Moparts

7.1 h beam strength?

Posted By: gregsdart

7.1 h beam strength? - 01/21/21 08:27 PM

I am looking at Molnor or K1 7.1 long hbeams for my new shortblock. Someone from Campbell enterprises said the Molnors would be on the edge at 1000 hp. I will have a stroke of 4.315 and flat top 4.5 bore 1.45 compression height Gibtech piston, lightened, and rpm will be 7500 or less. About 950 hp. 15/1 compression and alky. Is there a differance between Molnor or K1 in strength? Any other options for a 7.1 rod?

Posted By: cudatom

Re: 7.1 h beam strength? - 01/21/21 08:50 PM

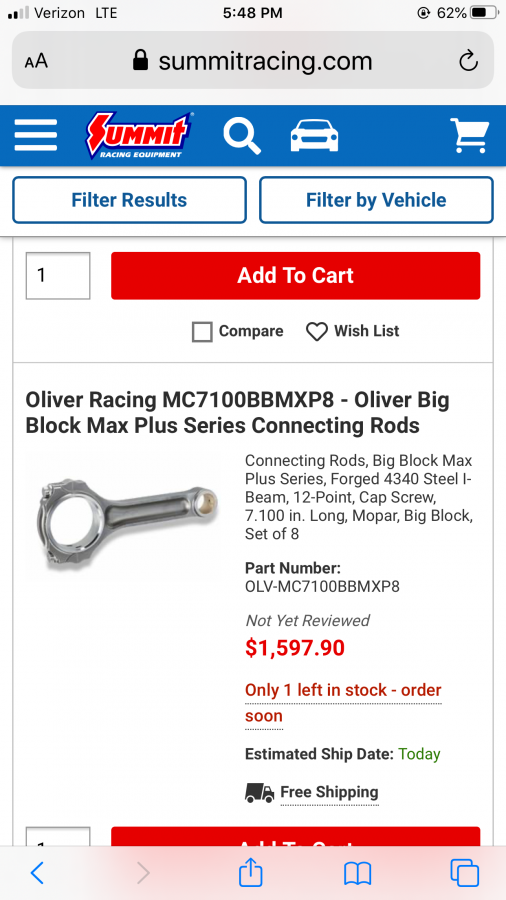

Not sure but I chose Oliver 7.1 I beams for my 553(4.5 bore 4.35 stroke ) build. Compression will be a tad less than yours and should cross the line at the same rpm. I just wasn't comfortable with the others given the cost of my KB block.

Not that Olivers can't fail but I think it would be less likely.

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/21/21 09:02 PM

Only read posts you agree with

Posted By: sasquatch

Re: 7.1 h beam strength? - 01/21/21 09:31 PM

For a 1000 Hp I would suggest the Olivers. BUT keep in Mind that Molnar and K1 were both started by the same guy. They both come with ARP 2000 bolts. The Molnar also has the option for what they call Power Adder and Power Adder Plus where they add more Material to the beam. Actually they machine less. This makes the rod a bit heavier but also stronger. You could also look at the Pro Series from Manley.

Todd

Posted By: B1MAXX

Re: 7.1 h beam strength? - 01/21/21 10:06 PM

Why not aluminum. BME, and R&R.

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/21/21 10:23 PM

Posted By: B1duster

Re: 7.1 h beam strength? - 01/21/21 10:36 PM

Is crank set up for Mopar or Chevy width rods ?

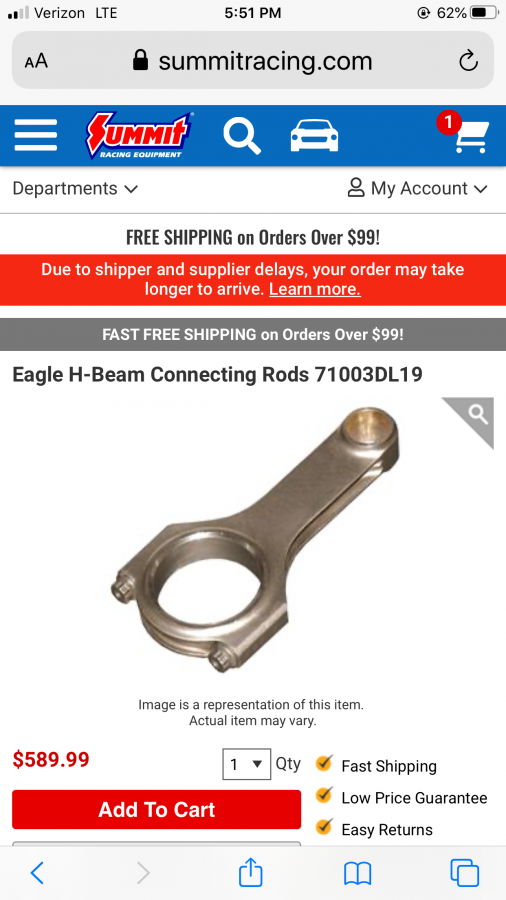

On the cheap Eagle with L-19 bolts

Not so cheap Oliver

Crower ?

