Posted By: Craig J

Rod bearing wear with 440 Source crank & rods - 06/16/22 01:46 PM

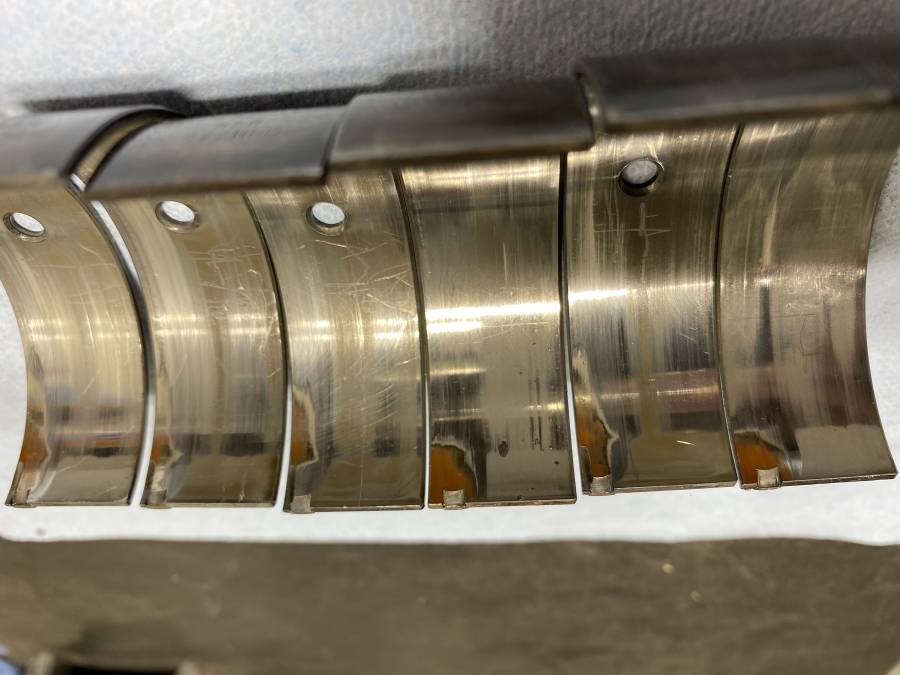

Please note that I don't do this for a living... I never saw wear only near the tang before.

10.5:1 CR RB with 4.15 stroke in a 73 barracuda I purchased last year, I don't think the previous owner drove it very often, but when he did I suspect it got beat on pretty hard.

I took it apart because I found the #3 cam bearing spun during a cam swap and the more I look the worse it gets.

The crankshaft has no visible wear.

Main bearings are also in very poor condition, but do not have this concentrated wear by the tang, they just look bad everywhere.

10.5:1 CR RB with 4.15 stroke in a 73 barracuda I purchased last year, I don't think the previous owner drove it very often, but when he did I suspect it got beat on pretty hard.

I took it apart because I found the #3 cam bearing spun during a cam swap and the more I look the worse it gets.

The crankshaft has no visible wear.

Main bearings are also in very poor condition, but do not have this concentrated wear by the tang, they just look bad everywhere.