Haven't found any evidence other than commentary on the subject. Factory windage trays loose power? Aftermarket windage trays loose power(not including crank scraper)? Any hard evidence, something like a real design, where the tray does its job and makes power? No" dry sump" as the solutions please.

So, to the OP, it seems that those that have been doing this for years do not think it has value. I too agree that in my low level bracket/grudge racing I have not seen any improvements just by adding a tray. Never did any Dyno testing on small blocks back in my racing/hot rod days.

In the tests by the Mopar test group back in the days I seem to remember they were getting some HP gains but everyone was only reving their engines to 6,000 or so back then.

E-58 small block cop car engine would only rev to 5,500 in most cases, first gear was locked out with a bracket.

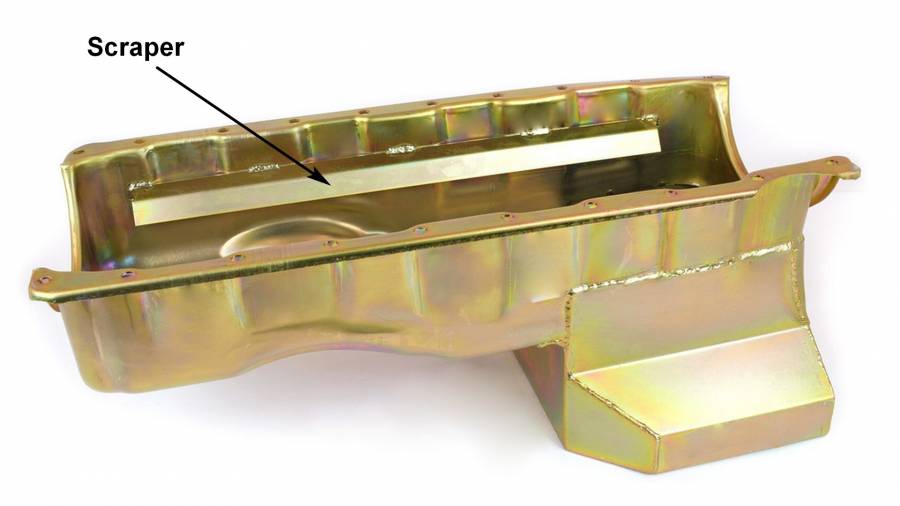

So, as posted above, a better course would be a deeper sump with the same amount of oil down lower in the sump, proper baffels and a scraper of some sort.