Moparts

ladder bar setup

Posted By: birdtracker

ladder bar setup - 05/02/23 01:50 AM

3,000 pound car 14X32 slicks, trans brake. 28 inch bars. Bar flat or angled? Birdtracker

Posted By: 68roadrunner

Re: ladder bar setup - 05/02/23 02:32 AM

Depends on hp, front travel and weight bias

Typically 2-4 degrees down in the front

Posted By: Cab_Burge

Re: ladder bar setup - 05/02/23 07:01 AM

3,000 pound car 14X32 slicks, trans brake. 28 inch bars. Bar flat or angled? Birdtracker

Test, test and test some more so you learn what works best on YOUR CAR

Both Dusters I had (one leaf spring and one coil over) like, best 60ft. and reaction times, the front eye in the lowest hole in the front brackets

Posted By: modelmakerinc

Re: ladder bar setup - 05/02/23 10:41 AM

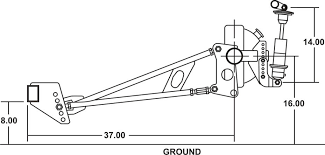

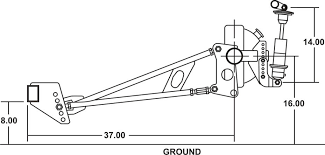

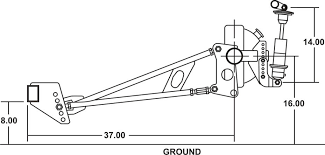

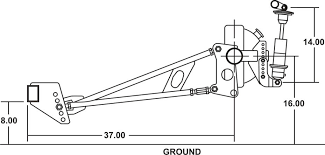

78 D-150 I installed the bars at 2.5* nose down in their lowest position, with the expectation to be installed for initial use one hole up. this will give us a little adjustment to increase or soften (lower or raise respectively) the "Hit'

The trucks chassis posed some issues due to how low the front crossmember was going to be installed, a cars chassis is considerably different and you should be able to set it up to use (adjust-ability for tuning) 4 or all 5 front holes

Posted By: DoubleD

Re: ladder bar setup - 05/02/23 11:43 AM

Personally I like flat (AKA Neutral) - in the middle hole - that gives you adjustment up or down - I have tried the deep down angle with canted shocks before in a 64B body full chassis car- it lasted one race and then we re-did the whole back end to a neutral position

If you have the room for a five hole front mount - go for it - in the end once you have it where it performs best - you probably will never change the front location again - just adjust with shocks.

Posted By: moparacer

Re: ladder bar setup - 05/02/23 12:48 PM

Slicks, I say it's going to work best with a few degrees down angle.

If you put a drag radial on it then you might level it out.

Posted By: jwb123

Re: ladder bar setup - 05/02/23 01:03 PM

The only bad thing about a ladder bar setup is if it is right, it works great, if it is installed wrong not much you can do about it, except cut brackets off and start again. Plus if you keep the car and keep improving it, what happens when you overpower the suspension and lack of adjustment keeps you from tuning it? For just a little more time and money a 4-link will give you adjustment and maybe even make the car worth more when it is time to sell.

I like to use a suspension program like Performance Trends 4-link calculator, it also does ladder bar setups. plug in the numbers and see where those brackets need to be welded.

https://www.performancetrends.com/4link.htm

Posted By: moparacer

Re: ladder bar setup - 05/02/23 01:38 PM

The only bad thing about a ladder bar setup is if it is right, it works great, if it is installed wrong not much you can do about it, except cut brackets off and start again. Plus if you keep the car and keep improving it, what happens when you overpower the suspension and lack of adjustment keeps you from tuning it? For just a little more time and money a 4-link will give you adjustment and maybe even make the car worth more when it is time to sell.

I like to use a suspension program like Performance Trends 4-link calculator, it also does ladder bar setups. plug in the numbers and see where those brackets need to be welded.

https://www.performancetrends.com/4link.htm Years ago I had a Dakota pickup that had the chassis brackets installed too high for ladder bars. The bottom hole they still had a slight upward angle. It was too violent and we ended up cutting them off and lowering them to get the bars angles down. Truck was fine after that.

I say put the brackets were the bars are level in the middle hole and you have holes to go up and down for either adjustment.

