Good troll JCC but you aren't "shooting from the hip" you are blowing smoke out your backside.

Nice attempt at taking the high road. After over a decade on this topic on Moparts, they usually take this course, unilaterally. I can go back locate/link them if needed

The smaller part will wear out faster than an = larger part given the same load.

Other then stating the obvious , what is your point?

It's up to the individual to decide what is acceptable,

Other then stating the obvious, what is your point?

save a few pound VS shorter service life.

And who here has worn out a TR in under say 50K? on one of our maintained not abused cars?

My car is far from a daily driver, so I'll save a few pounds.

I doubt It

Really, what does it hurt if someone puts bigger tie rod ends on their car- seriously.

I clearly addressed that, "what can it hurt?"

Most people don't need the power their engines are capable of, nor the ginormous brakes that are so popular.

Yes, a prime example of the Herd

Don't get your panties in such a bunch about it.

That would be counterproductive for "blowing smoke"

Nobody is going to force you to put big tie rods on your car.

that's great, and likely means nobody can make a solid case for doing so.

Regarding hollow drilling, I assume most of loading on a TR in the shank is direct compression or tension loads, little bending, the math on CSA which is directly proportional to the items strength in this application, between a 11/16" and a 9/16", not using root thread diameter, is an approx 52% difference. Using the thread root diameters that will lower slightly, but i don't have that data at my fingertips, and am satisfied with my shooting from the hip 40% guess.

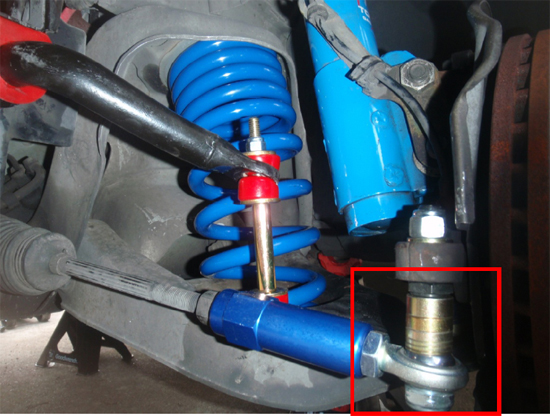

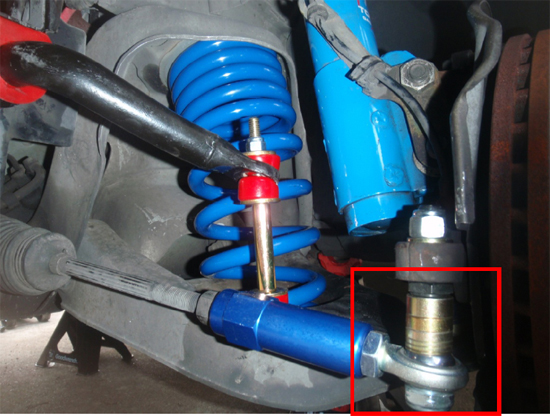

Attached is a typical Mustang TR with adjustable bump steer adjustability. Guess they have not heard about all the Mopar defection issues with the 9/16" TR.