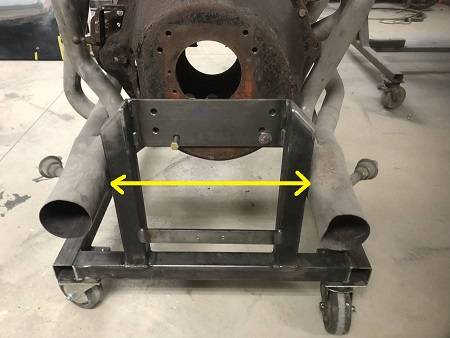

Uses an old cast iron 4 speed bellhousing and flywheel I had laying around. Standard motor mounts.

CHIP,

Do you have a picture of how you supported the rear of the bellhousing?

Jim, no, but I can get you a pic. The bellhousing just butts up to the flat face of the angle iron and I drilled the 4 holes for the transmission mount bolts. Just something to hold up the rear of the whole deal.

Like I said, mine is ugly and crude, but I have basically zero money in it and it works great. I got tired of retorquing heads in the car after a fresh build...that's what led me to build this thing. It's SOOOO much easier now. Nice for when I occasionally build an engine to sell or for someone else.

![[Linked Image]](https://i.imgur.com/4diQqn8h.jpg)

![[Linked Image]](https://i.imgur.com/5PiV8Hzh.jpg)

![[Linked Image]](https://i.imgur.com/bDgwGFNh.jpg)

![[Linked Image]](https://i.imgur.com/bJS9xHKh.jpg)