Posted By: dvw

Re: ladder bar setup - 05/02/23 01:49 PM

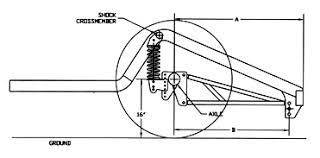

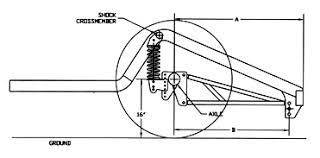

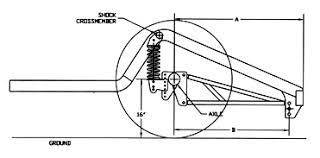

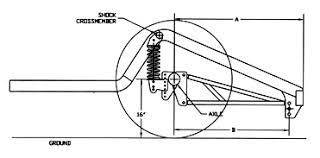

Amgle isn't really a good indicator of what it will want. The centerline of the front heim from the ground is a better indicator. This measurement along with the rear axle centerline from the ground is what matters. Think about the imaginary line drawn between those two points. You could concievably use many different mounting posistions to attach the ladder bar to the rear housing. The bar could end up point up/ down, or level. If those two points remain the same, nothing changes. Most brackets mount in a similar spot on the housing, but not all. This is why people use the bar "level or slightly down" idea. Not because thats necesarrilly where it needs to be. But it happens to fit for their cars set-up. The suspension would react exactly the same. Now what can we change? The height of the axle C/L based on rear tire diameter. The length of the ladder bar itself. This is chosen when they are built. Generally somewhere between 28"-36". And lastly the C/L of the front of the bar from the ground. This will have an adjustable range. How do we chose? Expected power, weight distribution, and type of tire are the four that I think make the most difference. Radial tires will want the heim C/L high. Bias slicks lower. High power will want a longer and lower C/L. If the car doesn't have a ton of power and it's heavily weight biased towards the front the bar could be shorter. No prep needs a higher C/L. 28" is very short. The average bar is about 32". A shorter bar acts on the anti-squat line similar to a higher heim C/L. Ladder bars can provide a ton of hit. Thats why sometimes you can't get the C/L low enough. It takes a longer bar to get the C/L down on the anti-squat line. Radials and no prep want a higher C/L. My car runs 31.5" bias slicks with tubes. The bar is about 7.5" off the ground. The bars are 36" long. Car has 55% of the weight on the nose. Even with 13.5psi and the shocks tight on rear rebound. It wads the tires 20-25 out from the start. Think about how hard a shorter bar would hit.

Doug

Posted By: moparacer

Re: ladder bar setup - 05/02/23 04:53 PM

The attachment point is the IC DVW as you know and higher is always a higher AS value. Ladder bars are always so short that you always have some ridiculous amount of AS value and are trying to take some of that initial hit out of it and control it with slicks. That is why with slicks its usually better to have the bars running downhill slightly IMO but I realize all cars are different. Shocks control it all too and years ago we never had valving to control the hit properly so we always ran them downhill. Radials and no prep are a different animal.

Posted By: 68roadrunner

Re: ladder bar setup - 05/03/23 01:05 AM

I have found a huge difference In 32" to 36" bar length. And 42" on a 116" nose heavy truck works awesome

Posted By: birdtracker

Re: ladder bar setup - 05/03/23 01:55 AM

as always anything I attempt to do, all that I succeed in is the collection of spare parts that end up on a shelf. And today I was mentally exhausted from thinking, numbers, calculating. I guess Rome wasn't built in a day. Birdtracker

Posted By: cudaman1969

Re: ladder bar setup - 05/03/23 04:09 PM

Draw a line from bottom of tire through front eye to back of cam, first place to start. Moving up one hole brings instant center toward back of car, one hole down goes past engine a little. Weight bias front to back determines where you want the instant center. Farther back the more the a$$ end moves up till HP goes up, it’s a balancing act till car rotates. The front suspension has a tremendous effect on how it all works together. Theoretically you want entire weight of car on the back tires on launch but not rotating to far back.

Posted By: Cab_Burge

Re: ladder bar setup - 05/03/23 08:32 PM

My old pump gas Duster had 49.4 % weight on the rear tires and 50.6 % on the rear tires, it had coil overs and ladders bars with four holes in the front mounting brackets. It like the lowest whole on the street and at the track

I think the lower bar on them was either level or slightly nose down. I did end up changing the rear Strange Egnr. single adjustable shock to their same shock that was double adjustable, that car liked them also, especially at tracks that were not the best on the starting lines

Try all positions and then decide which one on your car is the best choice.

Posted By: birdtracker

Re: ladder bar setup - 05/03/23 08:48 PM

so I have the car up on stands right now and the rearend out of it. The axles and pig are out of it. The car will not 60 foot the way it was.The bars were down 9 degrees. I talked to another racer that is old school and he recommended the string from the tire to camshaft and see where that intersects. Work in progress. Birdtracker

Posted By: jwb123

Re: ladder bar setup - 05/03/23 09:52 PM

so I have the car up on stands right now and the rearend out of it. The axles and pig are out of it. The car will not 60 foot the way it was.The bars were down 9 degrees. I talked to another racer that is old school and he recommended the string from the tire to camshaft and see where that intersects. Work in progress. Birdtracker

The height of the camshaft is what is usually used when you don't take the time to calculate the center of gravity vertically for the car. It is a good estimate and I have used it a lot. Real way is to use scales and then jack up the front and use a formula with the weight change to get the real center of gravity height. Most of my experience is with 4-links, and I chased my tail one time, over 60 foot times and when all was said and done the rear spring rates were too stiff. Instant center changes would not solve the issue.

