Posted By: Dragula

And this is why Alum G2 Hemi's are such a PITA

Posted By: Hot 340

Re: And this is why Alum G2 Hemi's are such a PITA - 04/08/24 10:45 PM

Originally Posted by Dragula

Posted By: gtx6970

Re: And this is why Alum G2 Hemi's are such a PITA - 04/08/24 11:07 PM

1600 hp is nuts on a street car

Posted By: rickseeman

Re: And this is why Alum G2 Hemi's are such a PITA - 04/08/24 11:24 PM

Originally Posted by gtx6970

1600 hp is nuts on a street car

Yes, on a 10" tire no less. I would rather have had the 1200 at 5 psi.

Posted By: Craig J

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 12:15 AM

Originally Posted by Dragula

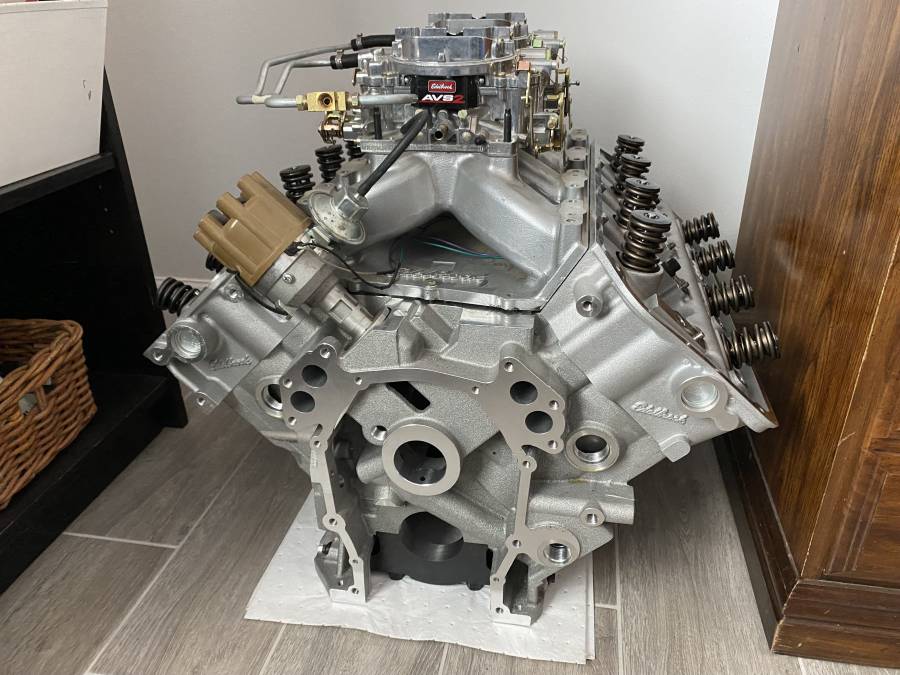

yeah...considering the fairly expensive pile of aluminum sitting next to my desk, that video was not what I wanted to see...

Posted By: Dragula

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 12:22 AM

Originally Posted by Hot 340

Originally Posted by Dragula

Well I would blame World more than anything, cause he has done that before, along with drilling head deck holes into the water jackets, as well as the trans holes into the water jackets, but figured I would take the high road. But this is a potential problem on any aluminum G2 Mopar block where the sleeve installer does not have a good process...I really like the newer Non-mopar dry deck blocks that have evolved to eliminate this issue. Mopar should follow.

When I worked at GM, we put the sleeves in with liquid nitrogen and a automated sleeve hammer that hammered them to the bottom...Seems the after market has not figured this out yet. It changes sound when it hits the bottom. Then we heat cycled them. Seems like a PITA process, but you don't see factory engines having that issue too often.

Posted By: turbobitt

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 12:32 AM

Why does this dropped sleave problem seem to come up from time to time ??

AG.

AG.