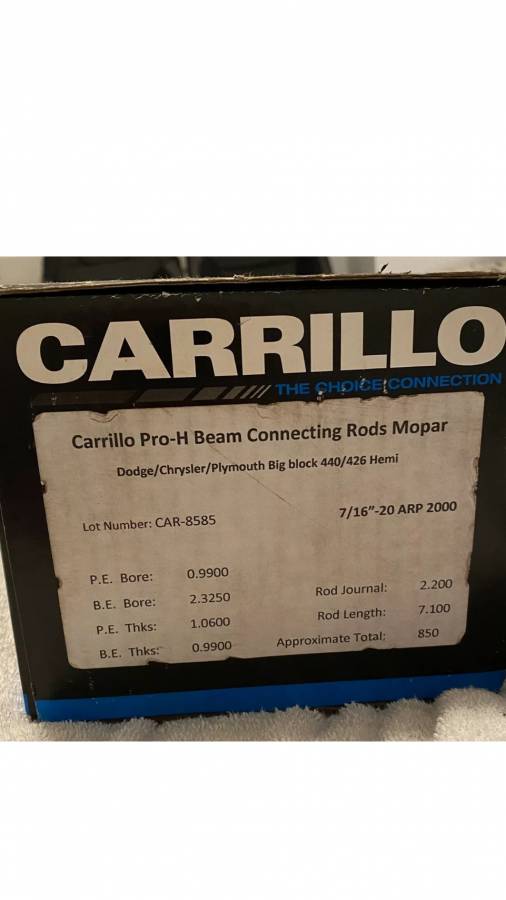

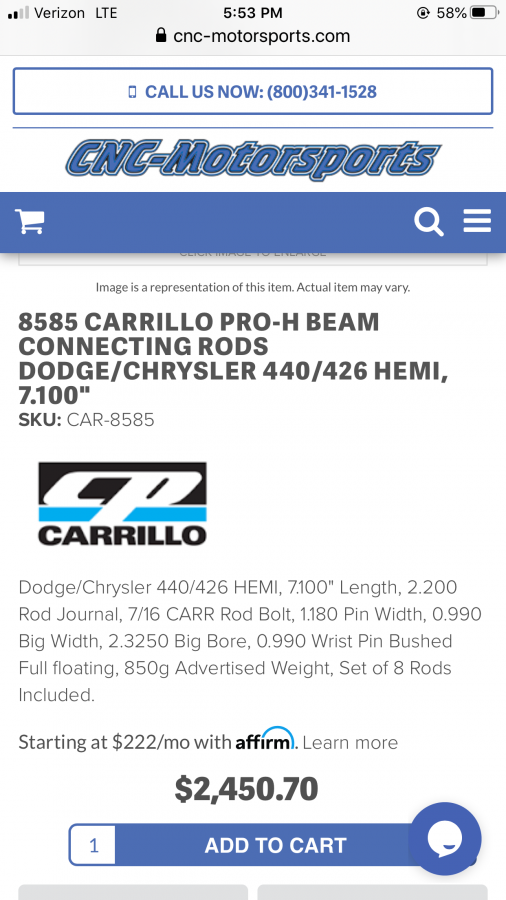

and deep pockets Carrillo

Posted By: gregsdart

Re: 7.1 h beam strength? - 01/21/21 11:53 PM

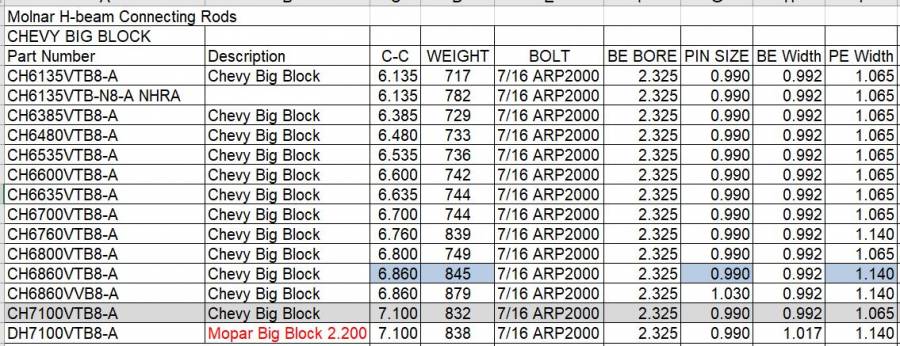

Like it or not i may have to go with Manley or Oliver rods, about 850 more than the h beams i was looking at. I got away with running Molnor 6.86 Hemi H beams in the megablock, but what shakes my confidance in the 7.1 rods is the fact that the 7.1 rods are 11 grams lighter than the 6.86 rods.

Posted By: EchoSixMike

Re: 7.1 h beam strength? - 01/22/21 12:07 AM

Why not call Molnar and ask them? I talked to Tom Molnar at PRI two yrs ago and the guy is a font of knowledge. Honestly, I don't see your setup as all that aggressive. S/F....Ken M

Posted By: dvw

Re: 7.1 h beam strength? - 01/22/21 12:22 AM

HP means squat. What counts is reciprocating weight, rpm, and load if you run a power adder. The 7.100 rods are a modern design where unnecessary bulk was removed. Call Tom and ask. He'll give you an honest answer. Mine has Molnar 7.100". The bobweight is 2222. I was told my self imposed 7500 rpm limit was safe. Though it only runs to about 7300.

Doug

Posted By: B1duster

Re: 7.1 h beam strength? - 01/22/21 12:33 AM

I know they are cheap and might need touched up but I don’t see the Eagles with L-19 bolts failing

They come standard with 190,000 psi rated 7/16 ARP 8740 (750 Horsepower rating) and 230,000 psi rated, 7/16 ARP 2000 rod bolts (1200 horsepower rating) or 265,000 psi rated 7/16 ARP L-19 bolts (1500 Horsepower rating) as upgrades. Each set includes Instructions and rod bolt lubrication.

I got a deal on these. If they check out ok I’m using them in my 572 Street Hemi.

They are old with Arp 2000s, but new

Posted By: Chargerfan68

Re: 7.1 h beam strength? - 01/22/21 01:02 AM

My friends rb stroker used the Callies Ultra I beam rod. Part no U15270

Very nice piece. Not cheap but supposed to be a pretty stout piece. Quality was very good and so was machining ootb.

