Posted By: davenc

Tips on assembling socketless hose? - 11/20/10 06:21 AM

I have the black Aeroquip AQP socketless hose, the Aeroquip fittings, and the Aeroquip assembly lube. However, I can't seem to get the fitting fully seated. It is about 1/4" from full in.

Are they any tricks to doing this assembly? I am lubricating both the inside of the hose, and the barbed end of the fitting. I am pushing as hard as I can on a hose (already busted up several fingers when the hose bent suddenly), but can't get the darn things complete.

I thought this hose system was "easy to assemble" and am assuming I am doing something wrong.

Help!

Dave

Posted By: topside

Re: Tips on assembling socketless hose? - 11/20/10 06:40 AM

I use the similar Earl's stuff - collar goes over the end of the hose, hose goes onto a barbed fitting - and the thing that works for me is brushing some STP on the barb and a little bit on the ID of the hose. Fitting on a non-marring surface, push the hose (with collar over its end) on with a bit of effort, done. I used to have a harder time of it with any other lubricant.

Posted By: davenc

Re: Tips on assembling socketless hose? - 11/20/10 06:47 AM

I think I might have some STP in the garage. I will try that on the next one I try to assemble. I still need to get the first hose complete though!

Does the age of the hose make it harder to assemble? The hose I have is about 1 year old.

Thanks, Dave

Posted By: AndyF

Re: Tips on assembling socketless hose? - 11/20/10 07:45 AM

warm the hose up a little bit with a heat gun.

Posted By: BIGBLOCK_KAT

Re: Tips on assembling socketless hose? - 11/20/10 11:37 AM

Check and make sure the nipple that is going into the hose has not dug into the hose liner. Also another problem is certain hoses must not be to close to the socket base as it will bottom out before the assy. is drawn up.

I know you said socketless, but just in case.

Posted By: davenc

Re: Tips on assembling socketless hose? - 11/20/10 03:38 PM

Thanks everyone for the tips! It was a little chilly in the garage last evening, and I guess that wasn't helping any.

Dave

Posted By: Jeremiah

Re: Tips on assembling socketless hose? - 11/20/10 08:25 PM

I dip the hose in hot water for a minute or two and on we go! Socketless hose rules!

Posted By: davenc

Re: Tips on assembling socketless hose? - 11/21/10 02:55 AM

How hot is the water? Today I tried heating up the hose with a 1800W hair dryer. I got the hose hot enough that it was difficult to hold for any length of time even with my mechanic's gloves. On top of that it was still almost impossible to close that last 1/4" gap on the fitting. From what everyone is saying, it should be easier than this!

Which brand of socketless hose did you use? I don't know if it is something I am doing wrong, but at the moment, I am not impressed with the Aeroquip hose. Its rated to 250PSI, and there is no way this stuff is coming apart. However, I'm just trying to use it in my fuel system.

Dave

Posted By: dusturbd340W5

Re: Tips on assembling socketless hose? - 11/21/10 05:44 AM

I use nothing but the Aeroquip hose with a true heat gun not a hair dryer and have 0 problems getting the fittings in.You have to heat the hose back far enough to equal the fitting length

Posted By: jb500

Re: Tips on assembling socketless hose? - 11/21/10 06:18 AM

No need to use hot water or a heat gun. Made hundreds of push on hose assemblies and only used 80-90w gear lube.

However, I will say that Aeroquip ends are the worst push on fittings to assemble from personal experience. The barbs are bigger when compared to others and takes a little more effort to get the hose to seat.

