Moparts

Ported edelbrock heads.......pics & flow #'s

Posted By: Brian Hafliger

Ported edelbrock heads.......pics & flow #'s - 11/16/07 02:23 AM

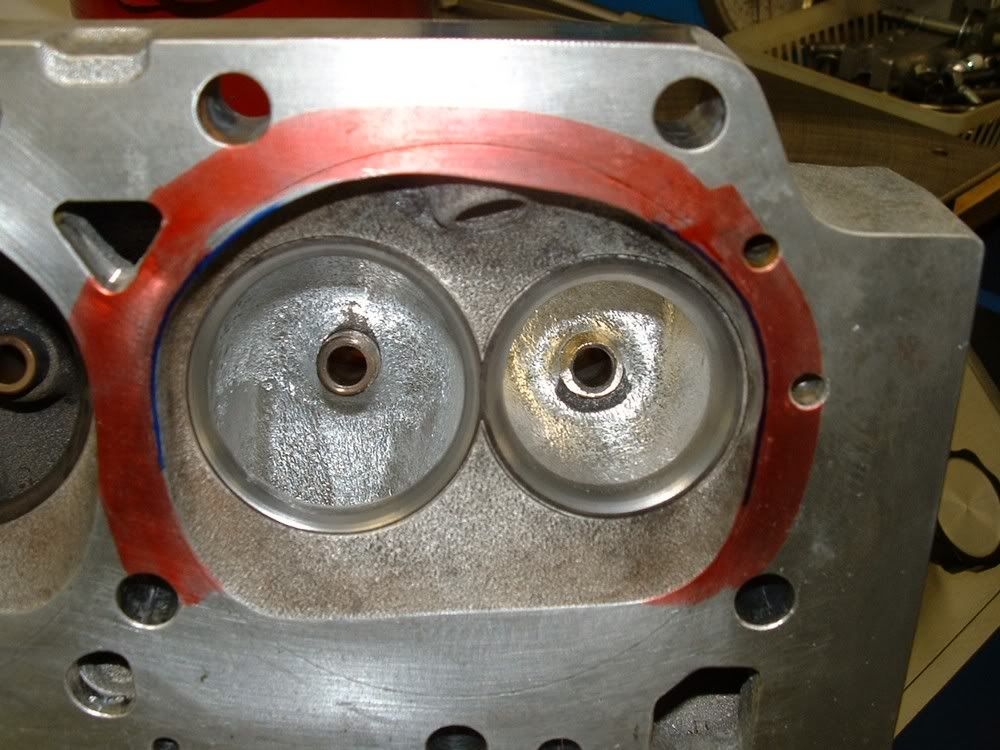

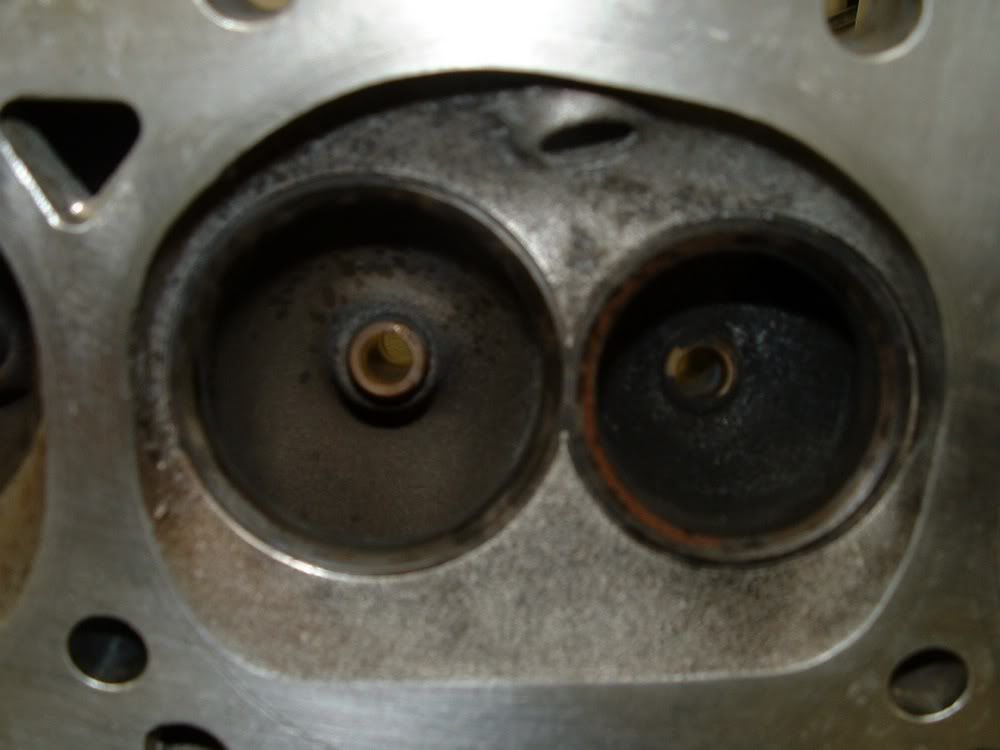

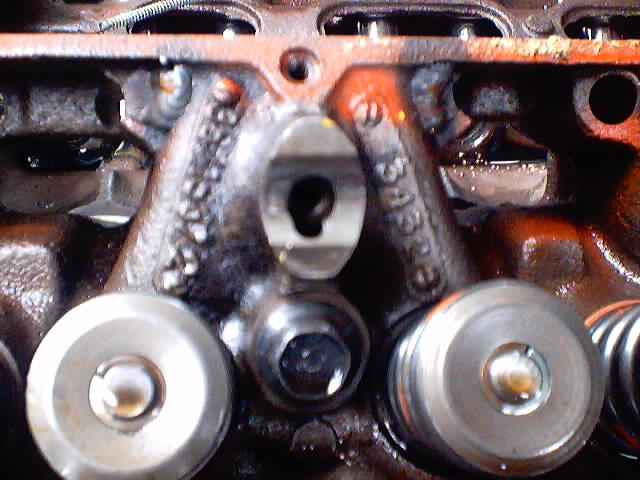

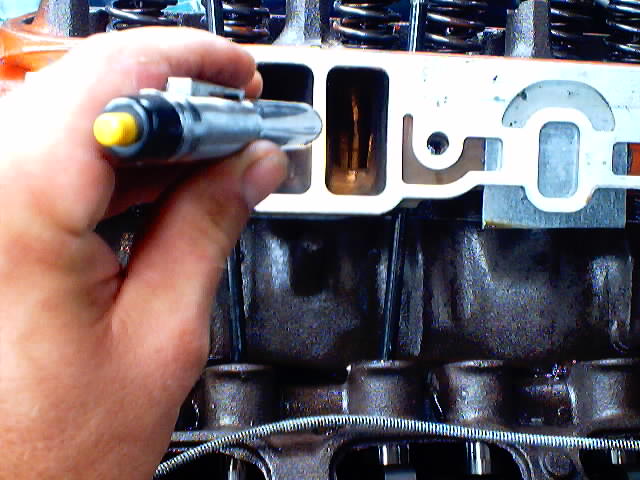

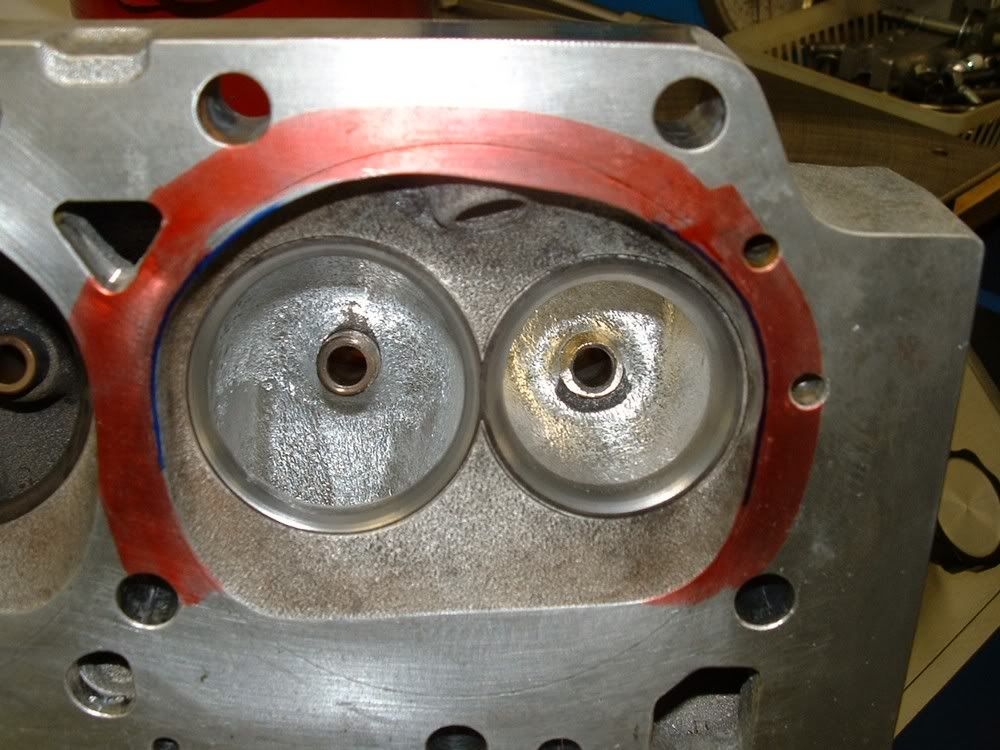

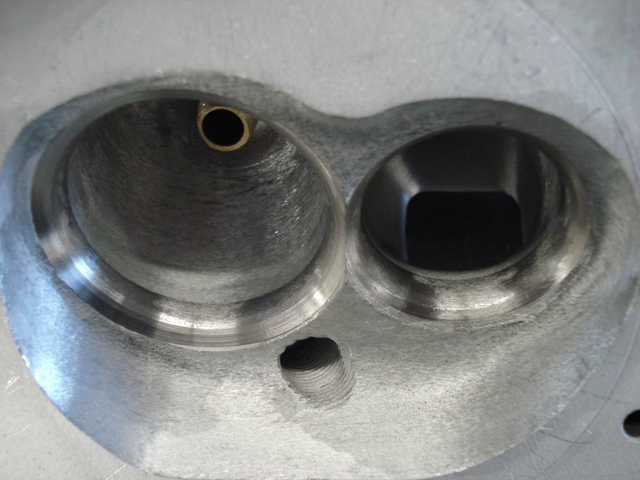

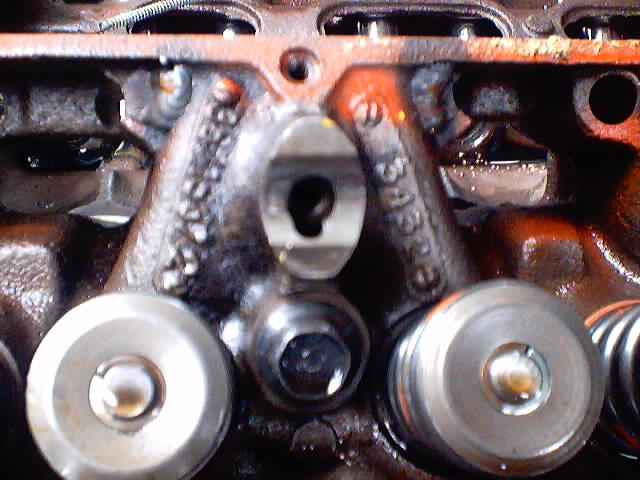

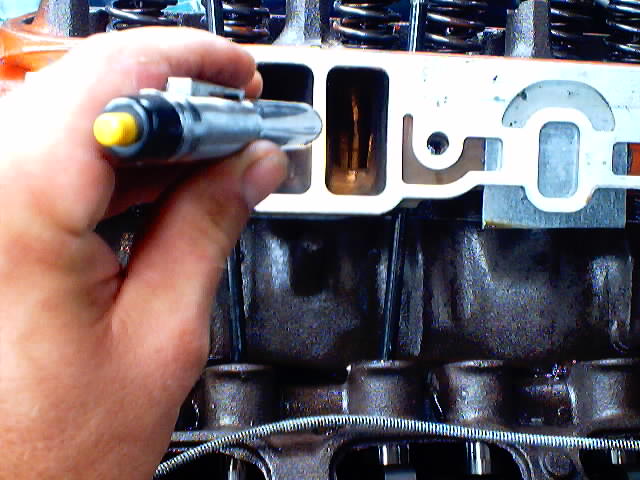

Just some pics of DiegoTed's buddy Steve's sb eddy heads. I'm gathering pics for our website and thought I'd throw them up here.

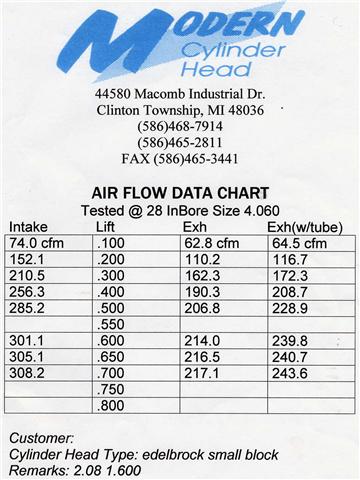

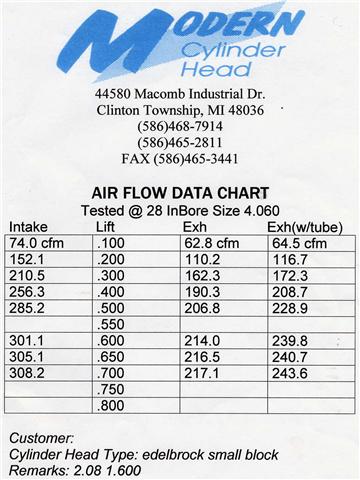

Here are the flow #'s at 28" using a 4.03 bore.

Lift Int. Ex.

.200 150 108

.300 213 150

.400 257 188

.500 278 209

.600 288 220

.700 292 228

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/16/07 02:24 AM

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/16/07 02:24 AM

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/16/07 02:25 AM

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/16/07 02:25 AM

Posted By: instigator

Re: Ported edelbrock heads.......pics - 11/16/07 02:50 AM

Looks good...how many cubes...just a question..but is slimming down the space between the intake ports a bad place to gain cross sectional area by the pushrod pinch...I don't see any problem with a narrow gasket area between the ports due to compressive forces being greater on a smaller surface are...just thoughts????

Hope itydon't hurt..I worked mine down to about .080 wide but have not seen any degradation of the gasket with 22psi pushing on it.