Posted By: cudabin

Re: 7.1 h beam strength? - 01/22/21 01:24 AM

Hey Greg,

I went with the Oliver pro billet option, and the peace of mind has been worth it to me...

Good Luck,

Arnie

Posted By: tubtar

Re: 7.1 h beam strength? - 01/22/21 01:33 AM

Don't skimp on fasteners , which ever rod you choose.

I believe it was Barton who said it , in an article about the building of an AA/AH motor..............Use the best fasteners you can get.

Relative to all the other costs , it really seems like sound advice.

I would call Molnar and speak with Tom too. He has forgotten more about connecting rods that I ever knew.

Posted By: Cab_Burge

Re: 7.1 h beam strength? - 01/22/21 02:05 AM

L19 or SPS rod bolts are better than ARP2000

Posted By: EvilB1Dart

Re: 7.1 h beam strength? - 01/22/21 02:19 AM

Oliver H Beams or GRP Alum.

Posted By: B1duster

Re: 7.1 h beam strength? - 01/22/21 02:49 AM

7.05 GRP in my 604 B1

7.15 in my 540B1

Posted By: B1duster

Re: 7.1 h beam strength? - 01/22/21 07:40 AM

Or these

Posted By: dvw

Re: 7.1 h beam strength? - 01/22/21 11:45 AM

Beware of L19 bolts. For a motor that sits a lot corosion could be an issue. My Molnars have over 400 passes.

Doug

Posted By: gregsdart

Re: 7.1 h beam strength? - 01/22/21 05:15 PM

Thanks everybody. I talked to Ed at Molnar, he said the 7.1 rods from Molnar would be fine. Two other things that will help- the new piston is going to be lighter and i plan to go to a clean neutral valvebody.

Posted By: JACK1440

Re: 7.1 h beam strength? - 01/22/21 05:29 PM

I run a 7.100 Molnar also with a similar power range. I do have an experience with Manley rods that I like to tell folks. About 5 years ago I broke a crank at the 1/8 mile mark at MIR. The block split in half, blew the bell housing to pieces but, never broke a rod. They were twisted all to hell but never broke. Good stuff

Posted By: Chief

Re: 7.1 h beam strength? - 01/22/21 06:11 PM

Just for information. I just broke a K1 rod in my 500 inch 8.71 engine. Big end of the rod was still attached to the crank, the section from about 2 inches up to the pin was lodged between the cam and the lifter galley, which broke two lifter bores out of the block.

Also took out 2 sleeves. One piston and pin were in the oil pan and I don't think there were any pieces bigger than a quarter left.

Car was on it's best pass to date and it let go about 550 ft into the run. The rods had been in the engine for 8 years so I think I found the limit. 1300 + HP.

My replacement engine until I get the block repaired will be my 572 with B1 heads, and 7.1 Oliver rods. Only complaint with the rods are the rod bolts are proprietary to Oliver. NOT Cheap. They are ARP and you can buy them through Summit and Jegs but they are Oliver design.

I'm thinking MGP when blower motor goes back.

Dave

Posted By: Cab_Burge

Re: 7.1 h beam strength? - 01/22/21 06:15 PM

Just for information. I just broke a K1 rod in my 500 inch 8.71 engine. Big end of the rod was still attached to the crank, the section from about 2 inches up to the pin was lodged between the cam and the lifter galley, which broke two lifter bores out of the block.

Also took out 2 sleeves. One piston and pin were in the oil pan and I don't think there were any pieces bigger than a quarter left.

Car was on it's best pass to date and it let go about 550 ft into the run. The rods had been in the engine for 8 years so I think I found the limit. 1300 + HP.

My replacement engine until I get the block repaired will be my 572 with B1 heads, and 7.1 Oliver rods. Only complaint with the rods are the rod bolts are proprietary to Oliver. NOT Cheap. They are ARP and you can buy them through Summit and Jegs but they are Oliver design.

I'm thinking MGP when blower motor goes back.

Dave

Molnars ARP 2000 bolts are different also and you can NOT buy them directly from ARP

Does MGP make and steel steel rods or aluminum only?

Posted By: A727Tflite

Re: 7.1 h beam strength? - 01/22/21 07:24 PM

Just for information. I just broke a K1 rod in my 500 inch 8.71 engine. Big end of the rod was still attached to the crank, the section from about 2 inches up to the pin was lodged between the cam and the lifter galley, which broke two lifter bores out of the block.

Also took out 2 sleeves. One piston and pin were in the oil pan and I don't think there were any pieces bigger than a quarter left.

Car was on it's best pass to date and it let go about 550 ft into the run. The rods had been in the engine for 8 years so I think I found the limit. 1300 + HP.

My replacement engine until I get the block repaired will be my 572 with B1 heads, and 7.1 Oliver rods. Only complaint with the rods are the rod bolts are proprietary to Oliver. NOT Cheap. They are ARP and you can buy them through Summit and Jegs but they are Oliver design.

I'm thinking MGP when blower motor goes back.

Dave

Would be interesting to have the other rods checked for length and to have them x-rayed to see if any others were ready to exit stage left.

Posted By: Chief

Re: 7.1 h beam strength? - 01/22/21 07:34 PM

Molnars ARP 2000 bolts are different also and you can NOT buy them directly from ARP

Does MGP make and steel steel rods or aluminum only?

I didn't know that about the Molnar rod bolts.

MGP only makes aluminum rods that I'm aware of. I'm going aluminum because I may have reached the limit of a steel rod with a blower. I haven't had an issue with detonation is the reason I used the steel rod.

