Moparts

Pushrod Falls Out of Rocker

Posted By: MarkZ

Pushrod Falls Out of Rocker - 11/21/20 08:33 PM

Got a weird one. The pushrod on number eight intake fell out of the rocker arm today. Noticed it immediately when the motor fired up. Slight miss and mechanical ticking sound - hard to distinguish from the normal racket the roller lifters make.

Motor is a 400 based 512 with Comp Cams retrofit roller lifters and adjustable rockers.

This is the second time it has done it. Same hole as last time. Some of the photos show damage to the rocker, adjuster and scuffing on the pushrod end. Lash is set the same as the others. Inner and outer springs seem to be ok. Motor is three years old now with a few thousand street miles. Any ideas? I'm just fishing for advice before I pop the intake to inspect the lifters.

Thanks...

Posted By: AndyF

Re: Pushrod Falls Out of Rocker - 11/21/20 08:36 PM

Hyd roller lifter collapsed?

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/22/20 12:27 AM

This is only if it’s a hyd roller.......

Too much to type for the long version.........

Always happens right at start up?

I’ve had it happen here, and have talked to several others that have had the same thing happen.

The short answer is........try running more lifter preload.

From the point of where the plunger is preloaded to, to the plunger being bottomed out in the lifter...... has to be less distance than the depth of the adjuster screw cup in the rocker arm.

The adjuster cup is .120” deep.

Set the lifter preload so it’s .090”-.100” from being bottomed out.

Posted By: MarkZ

Re: Pushrod Falls Out of Rocker - 11/23/20 05:12 PM

Sorry, should have lead with this information. Yes, it is a hydraulic roller and the couple times this has happened was at startup. Motor always ran fine until parked and this only happened after it was allowed to sit overnight.

I'll give it a go with more preload then, .095" from the bottom.

I'm still going to pop the intake and inspect the lifter. While I'm in it I can use the opportunity to rephase the distributor gear and install the Holley distributor to allow for computer controlled timing.

Do you think the damage the underside of the rocker warrants replacement? I'm going to get a new adjuster screw anyways seeing as how it's beat up.

Thanks guys.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/23/20 05:16 PM

I wouldn’t worry about the rocker, but would replace the adjuster.

Posted By: moparx

Re: Pushrod Falls Out of Rocker - 11/23/20 06:23 PM

i would polish out the rocker damage to prevent any stress cracks from forming.

Posted By: Cab_Burge

Re: Pushrod Falls Out of Rocker - 11/23/20 07:00 PM

I wouldn’t worry about the rocker, but would replace the adjuster.

Been there done that, had to do it more than once

Buy the good adjusters, not the cheapest ones you can find

Posted By: TRENDZ

Re: Pushrod Falls Out of Rocker - 11/23/20 07:42 PM

I would add... Do a leakdown or at least a compression test. Looks like it ran with the pushrod real close to the fulcrum. That is a huge rocker ratio jump. Possible to bend a valve or squash a valve seal, etc..

Just as precaution, no likely damage. Best to be sure though.

Posted By: topside

Re: Pushrod Falls Out of Rocker - 11/24/20 12:40 AM

Good time to look at the rest of the valvetrain.

I'd be wondering "why just one?" and "why that one?"

Posted By: INTMD8

Re: Pushrod Falls Out of Rocker - 11/24/20 03:13 AM

How much preload are you currently running? And, how did you arrive at that?

Posted By: INTMD8

Re: Pushrod Falls Out of Rocker - 11/24/20 03:33 AM

Looks like it ran with the pushrod real close to the fulcrum. That is a huge rocker ratio jump. Possible to bend a valve or squash a valve seal, etc..

Just as precaution, no likely damage. Best to be sure though.

Good thinking, I thought the same, but also thought it lost a bunch of preload with no adjuster. Maybe the two to one ratio was made up for by a loss of .100+ length

Posted By: Rollo!

Re: Pushrod Falls Out of Rocker - 11/25/20 04:04 AM

You have a naughty lifter due to dirt or other issues. It collapses when shutdown depending on lobe position. Pops the push rod on startup. Pull the intake and replace or rebuild lifter. I don't recommend adding adding preload unless it was a temporary repair as it messes up geometry. Better replace the push rod and rocker arm too.

Posted By: INTMD8

Re: Pushrod Falls Out of Rocker - 11/25/20 01:26 PM

Agreed that hyd lifter gets it's oil pushed out when parked at an open position but the pushrod could come out if running very little preload. Some run 1/2 turn preload on an adjuster directly on the pushrod which is only .020 preload.

Could run 2 full turns for .083 with less chance of this happening.

More preload could also help, just starts getting risky if your valve/piston is close and the system loses control at high rpm. (though that's obviously a problem either way, could crash valves if it lofts and there's a ton of preload).

Doesn't change much geometry on a shaft system, well at least rocker to valve. I suppose too many threads below the rocker on the adjuster isn't the best thing but from the photos it seems like it would be ok.