Posted By: DemonKyle

Re: Ported edelbrock heads.......pics - 11/16/07 03:10 AM

Looks good Brian. Hope my engine comes out like that

Posted By: j.mcconnell

Re: Ported edelbrock heads.......pics - 11/16/07 03:34 AM

what would it cost to get something to that level

Posted By: Diego_Ted

Re: Ported edelbrock heads.......pics - 11/16/07 03:59 AM

Quote:

I forgot the flow numbers at work though, so I'll post them tomorrow nite.

Brian

Now that's what Gamala needs!!

Good Job Brian  Nice looking ports, now lets get back to work on the Picoso motor!!

Nice looking ports, now lets get back to work on the Picoso motor!!

Diego

Posted By: BobsProFab

Re: Ported edelbrock heads.......pics - 11/16/07 04:02 AM

looks good 0U8

Posted By: Stroker Scamp

Re: Ported edelbrock heads.......pics - 11/16/07 04:19 AM

looks good brian, im just looking for someone to sell a kidney to so i can get to work on the new motor

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/16/07 05:53 AM

Quote:

Looks good...how many cubes...just a question..but is slimming down the space between the intake ports a bad place to gain cross sectional area by the pushrod pinch...I don't see any problem with a narrow gasket area between the ports due to compressive forces being greater on a smaller surface are...just thoughts????

Hope itydon't hurt..I worked mine down to about .080 wide but have not seen any degradation of the gasket with 22psi pushing on it.

There are a few tricks to get the air speed down at the pinch. Common wall is good, corner radius can be tighter than other parts of the port. Floor and roof are where you can really slow it down. It still ends up being fast, but if you don't probe the pinch area at the lifts you'll access, you may have a problem with flow at high lifts and also power loss at higher rpms.

These were left somewhat fast because it won't be an all out race engine.

Brian

Posted By: ZIPPY

Re: Ported edelbrock heads.......pics - 11/16/07 03:17 PM

Very pretty looking work, thanks for posting the pics!

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/17/07 03:32 PM

Quote:

I forgot the flow numbers at work though, so I'll post them tomorrow nite.

Nothing to add. Just want to keep track of this thread.

Posted By: Dunnuck Racing

Re: Ported edelbrock heads.......pics - 11/17/07 05:17 PM

Yes,I'm keeping track also.Waiting for flow numbers.

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/17/07 08:18 PM

Quote:

Yes,I'm keeping treack also.Waiting for flow numbers.

OK....I haven't been feeling so great, so I keep forgeting them at work. I'm going down there in a little bit to talk with a customer, so I'll grab them and post them sometime this afternoon.

They're not much different than what Ryan has on his site.

They topped out at 292 with a 2.055 valve.

Exhaust flow is a little weak, due to the edelbrock valve. But we may go to a tulip valve, so that will pick them up.

Posted By: Dunnuck Racing

Re: Ported edelbrock heads.......pics - 11/18/07 02:24 AM

Sorry to hear you are not feeling well.Take your time,we are not going anywhere!

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/18/07 02:34 AM

Quote:

Sorry to hear you are not feeling well.Take your time,we are not going anywhere!

Good....cause I forgot them again

Sorry guys. I'll have them monday nite or you can hang me out to dry!!

Sorry guys. I'll have them monday nite or you can hang me out to dry!!

Posted By: StrokedDart

Re: Ported edelbrock heads.......pics - 11/18/07 05:10 PM

Too bad those will sit on a shelf for ten years.....doh!

Posted By: Cab_Burge

Re: Ported edelbrock heads.......pics - 11/18/07 06:06 PM

Quote:

Too bad those will sit on a shelf for ten years.....doh!

How close is the new A body to being ready, big boy?

Posted By: Diego_Ted

Re: Ported edelbrock heads.......pics - 11/18/07 07:45 PM

Quote:

Too bad those will sit on a shelf for ten years.....doh!

Ouch that's going to leave a huge mark!!!

Ouch that's going to leave a huge mark!!!

Diego

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/18/07 11:46 PM

Flow #'s are in first post....

Posted By: MIKES_DUSTER

Re: Ported edelbrock heads.......pics - 11/19/07 01:01 AM

brian,

this is probably a dumb question but did you port them by hand or CNC??

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/19/07 01:03 AM

No cnc machine...all by hand

Posted By: MIKES_DUSTER

Re: Ported edelbrock heads.......pics - 11/19/07 01:29 AM

Quote:

No cnc machine...all by hand

NICE job!!!!!

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/23/07 02:13 PM

Did you measure port volumes? if so please post.

I have ported my e-brocks myself and came up with 178 cc in & 79 cc ex.

I installed sleeves in the pushrod holes so the entrance is as big it could get without offset rockers.

I completly removed the headbolt bulge(?)wich also required sleeves.

I took out a lot of the bowlarea and polished the ports.

Not really knowing what im doing have i actally increased port flow?

Is it possible to improve flownrs without touching the short turn?

I will try to post some pics in a few days.

Joel

Posted By: clonestocker

Re: Ported edelbrock heads.......pics - 11/23/07 03:50 PM

And your Magic Die Grinder

matt

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/23/07 06:45 PM

Quote:

Did you measure port volumes? if so please post.

I have ported my e-brocks myself and came up with 178 cc in & 79 cc ex.

I installed sleeves in the pushrod holes so the entrance is as big it could get without offset rockers.

I completly removed the headbolt bulge(?)wich also required sleeves.

I took out a lot of the bowlarea and polished the ports.

Not really knowing what im doing have i actally increased port flow?

Is it possible to improve flownrs without touching the short turn?

I will try to post some pics in a few days.

Joel

With the edelbrocks, the short turn is not only THE most critical part (usually true with most heads) but if you did almost nothing to it I can assure you it is stalling at .500 lift or before.

There's no need to sleeve the pushrod holes, but you have to be crafty about slowing the air down right there.

I can get it to 305fps but I have to flow each and every intake port to do it. Measuring is not accurate enough. That's when I charge!!

But it works awesome and these heads will make power for alot less money than other heads.

There is a TON of work on these heads, about 20 hours of porting, seat work and chamber work.

I don't really pour heads anymore, it seems to me that it's really useless because the castings will only allow so much but I would say they are not small! I have to sonic test the ports in some spots when I start cutting to make sure the port will allow my shape.

I'll say this...I spot check the intake ports at 36" from .500 to .700 to see how it works and at .600 it's fairly stable but after that it gets a little turbulent!!

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/23/07 06:47 PM

Quote:

And your Magic Die Grinder  matt

matt

Ha ha ha...Merlin porting eh....

Posted By: BobsProFab

Re: Ported edelbrock heads.......pics - 11/23/07 07:55 PM

nice flow #'s

what type of bench do you have.

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/23/07 09:39 PM

With the edelbrocks, the short turn is not only THE most critical part (usually true with most heads) but if you did almost nothing to it I can assure you it is stalling at .500 lift or before.

There's no need to sleeve the pushrod holes, but you have to be crafty about slowing the air down right there.

I can get it to 305fps but I have to flow each and every intake port to do it. Measuring is not accurate enough. That's when I charge!!

But it works awesome and these heads will make power for alot less money than other heads.

There is a TON of work on these heads, about 20 hours of porting, seat work and chamber work.

I don't really pour heads anymore, it seems to me that it's really useless because the castings will only allow so much but I would say they are not small! I have to sonic test the ports in some spots when I start cutting to make sure the port will allow my shape.