Posted By: dvw

Re: ladder bar setup - 05/04/23 12:50 AM

What is the current set up? Weight, F/R weight distribution, shocks, springs, ladder bar length, ladder bar front heim bolt C/L height from the ground, ladder bar length, converter, rear gear ratio trans 1st gear ratio, power level.

Doug

Posted By: birdtracker

Re: ladder bar setup - 05/04/23 12:54 AM

DVW I sent you a pm. If you want me to post all of it on here I will. This is what I am starting at. Sixtty foot is 1.45 Birdtracker

Posted By: birdtracker

Re: ladder bar setup - 05/04/23 01:11 AM

Posted By: jwb123

Re: ladder bar setup - 05/04/23 02:02 AM

Opinions are like assholes everybody has one. In watching the video, not sure what your ET was, 60 foot and ET has a relationship, but if that video was a 1.45 60 foot, I would be looking for a different converter. The car looks to me to be working pretty well. I could not see real well how it was hitting the tires, but it did not look out of line to me.

Posted By: Kam*Kuda

Re: ladder bar setup - 05/04/23 02:06 AM

I learned a lot from watching and rewatching SBCWilson

https://www.youtube.com/watch?v=HF9cvi4I_OUI am a radial tire car and look for as much separation as I can get (aka AntiSquat)

Posted By: Cab_Burge

Re: ladder bar setup - 05/04/23 06:39 AM

Posted By: birdtracker

Re: ladder bar setup - 05/04/23 09:45 AM

that was a 1.45 sixty foot. Best has been 1.42. Birdtracker

Posted By: dvw

Re: ladder bar setup - 05/04/23 12:13 PM

Hit the little gear icon 5th from the right lower corner of the video screen. Then go to playback speed. Set it to .25 speed. Now you can watch it slow. For this video. If you click your mouse on the red line right above the sound icon you can watch the hit over and over everytime without watching the entire video. I see a few things. First the rear axle housing separates from the body and slams the tire violently. This is a result of the rear shock rebound (extension) setting being too loose. Then the tire bounces the housing back towards the body causing spin. The rear shock compresion is also to loose. With a 28" ladder bar the rear shock settings are going to have to be pretty tight to control the housing movement. Next is the front. The rebound is to loose there as well. The tire comes off the ground nearly immediately. then any help from the front suspension is lost. This makes the spin even worse. Ideally the front tire should stay on the ground 1/2- one full revolution of the rear tire. Your shocks are so out of whack I'd start there before changing anything else. Watch this video at the same .25 playback speed. It's already slow mtion but .25 makes it even slower. watch the rear housing to the body. And in reality the front shock rebound is too loose.

https://youtu.be/D3G3mR1WxjIDoug

Posted By: TheOtherDodge

Re: ladder bar setup - 05/08/23 07:28 PM

I agree with dvw. You need to soften the hit to the tire a bit with the shock. If you can't you need to move the bar up 1 notch.

You didn't say what ET your car runs so it's hard to say if a 1.42 is a good 60ft, but at only 3,000 lbs I would think you should be in the mid 1.3's even if you are in the low 10's.

Posted By: FastmOp

Re: ladder bar setup - 05/08/23 10:08 PM

I need more info. Power plant, converter, spring rate, is that 28"heim to heim, that's a short bar. What shocks. That's a big tire. You could be off a mile and it still hook.

Posted By: birdtracker

Re: ladder bar setup - 05/08/23 11:56 PM

car only went 9.50 at 140 mph. It will go 8.90 or 8.80 when I get the rear sorted out. I actually have the rearend out of it right now. It was tearing the lower shock mount off the rearend.I am supposed to stop by my welder guy to see what he says. I bought a Fab rearend but there is a couple issues with width of the center section is wider than my old housing mounts by an inch. If he can fix it I will go that route. If not a road trip of 4 hours will be in my future. Birdtracker

Posted By: TheOtherDodge

Re: ladder bar setup - 05/09/23 02:21 PM

car only went 9.50 at 140 mph. It will go 8.90 or 8.80 when I get the rear sorted out. I actually have the rearend out of it right now. It was tearing the lower shock mount off the rearend.I am supposed to stop by my welder guy to see what he says. I bought a Fab rearend but there is a couple issues with width of the center section is wider than my old housing mounts by an inch. If he can fix it I will go that route. If not a road trip of 4 hours will be in my future. Birdtracker

If you only went a 1.45 short time but a 9.50, then you are leaving a lot on the line, literally! You should be in the 1.2x. My truck will go 1.37-1.39 on a 9.7 and is 350 lbs heavier so you have some work to do on the short times!

Posted By: birdtracker

Re: ladder bar setup - 05/10/23 12:28 AM

that was my exact thought. I started digging into all the little things. Pinion angle was horrendus, ladder bars were down, I even found that it had bent the lower shock mount attaching points. My metal guy fabbed me up a new brace so I got a bunch of trimming and fitting. We already dug out the pucks and bar so when its ready to weld. I don't remember it being this way before so I am glad I dug into it. Birdtracker