Posted By: JAKE68

Re: Pushrod Falls Out of Rocker - 11/25/20 02:18 PM

I have done several hyd roller cams. The first few I had comp lifters and had the exact problem. I tried with putting more pre load in it and that worked but didn't feel comfortable with that so after that only used morels and never had a problem again.

Posted By: jwb123

Re: Pushrod Falls Out of Rocker - 11/25/20 02:57 PM

I would agree it is most likely lifter pump down. It might be a tight valve guide, but with the time on the engine not likely. I think I would rather go with a better rocker set up, and the traditional ball and cup type push rod. Paying attention to pushrod length. The further the adjuster extends past the rocker arm, the arc of movement, will have a greater tendency to kick out the push rod. The fit of the pushrod in the rocker is critical as well, no mater which type of push rod you use. I never use the type of rocker arm you show because of the issues I mentioned. Just me never liked the look of them.

This a very common problem. It used to be believed ALL these types of failures was do to dirt and debris etc, but I am here to tell you, not always the case. Sometimes a little more pre load helps, but more so, the industry is having issues with hydraulic roller lifters from several manufactures. Especially Comp and Morel. ( yes, Morel also) .I am in a group of engine builders on a private forum from across the country, and almost everyday, a hydraulic lifter issue pops up. I could write for hours about this. But here is my best condensed version. Buy Gatorman, GS Products,Crane or Johnson ( NOT Hylift Johnson).

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/25/20 03:22 PM

In every case where I’ve had a conversation with someone about the pushrods falling out........ it’s always been at start up(and was running fine when the engine was shut off)........ and was involving a hyd lifter(the motor we had here with this problem had a very mild HFT cam).

I have not heard of a single incident where the pushrod fell out during start up when a solid lifter was being used.

Some of the people I spoke to that had it happen multiple times(on random cylinders) solved it by swapping to solid roller lifters being run with very tight lash settings.

The deeper the “cup” is(whether in the rocker or the pushrod), and the more preload you run......the less likely it is you’ll encounter this issue.

Also, hyd lifters with less plunger travel will be less prone to have this issue.

Posted By: AndyF

Re: Pushrod Falls Out of Rocker - 11/25/20 05:08 PM

I've never heard of this issue with an OEM engine so I'm wondering if the problem has something to do with aftermarket parts and/or assembly error and/or high lift lobes?

Posted By: TRENDZ

Re: Pushrod Falls Out of Rocker - 11/25/20 05:21 PM

There was a post on here not long ago. It was asking about big cam/ spring/ hydr roller lifter. I’ve never known anyone personally to make it work, I read about others that have no problem. The cure for bleed down in my shop is to put a solid lifter in the car. 100% success rate.

I wish I knew more about making a hydr roller work well.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/25/20 07:10 PM

I've never heard of this issue with an OEM engine so I'm wondering if the problem has something to do with aftermarket parts and/or assembly error and/or high lift lobes?

The pushrod socket on an OE stamped rocker is .180” deep, and the lifters are preloaded to about 1/2 their travel.

Aside from a valve getting stuck open, there isn’t any way the pushrod could come out........ even if the lifter plunger were stuck bottomed out.

Posted By: gregsdart

Re: Pushrod Falls Out of Rocker - 11/25/20 07:16 PM

A pushrod a bit longer would be trapped even at full lifter colapse and still allow proper adjuster hieght? What are the consequences of increasing preload that way to eliminate most of the travel from bleed down? ?

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/25/20 07:47 PM

A pushrod a bit longer would be trapped even at full lifter colapse and still allow proper adjuster hieght? What are the consequences of increasing preload that way to eliminate most of the travel from bleed down? ?

That is the way mine is set up now. I am .020 off the bottom with Morel Hydro;s my pushrods are Ball,ball

Posted By: gregsdart

Re: Pushrod Falls Out of Rocker - 11/26/20 10:21 AM

A pushrod a bit longer would be trapped even at full lifter colapse and still allow proper adjuster hieght? What are the consequences of increasing preload that way to eliminate most of the travel from bleed down? ?

That is the way mine is set up now. I am .020 off the bottom with Morel Hydro;s my pushrods are Ball,ball

Your post kinda answers my question. Obviously your car is running well? What cam and rpm?

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/26/20 01:52 PM

Are you guys suggesting to run multiple turns of preload? That has always made the car run horribly, and occasionally bend valves. My vote is for crappy parts. I have a Comp set of lifters in my truck that there are two lifters that will clack like a machine gun here and there, One day its fine, 3 days later will clack, 2 days later will go away for a while then come back a couple of days later. The clacking begins an ends on start-up. I have isolated them dis assembled them and nothing there, just in my opinion a poor valving design, a plate instead of a steel ball. Been like this since 2003.

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/26/20 03:22 PM

A pushrod a bit longer would be trapped even at full lifter colapse and still allow proper adjuster hieght? What are the consequences of increasing preload that way to eliminate most of the travel from bleed down? ?

That is the way mine is set up now. I am .020 off the bottom with Morel Hydro;s my pushrods are Ball,ball

Your post kinda answers my question. Obviously your car is running well? What cam and rpm?

It is a street strip car, with the long runners I shift @ 6200, the car runs ok, I run 1.6 T&D rockers, sorting out a fuel delivery problem at the moment.