I'll say this...I spot check the intake ports at 36" from .500 to .700 to see how it works and at .600 it's fairly stable but after that it gets a little turbulent!!

So your telling me all thework ive done on these heads are worth nothing?

Posted By: J_GAMALA

Re: Ported edelbrock heads.......pics - 11/23/07 09:40 PM

Quote:

Quote:

I forgot the flow numbers at work though, so I'll post them tomorrow nite.

Brian

Now that's what Gamala needs!!

Good Job Brian  Nice looking ports, now lets get back to work on the Picoso motor!!

Nice looking ports, now lets get back to work on the Picoso motor!!

Diego

exactly my thought as well!!!

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/24/07 12:33 AM

Quote:

With the edelbrocks, the short turn is not only THE most critical part (usually true with most heads) but if you did almost nothing to it I can assure you it is stalling at .500 lift or before.

There's no need to sleeve the pushrod holes, but you have to be crafty about slowing the air down right there.

I can get it to 305fps but I have to flow each and every intake port to do it. Measuring is not accurate enough. That's when I charge!!

But it works awesome and these heads will make power for alot less money than other heads.

There is a TON of work on these heads, about 20 hours of porting, seat work and chamber work.

I don't really pour heads anymore, it seems to me that it's really useless because the castings will only allow so much but I would say they are not small! I have to sonic test the ports in some spots when I start cutting to make sure the port will allow my shape.

I'll say this...I spot check the intake ports at 36" from .500 to .700 to see how it works and at .600 it's fairly stable but after that it gets a little turbulent!!

So your telling me all thework ive done on these heads are worth nothing?

No....I'm giving an overview of what I've seen after doing like 15 sets of these heads.

And on the street stuff we actually speed up the air if the lifts are low and it's a 340/360. I'll speed the air up so it's so fast it won't take much more than .550 lift but roll-on power is instant!

My porting is application specific, like any good porter's. I don't subscribe to the cnc "port the head to it's max" jobs because of this. Nothing against good cnc work, but every time I get a cnc'd head I can gain flow and sometimes alot without much work.

There's a guy out here that will digitize ports for me and create programs with really good Haas machine's for cheap as long as I supply him with monthly work, but I just don't want to give up the hands on application specific work that I like to do.

Call me old fashoned I guess...

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/24/07 12:55 AM

Quote:

nice flow #'s

nice flow #'s

what type of bench do you have.

It's a superflow 600. I have the same orfice plates that Curtis Boggs uses to verify the machine ever now and then.

I use the flow com computer and I have 4 different pitot tubes to play with.

I also forgot to add....I've changed my valve jobs in the last couple of years based on things I've learned and they have actually hurt my flow numbers a bit but I see more power from my heads. I flow all my intake ports in reverse just to see what they do from .100-.250 and it's crazy how much that changes with very little effort. My old valve jobs would allow 30-35% more flow backwards than my current work!

Posted By: moderncylinder

Re: Ported edelbrock heads.......pics - 11/24/07 02:01 AM

brian, do you really think that the engine see's a depression representative of 36" when the valve is at .500 lift or higher? i know alot of that stuff is guessing unless youre privilage to pressure sensor info from intake ports and combustion chambers, though that data would be respective to that particular combo. do you try for different air speeds if the same head was being used on a 408 or a 340, since the depressions that both those engines will run at with the same head are so different? do you ever try to influence the intake port when flowing backwards to compensate for inertia like when the engine is running, and how easy or not so easy it is to counteract the pressure you have in the intake port?

ive worked on super stock 318/340/360 combos with moving the pushrod pinch over,, i dont remember exact cross sections but i think we went from .950 across to 1.200 and the motor peaked the same within 100 rpm or so, but past peak made more power. if i remember a 9/1 360 thermoquad made 565 with the .950 pinch and then 570 with the moved pushrod wall both at about 6800rpm, but at 7400 was 40 hp better than with the .950 dimension. you can have too much air speed where fuel will fall out of the air stream but i think thats very uncommon,, or using the wrong parts for a particular combo like a 318 head on a 408 or something like that.

jeff

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/24/07 06:55 AM

Quote:

brian, do you really think that the engine see's a depression representative of 36" when the valve is at .500 lift or higher? i know alot of that stuff is guessing unless youre privilage to pressure sensor info from intake ports and combustion chambers, though that data would be respective to that particular combo. do you try for different air speeds if the same head was being used on a 408 or a 340, since the depressions that both those engines will run at with the same head are so different? do you ever try to influence the intake port when flowing backwards to compensate for inertia like when the engine is running, and how easy or not so easy it is to counteract the pressure you have in the intake port?

ive worked on super stock 318/340/360 combos with moving the pushrod pinch over,, i dont remember exact cross sections but i think we went from .950 across to 1.200 and the motor peaked the same within 100 rpm or so, but past peak made more power. if i remember a 9/1 360 thermoquad made 565 with the .950 pinch and then 570 with the moved pushrod wall both at about 6800rpm, but at 7400 was 40 hp better than with the .950 dimension. you can have too much air speed where fuel will fall out of the air stream but i think thats very uncommon,, or using the wrong parts for a particular combo like a 318 head on a 408 or something like that.

jeff

When I flow backwards I have played with both air speed and flowing it with the intake on. I haven't been doing it enough to have a strong data base for what I find, but I do refer to guy I trust that does great work.

I do change air speed for different applications, but I think on a fast port that might see 7000 rpm it's likeley it will see in excess of 28" of depression, however not steady that's for sure.

I do it basicly to see how the port reacts to higher air speed. I do it to everything just to see how it reacts.

Looking at your example, it would seem that if you took that engine and raised the compression and rpm point that the pushrod work would be worth alot more because of the demand on the intake tract. Infact, I bet it would double the power output that you gave.

Jeff...I'm not the best head porter out there, so not to worry! Just wondering why you would care about a little guy like me??

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/24/07 02:40 PM

Posted By: moderncylinder

Re: Ported edelbrock heads.......pics - 11/24/07 05:00 PM

brain i wasnt poking at ya or anything... there are alot of things going on in an engine and its hard to test 100% accurately to see the effects of inertia, what air speeds are present and so on,, plus air speeds at the accleration rates of a fast drag car. its good to flow things up that high to see if the air is still stable,, but then with humidty, fuel in the air, it gains a cohesion to the walls and becomes more stable yet. reading some of your posts through the last few years i think youre a sharp guy and i like to talk about whats going on,, and theory of internal combustion engines and so on,, and noone usually welcomes that stuff here.

jeff

Posted By: Dunnuck Racing

Re: Ported edelbrock heads.......pics - 11/24/07 06:27 PM

I like to read all the posts like that I can.Keep'em coming.By the way,Jeff,you should write a book,I'd buy it!

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/24/07 09:14 PM

Quote:

brain i wasnt poking at ya or anything... there are alot of things going on in an engine and its hard to test 100% accurately to see the effects of inertia, what air speeds are present and so on,, plus air speeds at the accleration rates of a fast drag car. its good to flow things up that high to see if the air is still stable,, but then with humidty, fuel in the air, it gains a cohesion to the walls and becomes more stable yet. reading some of your posts through the last few years i think youre a sharp guy and i like to talk about whats going on,, and theory of internal combustion engines and so on,, and noone usually welcomes that stuff here.

jeff

That's what the happy face was for at the end of my post!! I know you weren't poking....or at least I'm glad you weren't

I have no problem with these kind of discussions, but you'll find that I don't have all the answers that's for sure!! I learn every day, and it's crazy to think I still have learning to do.