Posted By: 6PKRTSE

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 01:59 AM

We use liquid nitrogen on our sleeves and heat our blocks om an oven when installing sleeves and make sure they are seated. I always pressure check my blocks and heads before machining, even used OEM blocks and heads to verify that they are not junk before wasting time and money on machining them.

Posted By: AndyF

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 02:38 AM

The 572 Indy engine that Best Machine built for me a couple of years back dropped the sleeves. I never talked to Chuck about it but I assume that the block came from Indy with the sleeves installed. If so, then Indy might have the same issue with sleeves dropping. If you're buying an aluminum block it makes sense to ask the vendor about the sleeves.

On the flip side, we've run a ton of aluminum Chevy engines over the years and never seen a dropped sleeve. So maybe Dart and Brodix and others have it figured it out?

On the flip side, we've run a ton of aluminum Chevy engines over the years and never seen a dropped sleeve. So maybe Dart and Brodix and others have it figured it out?

Posted By: Cab_Burge

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 02:43 AM

Originally Posted by Hot 340

Originally Posted by Dragula

I had the same thing happen on the sleeves on the first KB aluminum street hemi blown motor I built but they were .002 to .004 to high from KB back in the early 2000s causing water leaks into the motor

That was a much smaller motor with a bad BDS blower and a early FAST EFI system built by the owner at that time of BDS, Craig Raisbeck

That motor ended up with a10:71 Littlefield Blower and a Motech EFI system with a 3 hole bug catcher hat (3000CFM I think)) on the blower back in 2005 or so on CA pump swill

Posted By: gearhead01

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 02:55 PM

Originally Posted by Dragula

Originally Posted by Hot 340

Originally Posted by Dragula

Well I would blame World more than anything, cause he has done that before, along with drilling head deck holes into the water jackets, as well as the trans holes into the water jackets, but figured I would take the high road. But this is a potential problem on any aluminum G2 Mopar block where the sleeve installer does not have a good process...I really like the newer Non-mopar dry deck blocks that have evolved to eliminate this issue. Mopar should follow.

When I worked at GM, we put the sleeves in with liquid nitrogen and a automated sleeve hammer that hammered them to the bottom...Seems the after market has not figured this out yet. It changes sound when it hits the bottom. Then we heat cycled them. Seems like a PITA process, but you don't see factory engines having that issue too often.

I have been PM/Chief Engineer on several of the machines that automatically install sleeves in aluminum blocks. Have done the nitrogen sleeve (Saturn/GM) and heating the block (Mercury Marine) method. In both, the sleeves are held down and the tooling is hammered to seat the sleeve. The amount of movement is measured to verify that on the last hit, the sleeve did not move. Yes, you can hear the difference in sound. The reason to seat is not just to prevent the water leakage problem in the Steve Morris video. If the deck is cut with a gap under the head of the sleeve, in operation, the bore in the aluminum expands expands more than the sleeve outside diameter. The sleeve will "float" and will move up and down with the piston. Eventually can damage the block and head.

John

Posted By: JohnRR

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 03:44 PM

Originally Posted by Craig J

Originally Posted by Dragula

yeah...considering the fairly expensive pile of aluminum sitting next to my desk, that video was not what I wanted to see...

Perfect timing for this video then.

Even though they are extremely heavy I'm glad my hemi is iron ...

Posted By: rickseeman

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 03:49 PM

I don't get it. Yes, when you put a sleeve in a 440 you hammer it down to the bottom and "seat it". It has no register on the top to keep it from going up and down if it wasn't seated. But everything I've worked with that had "real" sleeves has a register on the top. The OD dependent on the bore spacing, and the depth of around .250". The block is counterbored .250" and you put the sleeve in that also has a .250" register. Now this isn't rocket science. You stick a sleeve with a .250" register in a hole that has a .250" counterbore and the top of the sleeve will be flush with the deck. You can verify this by running your finger across it. I bought a new Indy block once. The sleeves were about .002" below the deck. I was afraid that wouldn't seal so I decked it 003". Again, this is basic math. Either the counterbore was too deep or the sleeve was cut too thin. So much for Indy's quality control. So I don't have any idea how the sleeves in the video could "settle".