Posted By: 4406bbl

Re: Pushrod Falls Out of Rocker - 11/26/20 03:30 PM

Are you guys suggesting to run multiple turns of preload? That has always made the car run horribly, and occasionally bend valves. My vote is for crappy parts. I have a Comp set of lifters in my truck that there are two lifters that will clack like a machine gun here and there, One day its fine, 3 days later will clack, 2 days later will go away for a while then come back a couple of days later. The clacking begins an ends on start-up. I have isolated them dis assembled them and nothing there, just in my opinion a poor valving design, a plate instead of a steel ball. Been like this since 2003.

Agree with this, .080-.090 has always ran bad for me when engine is cold, always set them .020-.030 from the clip. Maybe it is thick oil, high oil pressure that can't bled down. How about a spacer for the plunger to limit the travel? I know stock motors never seem to be an issue, aftermarket cams, lifters and heavy valve springs do. You would also need to be sure that the piston to valve clearance is more, and valve spring coil bind is not an issue if you want to run them .090 in the lifter, or bigger problems are going to show up.

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/26/20 03:57 PM

Are you guys suggesting to run multiple turns of preload? That has always made the car run horribly, and occasionally bend valves. My vote is for crappy parts. I have a Comp set of lifters in my truck that there are two lifters that will clack like a machine gun here and there, One day its fine, 3 days later will clack, 2 days later will go away for a while then come back a couple of days later. The clacking begins an ends on start-up. I have isolated them dis assembled them and nothing there, just in my opinion a poor valving design, a plate instead of a steel ball. Been like this since 2003.

Agree with this, .080-.090 has always ran bad for me when engine is cold, always set them .020-.030 from the clip. Maybe it is thick oil, high oil pressure that can't bled down. How about a spacer for the plunger to limit the travel? I know stock motors never seem to be an issue, aftermarket cams, lifters and heavy valve springs do. You would also need to be sure that the piston to valve clearance is more, and valve spring coil bind is not an issue if you want to run them .090 in the lifter, or bigger problems are going to show up.

In my experience if it runs bad then the lifter is bottomed out & holding the valve open. use a .020 feeler gauge & go from the bottom of the piston travel. I will also say this, the ONLY reason I went hydro roller is this is a street car, many have said solids will not live on the street long term. I have my theory on why, I will not EVER use Morel lifters again.

Posted By: dvw

Re: Pushrod Falls Out of Rocker - 11/26/20 04:02 PM

How can more preload change the way the engine runs? It can’t. It will only change if the lifter Is bottomed out. Oil viscosity has nothing to do with it. This issue is a case of the lifter bleeding down when stationary load is applied. If the lifter is functioning properly, this doesn’t happen. Obviously there are issues with some lifters. When the lifter fails to hold oil it bleeds and increases lash. The extra preload is a bandaid to keep the pushrod in the cup. Nothing more, nothing less. If it works in your situation it could be a good alternative to swapping parts.

Doug

Posted By: BillR1212

Re: Pushrod Falls Out of Rocker - 11/26/20 05:39 PM

This was happening to my 505 stroker. I was using a Comp Cams hydraulic set up. Was very frustrating and usually at start up. Nothing worse than having to pull a valve cover in parking lot to get the pushrod back in. My engine builder finally fixed it. I'd have to call to see what specifically he did if you still need help with it. I believe he used a good amount of pre load and some different springs/retaining clips. Have not had an issue since he did that. I've known a few people with 440's locally that have had issues with similar set ups.

Posted By: 4406bbl

Re: Pushrod Falls Out of Rocker - 11/26/20 06:43 PM

If you read up on this issue there are or were hydraulic lifters with .060 travel, I do not know where to buy them, and lifters with .215 travel johnson is one brand. If I had .060 travel it would be no issue. Thick oil will cause problems, the experts say the lifter can only bleed down from the clearance between the plunger and the lifter body. If you Google lifter preload, everybody most recommend .020-.060, because hydraulics will pump up and cause pistons and valves to hit, and cause valves to hang open cold, so they run bad. If I could buy lifters with that .060 travel it would solve all my problems, or I will just buy a solid cam.

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/26/20 06:57 PM

If you read up on this issue there are or were hydraulic lifters with .060 travel, I do not know where to buy them, and lifters with .215 travel johnson is one brand. If I had .060 travel it would be no issue. Thick oil will cause problems, the experts say the lifter can only bleed down from the clearance between the plunger and the lifter body. If you Google lifter preload, everybody most recommend .020-.060, because hydraulics will pump up and cause pistons and valves to hit, and cause valves to hang open cold, so they run bad. If I could buy lifters with that .060 travel it would solve all my problems, or I will just buy a solid cam.

The only way a hydro lifter will pump up is if the springs are to weak, ie valve float, valve train instability at RPM, & at rpm with good spring they bleed down not pump up

Posted By: TRENDZ

Re: Pushrod Falls Out of Rocker - 11/26/20 06:57 PM

The last set I replaced(sbc with comps) I contemplated opening up the lifters and adding shims. Then, I thought, why bother.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/26/20 07:12 PM

An important thing to keep in mind is....... not all the lifters are designed to be run with the same amount of preload.