I appreciate it when guys like yourself want to talk about things I consider important. I've learned from really smart guys and I've learned from people that I would not have expected to learn anything from

Jeff you may find somethings you want to talk about may be over my head  I'm still learning

I'm still learning

So let me ask you a question...this was talked about over on speedtalk some, and I've heard mention of this before, but with no confirmation. Have you found that with an engine that's accelerating like a drag engine, that the depression is actually higher at low lifts than at higher lifts in the upper rpm ranges?

I've just started trying high depressions (36") at .100-.300 to see what happens. You ever try this or am I behind the times here????

I know pressure differentials change as the engine accelerates and I understand they are not linear from valve opening to valve closing but it's been said that because of the wave action inside the runner that there could be as much as 3 psi present as the intake valve opens at high rpm where the intake and exhaust lengths are in tune. What's your take on this??

Thanks Jeff, I for one look forward to you posting on this board!

Brian

Posted By: PUNK

Re: Ported edelbrock heads.......pics - 11/24/07 11:28 PM

This is getting good. Both you guys do really good work and I say this with experiance based on Brian doing head work for my friends cars and my own personal stuff and then with Jeff working his magic with Bob Mazzolinis and Ken Etters stuff for Super Stock. All the cars that I have seen with Brians head and Jeffs heads are FAST! To both guys keep up the good work! Look forward to reading both of your posts at any given time.

Posted By: moderncylinder

Re: Ported edelbrock heads.......pics - 11/25/07 03:24 PM

sure you could have 3psi of pressure on the back side of the intake valve,, depends on the combo, rpm range, really just about everything that has to do with the engine. really when you get to looking at a depression, and trying to effectively filling a cylinder,, it takes a free or good flowing head which is usually larger in cross section therefore you need to try to evenly pull on the port with how the piston comes off tdc. alot of guys think the rod connects the crank to the piston, but it will dictate the rate of accleration the piston will decend till the mid point of the cylinder, which is the same for any rod. usually this is a rod ratio of 1.65-1.7, dependning on the storke respective to the port cross section again, that can be changed to help an rpm range thats desired to run, or able to be run, we all want to run it as high as you can without the valve train blowing up.

another thought with sheet metal manifolds,,, its common knowledge that you should contain your swept volume at whatever efficiency your engine will run at,, i usually say 115%,,, in the runner so that your complete mixture that will end up in the cylinder has the initial inertia of being in the runner when the valve first opens to get maximum pressure effecting on the cylinder. by working on volumes in manifolds like that its crazy how much power you can gain,, for every degree of intake valve timing that i can hold it open longer ill get about 7hp. but for an engine like a pro stock, its closer to 12hp,, when you consider how much piston movement 1 degree is you understand how tempermental the pressures are and how a little bit,, can be a whole lot.

did i run on??,, i had a late night

jeff

Posted By: Streetwize

Re: Ported edelbrock heads.......pics - 11/25/07 03:56 PM

I had lunch with David Vizard not long ago and we discussed this tuning a little bit, I asked him specifically about cylinder filling particularly as it related to long intake durations where the valve is closing well past BDC and the piston is rapidly moving back up the cylinder removing effective displacement with every degree.

He mentioned the one fact that manyt people don't completely comprehend...something a motor depends on but we're not really concieous of...the fact that air has mass and a column of air mass in motion has momentum. The very notion that VE's can exceed 100% in a race engine is testament to that fact. You also see and understand how variables in the air density effect power output if there is more or less pressure in the intake tract.

What dry flow benches do not take into account is the fuel atomization and if or how it stays in suspension at various RPM (proportional velocities) through the powerband, Also it's imprtant to realize that with an example 12.5:1 A/F ratio, ~7.5% of the potential flow is displaced by the fuel the air is carrying in suspension...especially in a carburetted motor. to muddy the waters further, on a bench we tend to only look at air moving one way (either into or out of the cylinder)...the effects of reversion when the rapidly moving column of air suddenly gets the door slammed shut as the valve closes and has to regain it's momentum. Then you think that all the airflow moving through an engine in a minute's time when we know that any intake or exhaust valve is closed roughly 2/3'd of the time....regardless of crankshaft RPM this is a mechanical constant.

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/25/07 05:36 PM

I'm glad you touched on rod length....it's a great tuning tool. The best combo's I've build or seen had EVERY component working in the same rpm range. That is why alot of times I suggest to guys who get their heads ported, that they change the cam. Porting changes rpm range as much as it changes power.

A few times a year, I email back and forth with Larry Meaux in Louisiana and he has really helped me to understand some of the things I find. He's also helped me to realize what you just said Jeff about every little detail affecting power.

I see you have a nice write up in Engine Masters magazine about your BB edelbrock heads!!

Brian

Posted By: CRIKEY

Re: Ported edelbrock heads.......pics - 11/27/07 11:50 AM

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/28/07 04:42 PM

If i would like to change the intake valves to 2.05" what length or maybe even a partnr.

Is it worth much?

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/28/07 07:11 PM

Quote:

If i would like to change the intake valves to 2.05" what length or maybe even a partnr.

Is it worth much?

Yes, the bigger valve is worth it. The edelbrock bowls are big enough with some amount of work that the bigger valve is worth the extra dollars. It's not just the valve, it's what you do with the seat, bowls, chamber, etc...that makes it so much better. Just cutting the seats and using a bigger valve is not the way to do it!

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/28/07 07:23 PM

I am not any kind of expert in this subject.

I have unshrouded(?)the valves as much as possible (head gasket) and I have opened the bowls to the point where I am sure I will not risk any performence loss and i guess the valve seat will be proffesionaly done. I will try to post some pics.

Where can i get the valves? are they chevy valves?

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 11/28/07 08:54 PM

You can use any chevy type valve, it just needs to be .100 long chevy valve. .100 longer is almost exactly the stock sb mopar length.

I use Manley and Ferrea but there are others out there...

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/28/07 09:17 PM

You dont happen to have a partnr of the one you preffer to use?

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/28/07 09:44 PM

Quote:

You dont happen to have a partnr of the one you preffer to use?

Ferrea #F6114 has the same specs as their Edelbrock replacement

valve in the 6000 series, other than 2.055" diameter.

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 09:13 AM

How much gain could i expect from upgrading to 2.055 valve?

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/29/07 02:20 PM

Quote:

How much gain could i expect from upgrading to 2.055 valve?

I'm not sure exactly what you can gain as far as CFM. The factory SB Edelbrock

intake bowl is pretty big and throat is over 90%. By going to a 2.05" valve, it

allows you to cut a completely different seat with the extra material. It also

slightly steepens the approach to short turn and gives you more curtain area

throughout the lift cycle. I don't like the Edelbrock chamber, as it has flat chamber

and very pronounced corner adjacent to the intake valve that I find is nearly

impossible to fix without blowing the chamber past the bore it will run on. A 2.05"

valve makes this close proximity even worse.

Can you gain by adding the bigger valve? Yes.......but, there is more air flow to be

gained further back in the port. I'm sure Brian or Ryan will have something to add.