And, other than Oliver I don't know of any other manufacturer who's rods will handle up to 2000 HP. I'm sure there are some however.

I really haven't researched a steel rod under power adder conditions that much, at the time I got the Oliver's I was running NA.

I don't like the idea of changing out the rods often, but......

Not to mention it's hard to get a intelligent answer on how many runs I can reasonably expect. I'm told 50-1000 by different people

Dave

.

Posted By: Chief

Re: 7.1 h beam strength? - 01/22/21 07:40 PM

[quote=Transman

Would be interesting to have the other rods checked for length and to have them x-rayed to see if any others were ready to exit stage left. [/quote]

Pay shipping and I'll send the leftovers to you

cause the rest of them will never see the inside of one of my engines again.

I have no complaints about them really, other than the expense of getting the block repaired.

This is the first time I have ever had a rod break, other than one broke at the wrist pin that was caused by having a rod converted from press fit to floating. (machine shop had over heated them during previous swap)

Dave

Posted By: A727Tflite

Re: 7.1 h beam strength? - 01/22/21 08:59 PM

[quote=Transman

Would be interesting to have the other rods checked for length and to have them x-rayed to see if any others were ready to exit stage left.

Pay shipping and I'll send the leftovers to you

cause the rest of them will never see the inside of one of my engines again.

I have no complaints about them really, other than the expense of getting the block repaired.

This is the first time I have ever had a rod break, other than one broke at the wrist pin that was caused by having a rod converted from press fit to floating. (machine shop had over heated them during previous swap)

Dave [/quote]

I wouldn’t use them either. Without exact measurements when they were new, checking them now would obviously be a waste.

As for x-ray, only as a learning tool at this point.

I can hear them hitting the garbage can from here.

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/22/21 10:01 PM

What about "I" beam vs. "H" beam?

The tensile strength (pulled apart) is relative to the beam's cross-sectional area in inches. Either one may be heavier there. No, they don't publish that.

However, in nitrous, boosted applications where cylinder pressure greatly exceeds NA, the shape with the most effective use of material is the "H": the sides add bending resistance in compression to the rod's cross-plane axis (90 degrees to the crank, where it is free to pivot). The piston keeps it straight in the crank axis.

What else don't they do?

Run rods on big electric motors to destruction: spin it at high RPM with a piston. Add RPM, weight, then both to establish relationships: "rod X failed at 8,790 RPM with a 560 gram piston, but at 7,120 with a 770 gram piston" etc. I can't think of a way to incorporate the thrust vector (from the rod-to-stroke ratio angle) into this, but some polymath will.

Why not?

1. SEMA will boycott you

2. HRM etc. will link you to terrorism

2. your magazine/web site has 10 rod dealer ads, after the test you'll have 1

Posted By: CSK

Re: 7.1 h beam strength? - 01/22/21 10:09 PM

Just for information. I just broke a K1 rod in my 500 inch 8.71 engine. Big end of the rod was still attached to the crank, the section from about 2 inches up to the pin was lodged between the cam and the lifter galley, which broke two lifter bores out of the block.

Also took out 2 sleeves. One piston and pin were in the oil pan and I don't think there were any pieces bigger than a quarter left.

Car was on it's best pass to date and it let go about 550 ft into the run. The rods had been in the engine for 8 years so I think I found the limit. 1300 + HP.

My replacement engine until I get the block repaired will be my 572 with B1 heads, and 7.1 Oliver rods. Only complaint with the rods are the rod bolts are proprietary to Oliver. NOT Cheap. They are ARP and you can buy them through Summit and Jegs but they are Oliver design.

I'm thinking MGP when blower motor goes back.

Dave

Did that rod bearing spin, or the wrist pin seize ?

Posted By: B1MAXX

Re: 7.1 h beam strength? - 01/22/21 10:56 PM

Large cubes/high rpm, should have aluminum. If your going to run 7500+ . Just my

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/22/21 11:15 PM

I’m really leaning to billet also, 7.1 Hussy rods for my 572.. on the street, and they clear everything with a 4.5 crank. I also have K1s but they look to skinny in the beam. Both are 2.20 bottoms and .990 top. Might never see 6500, yea right!

Still need 4.53 Hemi pistons though, hint hint

Posted By: B1MAXX

Re: 7.1 h beam strength? - 01/23/21 02:42 PM

I have built 632 Chevys with aluminum rods, 4.75 stroke with standard cam height (same crank to cam centerline as a big block Mopar). You need 4/7 swap and sometimes need to add a little extra clearance on the rods depending on the brand. You put a medium zip tie on all the lobes of the cam and mock it up.

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/23/21 03:59 PM

"Billet": advertising term, actual meaning "cheaper than a forging".

It's what to do if you only need a small volume.

Posted By: Chief

Re: 7.1 h beam strength? - 01/23/21 04:14 PM

Did that rod bearing spin, or the wrist pin seize ?

Bearing still looked good. Pin was in a million pieces. Nothing left of the piston and pin to analyze.

Dave

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/23/21 04:32 PM

"Billet": advertising term, actual meaning "cheaper than a forging".

It's what to do if you only need a small volume.

I only need 8

Posted By: Chief

Re: 7.1 h beam strength? - 01/23/21 07:33 PM

Some good info for Aluminum Rods..

Ignor the magazine but read the articleI would like to have some confidence on when the aluminum rod "must" be changed. I don't normally pull the engine down every season unless I must or I'm changing something.

For instance because I broke at the end of the season and It's going to be mid season before I can get the blower motor back in, I'm going to put my 572 in the car. To run mid 4.60's I hope,

I am replacing the rear gear (3.90-4.30), shorter(Big Bubba to Little Bubba)changing converter from the blower converter. Otherwise the car would have got a new set of tires.