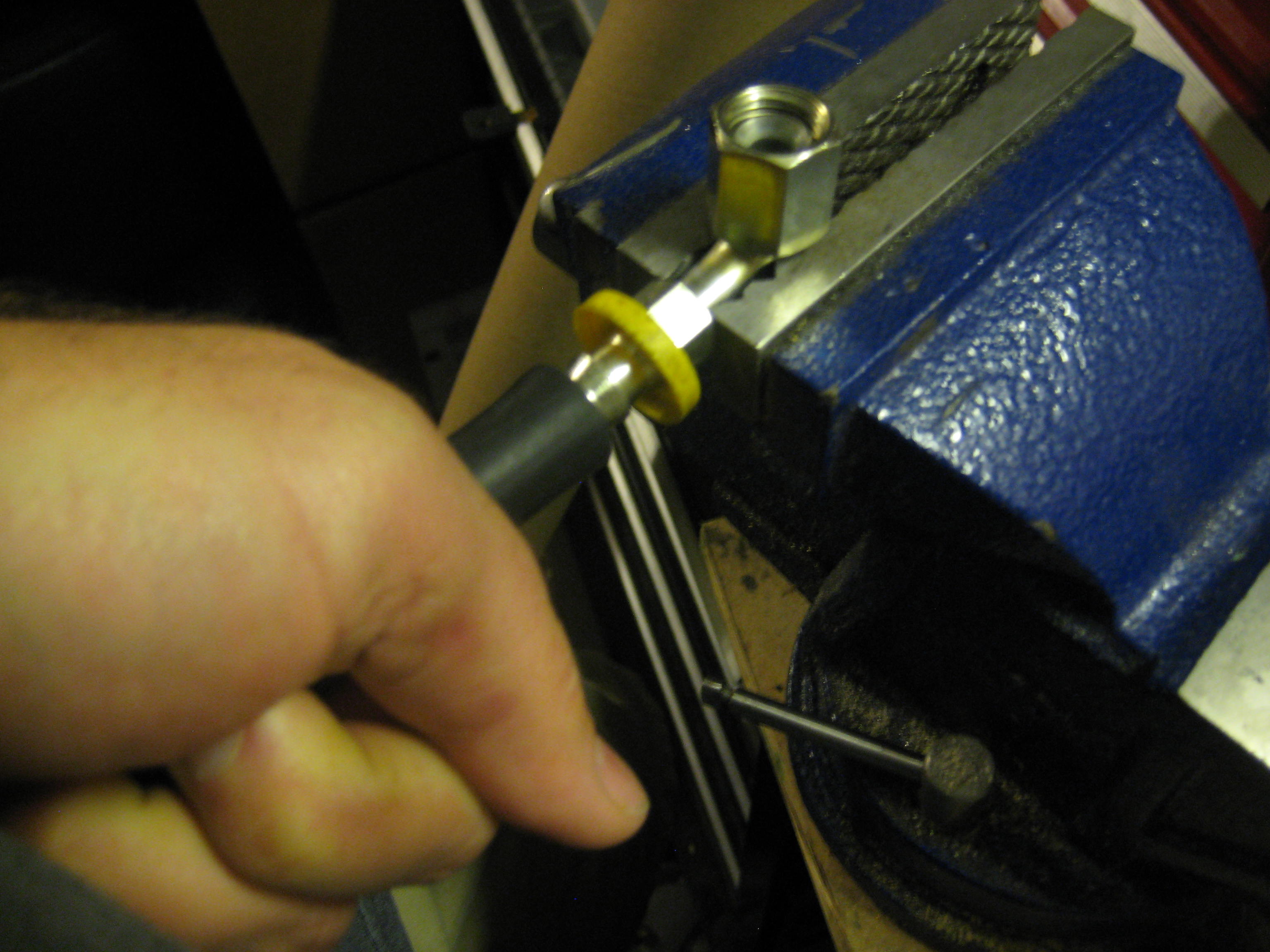

Connect a fitting to the hose end and secure it in a vise for a better base to push against. The most important part is to make sure you coat the barbs with plenty of lube. Give the hose a little wiggle from side to side as you push the hose over the barbs and you should be able to slide it right on.

Yes, it is a little like pushing rope, but once you get the hang of it (individual technique and a few F bombs) it becomes a snap.

Posted By: Jeremiah

Re: Tips on assembling socketless hose? - 11/21/10 09:39 PM

The water I used was just from the tap on the hottest setting. If you are having trouble perhaps try some WD40 or some other cheap lubricant. It does take lots of grunt on my part but they always go together. The only reason I did not use oil is because it is messy and slippery. I'd imagine that works just fine.

Posted By: davenc

Re: Tips on assembling socketless hose? - 11/22/10 01:33 AM

OK, I finally got the first three hoses assembled. Ended up putting the fitting into a vice and then pushing down on the hose after lubing and heating the hose with a hair dryer. All the fittings are now fully seated.

It was still an adventure with the 45 and 90 degree fittings I was using, since it was rather difficult to get them into the vice in a position that I could then get good downward force on.

I had some Summit fittings and the barbs are a smaller diameter than the Aeroquip fittings. However, I went with the Aeroquip fittings because I could get them with female AN ends. With the Summit fittings, I would have needed a coupler since I only had male AN ends on the hose barb.

I still need to assemble the hoses back at the tank, but at less those are straight fittings. I really like the idea of the socketless hose, but next time I am look further for different fittings.

Thanks to all for the help!

Dave

Posted By: jb500

Re: Tips on assembling socketless hose? - 11/22/10 03:26 AM

I think you would have better luck if you were to put the fittings in a vice and orient them horizontally. Then use two hands and your body weight to push the hose onto the barbs. You can clamp the tube portion of the fitting or the hex to get a good bite in the vise.

I know you said socketless, but just in case.

I know you said socketless, but just in case.