Posted By: ScottSmith_Harms

Engine Run In Stand Design- Who's is best and Why? - 09/14/11 04:46 AM

I posted over in general but figured the racer crowd might be more in touch with the subject.............

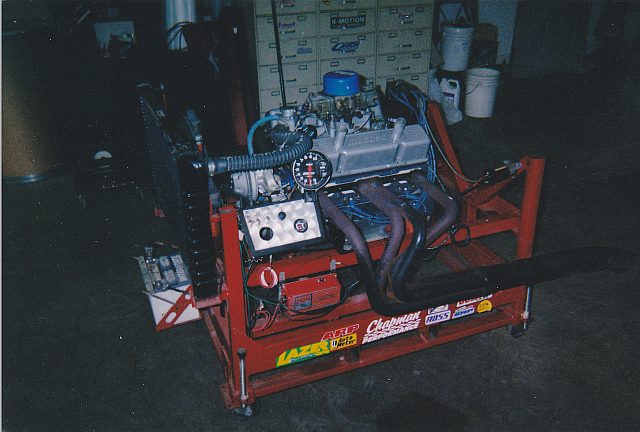

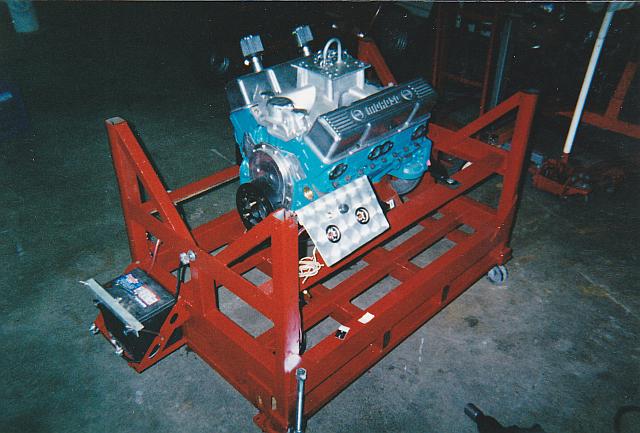

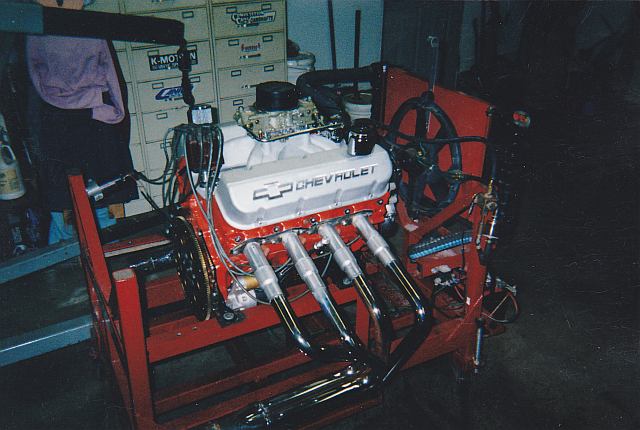

I was checking out the features of the "Easy-Run" design and like it, the placement of the controls, battery, radiator, etc. is very nicely laid out. However there's no way I'm dishing out over 2K to buy one when I can build my own with some simple box tubing and a few ready made store bought componants so I'm going to build my own.

I can tough it out and start from scratch but if anyone has design plans/dimensions, etc. for a similar design as the Easy-Run I'd love to have a head start!

I was checking out the features of the "Easy-Run" design and like it, the placement of the controls, battery, radiator, etc. is very nicely laid out. However there's no way I'm dishing out over 2K to buy one when I can build my own with some simple box tubing and a few ready made store bought componants so I'm going to build my own.

I can tough it out and start from scratch but if anyone has design plans/dimensions, etc. for a similar design as the Easy-Run I'd love to have a head start!

.

.