Posted By: 19_Dart_68

Full Groove vs. 3/4 Groove Mains for BB Mopar - 03/01/24 07:44 PM

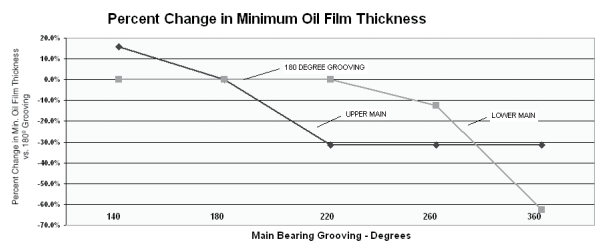

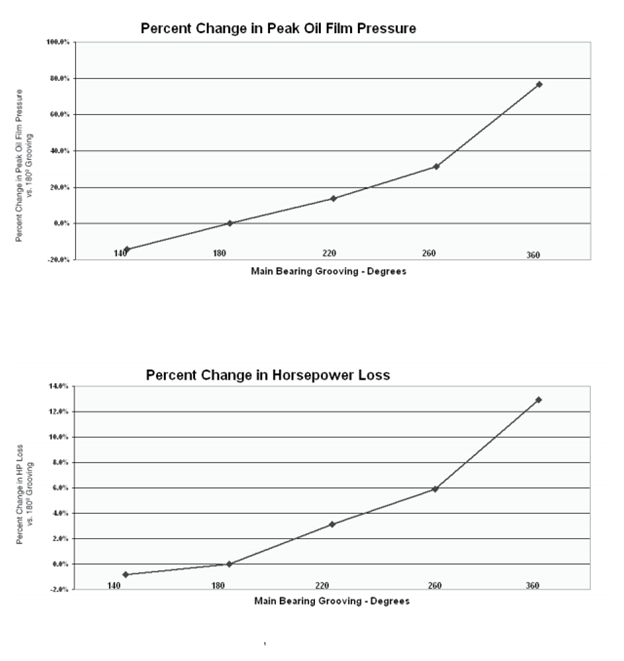

According to Mahle-Aftermarket's documentation, 3/4 groove bearings promote less HP loss and don't suffer any lubrication loss vs. Full Groove bearings.

Is there any reason to not use 3/4 groove bearings in a BB Mopar stroker engine? Or any better reason(s) to use Full Groove instead of the 3/4-groove?

Is there any reason to not use 3/4 groove bearings in a BB Mopar stroker engine? Or any better reason(s) to use Full Groove instead of the 3/4-groove?