And some of the pricier, higher end, high rpm units call for very specific preload settings....... and many people successfully run that type of lifter with the adjustment made by setting them “from the bottom”.

That’s probably not going to be a good practice(running them nearly bottomed out) for many of the “lesser” lifters that aren’t designed for “extreme duty”.

For example, in their FAQ section, Gaterman specifically says not to run them bottomed out.

The bottom line is, if your combination of parts is assembled in a manor where the plunger in the lifter, after preload, can travel farther than the depth of the pushrod cup at the rocker arm, then there is a possibility for a certain situation to occur after engine shut down, that can result in the pushrod falling out on the next start up.

My personal opinion on it is, I can’t see any reason why any retrofit hyd roller lifter sold by a performance cam company would need more than .060” total plunger travel.

This problem just wouldn’t be happening if the lifters were made that way.

Posted By: 4406bbl

Re: Pushrod Falls Out of Rocker - 11/26/20 08:18 PM

An important thing to keep in mind is....... not all the lifters are designed to be run with the same amount of preload.

And some of the pricier, higher end, high rpm units call for very specific preload settings....... and many people successfully run that type of lifter with the adjustment made by setting them “from the bottom”.

That’s probably not going to be a good practice for many of the “lesser” lifters that aren’t designed for “extreme duty”.

For example, in their FAQ section, Gaterman specifically says not to run them bottomed out.

The bottom line is, if your combination of parts is assembled in a manor where the plunger in the lifter, after preload, can travel farther than the depth of the pushrod cup at the rocker arm, then there is a possibility for a certain situation to occur after engine shut down, that can result in the pushrod falling out on the next start up.

My personal opinion on it is, I can’t see any reason why any retrofit hyd roller lifter sold by a performance cam company would need more than .060” total plunger travel.

This problem just wouldn’t be happening if the lifters were made that way.

Kinda my point with .060 lifter, even .090, it is not just the mopar guys with issues, seems to be widespread if the combo is just right.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/26/20 09:11 PM

If you dig around enough, there are plenty of stories.......like this one, using some expensive lifters(well...... trying to use them):

https://www.speed-talk.com/forum/viewtopic.php?t=36843I’m still of the mindset.......”just give me a solid”

Particularly if the HR option is a “retrofit” scenario.

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/26/20 09:11 PM

How can more preload change the way the engine runs? It can’t. It will only change if the lifter Is bottomed out. Oil viscosity has nothing to do with it. This issue is a case of the lifter bleeding down when stationary load is applied. If the lifter is functioning properly, this doesn’t happen. Obviously there are issues with some lifters. When the lifter fails to hold oil it bleeds and increases lash. The extra preload is a bandaid to keep the pushrod in the cup. Nothing more, nothing less. If it works in your situation it could be a good alternative to swapping parts.

Doug

go take an good running engine with a 1/2, to 3/4 turn preload and put 2-3 turns on all the rockers and tell me how that works out for you.

Posted By: hemienvy

Re: Pushrod Falls Out of Rocker - 11/26/20 11:30 PM

I thought the oil pressure to the hydraulic lifter only took out valve lash, when the lash is

then zero, oil pressure will not compress the valve spring. Then when the cam lobe pushes

against the lifter to open the valve, there is a little bleeddown, but this happens so quickly

that the lifter is ALMOST hydrolocked. The lifter is not bottomed out at this point. And then the valve is pushed open.

Unless I misunderstand something.

Posted By: slantzilla

Re: Pushrod Falls Out of Rocker - 11/27/20 03:55 AM

If you tighten them down 2-3 turns it seems like the cups would be bottomed out?

Posted By: Cab_Burge

Re: Pushrod Falls Out of Rocker - 11/27/20 04:35 AM

The 3/8x24 threads per inch adjusters move the tip in or out .041666, which I round up to .042, per one full turn of the adjusters so doing the math on the lifter side of the rocker arms make the lifter plunger see the same amount of change, correct

1 divided by 24 =.041666

If your using 7/16 x 20 adjusters each full turn equals .050 looser or tighter per each full turn of the adjuster.

I use between 1/4 to 1/2 turn preload on both the 3/8 and 7/16 adjusters, maybe a tiny bit more on aluminum heads, 1/3 to 1/2 turn on 3/8 and 2/3 to 3/4 turn on the 7/16 adjusters at room temps and then reset them warmed up

I am not a big fan of any of the after market .903 or .904 hydraulic roller lifters that I have used yet

Hopefully soon, in the near future

In the meantime I'll stick with a good set of solid roller lifters

To honestly see what works, and doesn’t work, follow the boat engines. Hyd rollers are used extensively in marine applications, and if you want to break something, that’s where it will happen, in a boat. Only circle track dirt racing breaks more parts....lol. The boat guys have narrowed it down to only a couple brands that will survive. Mopars are even worse than a BBC, because of lifter weight.

