Posted By: Diplomat360

W2 stroker build - head flow numbers check please - 10/03/22 04:11 AM

Alright...so my DIY home porting efforts have been completed. The W2 Econo heads (810 open chamber casting) were NEW, I kept the original MP valve job (previously had the machine shop look them over as they installed the liners in the guides for 11/32" stem valves, they said the valve job was "fine" as-is).

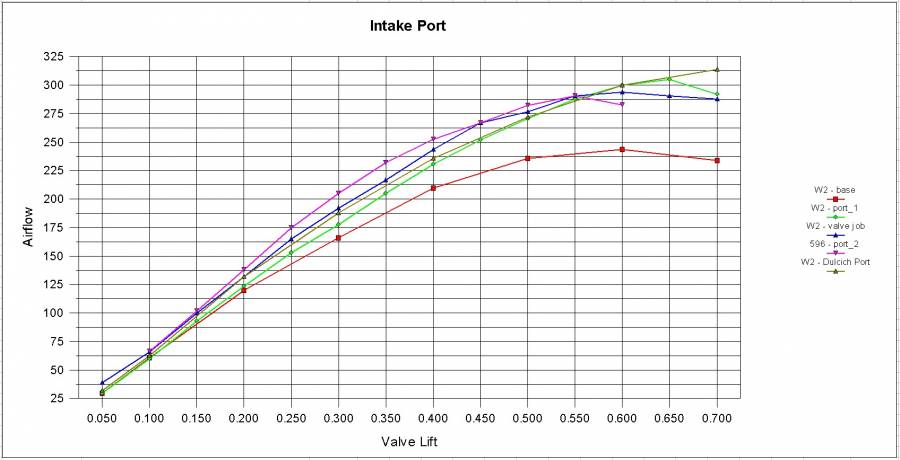

Anyways, I then spent a few hours (quite a few to be honest) with the W2 MP porting templates, nothing crazy, just enough to remove the extra casting materials. The aim here is to just have a better flowing port as the car is a weekend river, not a racer, but of course engine performance matters to me.

