Posted By: 440Jim

572 B1 org Part 1-Buying Parts - 05/16/21 11:37 PM

This year I am building a 572 CID engine with B1 original heads.

I hope to have it in my 1993 Daytona in the fall, after all points races and the Summit Bracket Team Finals are done.

Here is my plan for posting progress:

572 B1 org Part 1-Buying Parts

572 B1 org Part 2-Component Observations

572 B1 org Part 3-Machine Shop Report

572 B1 org Part 4-Mock-ups

572 B1 org Part 5-Build Notes

572 B1 org Part 6-Dyno Results

572 B1 org Part 7-Track Testing

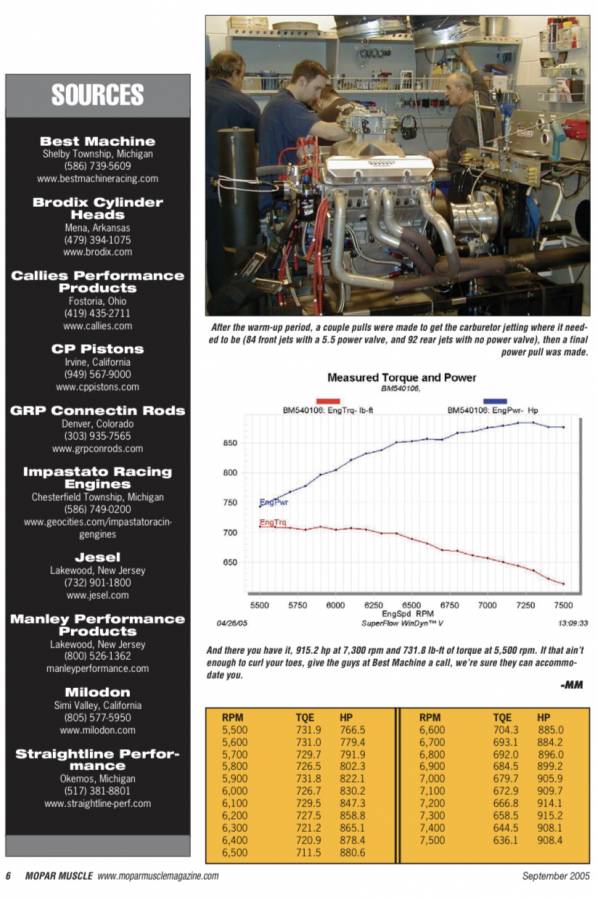

This is not an all out build, but rather a bracket racing motor hopefully making between 900-1000 HP.

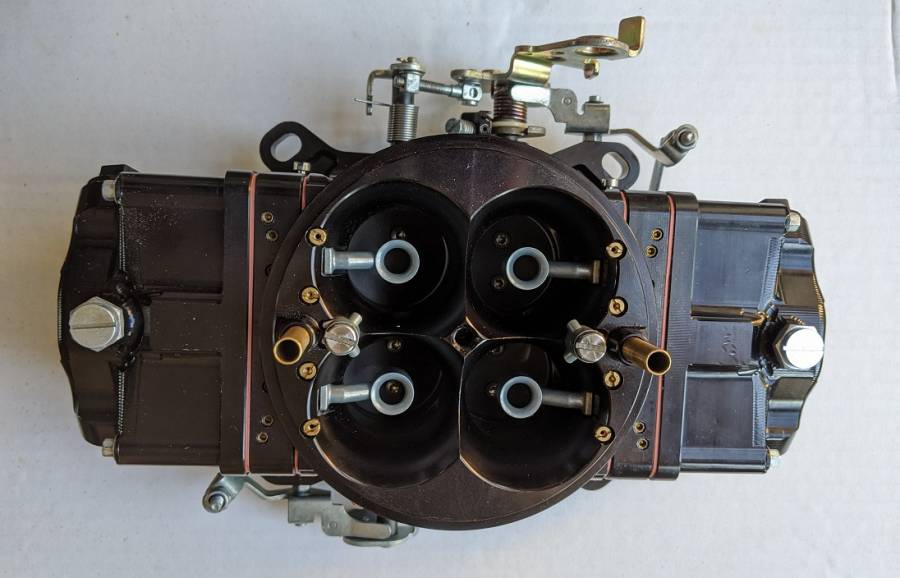

One limiting factor will be the single 4-barrel B1 intake manifold and 4150 series Alky carb.

I plan to dyno test the engine with both a Dominator carb, and my existing Alky carb. If the engine makes 950 hp with the Dominator and 900 hp with my 4150 Alky carb, I am good with that. Please post any experiences you had for what I should expect swapping carbs.

Basic engine plan is as follows:

4.500” bore x 4.500” stroke, 14.3 CR 14.5 to 15.0 CR

I need to build headers, 2.25” tubes, 4” collectors

Cam duration 280/294 at 0.050”, 0.800” lift, 113 LSA (I have this, but may change)

More Part 1 info later...

I hope to have it in my 1993 Daytona in the fall, after all points races and the Summit Bracket Team Finals are done.

Here is my plan for posting progress:

572 B1 org Part 1-Buying Parts

572 B1 org Part 2-Component Observations

572 B1 org Part 3-Machine Shop Report

572 B1 org Part 4-Mock-ups

572 B1 org Part 5-Build Notes

572 B1 org Part 6-Dyno Results

572 B1 org Part 7-Track Testing

This is not an all out build, but rather a bracket racing motor hopefully making between 900-1000 HP.

One limiting factor will be the single 4-barrel B1 intake manifold and 4150 series Alky carb.

I plan to dyno test the engine with both a Dominator carb, and my existing Alky carb. If the engine makes 950 hp with the Dominator and 900 hp with my 4150 Alky carb, I am good with that. Please post any experiences you had for what I should expect swapping carbs.

Basic engine plan is as follows:

4.500” bore x 4.500” stroke, 14.3 CR 14.5 to 15.0 CR

I need to build headers, 2.25” tubes, 4” collectors

Cam duration 280/294 at 0.050”, 0.800” lift, 113 LSA (I have this, but may change)

More Part 1 info later...

![[Linked Image]](https://i.postimg.cc/jjxNR9JG/8-B737427-8927-4-FA9-B4-A4-FB8880-AE6053.jpg)