Posted By: dvw

Re: Pushrod Falls Out of Rocker - 11/27/20 01:29 PM

How can more preload change the way the engine runs? It can’t. It will only change if the lifter Is bottomed out. Oil viscosity has nothing to do with it. This issue is a case of the lifter bleeding down when stationary load is applied. If the lifter is functioning properly, this doesn’t happen. Obviously there are issues with some lifters. When the lifter fails to hold oil it bleeds and increases lash. The extra preload is a bandaid to keep the pushrod in the cup. Nothing more, nothing less. If it works in your situation it could be a good alternative to swapping parts.

Doug

go take an good running engine with a 1/2, to 3/4 turn preload and put 2-3 turns on all the rockers and tell me how that works out for you.

It will run rough because the valve won’t shut. If you don’t bottom the lifter all the way it will bleed the excess oil and return to normal.

Doug

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/27/20 05:37 PM

2-3 turns doesn't bottom any lifter I have come across. A brand new Comp hydro roller takes over 5.

the seat or cup will not stay stationary, the effective height changes all the time. The more pre-load you run the lower the rpm you'll float (lifter pump up} the engine. The more pre-load you run effects the vacuum at idle, and quality of the idle. I'm not talking about enough pre-load to collapse the lifter either. The less pre-load the higher the rpm potential. A race hydraulic lifter will have a robust snap ring and suggest little to no pre-load. A half turn ether way setting valves always has a noticeable effect on the engine. Let alone 2-3.

Back to the original post unless you have less than a quarter turn of pre-load that shouldn't have caused the issue. I will say though a 1/4 turn of pre-load typically that will be noisy (they run good there though). My guess would be a collapsed (bled down) lifter at startup stuck for a second. How much pre-load are you using? What brand lifter?

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/27/20 05:59 PM

Posted By: dvw

Re: Pushrod Falls Out of Rocker - 11/27/20 06:50 PM

2-3 turns doesn't bottom any lifter I have come across. A brand new Comp hydro roller takes over 5.

the seat or cup will not stay stationary, the effective height changes all the time. The more pre-load you run the lower the rpm you'll float (lifter pump up} the engine. The more pre-load you run effects the vacuum at idle, and quality of the idle. I'm not talking about enough pre-load to collapse the lifter either. The less pre-load the higher the rpm potential. A half turn ether way setting valves always has a noticeable effect on the engine. Let alone 2 or 3

I edited these statements. Maybe I have something to learn. But I see no concrete basis for the statements listed above.

Doug

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/28/20 12:48 AM

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/28/20 01:23 AM

I’m not really sure what you’re implying, but there are parts of those 3 articles that discuss the pros and cons of running a little....... or a lot......of preload.

Also, I can’t tell by the pic...... is that a hyd roller lifter?

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/28/20 03:03 PM

Yes, Comp hydro roller. In the one article you have someone saying that stock lifters have .120 travel and a suggestion that cheap lifters have had upwards .180 well ,wrong A $400+ set of Comps has .198. I trust in my experience/knowledge (and a few old timer friends that have been there ,done that a thousand times, Thanks guys!) and believe very little what I read on the internet sadly because of all the b.s. you get mainly for marketing purposes. I'd rather hear it from experience than a Hot Rod article

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/28/20 03:12 PM

I'd rather hear it from experience than a Hot Rod article up

You’re in luck.

I guess you skipped right past csk’s post where he said:

That is the way mine is set up now. I am .020 off the bottom with Morel Hydro;s my pushrods are Ball,ball

Running them like that is more common than you think.

Nonetheless, I’m a firm believer in doing what works for you....... so if you don’t have any luck running that way...... stick with what you’re having success with.

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/28/20 03:25 PM

So just so I can understand in the case of the comps , there are those who are running/suggesting to run them, with 4 and 1/2 turns after 0 lash?

Posted By: 4406bbl

Re: Pushrod Falls Out of Rocker - 11/28/20 03:27 PM

Stock magnum lifters have .200 or more, stock ls lifters are .215, looks like the 3rd gen hemi are that way too, so like you I have never seen a stock hydraulic roller lifter that has .120 or less. I would sure buy a set, .060 would be even better. I would like to know what kind of seat pressure, and wt oil these guys are running that can run the lifter near bottomed out, and never have piston to valve issues. I am betting it is not 130 like most cam companies recommend so the cam does not go flat, or they have .250 piston to valve clearance. If I turned mine down 4-5 turns I bet it would not start with 125 on the seat, disregarding the pistons hitting the valves, at least with cold oil.

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/28/20 03:43 PM

Stock magnum lifters have .200 or more, stock ls lifters are .215, looks like the 3rd gen hemi are that way too, so like you I have never seen a stock hydraulic roller lifter that has .120 or less. I would sure buy a set, .060 would be even better. I would like to know what kind of seat pressure, and wt oil these guys are running that can run the lifter near bottomed out, and never have piston to valve issues. I am betting it is not 130 like most cam companies recommend so the cam does not go flat, or they have .250 piston to valve clearance. If I turned mine down 4-5 turns I bet it would not start with 125 on the seat, disregarding the pistons hitting the valves, at least with cold oil.

