Posted By: 440Jim

572 B1 org Part 3 -Machine Shop Report - 09/09/21 03:59 PM

This topic is 572 B1 org Part 3 - Machine Shop Report

Here is my plan for posting progress:

572 B1 org Part 1-Buying Parts

572 B1 org Part 2-Component Observations

572 B1 org Part 3-Machine Shop Report

572 B1 org Part 4-Mock-ups

572 B1 org Part 5-Build Notes

572 B1 org Part 6-Dyno Results

572 B1 org Part 7-Track Testing

------------------------------------------------------------------------------------------------

Part 3-572 B1 org - Machine Shop Report

Based on Parts 1,2, and 3; along with other racer’s input; I gave the block to the machine shop for the following:

1) Bore/hone to final size for the pistons

2) Finish size the lifter bores for Comp Cams roller lifters (892-series, FWIW).

3) Check the deck for equal heights and square to the block centerline (for equal piston to deck each cylinder).

4) Install cam bearings

I also gave them the crank, rods, pistons, etc to balance the reciprocating assembly.

I dropped it all off on Monday Aug 9th.

I called 2 weeks ago, when they said it would be done; but they said another week or two.

I called this morning (Sep 9th) just before lunch; and they said I can pick it up this afternoon.

So, follow this post as I check out the machine work.

Here is my plan for posting progress:

572 B1 org Part 1-Buying Parts

572 B1 org Part 2-Component Observations

572 B1 org Part 3-Machine Shop Report

572 B1 org Part 4-Mock-ups

572 B1 org Part 5-Build Notes

572 B1 org Part 6-Dyno Results

572 B1 org Part 7-Track Testing

------------------------------------------------------------------------------------------------

Part 3-572 B1 org - Machine Shop Report

Based on Parts 1,2, and 3; along with other racer’s input; I gave the block to the machine shop for the following:

1) Bore/hone to final size for the pistons

2) Finish size the lifter bores for Comp Cams roller lifters (892-series, FWIW).

3) Check the deck for equal heights and square to the block centerline (for equal piston to deck each cylinder).

4) Install cam bearings

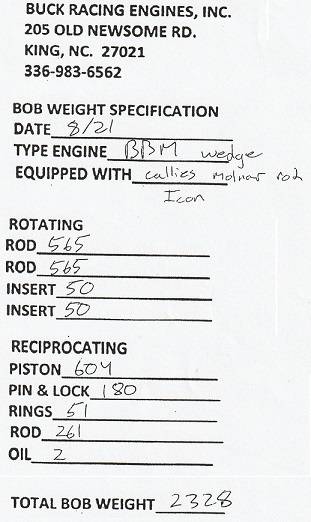

I also gave them the crank, rods, pistons, etc to balance the reciprocating assembly.

I dropped it all off on Monday Aug 9th.

I called 2 weeks ago, when they said it would be done; but they said another week or two.

I called this morning (Sep 9th) just before lunch; and they said I can pick it up this afternoon.

So, follow this post as I check out the machine work.