine issues. He added Edelbrock aluminum heads to a 440 and now he wants to put on a Weiand aluminum manifold. I've never messed with aluminum heads, so I'm unsure about the gasket situation. Does he use just the valley pan gasket and brush on the tacky sealant stuff around the pan gasket (and rtv at the corners) like I do my steel heads and aluminum manifolds or is this the time to use the additional gaskets that come in the set?

Wile E. Coyote

Super Genius, Lover of FCA US LLC Products

*************

68 Road Runner (440 4-spd), 71 Superbee (383 slap), 71 Charger 500 (383 4-spd wA/C 1of 182), 72 Imperial, 74 Charger SE (440 sunroof), 84 D350 Crew-cab Dually (440), 75 D300 Dually Tandem (318 4-speed)

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1736999

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1736999

01/23/15 07:00 PM

01/23/15 07:00 PM

|

Joined: Sep 2009

Posts: 1,377

Tennessee

WyleECoyote

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Sep 2009

Posts: 1,377

Tennessee

|

Quote:

Depends how much space there is which in turn depends on if the heads/block/intake have been milled or not.

You have to mock it up to see and then go from there. I always mill the intake side of my cylinder heads so I can use a double paper gasket but most people don't do that.

To do it correctly the head and the block should be milled so you get a three way match at the top of the valley rail. The cylinder head, deck surface and valley rail should all meet at the same point. Lots of guys never check that which is why they have problems with the intake leaking.

I'm tracking with ya - I'll put the manifold on with no gaskets and see how it all matches up bare - then determine if the paper gaskets are needed. Makes sense with how you explained it, thank you.

Wile E. Coyote

Super Genius, Lover of FCA US LLC Products

*************

68 Road Runner (440 4-spd), 71 Superbee (383 slap), 71 Charger 500 (383 4-spd wA/C 1of 182), 72 Imperial, 74 Charger SE (440 sunroof), 84 D350 Crew-cab Dually (440), 75 D300 Dually Tandem (318 4-speed)

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: cl440]

#1737001

Re: Alum Heads & Alum Intake - valley pan question.

[Re: cl440]

#1737001

01/23/15 07:35 PM

01/23/15 07:35 PM

|

Joined: Sep 2009

Posts: 1,377

Tennessee

WyleECoyote

OP

OP

pro stock

|

OP

OP

pro stock

Joined: Sep 2009

Posts: 1,377

Tennessee

|

Quote:

we've ran with no paper gaskets, with only one set of paper and with both sets of paper. Just depends on how everything lines up.

Roger that, thanks for the feedback. Made total sense when Andy laid it out like that in layman's terms!!!

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: 64Post]

#1737006

Re: Alum Heads & Alum Intake - valley pan question.

[Re: 64Post]

#1737006

01/24/15 07:47 PM

01/24/15 07:47 PM

|

Anonymous

Unregistered

|

Anonymous

Unregistered

|

The hot lick is to use the paper gaskets that are available now in .015 thick( not .030 each like Fel Pros ) making it easier to use one on each side of the pan..but the coolest trick is use Holomar around the intake ports--I mean... I use RTV at the ends and up to the first bolt hole--You have to--never a leak but...fuel kills RTV so you turn to a product invented by Mercedes (I think) called Holomar--a blue goo that is NOT affected by fuel or oil or temp it will seal up around intake ports like a bank vault

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1737007

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1737007

01/24/15 08:53 PM

01/24/15 08:53 PM

|

Joined: Feb 2005

Posts: 4,313

Prospect, PA

BSB67

master

|

master

Joined: Feb 2005

Posts: 4,313

Prospect, PA

|

Quote:

I always mill the intake side of my cylinder heads so I can use a double paper gasket but most people don't do that.

Doing that for over 30 years. No adhesive or sealant on the head or the intake. Makes intake swaps a snap.

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1737009

Re: Alum Heads & Alum Intake - valley pan question.

[Re: AndyF]

#1737009

01/25/15 07:33 AM

01/25/15 07:33 AM

|

Joined: May 2008

Posts: 5,399

Aurora, Colorado

451Mopar

master

|

master

Joined: May 2008

Posts: 5,399

Aurora, Colorado

|

Quote:

Depends how much space there is which in turn depends on if the heads/block/intake have been milled or not.

You have to mock it up to see and then go from there. I always mill the intake side of my cylinder heads so I can use a double paper gasket but most people don't do that.

To do it correctly the head and the block should be milled so you get a three way match at the top of the valley rail. The cylinder head, deck surface and valley rail should all meet at the same point. Lots of guys never check that which is why they have problems with the intake leaking.

My old 451 engine with the B-1 B/s heads and M1 intake, I had to have 0.100" taken off each side of the manifold. I think the block may have been milled down, not sure about the heads, but that is most I have ever had to take off to get an intake to fit.

|

|

|

Re: Alum Heads & Alum Intake - valley pan question.

[Re: WyleECoyote]

#1737010

Re: Alum Heads & Alum Intake - valley pan question.

[Re: WyleECoyote]

#1737010

01/25/15 12:00 PM

01/25/15 12:00 PM

|

Joined: Jan 2003

Posts: 21,072

Niles , Ohio

therocks

oh wait.but hey.lets see.oh yeah.

|

oh wait.but hey.lets see.oh yeah.

Joined: Jan 2003

Posts: 21,072

Niles , Ohio

|

Ive run aluminum intakes since the 60s.Never used papers.Ran the kids 413 and my 440 for the last 20 years with none.My 440 also has aluminum heads for the last 5 years at least.No papers.Rocky

Chrysler Firepower

|

|

|

|

|