Yes curious about this set up also. A younger me ran the valves down too far (nowhere near 4-5 turns either) on a small block Chevy and bent a bunch of valves.

Posted By: BSB67

Re: Pushrod Falls Out of Rocker - 11/28/20 08:38 PM

Hydraulic lifters. Either plagued with pump up, or bleed down. Different problems, different solutions. Questions is there a place in the middle where they work. Maybe?

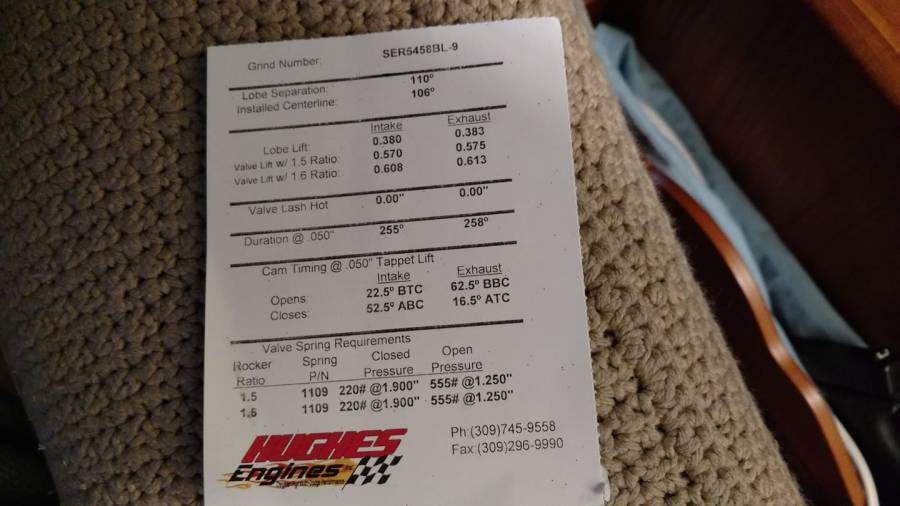

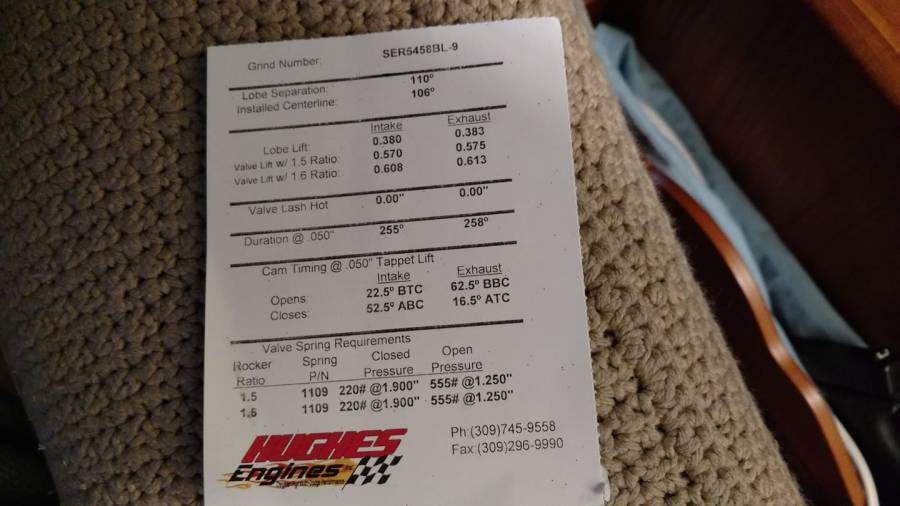

Charlie's hydraulic from Hughes specs a 220 lbs seat and 550 lbs over the nose pressure. Same as my solid roller. I would view the 0.020" off the bottom more like a lash verses a preload, IMO.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 11/28/20 09:15 PM

Charlie's hydraulic from Hughes specs a 220 lbs seat and 550 lbs over the nose pressure.

I’m pretty sure he’s running beehive springs with a fair amount less load than that.

I also believe his lifters have .120” plunger travel.

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/28/20 11:40 PM

Charlie's hydraulic from Hughes specs a 220 lbs seat and 550 lbs over the nose pressure.

I’m pretty sure he’s running beehive springs with a fair amount less load than that.

I also believe his lifters have .120” plunger travel.

Sorry about that Russ, I had forgotten about the wrong spring specs until you mentioned it,, the cam card is wrong that came with my cam,,, on the web site for my Hydro cam it says 155 seat 415 open, when I got the cam I had to call & sort out what springs are correct & they said it was a missprint for the 220 seat springs, as Dwayne said I have Beehives, also I totally agree on my .020 from the bottom is really just a lash setting. here is the cam card from the website The lifters are .120 travel, I got longer pushrods so I could set them from the bottom of travel & keep the amount of threads on the adjusters correct,, Needless to say but, the only way a pushrod can fall out on my junker is if something REALLY breaks & fails, not just a collapsed hydro lifter

.png)