I guess instead of aluminum rods I could just go with a set of killer steel one's.

It's a dilemma..

Dave

Posted By: FastmOp

Re: 7.1 h beam strength? - 01/23/21 09:56 PM

What it run with the blower ?

Is this in a lawn dart?

I run GRP rods.

Posted By: B1MAXX

Re: 7.1 h beam strength? - 01/24/21 03:00 PM

around 300 runs depending on where its at at the end of a season on aluminum. Again just my opinion. Which used to be about 3-4 years/seasons when we used to race every weekend. I guess that could be every year for some.

How often should the steel rod be changed, in those conditions, would be the one I don't have a good answer for. They will need changed at some point also. Might be best to use Scat/Eagle and change those every 300.

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/24/21 03:10 PM

Aluminum rods are permanently stretched every time they're run near their limit.

Steel rods recover to some extent, last much longer.

It's not design or quality control, it's metallurgy.

Posted By: 440Jim

Re: 7.1 h beam strength? - 01/24/21 03:38 PM

Aluminum rods are permanently stretched every time they're run near their limit.

The important thing is the modern designs can be done to not run near their "limit"; so no permanent stretch occurs in applications like bracket racing.

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/24/21 04:41 PM

Aluminum rods are permanently stretched every time they're run near their limit.

Steel rods recover to some extent, last much longer.

It's not design or quality control, it's metallurgy.

Did you read the article from the GRP guy? For bracket racing they claim 1000s of runs, top fuel 8. And he said they were compressed not stretched. I’m sure they went to school and do all kinds of testing to improve their products.

Posted By: B1MAXX

Re: 7.1 h beam strength? - 01/24/21 06:24 PM

I think 1000's of runs at 1000hp is pushing your luck. If possible at all. Things like a tire shake in a 1000hp bracket car can beat things up. At 1000+hp I think it is wise to cycle your parts at some point.

Posted By: Chief

Re: 7.1 h beam strength? - 01/24/21 06:59 PM

What it run with the blower ?

Is this in a lawn dart?

I run GRP rods.

Yes, I call it Ghost on a Stick. It is a 245 in Yancer RED, ran a best of 4.32, best 60 was .897. That was in killer air and letting it eat and on the run it blew up..lol

Normally it ran 4.42 and 1.00 pulling 10* timing from the hit to 2 seconds out. Look at my avitar. That is what it normally looked like.

How many runs are you putting on the GRP before swapping them out?

Dave

Posted By: Chief

Re: 7.1 h beam strength? - 01/24/21 07:01 PM

around 300 runs depending on where its at at the end of a season on aluminum. Again just my opinion. Which used to be about 3-4 years/seasons when we used to race every weekend. I guess that could be every year for some.

How often should the steel rod be changed, in those conditions, would be the one I don't have a good answer for. They will need changed at some point also. Might be best to use Scat/Eagle and change those every 300.

Kind of what I was thinking.

Dave

Posted By: Chief

Re: 7.1 h beam strength? - 01/24/21 07:08 PM

I think 1000's of runs at 1000hp is pushing your luck. If possible at all. Things like a tire shake in a 1000hp bracket car can beat things up. At 1000+hp I think it is wise to cycle your parts at some point.

LOL.. At this point you will get no argument from me. At 7+ years and unknown number of runs I know I found the limit on the K1's.

Mine dyno'd at 1300 HP. But that was before I went to hat and port nozzles which cleaned up cylinder to cylinder fuel distribution. So I was making in excess of 1300.

I would say the 1000 runs would be on your average bracket car, also need to look at when the article was written. And, what if any improvements have been made in metallurgy since.

Dave

Edit: I just looked again. Article was written in 2011, so 10 years ago..

Posted By: Chief

Re: 7.1 h beam strength? - 01/24/21 07:18 PM

Gregsdart..

Apologies for side tracking your post..

Dave

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/24/21 08:26 PM

At 1500 HP I don’t care what you put in there it’s gonna break stuff.

Posted By: Twostick

Re: 7.1 h beam strength? - 01/25/21 01:22 AM

around 300 runs depending on where its at at the end of a season on aluminum. Again just my opinion. Which used to be about 3-4 years/seasons when we used to race every weekend. I guess that could be every year for some.

How often should the steel rod be changed, in those conditions, would be the one I don't have a good answer for. They will need changed at some point also. Might be best to use Scat/Eagle and change those every 300.

Kind of what I was thinking.

Dave

There's a guy up my way that builds DIRT Modified engines that run up front consistently and he tells his customers to change the rods at 600 laps.

These engines are upwards of $30K and some of his customers seemed to think they should last longer for that price and ignored the advice.

None of them made it to 700 laps...

Physics doesn't much pay attention to price points.

Kevin

Posted By: FastmOp

Re: 7.1 h beam strength? - 01/25/21 12:06 PM

I'm still putting laps on these rods. I bought a pro mod rod from GRP.

Cool ride,

My deal is turbo so there a little easier on rods.

Posted By: Al_Alguire

Re: 7.1 h beam strength? - 01/25/21 03:07 PM

I routinely put 400 laps on GRP's in my junker. They usually got cycled into something else as long as the new owner was aware of the run time and I know of at least one set that has hundreds more laps and over 5K street miles. Of course my engine was not a blower deal and made what it made, I let the pros decide on power but it went 171 at 2975lbs.