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 07:24 PM

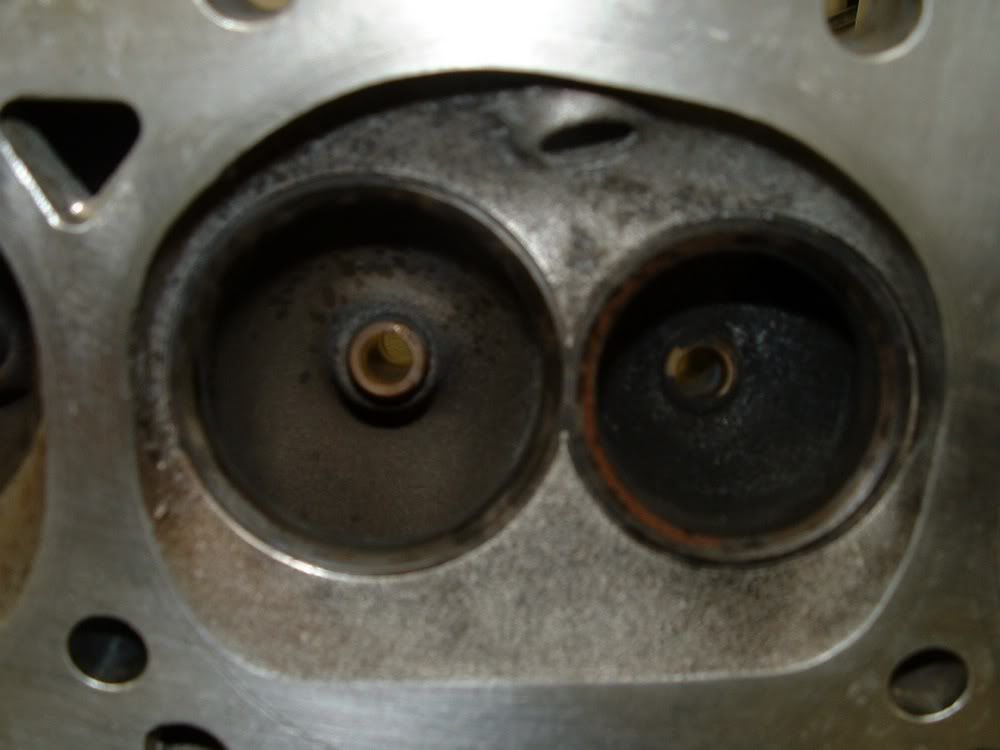

some pics.

Tell me have I ruined these heads?

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 07:24 PM

nr 2

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 07:25 PM

3

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 07:26 PM

4

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 07:27 PM

5

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/29/07 08:23 PM

Quote:

Tell me have I ruined these heads?

Can I think it, without saying it?

Seriously, I'm inclined to think you may have compromised the structure

of the head, despite any air flow improvements you have gained.

That's a lot of meat out of the straight wall.

What are your flow numbers?

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 08:36 PM

I didnt take much off the straight wall just the headboltbulge and some polishing. guess there is some amount of core shift. As for flownrs I wouldnt ask if i ruined the heads if i had flownrs. 200 cfm bad 300 good.

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 11/29/07 09:26 PM

Quote:

Not really knowing what im doing have i actally increased port flow?

Is it possible to improve flownrs without touching the short turn?

I will try to post some pics in a few days.

You can increase flow on it without touching the short turn.

I removed the head bolt bulge (even with the wall) and

opened up the push-rod pinch and minor entrance work and

picked up 21 CFM. I got an additional 16 CFM with short turn

work. I haven't finished the chambers yet or decided on seat

angles so there's a few more in them but, that's all I'm saying.

Good luck.

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/29/07 10:01 PM

What to do with the short turn???

Without destroying it....

I WANT TO LEARN!!!

Ill probably flowbenchtest these heads when im done.

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 11/30/07 09:41 PM

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/01/07 07:56 PM

Quote:

You have to realize, if we could explain to you what to do, everyone could port heads. Porting takes so many years of trial and error, just imagine if someone could explain how to be a NINJA with a few simple words!!!!

It can't be done. Sorry, but that's a fact.

Brian

Posted By: PUNK

Re: Ported edelbrock heads.......pics - 12/01/07 08:47 PM

Now thats funny stuff right there!

Posted By: cheapstreetdustr

Re: Ported edelbrock heads.......pics - 12/02/07 04:23 AM

Quote:

What to do with the short turn???

Without destroying it....

I WANT TO LEARN!!!

Ill probably flowbenchtest these heads when im done.

you should have flow tested them before during and after..its the difference or change your really after..

that short turn looks really sharp/square to me..

but thats all i can say.

0u812.. do you have any pics of the guide area or roof of the bowl..?

you guys dont have any issues with removing all that guide boss?

Posted By: cheapstreetdustr

Re: Ported edelbrock heads.......pics - 12/02/07 04:29 AM

i am currently running a set of stock irons with the pushrod pinch removed and offset rockers..

the short turn and valve job made a big difference.and took a while to hit the right combination..

including cam shaft..the wrong one just flat killed it..this thing likes lift.

cheapst.

Posted By: cheapstreetdustr

Re: Ported edelbrock heads.......pics - 12/02/07 04:30 AM

#2

Posted By: sshemi

Re: Ported edelbrock heads.......pics - 12/02/07 09:52 AM

Quote:

Quote:

You have to realize, if we could explain to you what to do, everyone could port heads. Porting takes so many years of trial and error, just imagine if someone could explain how to be a NINJA with a few simple words!!!!

It can't be done. Sorry, but that's a fact.

Brian

You have to realize that i realize that. sorry that I didnt make myself clear. What i meant was is the shortturn so bad from e-brock so you have to do something to it just to make it ok.

I am no complete idiot.

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/02/07 06:11 PM

Quote:

Quote:

Quote:

You have to realize, if we could explain to you what to do, everyone could port heads. Porting takes so many years of trial and error, just imagine if someone could explain how to be a NINJA with a few simple words!!!!

It can't be done. Sorry, but that's a fact.

Brian

You have to realize that i realize that. sorry that I didnt make myself clear. What i meant was is the shortturn so bad from e-brock so you have to do something to it just to make it ok.

I am no complete idiot.

I sure didn't mean to sound like I thought you were an idiot! Sorry if you took it that way. I was trying to lighten the situation up a bit that's all.

I can tell you this, the short turn will end up looking like it would not work at all. But it will.

Just be carefull you dont go too far with it!

I'll post a mold I did of the stock port tomorrow nite so you can see what I mean. Infact the whole floor can be lowered quite a bit...

Brian

Posted By: Stroker Scamp

Re: Ported edelbrock heads.......pics - 12/02/07 11:48 PM

this is a really good read guys BTW i am a NINJA

Posted By: fast68plymouth

Re: Ported edelbrock heads.......pics - 12/29/07 06:33 AM

i'll bump this one back from the dead zone, since i'm actually hoping for a little more info to trickle out from Brian and S/ST.

ive ported a few sets of these heads, and frankly.....have never really been satisfied with what i got from them on the bench.

although, two of the sets i ported went on motors i got to dyno, and both made decent power. one of those 2 motors is in a bracket car that sees regular use, and i feel is a pretty strong runner for as basic of a combo as it is......yet, ive always felt there should be more to get out of these heads than what ive gotten from them.

what ive found is that they arent too bad OOTB, and respond nicely to a very minimal clean-up and valve job.

but beyond that, the gains come very hard, for me at least.

i'd like to hear an overview from Brian and S/ST, as to the approach they take in reshaping the short turns, roof, and chambers, to see how that might differ from what ive tried.

where are you grinding....and why?

ive tried several different approaches to the roof and short turns.......with about the same results either way.

how far are you sinking the valves to get a better blend from the V/J into the chamber?

when i look into the intake runners on these things....and look at the roof shape and angle......it just doesnt seem to make any sense to me.

what am i missing???