Posted By: dvw

Re: Pushrod Falls Out of Rocker - 11/29/20 01:35 AM

Let's assume the lifter preload is some where between .xxx preload and not bottomed out. Let's also assume the lifter doesnt bleed down and the valve train doesnt go into false motion. In this case the amount of preload means absolutely nothing. Now if it bleeds extra preload may keep the valve train clearances close enough so the valve drain doesn't gain enough lash to fall apart. If the valve train is unstable to some degree minimal preload will limit the amount of positive lash in the valve train. If you have both issues you have a problem. Other than this there is no magic. As usual it's a case of over thinking.. My 2 cents

Doug

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/29/20 01:43 AM

Let's assume the lifter preload is some where between .xxx preload and not bottomed out. Let's also assume the lifter doesnt bleed down and the valve train doesnt go into false motion. In this case the amount of preload means absolutely nothing. Now if it bleeds extra preload may keep the valve train clearances close enough so the valve drain doesn't gain enough lash to fall apart. If the valve train is unstable to some degree minimal preload will limit the amount of positive lash in the valve train. If you have both issues you have a problem. Other than this there is no magic. As usual it's a case of over thinking.. My 2 cents

Doug

I agree with you. not arguing with you, my setup is proof of your statement

Posted By: B1MAXX

Re: Pushrod Falls Out of Rocker - 11/29/20 03:05 PM

Too many assumptions, real world/valve-trains ain't perfect, My 2 cents

Have you ever over-reved (floated)a hydraulic engine, I've done it many times. Minimizing pre-load helps this.

CSK to be clear, you set you valves by putting them on the base circle, turning the adjuster until the lifter is fully collapsed, then back off a 1/2 turn? My next question is have you ever set you valves after the engine was run/primed? I would think that the one time, you could get to the bottom of travel was with a clean empty lifter. After priming any inconsistent residual oil would put them all over the place. Sometimes they won't move at all (or anytime in the near future). What then?

DVW funny you said that..... I was thinking you guys are overthinking this. O lash, 1/4 to 3/4 turn and move on.

I want to say good luck to the original post trying to get all the lifters completely bled down, to do the bottom of travel method If you go that route.

Posted By: CSK

Re: Pushrod Falls Out of Rocker - 11/29/20 05:13 PM

Too many assumptions, real world/valve-trains ain't perfect, My 2 cents

Have you ever over-reved (floated)a hydraulic engine, I've done it many times. Minimizing pre-load helps this.

CSK to be clear, you set you valves by putting them on the base circle, turning the adjuster until the lifter is fully collapsed, then back off a 1/2 turn? My next question is have you ever set you valves after the engine was run/primed? I would think that the one time, you could get to the bottom of travel was with a clean empty lifter. After priming any inconsistent residual oil would put them all over the place. Sometimes they won't move at all (or anytime in the near future). What then?

DVW funny you said that..... I was thinking you guys are overthinking this. O lash, 1/4 to 3/4 turn and move on.

I want to say good luck to the original post trying to get all the lifters completely bled down, to do the bottom of travel method If you go that route.

Yes & it is not hard to do, they will bleed down, you just have to be patient , I use a feeler gauge, after waiting you can move the feeler gauge until it bottoms out THEN you know it is bottomed when the feeler is tight, it does take some practice, been doing it this way for a long time on other applications.

Posted By: MarkZ

Re: Pushrod Falls Out of Rocker - 12/06/20 10:04 PM

Had a bit more time to further tear things down. Popped the intake off and pulled the problem lifter set out. Can't see anything out of the ordinary with it externally, but I don't have a set of snap ring pliers to take the lifter apart. I lost the original lash measurements, so I measured the adjuster in relation to the rocker to get an idea the variation between all of them. Came out with these numbers:

8E: .711"

8I: .696" <----Problem lifter

6I: .718"

6E: .698"

4E: .731"

4I: .697"

2I: .705"

2E: .702"

Are variations in lash like this acceptable? The problem hole is the lowest, but only by .001" from two other lifters that have never done this. I'm going to assume I should put it back together and get proper measurements before deciding what to next. I liked the idea of converting over to solid, but I just don't have $1k to drop on lifters right now.

I didn't put this motor together either. So far I've been into it for a blown head gasket, worn bronze cam gear and this.

Posted By: fast68plymouth

Re: Pushrod Falls Out of Rocker - 12/06/20 10:31 PM

Imo, what you’re measuring on the adjuster is meaningless.

Different valve tip heights, and camshaft base circle diameter will impact where the adjusters are.

Just curious.......How sure are you those are Comp lifters?

I haven’t seen any Comp HR lifters for a BB Mopar in quite a while, but I don’t recall them having the skirted wheel.

Of course..... they may have made revisions or changed vendors over the years.

( Edit - I looked through some pics on line. It appears they have had shrouded/skirted wheels for quite a while..... see pic, BB and SB )

Nonetheless........ if you adjust them like I suggested in my first post, I think you’ll find the problem goes away.

Yes, that may require different length pushrods.

Btw, what I see....... looking at your measurements is...... the “left” rockers have the long measurement, and the “right” have the short measurement.

Though....One thing you could check now is...... how far from being bottomed out does your current preload put the plunger?

What you have for total plunger travel would also be interesting to know.

