Posted By: ric3xrt

Eagle Head - 12/16/18 02:22 PM

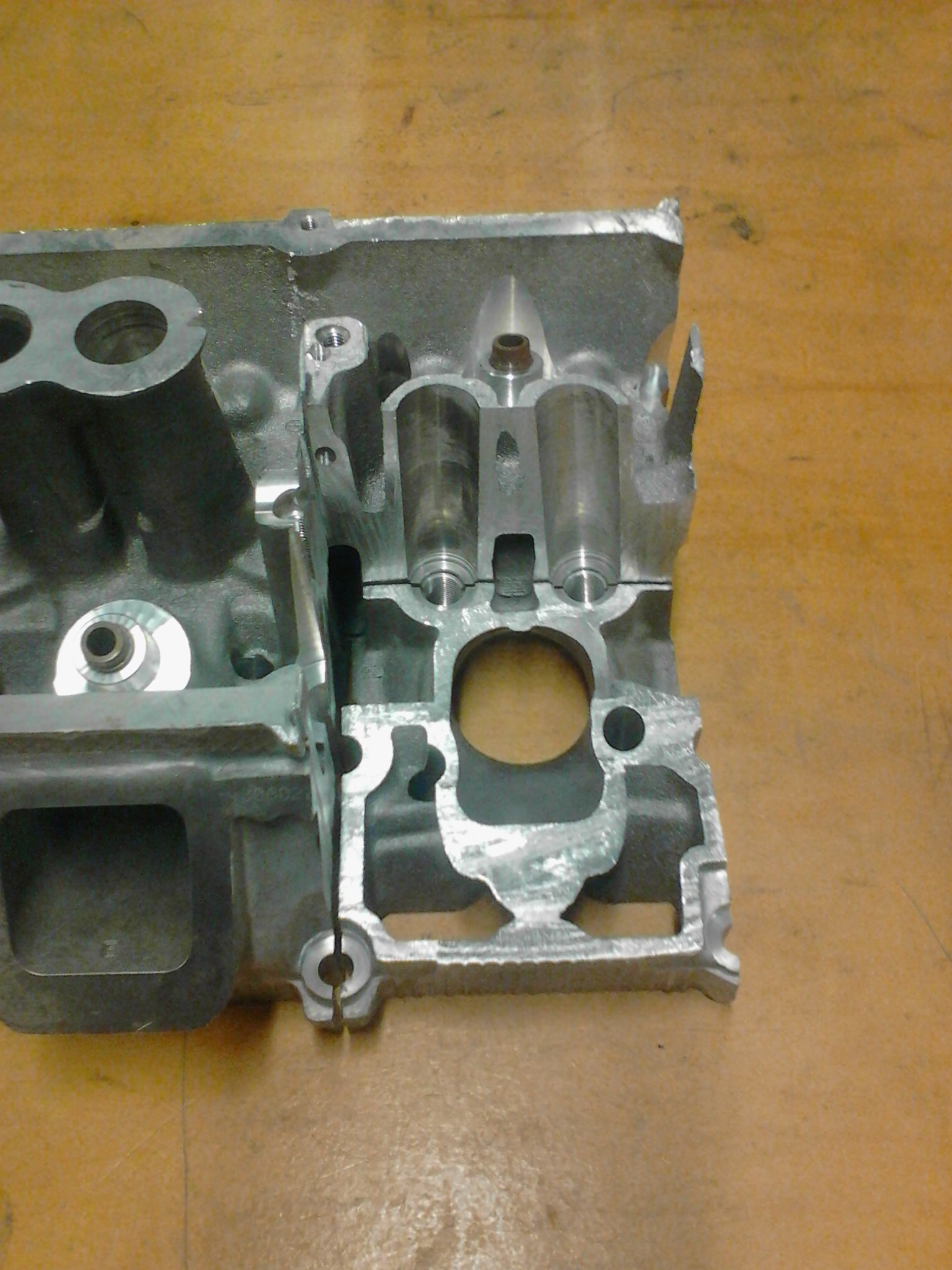

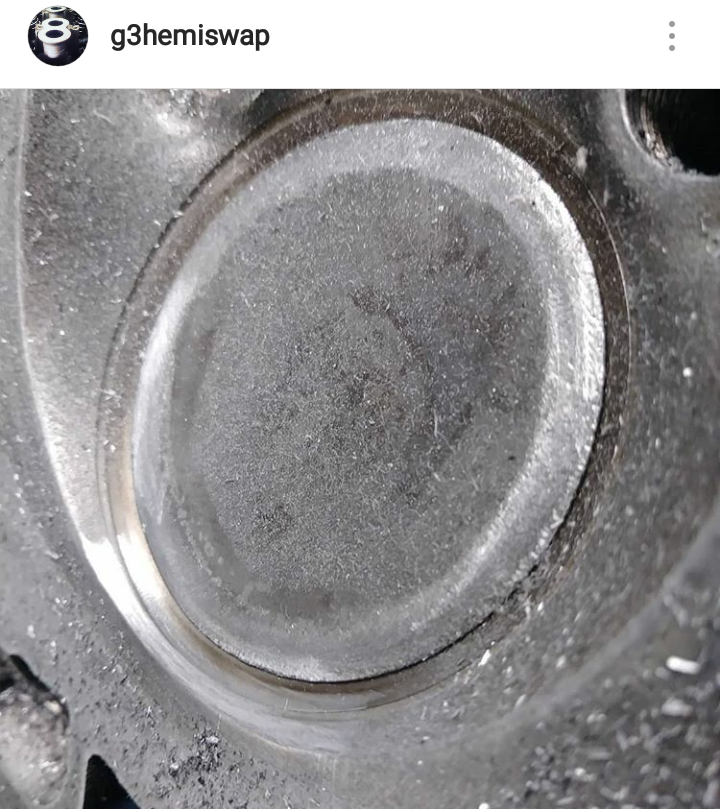

My supplier dropped of some Eagle heads the other day, and I know most of us have seen these heads cut open, but here's some of the dissected parts I wanted to see.

1st boring head shot, 2 is what the oil passages look like(kind of), 3rd is a cross-section where the spark plugs mount...notice the water pocket. 4th is also of the water jacket between cylinders.

1st boring head shot, 2 is what the oil passages look like(kind of), 3rd is a cross-section where the spark plugs mount...notice the water pocket. 4th is also of the water jacket between cylinders.