Posted By: Cab_Burge

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 05:06 PM

Originally Posted by JohnRR

Originally Posted by Craig J

[quote=Dragula]https://www.youtube.com/watch?v=8TF2hNLb3b0

Even though they are extremely heavy I'm glad my hemi is iron ...

The difference in weight does not make me want to run aluminum blocks unless they are blown or supercharge, the ring seal on the starting line versus how much the sleeves change in a aluminum block dring the run makes me stay away from them.

A friend of mine saw the crankcase pressure go from 12 inches of vacuum on the starting line on the 1/4 mile tracks go up to1.5 lbs. of crankcase pressure on a mid to low 7 second car with his aluminum race motor compared to his iron block race motor starting the run with 17.5 inches of vacuum on the starting line and cross the 1/4 mile finish line with 12.0 inches of vacuum.

I'm pretty sure they got a lot less runs (25 to 30 more runs on the iron blocks) out of the rings also on the aluminum race motor compared to the iron block race motors

Posted By: Al_Alguire

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 09:55 PM

All my engines are aluminum and I have seen NONE of those issues. But we also make sure everything is correct before we start, and yes checking sleeves is on the list. Never ASSume...FWIW my aluminum engines see 17+ inches of vacuum, never been an issue.

Posted By: Dragula

Re: And this is why Alum G2 Hemi's are such a PITA - 04/09/24 10:35 PM

Originally Posted by gearhead01

Originally Posted by Dragula

Originally Posted by Hot 340

Originally Posted by Dragula

Well I would blame World more than anything, cause he has done that before, along with drilling head deck holes into the water jackets, as well as the trans holes into the water jackets, but figured I would take the high road. But this is a potential problem on any aluminum G2 Mopar block where the sleeve installer does not have a good process...I really like the newer Non-mopar dry deck blocks that have evolved to eliminate this issue. Mopar should follow.

When I worked at GM, we put the sleeves in with liquid nitrogen and a automated sleeve hammer that hammered them to the bottom...Seems the after market has not figured this out yet. It changes sound when it hits the bottom. Then we heat cycled them. Seems like a PITA process, but you don't see factory engines having that issue too often.

I have been PM/Chief Engineer on several of the machines that automatically install sleeves in aluminum blocks. Have done the nitrogen sleeve (Saturn/GM) and heating the block (Mercury Marine) method. In both, the sleeves are held down and the tooling is hammered to seat the sleeve. The amount of movement is measured to verify that on the last hit, the sleeve did not move. Yes, you can hear the difference in sound. The reason to seat is not just to prevent the water leakage problem in the Steve Morris video. If the deck is cut with a gap under the head of the sleeve, in operation, the bore in the aluminum expands expands more than the sleeve outside diameter. The sleeve will "float" and will move up and down with the piston. Eventually can damage the block and head.

John

So I was also the engineer on the L850 line in NY here...The knocker machine did indeed measure the drop and it knows they are seated. But that is not the end of it. The sleeves are left proud of the head deck by .002-.003 if I remember, and then the blocks go thru the heat cycle'er....

Now one thing only a block engineer will know is, bad sleeve boring can also push the sleeves out. If you have a dull boring insert and bore the sleeve or sleeves with it, you will put a lot of residual force into the sleeve. This can be measured if you know what the sleeve height was before you bored it. If its higher after boring, the sleeve is junk, and needs to be pulled.

After sleeve boring and measuring, the block is decked and all should be flat....BUT only if the sleeves were seated & bored correctly.....I am not so sure the after market has the process down.

Posted By: mopar dave

Re: And this is why Alum G2 Hemi's are such a PITA - 04/10/24 03:39 PM

On the Bill Mitchell block the sleeve only has .001" interference fit or it will crack between the bores. Once the sleeves are set, they can push out just with temperature changes. They are to be reset before decking. I'm hoping Best Machine reset mine before decking. Fingers crossed.