Posted By: NITROUSN

Re: Pushrod Falls Out of Rocker - 12/06/20 11:40 PM

I didn't put this motor together either. So far I've been into it for a blown head gasket, worn bronze cam gear and this.

Also make sure the push rods do not rub the block. Ran into this years back with stage 6 heads and larger push rods. Had to clearance the block in several area's due to rubbing and deflection on the push rods. Just something to look for.

Posted By: MarkZ

Re: Pushrod Falls Out of Rocker - 12/07/20 01:17 AM

Imo, what you’re measuring on the adjuster is meaningless.

Different valve tip heights, and camshaft base circle diameter will impact where the adjusters are.

Just curious.......How sure are you those are Comp lifters?

I haven’t seen any Comp HR lifters for a BB Mopar in quite a while, but I don’t recall them having the skirted wheel.

Of course..... they may have made revisions or changed vendors over the years.

( Edit - I looked through some pics on line. It appears they have had shrouded/skirted wheels for quite a while..... see pic, BB and SB )

Nonetheless........ if you adjust them like I suggested in my first post, I think you’ll find the problem goes away.

Yes, that may require different length pushrods.

Btw, what I see....... looking at your measurements is...... the “left” rockers have the long measurement, and the “right” have the short measurement.

Though....One thing you could check now is...... how far from being bottomed out does your current preload put the plunger?

What you have for total plunger travel would also be interesting to know.

The entire motor was assembled by a shop. I provided the block, rotating kit, heads, pan and intake - the shop sourced everything else. I'm going off of what the shop wrote up in the receipts.

I'll reassemble it all and do exactly what you recommended. May be a while waiting for a warmer day in which to work, but I'll post my findings back this thread. Thank you very much for taking the time to help me with this.

Posted By: W.I.N. Racing

Re: Pushrod Falls Out of Rocker - 12/07/20 05:14 PM

I didn't put this motor together either. So far I've been into it for a blown head gasket, worn bronze cam gear and this.

Also make sure the push rods do not rub the block. Ran into this years back with stage 6 heads and larger push rods. Had to clearance the block in several area's due to rubbing and deflection on the push rods. Just something to look for.

As a side note...I will allow the push rod to rub as a dampening technique. But it can not alter the trajectory of the rod...now back to your regularly scheduled thread.

Posted By: MarkZ

Re: Pushrod Falls Out of Rocker - 03/21/21 07:42 PM

I finally got back out into the garage to continue working on this thing. Got parts and while giving everything one last look over before assembly I discovered the bushes on the offending rocker had worked their way to one side. I don't know if this the cause of the pushrod coming out from under the rocker, or if it was what happened after the fact. Either way I've got another rocker on order now too. Should have looked over the parts with a better eye last time I was out there.

Posted By: B3RE

Re: Pushrod Falls Out of Rocker - 03/21/21 09:27 PM

I see multiple issues here, but the pushrod popping out is simply a lifter bleeding down. As CSK mentioned, you can run the pushrod .020" off the bottom of the lifter, and it will eliminate that problem.

That could open up another can of worms though. If the motor goes into valve float, the lifter will do it's job and pump up. That will hold the valve open and if P2V clearance is tight, could bend valves. Looking at the sweep pattern on the valve tip, I'd say the geometry is pretty far off and instability is likely. Also, it appears the adjuster is out much further than it should be. The preferred setting is one turn out from seated in the rocker body, and no more than two turns. That's turns, not threads.

Something else that is misunderstood is that valve float does not limit rpm. The valve being off the seat when it is supposed to be closed is what limits rpm. If valve float did it, lift rule class racers that run lofting cam lobes couldn't turn any rpm due to the controlled valve float. A hydraulic lifter does not really get into valvetrain instability any earlier (or at least not much earlier) than a solid lifter. What it does do is hold the valve open when the lifter pumps up from float, which then holds the valve off the seat. A solid will go into float and jackhammer the valvetrain into oblivion, but won't stop revving until the instability is so severe that the lifter bounce causes the valve to bounce off the seat and rpms stop climbing. Either way, the instability is present and the valvetrain is not happy. The preload has nothing to do with rpm potential, and the only reason for a zero preload hydraulic lifter, with a heavy retaining clip, is to allow the engine to continue revving like a solid when valvetrain instability is present.

Do the best you can at getting the valvetrain stable, and you will improve rpm potential regardless which lifter style is used. I didn't say they would both be equal, but improved.

Posted By: polyspheric

Re: Pushrod Falls Out of Rocker - 03/21/21 10:08 PM

Adjuster length affects rocker ratio, but also changes the geometry triangle (lines connecting the roller axle, the shaft center, and the CL of the adjuster ball).

Posted By: B3RE

Re: Pushrod Falls Out of Rocker - 03/21/21 10:21 PM

Adjuster length affects rocker ratio, but also changes the geometry triangle (lines connecting the roller axle, the shaft center, and the CL of the adjuster ball).

Agreed, which is why I recommend not extending the adjuster any further than necessary. Especially considering the adjuster angles and placements are wrong on shelf rockers to begin with.

.png)