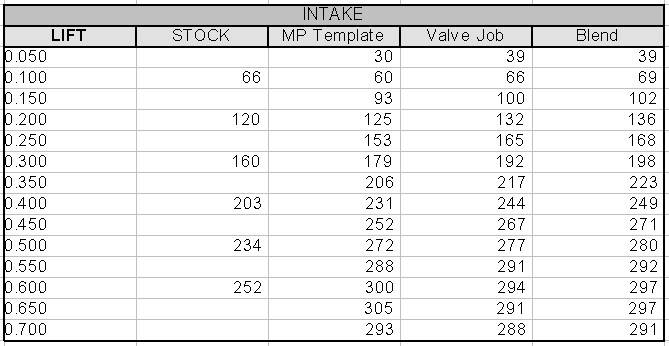

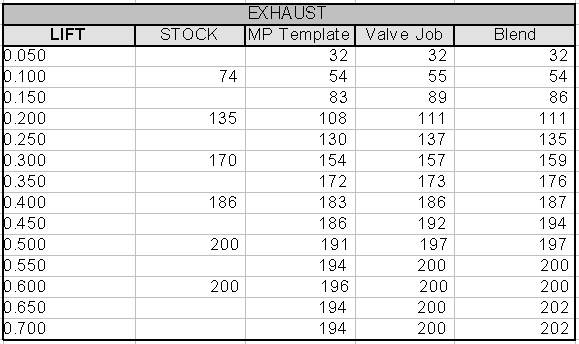

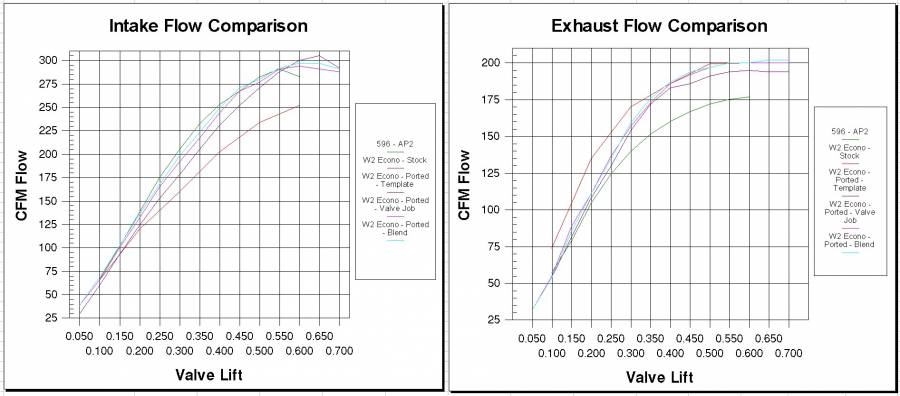

So here are the flow numbers I got from a local porting shop (measured at 28" with the exception of INTAKE at 0.650 & 0.700" lift, those were done at 25" and adjusted):

LIFT - INTAKE - EXHAUST - E_TO_I_%

0.050 - 030 - 032 - 107

0.100 - 060 - 054 - 90

0.150 - 093 - 082 - 88

0.200 - 124 - 108 - 87

0.250 - 153 - 130 - 85

0.300 - 178 - 154 - 87

0.350 - 205 - 172 - 84

0.400 - 231 - 183 - 79

0.450 - 252 - 186 - 74

0.500 - 271 - 191 - 70

0.550 - 288 - 194 - 67

0.600 - 300 - 195 - 65

0.650 - 305 - 194 - 64

0.700 - 292 - 194 - 66

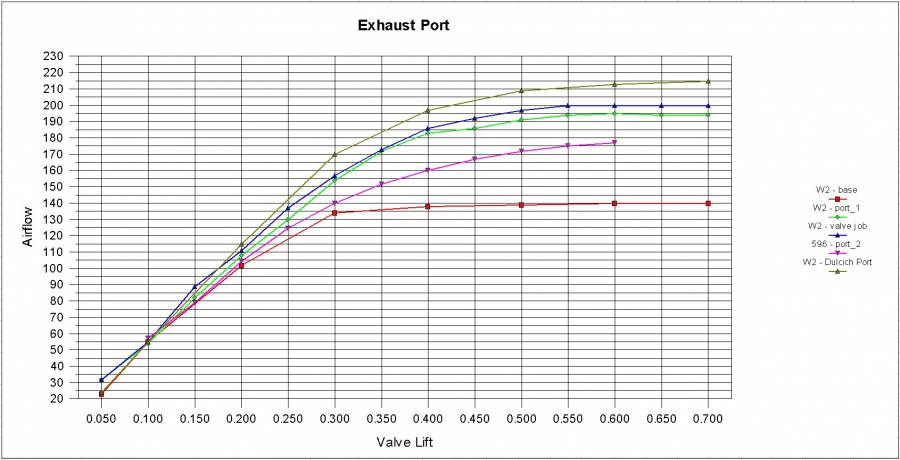

The Exhaust was done w/o a pipe, but I did ask him to check a couple of spots and got back a 226 cfm @0.600" lift reading.

Truth be told I am not sure what to make of these numbers.