Blower deal are a completely different deal for sure. The guys I know who run blower deals in TD seem to prefer a forged aluminum rod over a plate style rod. But these are cars that can go 3.70's or quicker at will, so a fair amount more HP, but they all prefer aluminum over steel. Been having this discussion with a friend who is putting together a lower HP hemi deal and talked to GRP and MGP and both said no worries for what he is looking to do, 7.50's in a 2800lb door car. I will say the engine he purchased had BME rods in it fwiw.

As for steel Carillo, Pankl, Crower all make killer steel rods, but they come at a price for sure. IMO all three are likely overkill for 1000HP. The only issue I see with steel rods is guys put them in the engine and forget about them.

Love to hear more about Mr Covey 4.50 set up. We run 4.50's in Vegas with our dragster NA with a single 4bbl. Always enjoy comparing notes.

Posted By: Chief

Re: 7.1 h beam strength? - 01/25/21 08:09 PM

.

Love to hear more about Mr Covey 4.50 set up. We run 4.50's in Vegas with our dragster NA with a single 4bbl. Always enjoy comparing notes.

Hey Al. I was Mr. Covey when I was active duty.. Now I'm just Dave or Hey You..lol

The basics on my ride are

:

Indy Maxx Aluminum block

4.390 bore x 4.150 stroke 502 Cu In

LMS Cam .lift 510/500 duration 284/300 lca 116.6 with a 1.6 rocker

440-1 Heads flowed by Muscle Motors 2.190 Int valve

TBS 871 with 3 strips per rotor lobe

Injected on alcohol

Glide with 1.69 low

FTI converter stall at 6100

9 inch 3.90-1

MT Big Bubba

Weight with me 1890

No secrets with me..

Just got back from dropping my block and heads off at machine shop to get the hole welded up and head repaired.

Going to bore to 4.445 and go with the larger 2.250 intakes.

And Al I have followed your stuff for several years now. I only wish I could build stuff as nice as yours.

I ran 4.48 in Vegas at the Million several years back. Would love to go again before I croak..

Dave

Posted By: Al_Alguire

Re: 7.1 h beam strength? - 01/25/21 09:56 PM

Awesome. My kid is always wanting to go faster for some reason, of course I pay for most of it so I guess that solves that mystery. Like to hear about some of the faster Mopar stuff for sure. A few procharged ones out here that run really really well. As for the Mr part, lol. I thought Sir was the big one, but if you were Navy thats a different story

I was a lowly enlisted guy but having to call my wife Ma'am sure gets old. But sometimes she lets me call her Col, or Dr

Posted By: Chief

Re: 7.1 h beam strength? - 01/25/21 10:28 PM

I was Army, and unlike a lot of the Warrant Officers I liked being called Chief..lol

About the only time I was called Mr. was when being introduced to someone. My daughter just resigned and she was a Captain (Army Nurse). Fortunately, I had already retired so she never got a salute..lol

I like the Pro Charger deal as it doesn't need to be spooled like a turbo but you can control the boost as if it were. Only disadvantage to them is it seems they are prone to breakage and upkeep in general, my opinion.

I've thought of ways to control the boost on a roots but not sure what dumping fuel and boost would do to the tune up. Can you imagine the flame a guy could get using a dump valve attached to the intake of a blower, and dumping into the headers??

Could make for some serious explosions too I guess if the flame traveled back up the pipe.

Dave

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/25/21 11:02 PM

doesn't need to be spooled like a turbo

Can't be spooled like a turbo, once your pulley sizes are fixed you're left with whatever stall speed your engine makes. If it won't launch, you need to turn it faster and reach serious boost within your stall speed, a looser converter, or re-purpose the engine for better lower end torque (earlier intake closing, more static CR).

AFAIK the biggest complaint to the ATI is that most brackets are nowhere near stiff enough. The attachment points are limited to the nose of the engine, but the wide span between the pulleys is bad. The brackets look big enough, but the force on them bends both pulleys forward. It's enough to slip and mis-align them. In some cases a simple doubler plate added to the mid-span (someone on Yellow Bullet said "I use a section of angle iron") by rivets, screws (welding not needed) helps a great deal. Remember: aluminum is only about 1/3 the stiffness of mild steel, strength is not the problem.

Posted By: Cab_Burge

Re: 7.1 h beam strength? - 01/26/21 01:49 AM

I think the crank driven Pro Charger is the best way to use them, no belts or slippage

BTW, did you fly or where you in maintenance or supply?

Posted By: Chief

Re: 7.1 h beam strength? - 01/26/21 05:20 PM

doesn't need to be spooled like a turbo

Can't be spooled like a turbo, once your pulley sizes are fixed you're left with whatever stall speed your engine makes. If it won't launch, you need to turn it faster and reach serious boost within your stall speed, a looser converter, or re-purpose the engine for better lower end torque (earlier intake closing, more static CR).

AFAIK the biggest complaint to the ATI is that most brackets are nowhere near stiff enough. The attachment points are limited to the nose of the engine, but the wide span between the pulleys is bad. The brackets look big enough, but the force on them bends both pulleys forward. It's enough to slip and mis-align them. In some cases a simple doubler plate added to the mid-span (someone on Yellow Bullet said "I use a section of angle iron") by rivets, screws (welding not needed) helps a great deal. Remember: aluminum is only about 1/3 the stiffness of mild steel, strength is not the problem.

Oh, I know how they work. I know they are fixed pully like a roots, they work like a turbo though in that they are a mechanical driven vane pump.

The converter plays a huge role with a roots, turbo, or just NA.

What I mean by my statement was the boost can be controlled like a turbo because they are compressing air. You can control when and how much boost they provide, whereas with a roots blower fuel is "usually" injected into the top of the blower mainly for cooling effect.

Not a Procharger expert by any means, but I have discussed with several who run them and have done some research.

