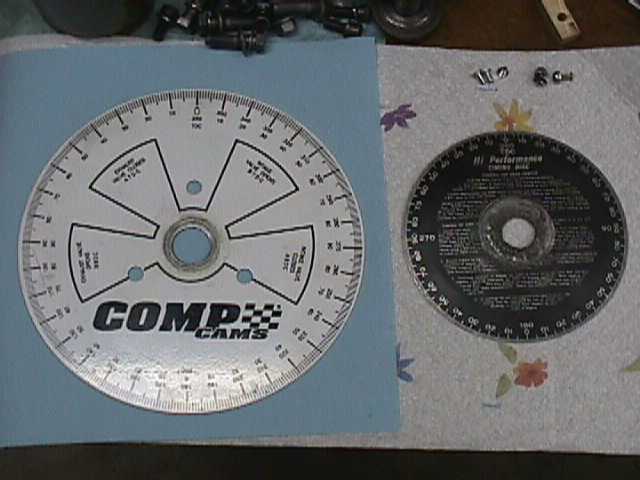

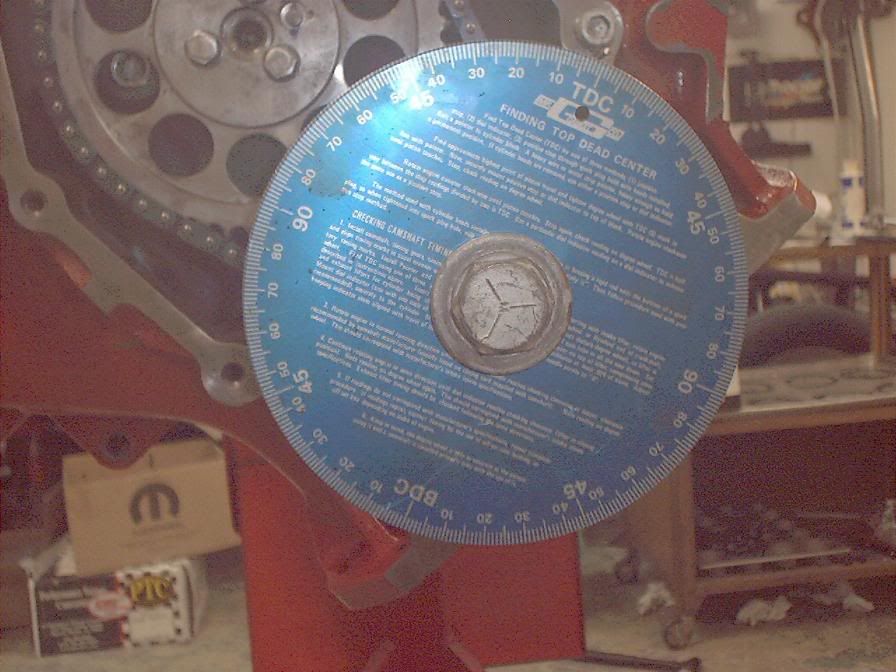

I had one Moroso degree wheel and one Mr Gasket, I gave one of them to 9secondPhil years ago, my point is that , as already pointed out, that some of the degree wheels will mislead you. I bought one form Comp Cams last year as the center of the old ones was getting worn and wouldn't always center good

, The new one doesn't have a centering adapter so I have to hold it on center and tighten the bolt up and hope it stays in the center

LOL

The intake cylce begins with the intake valve opening before top dead center and ends up closing after bottom dead center with max lift somewhere bewteen 90 degrees after top dead center and 120 after top dead center, some people will call that 90 degrees before bottom dead center and 60 degrees BBDC

The thing to remember on checking the cam timing on both lobes at .050 lifter rise is to add the 180 degrees between TDC and BDC that happens every time the valves open and close, if the intake valve opens at 35 .050 lifter rise before top dead center and closes at 56 degrees after bottom dead center you have 35+180+56 which equals 271 degrees intake valve duration at .050

Same thing on the other side but the exhaust valve timing starts before BBDC and closes ATDC, so its maximum valve opening is always going to occur before top dead center. On finding and checking lobe center you measure in relation to max lift .050 before and after, I measure in three places to make sure what the valve is seeing as it reaches maximum lift

don't be suprised to occasionally see one degree variation on those three places

My point on bringing this up is you can check it at .300 begore max lift or .050 BML, the lobe center will stay where the cam grinder made it

As far as degree wheels, here is a picture of the two I have now, they are confusing if you don't use them as a way to measure cranksaft degrees only

Bob

Bob

This is how I do mine also.

This is how I do mine also.

) know what the valves are doing, they don't know or care what the lifters are doing

) know what the valves are doing, they don't know or care what the lifters are doing

If it is hydraulic cam and lifters I use a solid lifter and set the lash at zero

If it is hydraulic cam and lifters I use a solid lifter and set the lash at zero

a

a

, The new one doesn't have a centering adapter so I have to hold it on center and tighten the bolt up and hope it stays in the center

, The new one doesn't have a centering adapter so I have to hold it on center and tighten the bolt up and hope it stays in the center  LOL

LOL  Same thing on the other side but the exhaust valve timing starts before BBDC and closes ATDC, so its maximum valve opening is always going to occur before top dead center. On finding and checking lobe center you measure in relation to max lift .050 before and after, I measure in three places to make sure what the valve is seeing as it reaches maximum lift

Same thing on the other side but the exhaust valve timing starts before BBDC and closes ATDC, so its maximum valve opening is always going to occur before top dead center. On finding and checking lobe center you measure in relation to max lift .050 before and after, I measure in three places to make sure what the valve is seeing as it reaches maximum lift