Posted By: 440Jim

Progress - slow going - 12/19/21 02:30 AM

I have been making progress on my Daytona engine upgrade to the new B1 572 CID. But it has been slow.

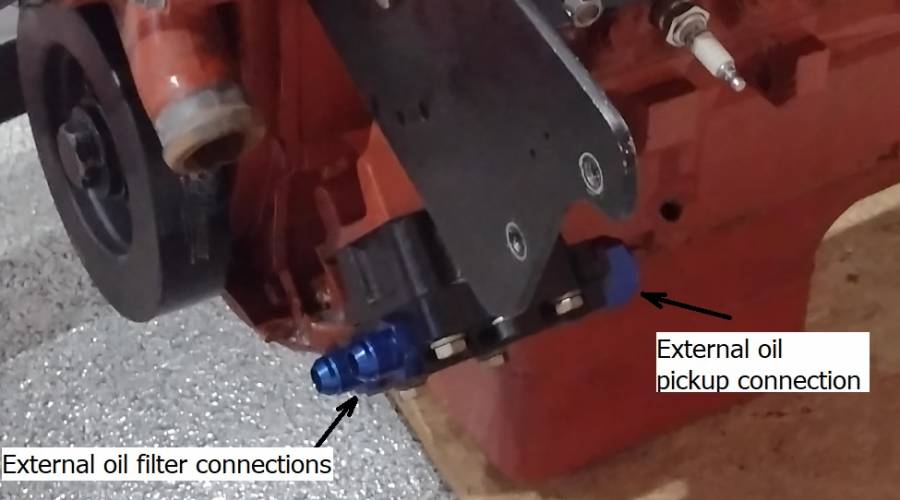

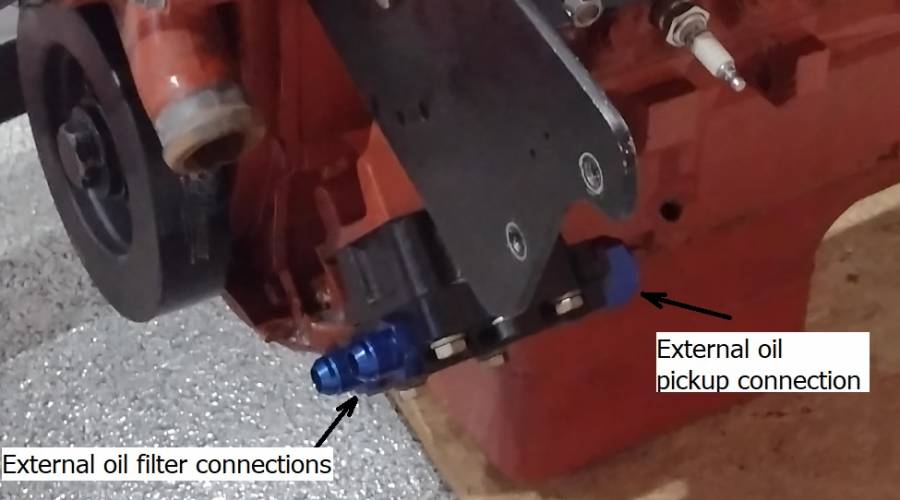

Today's milestone was removing the existing iron headed engine from the car. I need the oil pump since it has both the external oil filter connections needed for the chassis; and the external oil pickup connection which I need to make the pickup lines for the new motor with the new oil pan, etc. I think I have now received all the fittings/lines for the B1 oil drain back lines. Time to cut holes in the new oil pan and make the lines fit.

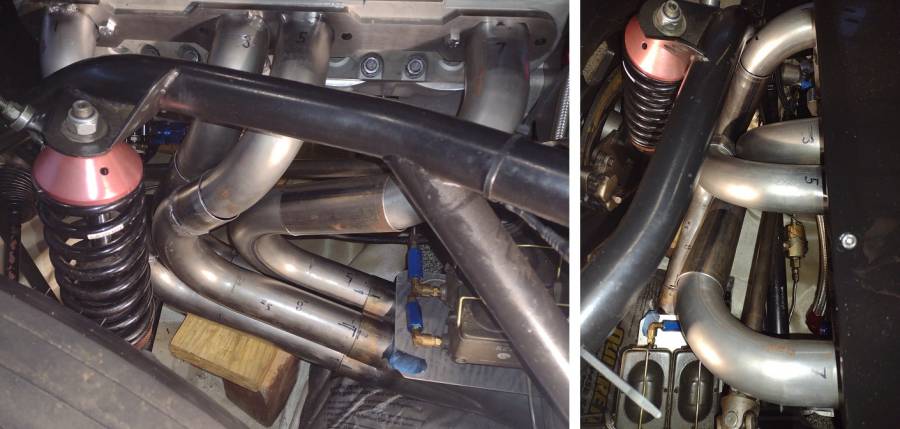

I did make notes and measurements of the engine midplate, firewall, etc. for the oil drain back lines fitting in the chassis.

Today's milestone was removing the existing iron headed engine from the car. I need the oil pump since it has both the external oil filter connections needed for the chassis; and the external oil pickup connection which I need to make the pickup lines for the new motor with the new oil pan, etc. I think I have now received all the fittings/lines for the B1 oil drain back lines. Time to cut holes in the new oil pan and make the lines fit.

I did make notes and measurements of the engine midplate, firewall, etc. for the oil drain back lines fitting in the chassis.