Posted By: an8sec70cuda

Re: And this is why Alum G2 Hemi's are such a PITA - 04/10/24 04:57 PM

Originally Posted by Al_Alguire

All my engines are aluminum and I have seen NONE of those issues. But we also make sure everything is correct before we start, and yes checking sleeves is on the list. Never ASSume...FWIW my aluminum engines see 17+ inches of vacuum, never been an issue.

I built it in 2006, freshened it twice. Then went .010" over in 2019. Ran a new best this past weekend.

Posted By: gregsdart

Re: And this is why Alum G2 Hemi's are such a PITA - 04/10/24 08:50 PM

Originally Posted by Cab_Burge

Originally Posted by JohnRR

Originally Posted by Craig J

[quote=Dragula]https://www.youtube.com/watch?v=8TF2hNLb3b0

Even though they are extremely heavy I'm glad my hemi is iron ...

The difference in weight does not make me want to run aluminum blocks unless they are blown or supercharge, the ring seal on the starting line versus how much the sleeves change in a aluminum block dring the run makes me stay away from them.

A friend of mine saw the crankcase pressure go from 12 inches of vacuum on the starting line on the 1/4 mile tracks go up to1.5 lbs. of crankcase pressure on a mid to low 7 second car with his aluminum race motor compared to his iron block race motor starting the run with 17.5 inches of vacuum on the starting line and cross the 1/4 mile finish line with 12.0 inches of vacuum.

I'm pretty sure they got a lot less runs (25 to 30 more runs on the iron blocks) out of the rings also on the aluminum race motor compared to the iron block race motors

Cab, i have ro wonder if the serious vacuum decrease was related to something with the rings, or too much oil in suspension at high rpm? My dart with a BMP aluminum block lost vacuum, but dropped from 6.8 to 4? 1/4 mile, and 7500 rpm in the traps.

Posted By: mopar dave

Re: And this is why Alum G2 Hemi's are such a PITA - 04/11/24 01:56 AM

My block is at my other home, so I can’t look at it right now, but can’t the sleeve be checked for seating by trying a .001” or .002” gauge under the sleeve?

Posted By: Cab_Burge

Re: And this is why Alum G2 Hemi's are such a PITA - 04/11/24 04:30 AM

I've never raced or had hands on help on any brand aluminum drag race motor so I'm repeating what I've heard or been told by those that do race them, other brand non Mopar aluminum blocks

Posted By: mopar dave

Re: And this is why Alum G2 Hemi's are such a PITA - 04/12/24 03:22 AM

Ok, but what if i find my sleeves have moved up above the deck? My block has all of the rotating assembly in it, cam included. Can i just heat the block and torque the head down to press them back in?

Posted By: rickseeman

Re: And this is why Alum G2 Hemi's are such a PITA - 04/12/24 03:56 AM

I don't think they will rise above the deck.

Posted By: Cab_Burge

Re: And this is why Alum G2 Hemi's are such a PITA - 04/12/24 08:25 AM

Call the block maker and ask them if the sleeves are suppose to be above the block .002 to .003 cold so they will be flush or a tiny bit down with the motor running and warmed up, The KB Street hemi blocks were designed that way back when I built my street hemi block in the early 2000s

Posted By: mopar dave

Re: And this is why Alum G2 Hemi's are such a PITA - 04/12/24 12:40 PM

When i purchased the block the sleeves were .003 above the deck. Best Machine decked the block, but i have no way of knowing if they reset the sleeves before hand. Doesn't mention it on the receipt and they are no longer in business. The sleeves in this block only have a .001 interference fit, so they move easily with temperature changes. I should be ok, i'm just being mindful of the situation. I now understand the French gentleman in the video had that block polished and the block was recleaned after, heating the block and allowing the sleeves to move. Steve missed it and they had that sleeve drop issue.