I still like the old standard though by far the least maintenance of the 2.

Dave

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/26/21 05:39 PM

Never seen one, how does it work?

Posted By: Chief

Re: 7.1 h beam strength? - 01/26/21 05:54 PM

I agree. Off the crank would eliminate the flexing and belt alignment issue. Except now the internal gearing has to be changed to make it spin as if it had the mechanical advantage that is lost. It's a neat system for sure, but can you imaging how fast that little mouse in there is running to spin it.. lol

I was a maintenance warrant. I always told the flyboys I had a skill.. Nothing but admiration for all my warrant brothers but I can still tease them.

I'm old school where we all wore the squashed bug ( Rising Eagle ) on our collar, now they wear branch insignia so everyone knows who and what they do. I had many senior officers ask what I did,

and the answer was whatever needed to be done.

I usually knew as much or more about anything touching the maintenance field. Not bragging, if you can do it.

Now I look totally bewildered when I talk to this new bunch of younger soldier/officer.

Dave

![[Linked Image]](http://i.imgur.com/rgwvntem.jpg)

Posted By: dthemi

Re: 7.1 h beam strength? - 01/27/21 02:59 PM

I've never seen a properly installed, with enough oil clearance eagle H beam break with a 2000 bolt. One I see running is a blown BBC 7.1 that runs 4 15 in a dragster over and over and over again. Bad tuning, and too little clearance breaks everything. When a 1500hp ps motor lives with 37 pound crank that pretty much says it all.

Posted By: B1duster

Re: 7.1 h beam strength? - 01/28/21 12:15 AM

I've never seen a properly installed, with enough oil clearance eagle H beam break with a 2000 bolt. One I see running is a blown BBC 7.1 that runs 4 15 in a dragster over and over and over again. Bad tuning, and too little clearance breaks everything. When a 1500hp ps motor lives with 37 pound crank that pretty much says it all.

There you go. I believe Indy use to build all their steel rod motors with Eagle not that long ago.

Not sure if this is current, maybe they still do ???

http://indyheads.com/images/price.2015.08.pdf

Posted By: JERICOGTX

Re: 7.1 h beam strength? - 01/28/21 11:13 AM

The kits from INDY still use Eagle rotating assemblies. Recently my machinist put together a 572 for another customer. INDY Block, 572-13 heads, and it made 1017hp, and was still climbing, when the machinist said that's enough... He wasn't worried about the rods, but didn't like the Eagle crank spinning any higher than it did.

Posted By: Chief

Re: 7.1 h beam strength? - 01/28/21 07:25 PM

The kit I used in mine that just blew was a K1 Kit from (defunct) Flatlander Racing. K1 is now part of Wisco.

Nice looking kit. Needed nothing done to correct anything balanced nice also. By they way over the course of several freshen's I replaced the ARP2000 bolts with L19.

I can't prove a rod broke initially or if it was a wrist pin as both were destroyed.

This was Tom Molnar who developed the K1 stuff, copied from another forum and may be helpful to this discussion..

We are frequently asked about power ratings for rods but this is a very difficult question to answer and it is nearly impossible to put a meaningful power rating on them. First off, while many people do rate rods by power, there is no certain power level that when reached, the rod will fail. Power is produced from the expanding gasses in the combustion chamber pushing down on the piston which in turn pushes down on the connecting rods. While there are certain situations that could lead to failed rods due to compressive loads, rods generally do not fail due to power loads. If they did, they would experience severe bending to the point of permanent deformation prior to breaking.

Fact #1 - When you see a broken connecting rod where there is no seizure of the bearing or failure of the piston/pin/cylinder wall, look closely and you will see that the rod was actually pulled in two. This high tension pulling load on the rod takes place at TDC on the exhaust stroke and is caused by the piston trying to continue up the cylinder wall and through the cylinder head, and the crankshaft trying to pull it back down. Keep in mind there is no power being made on the exhaust stroke. The heavier the piston, longer the stroke and the higher the RPM, the more pulling load is placed on the rod. Because of this, you could build two identical engines that both make the same power but if one has heavier pistons, you run a much higher risk of breaking the rods in this engine.

Fact #2 - When you look at a Dyno sheet, you will see that as the RPM is taken past peak power, the power falls off however, most of us have seen engines that have had rods break when over revved. If power broke rods, they would never break due to being over revved.

Fact #3 – If you ever see anyone who has broken a connecting rod at a dragstrip, you will notice it is normally after they cross the finish line. In a circle track engine, the rod will break just before they enter the corner. In both of these cases, the rod breaks when the throttle is closed. Since you are not making more power when the throttle is closed, you have to ask the question, why the rod broke at that point.

Once again, power does not break rods and people that are rating rods by power are using what I refer to as a “Brown Number”. A Brown Number is a number they pulled out of their rear end just to make the customer feel good and to get them to exchange their hard earned money for their product. At K1 Technologies, we use the best computer technology and draw on over 28 years experience in rod and crankshaft design to insure the rods we manufacture are correct for the application.

Dave

Posted By: polyspheric

Re: 7.1 h beam strength? - 01/29/21 12:19 AM

I wish I said that.

Oh, wait. I did.

Posted By: A727Tflite

Re: 7.1 h beam strength? - 01/29/21 01:03 AM

Good read from Molnar - thanks for posting.

He doesn’t talk above the crowd like some other people. Straight to the point.