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/29/07 06:47 AM

Quote:

i'll bump this one back from the dead zone, since i'm actually hoping for a little more info to trickle out from Brian and S/ST.

ive ported a few sets of these heads, and frankly.....have never really been satisfied with what i got from them on the bench.

although, the two sets that went on motors i got to dyno both made decnt power, and one of those 2 motors is in a bracket car that sees regular use, and i feel is a pretty strong runner for as basic of a combo as it is......yet, ive always felt there should be more to get out of these heads than what ive gotten from them.

what ive found is that they arent too bad OOTB, and respond nicely to a very minimal clean-up and valve job.

but beyond that, the gains come very hard, for me at least.

i'd like to hear an overview from Brian and S/ST, as to the appraoch they take in reshaping the short turns, roof, and chambers, to see how that might differ from what ive tried.

where are you grinding....and why?

ibe tried several different approaches to the roof and short turns.......with about the same results either way.

how far are you sinking the valves to get a better blend from the V/J into the chamber?

when i look into the intake runners on these things....and look at the roof shape and angle......it just doesnt seem to make any sense to me.

what am i missing???

Don't feel like the Lone Ranger, I went through that as well when I first started on them.

I first open the pushrod pinch up to max. I do raise the roof some, but not a bunch. Mostly where the roof tapers down to the wall.

Here's some info I don't like to give out, but without having a feel for it, most people probably couldn't do it...I move the pushrod side of the wall from right after the pinch to the bowl...alot. Think SB chevy brodix T1 head. It's real easy to get lost when moving this wall because it' a constant taper into the bowl. So I made templates to help me. They are only card board but it helps alot.

Then if you've ever seen an older afr chevy head's S/T that's what you shoot for on the short turn. And you have to measure the air speed at the pushrod pinch on each port if valve lift is going to exceed .650 lift. If the port is too fast here it will screw up the air speed over the short turn.

But Dwayne, I don't know if your bench will pull 28"'s....and I also check the ports at 36" when I'm done. Just to listen to the port and see how the air changes in the port from low lift to high lift. It's pretty amazing!!

Hope this helps, all I can say is that it takes a loooooong time to port when doing them this way.

Brian

Posted By: S/ST 3040

Re: Ported edelbrock heads.......pics - 12/29/07 03:50 PM

Dwayne....First of all, I'm glad to see you posting here more often.

Concerning the SB Edelbrock heads, these are the second set I've ever done. The first set was done in 1999. I'm in agreement with Brian here on the information I give out, even though it's hard for the average racer to duplicate. Hell, sometimes it's hard for me to duplicate!

This head came from a running bracket car that ran a best of 11.79 @ 114 (3340 lbs.) #1 Intake flowed 238.3 CFM @ .550" and went turbulent at .600"+

Here's what I did......Layed out the entry 1.100 x 2.250, opened pushrod pinch to .970" smoothly blending into curved wall. Next, I cut the head-bolt bulge even with the straight wall. I also blended away the "knob" at the base of 1/2" guide. These changes upped the flow numbers to 257.2 @ .500" and went turbulant above that.

Next was the S/T. Looking at the bowl into the short turn, you'll notice the s/t engages approximately 3/8 the circumference of the bowl. I pushed the corners back to the top of the s/t, making it appear more like a water fall than the "Horse Shoe Falls". I hope that makes sense. In the middle of the s/t is pretty much the way it came, with only the corners pushed back to match it. If you feel where the s/t and floor meet, you can feel a slight peak (factory). I very lightly sand roll that area only to smooth the transition. With these changes, it now flows 263 @ .500", 270.2 @ .550" and 273.6 @ .600"

I have since worked on the chambers some but, haven't checked them on the flow bench. I am also still undecided on the valve job, having measured and calculated and have come to the conclusion, I still don't like that flat chamber. These heads belong to a friend of mine so, I haven't cut on them like they were mine. I'd hate to ruin them since he's trusting me to make the car faster.

I'm not sure any of this is going to help an ace porter like you but, that's about all I can do.

What is your most common aproach to this head and what kind of flow are you getting from the SB Edelbrocks?

Posted By: moderncylinder

Re: Ported edelbrock heads.......pics - 12/29/07 06:52 PM

im going off memory here,, but i was surprised that when i "plugged" a port into one of these heads it went from like 250 to 270 or so,,, i thought that port should flow way more than that,, so i did a valve job,, which is a std deal anyways,, and dropped the depth down about .020-.025 and then it flowed a little over or around 300. the port recognized all the port work then,, cause an out of the box head with a good valve job only picks up 5 or so.

jeff

Posted By: fast68plymouth

Re: Ported edelbrock heads.......pics - 12/30/07 02:54 AM

Brian, when you move that curved wall, do you make it more "S" shaped(scallop out more as you get closer to the bowl), or leave it pretty straight, and just move it over?

as for the slope of the roof.....how much of the angle would you say you eliminate?

1/2 of it? 3/4 of it? all of it?

the way i see the roof, with the head upside down, looking into the intake runner, the roof slopes down away from the straight wall.

but, way up by the guide, its also slopes away from the curved wall, leaving somewhat of a peak in the roof just before the guide boss.

when you carve out that curved wall, do you take it out all the way to the roof?

do you leave the roof as is on the curved side, or do you flatten it out(as in, raise it adjacent to the guide boss to diminish the "peak")?

Vic,

i understand what you're saying about the short turn, and thats actually one of the shapes i tried.....but i was still getting some turbulence.

Brian is saying the pinch area is a player for how the short turn behaves at high lifts with these heads. i have a set in the shop now that were previously ported by??? and i'm trying to fix them.

frankly.....if i can get them to be pretty steady at .650 lift without losing a bunch of flow.....i'll probably leave them like that.

how you got the ones you're working on to be steady at .700 is what i'm shooting for on these.

this set has already had the chamber walls pushed out some, which frankly i dont think is helping at the high lifts.

Brain, one more thing.....in your pics, it looks like the short turn, on the straight wall side, has been pulled back some.

as cast, these heads seem to have the short turn biased towards the curved wall....and it looks like you're kind of going the other way.....or am i not seeing it right??

Jeff, this set of heads i'm working with now has had the intake valves lowered at least .025.

i mean....these things sure "look", and feel(at the short turn) like they would be good right up past .700 lift......but they're just weak from .500 and up.

Posted By: DrJ'sPerformance

Re: Ported edelbrock heads.......pics - 12/30/07 03:31 AM

Are your flow numbers with the Edelbrock valve Job? The on reason I ask is it can cause you to lose low lift flow.

Some flow numbers on a RPM Magnum I just ported

Edelbrock Performer RPM Magnum

.100 74cfm .100 62cfm

.200 151cfm .100 118cfm

.300 221cfm .300 160cfm

.400 263cfm .400 196cfm

.500 288cfm .500 217cfm

.600 294cfm .600 220cfm

.700 297cfm .700 236cfm

Intake Valve 2.02 Exhaust Valve 1.60

( Exh. Flow Tested with a Flow Pipe)

*Flow tested at 28 inches

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/30/07 07:19 AM

Dwayne, I don't move the entire wall. I like to make the walls more rounded than straight.

