Posted By: WadeMetzinger

Engine building tools - 06/15/20 07:23 PM

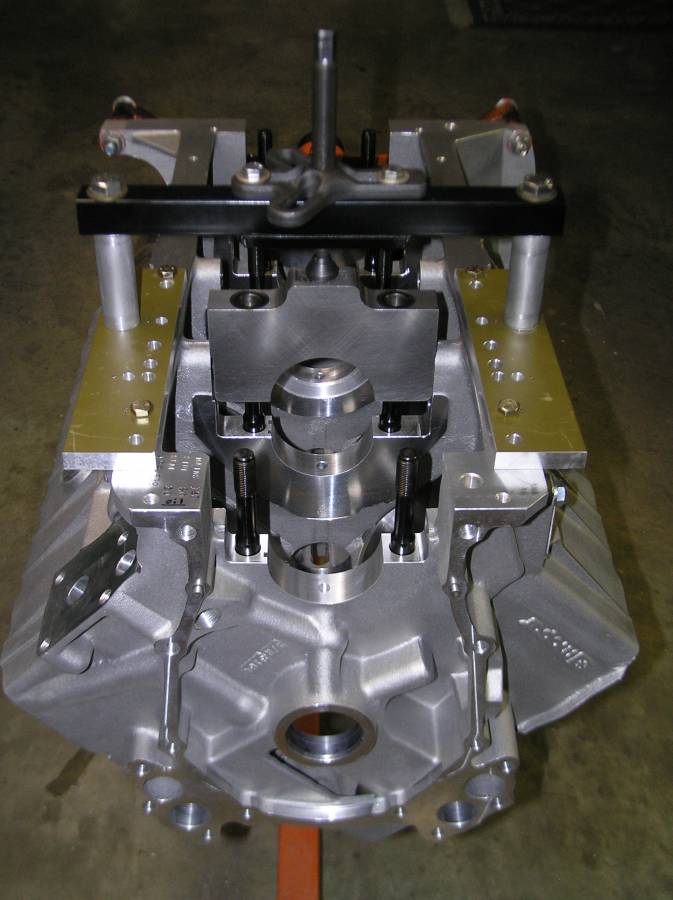

I typically pick up a new tool with each customer motor I build. It may be a simple as a ring compressor or more significant like the Total Seal electric ring filer.

Here are a few pictures of my main engine building tools, not shown are light valve checking springs, PAC install height gage/mic, Andy's BB and SB metal plates for mounting dial indicator for checking lifter, valve or rocker height/travel, adjustable length checking push rod, dial caliper, engine brushes, solvent tank, 9" bore flashlight, mirrors.

What other tools have you engine builders found useful that I don't have and should consider?

Here are a few pictures of my main engine building tools, not shown are light valve checking springs, PAC install height gage/mic, Andy's BB and SB metal plates for mounting dial indicator for checking lifter, valve or rocker height/travel, adjustable length checking push rod, dial caliper, engine brushes, solvent tank, 9" bore flashlight, mirrors.

What other tools have you engine builders found useful that I don't have and should consider?

![[Linked Image]](http://pic20.picturetrail.com/VOL1620/1011563/1887759/414442158.jpg)

![[Linked Image]](http://pic20.picturetrail.com/VOL1620/1011563/1886546/414415678.jpg)

![[Linked Image]](http://pic20.picturetrail.com/VOL1620/1011563/1886546/414415676.jpg)