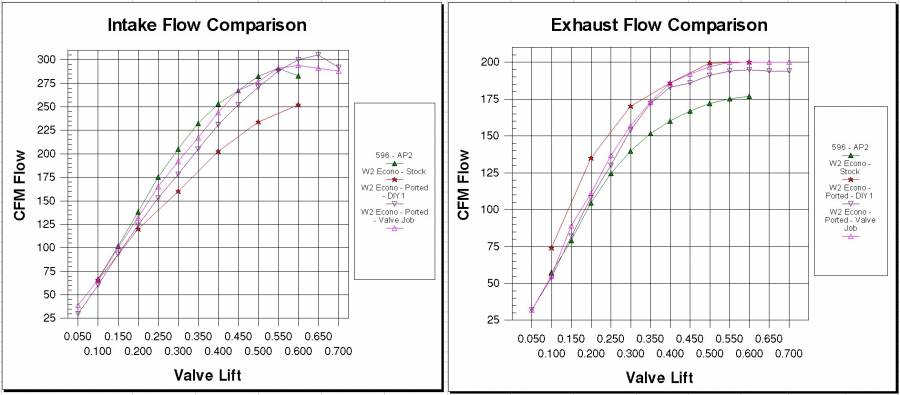

My old factory '596 castings (although heavily worked over with a much better valve job - multi angle) actually beat these all the way up to 0.600" lift, where the W2 then fly! The same guy who measured my W2 did my old '596 castings (flow numbers), and he did recall how well those ran.

OK, but who cares about the TOP flow reading, I care about the flow numbers at lower lifts, basically that "area under the curve" thing, and with my hydraulic roller cam with a .584 lift I'm not going to be benefitting from that 0.600 & over flow.

So I'm curious about a couple of things:

1) the numbers as they are, what do you guys make of them?

2) should I actually do a performance valve job on these heads? (OK, I know that sounds "silly" now, but the machine shop that did the liners install did look them over and I had no reason to think otherwise)

- the porting guy said: you are losing flow at low to med lift with this valve job, he can do a multi-angle seat cutter pass that will clean up the current seats

- measuring the valve seat lap markings you can actually tell that the diameter of the valve head that's actualy being utilized is not 2.02 but rather about 1.94, so the head seat is just a tad narrower which means it's not taking advantage of the full valve head diameter

OK, that's it. Attached are a couple of pics of the results, as always, I appreciate all the feedback!

Anyways, I then spent a few hours (quite a few to be honest) with the W2 MP porting templates, nothing crazy, just enough to remove the extra casting materials. The aim here is to just have a better flowing port as the car is a weekend river, not a racer, but of course engine performance matters to me.

So here are the flow numbers I got from a local porting shop (measured at 28" with the exception of INTAKE at 0.650 & 0.700" lift, those were done at 25" and adjusted):

LIFT - INTAKE - EXHAUST - E_TO_I_%

0.050 - 030 - 032 - 107

0.100 - 060 - 054 - 90

0.150 - 093 - 082 - 88

0.200 - 124 - 108 - 87

0.250 - 153 - 130 - 85

0.300 - 178 - 154 - 87

0.350 - 205 - 172 - 84

0.400 - 231 - 183 - 79

0.450 - 252 - 186 - 74

0.500 - 271 - 191 - 70

0.550 - 288 - 194 - 67

0.600 - 300 - 195 - 65

0.650 - 305 - 194 - 64

0.700 - 292 - 194 - 66

The Exhaust was done w/o a pipe, but I did ask him to check a couple of spots and got back a 226 cfm @0.600" lift reading.

Truth be told I am not sure what to make of these numbers.

My old factory '596 castings (although heavily worked over with a much better valve job - multi angle) actually beat these all the way up to 0.600" lift, where the W2 then fly! The same guy who measured my W2 did my old '596 castings (flow numbers), and he did recall how well those ran.

OK, but who cares about the TOP flow reading, I care about the flow numbers at lower lifts, basically that "area under the curve" thing, and with my hydraulic roller cam with a .584 lift I'm not going to be benefitting from that 0.600 & over flow.

So I'm curious about a couple of things:

1) the numbers as they are, what do you guys make of them?

2) should I actually do a performance valve job on these heads? (OK, I know that sounds "silly" now, but the machine shop that did the liners install did look them over and I had no reason to think otherwise)

- the porting guy said: you are losing flow at low to med lift with this valve job, he can do a multi-angle seat cutter pass that will clean up the current seats

- measuring the valve seat lap markings you can actually tell that the diameter of the valve head that's actualy being utilized is not 2.02 but rather about 1.94, so the head seat is just a tad narrower which means it's not taking advantage of the full valve head diameter

OK, that's it. Attached are a couple of pics of the results, as always, I appreciate all the feedback!