I use a 3/8 burr and tighten up the corner radius at the pinch. I also will lower the floor there and make it rounded.

When I'm done the s/t is lower and radiused more.

I also sleeve the bolt hole that has oil in it, so that wall is pretty thin at the bolt hole.

I also reshape the roof as it transitions to the backside of the bowl. And I widen the bowl at the roof so there is some taper from the roof to the seat.

I know some guys will not open up the chamber to help the port hang on, but I don't think this is productive to making power. I haven't done any testing like that though, so I cannot say it with full conviction.

I wouldn't worry about the port past .650 lift unless it's a serious engine that will rev past 7500rpm or going on a stout 4" sb.

If you can, bolt a good intake on it and flow it that way. It usually makes the port hold on to well over .700 lift. But I believe that when fuel is in the air stream, it can easily seperate from the air if the air has to do alot of slowing down-speeding up or has to turn abruptly.

Brian

Posted By: moper

Re: Ported edelbrock heads.......pics - 12/30/07 02:28 PM

Just a word of thanks guys...

This type of constructive posting has faded from this forum, at the publics' loss.

I do have aquestion tho, the intake plate, or intake manifold as opposed to a clay radius... I have not played with the clay because I no longer have access to a good bench, or a ton of interest in spending hours of time I no longer have. But, it's my feeling that resulting numbers can be skewed by playing with the shape and amount of clay. What kind of loss typically do you guys find in going from a hand done clay radius to a plate, and from a plate to a complete manifold? Brian, do you also use a carburetor too, or just the manifold? To what degree are you guys pushing to?

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/30/07 06:12 PM

Quote:

Just a word of thanks guys...

This type of constructive posting has faded from this forum, at the publics' loss.

I do have aquestion tho, the intake plate, or intake manifold as opposed to a clay radius... I have not played with the clay because I no longer have access to a good bench, or a ton of interest in spending hours of time I no longer have. But, it's my feeling that resulting numbers can be skewed by playing with the shape and amount of clay. What kind of loss typically do you guys find in going from a hand done clay radius to a plate, and from a plate to a complete manifold? Brian, do you also use a carburetor too, or just the manifold? To what degree are you guys pushing to?

I have done some testing with the intake and carb bolted on...  It's VERY time consuming.

It's VERY time consuming.

I have tried a couple of plates on sb chevy's and then used clay and there is almost no difference. If anything, the plate will be a tad better.

But I get stuff that has already been ported, and the plate does not fit the opening correctly, so clay is just faster.

On a high flowing head, with fast air speed I spend some time on the clay....but if you don't it can lead you astray.

Just for fun, I tried messing the clay up on a B1 original head a while back just to see where it starts to affect the flow...I had to almost square it off before it showed any negatives! But it was still 1/2 thick at that point.

I spend alot more time getting intake length's where they need to be for a particular combo than every last cfm. I have seen some pretty sizeable gains from under powered engines (compared to what they should make)by getting the intake length's right, and plenum correct.

And changing my seat cuts has brought around power in my stuff too. Like I said, I never seem to stop learning stuff....that's why I love this business.

Except when I'm beating my head on the flow bench like Dwayne's doing...those times are frustrating

Posted By: fast68plymouth

Re: Ported edelbrock heads.......pics - 12/30/07 06:55 PM

these heads i'm working on came off a 13.5:1 422" motor.

this particular build is definately a combo thats got a few shortcomings.

its in an early A body with like 1 1/2" primary tube headers for one.

it had a long duration aggressive flat tappet cam in it that i felt was really just wrong for the car, so thats getting changed to a roller.

the intake bowls on these heads have been enlarged slightly under the valve seat insert, and are already at about 93%.

they also left a little ridge at the bottom of the insert where it meets the casting.....and the bottom "angle" is about a 12mm radius off of the 45 deg seat.

i'm going to put a 2.055 intake valve in to get the percentage a little lower, and give me some meat to play with on the valve seat.

i'll post some numbers in the next couple of days.

as i said.....if i can just get them to not really take a dump after .500 lift, i'll be reasonably happy with that.

i dont have a race type SB intake at the shop, but i'm sure using it would "cure" the high lift issues.

Brian, as for the chambers.....the results you got would indicate that some chamber mods arent necessarily the kiss of death with these heads, but i think with a "better" initial shape of the chamber to start with, especially right off the seat, these heads would be less time consuming overall to get the kind of numbers you got out of them.

on some heads the flat roof doesnt seem to really be an issue(BB Mopar E heads, stage 6 heads), but on others.....they need that chamber wall in closer proximity to the valve.....especially as you get nearer to the seat.

if one were to have a scrap head to play with, it would be intersting to epoxy up one of these chambers and start from scratch, and see what happened then.

one last thing, since you have found the pinch area is a big player with these things......i guess that would bode well for the Indy-Brocks.....since it can be eliminated on those things.

maybe an Indy-Brock type head, with a "real" chamber, and true W-2 style exhaust ports might be a nice little unit someone should start making

Posted By: 64dartsb

Re: Ported edelbrock heads.......pics - 12/30/07 06:56 PM

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 12/30/07 09:29 PM

With that build, I would consider a 2.08 valve.

That combo sounds like the kind of crud I deal with all the time! Makes you wonder what the heck they were thinking???????

What top angle do you use?

Posted By: meus31

Re: Ported edelbrock heads.......pics - 02/25/10 02:51 AM

great post guys some real good info in this thing anybody got any new info

Posted By: WILD BILL

Re: Ported edelbrock heads.......pics - 02/25/10 03:20 AM

Quote:

anybody got any new info

Since you asked, Scott Koffel is in the process of doing mine now

We cc'd the chamber and found they were real close to their advertised volume of 84cc'ss. They measured a true 83.8 cc's.

OOTB flow was 269 @ 800 on a super flow bench

Flowed after getting worked they went to 306 @ 800. I think he said they were at 298 at 600 and 700. We also milled .090 off of them and got the chambers down to 64.6 cc's

Some comparison shots

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 02/25/10 04:25 AM

This was a post about small block edelbrock heads...Looks good though wild!

You guys dug this up from a while ago!!

Posted By: WILD BILL

Re: Ported edelbrock heads.......pics - 02/25/10 04:33 AM

Posted By: Triple Threat

Re: Ported edelbrock heads.......pics - 02/25/10 04:38 AM

Quote:

Its ok, we know you're new here lol

Posted By: WILD BILL

Re: Ported edelbrock heads.......pics - 02/25/10 04:44 AM

Posted By: Stroker Scamp

Re: Ported edelbrock heads.......pics - 02/25/10 04:49 AM

i just found my flow sheet, here ya go

Posted By: Brian Hafliger

Re: Ported edelbrock heads.......pics - 02/25/10 04:54 AM

Quote:

I'm sick as a dog with a cold, but that made me laugh!!

Nice looking ports, now lets get back to work on the Picoso motor!!

Nice looking ports, now lets get back to work on the Picoso motor!!

Sorry guys. I'll have them monday nite or you can hang me out to dry!!

Sorry guys. I'll have them monday nite or you can hang me out to dry!!

It's VERY time consuming.

It's VERY time consuming.