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/29/21 01:25 AM

Well that’s a good reason to let the piston hit the head, can’t stretch past the head

Posted By: Chief

Re: 7.1 h beam strength? - 01/29/21 05:13 PM

Well that’s a good reason to let the piston hit the head, can’t stretch past the head

Dave

Posted By: cudaman1969

Re: 7.1 h beam strength? - 01/29/21 06:06 PM

Well it was funny to me

Posted By: Chief

Re: 7.1 h beam strength? - 01/29/21 06:58 PM

Posted By: 440Jim

Re: 7.1 h beam strength? - 05/21/21 12:35 PM

I got away with running Molnar 6.86 Hemi H beams in the megablock, but what shakes my confidance in the 7.1 rods is the fact that the 7.1 rods are 11 grams lighter than the 6.86 rods.

Perhaps the weight of the 7.100" rods is reduced by making the pin end of the rod narrower.

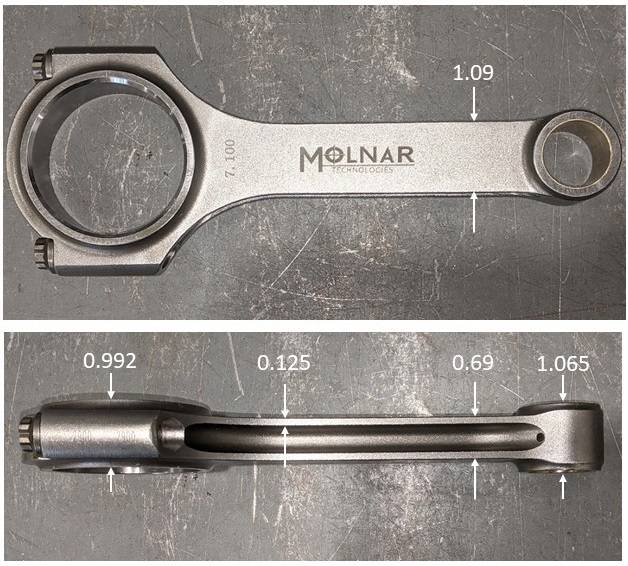

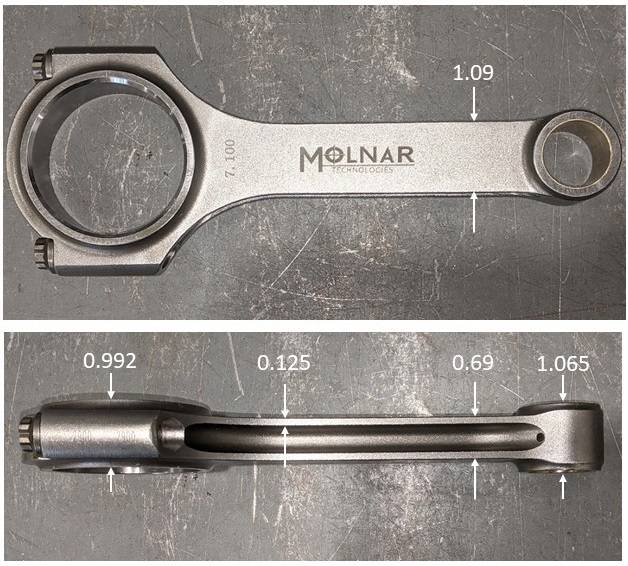

This table from Molnar web site. 1.140" vs 1.065"

Posted By: 440Jim

Re: 7.1 h beam strength? - 05/21/21 12:37 PM

Can anyone measure a 7.100" H-beam rod from another manufacturer to compare to my measurements?

The catalog weight of these is 832 grams.

Posted By: B1duster

Re: 7.1 h beam strength? - 05/21/21 04:29 PM

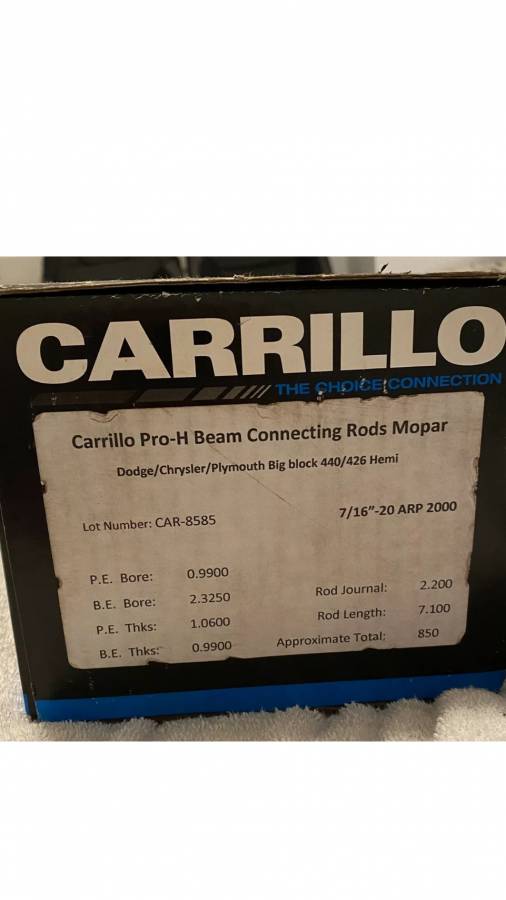

Carrillo 7.1 h beam 1.2 wide, .65 thick, and .13 beam. Big end and small end same .992 and 1.06

Eagle 7.1. ............ 1.375 wide, .627 thick and .090. These eagles were mopar width, forgot the measurements on the way from garage to the house

Posted By: Chief

Re: 7.1 h beam strength? - 05/21/21 06:44 PM

My K1 rods from my 500 inch blower motor 9.98 deck, and my Oliver from my 572 B1, 10.225 deck.

[img]

https://i.imgur.com/VWqxgO6.jpg?1[/img]

Dave

![[Linked Image]](http://i.imgur.com/rgwvntem.jpg)