Moparts

Why did my Cam Fail????

Posted By: markz528

Why did my Cam Fail???? - 12/10/19 10:23 PM

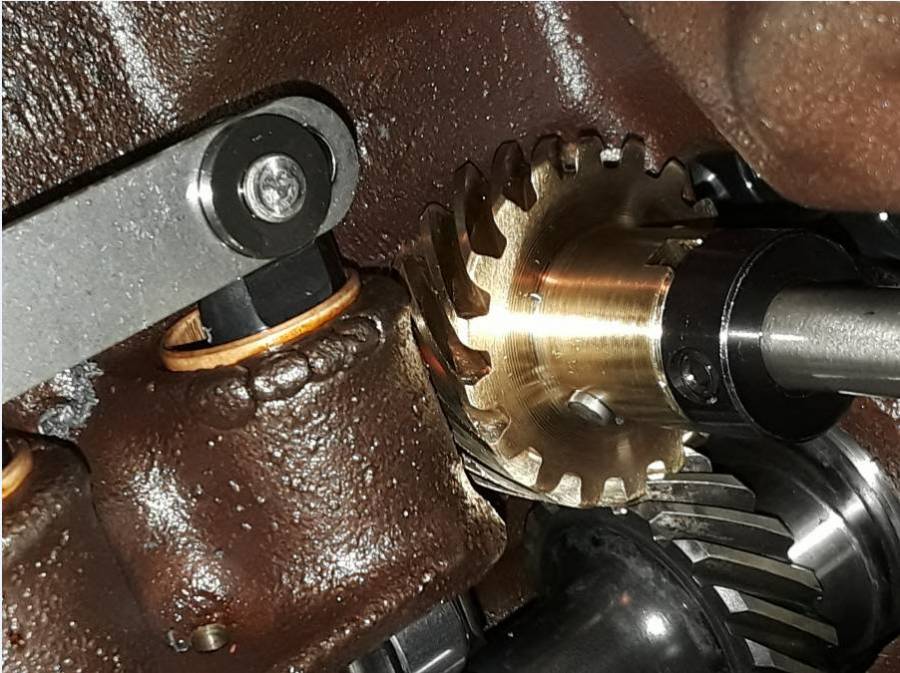

Comp Cams steel billet 23-000-9 mechanical roller. Bought new in 2006 but less than 100 runs.

Valve Adjustment .020 Intake/Exhaust (approx .017 cold)

Lift Intake/Exhaust .706/.676

Duration @ .020 Intake/Exhaust 318/328 (285/290 @ 0.050)

I don't know the spring pressures. Always used Castrol Synthetic Syntec 20w50 oil. Might have been 5w50 - can't remember right now.

The grooving is actually worse on the sides than on top. Most lobes are affected. Called Comp Cams and they were zero help.

Any thoughts?

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/10/19 10:40 PM

Honestly, that looks fairly normal to me.

I don’t consider that a cam that “failed”.

I hate to get into this kind of discussion(everybody has their favorites)....... but I’d have used different oil.

I still feel high zinc oils are best in HP applications.

There could have been some skidding going on with the rollers, and some anti-friction additives might have diminished what you’re seeing.

That being said, if the pics are the worst of it....... I’d reuse it.

Posted By: viperblue72

Re: Why did my Cam Fail???? - 12/10/19 10:40 PM

I don’t have your answer but I imagine you can have that reground. How do the lifters look?

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/10/19 10:50 PM

UD roller from 1993 or 94.

Crane 8620 billet core.

Springs were 200/500, 1.5 rockers, Herbert lifters.

2 dyno sessions and about 200 passes.

Pretty normal from what I’ve seen through the years.

Posted By: tex013

Re: Why did my Cam Fail???? - 12/10/19 10:53 PM

Honestly, that looks “fairly” normal to me.

I don’t consider that a cam that “failed”.

I hate to get into this kind of discussion(everybody has their favorites)....... but I’d have used different oil.

I still feel high zinc oils are best in HP applications.

There could have been some skidding going on with the rollers, and some anti-friction additives might have diminished what you’re seeing.

I am with Fast with this . It seems for a performance roller , hyd or solid , a mineral or semi synth oil is the go . With high pressure the wheel skids not rolls with full synthetic .

Tex

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/10/19 10:59 PM

Actually, I have no issue with synthetics....... I just would be using a race type oil with a higher zinc content than what’s on the shelf at WalMart.

Something like Driven.

If I pulled that cam out of a motor I was freshening........ I’d put it right back in when it was going back together.

Posted By: Cab_Burge

Re: Why did my Cam Fail???? - 12/10/19 11:06 PM

Are these pictures of the opening side or closing side or both?

If they are of the closing side I think you need more valve spring pressure to keep the rollers on the lobe all the time, not hopping over the nose and sliding when they hit the backside of the lobes

If it is on both sides I would add more spring pressures on the seats and opened both

I like 230+ lbs. on the seta sand from 600+ up opened

That is a big grind, lots of duration at .050

Do you know the spring pressures it had when you took it apart this time?

BTW, I don't like or use synthetic motor oil in any of my old motors, especially Hi Po drag race motors

I like and use Valvoline VR1 10W30Wt in them now

If they made 5W20 Wt. in VR1 I would use that instead of their 10W30Wt

Posted By: CMcAllister

Re: Why did my Cam Fail???? - 12/10/19 11:17 PM

I had an old Cam Dynamics 620/640 solid roller that looked like that. Ran it for years. Never got any worse.

Posted By: TRENDZ

Re: Why did my Cam Fail???? - 12/11/19 01:52 AM

I see no fail in that either. Can you feel the trace?

I had an old Cam Dynamics 620/640 solid roller that looked like that. Ran it for years. Never got any worse.

Hey I think I know that cam. Lol.

Posted By: Jeremiah

Re: Why did my Cam Fail???? - 12/11/19 03:37 AM

Skid marks for sure. If you have straight enough pushrods angles you could try a rev kit? I considered trying one but i did not have room due to the prod angles. You also have to use a compatible lifer and we used .180 offset isky ez roll max roller lifter which are not.

Id be interested to see the difference when you measure the roller area vs the virgin lobe.

Posted By: markz528

Re: Why did my Cam Fail???? - 12/11/19 04:03 AM

To answer some of the questions.....

This cam was not getting reused anyway. The motor will be a new combo including new cam and lifters. I sold the heads and will not bother to measure the spring pressure. I have the spring pressure written down somewhere, but can't find it right now.

I don't remember if it is the same on the up and down or not - would have to look when I get home. One lifter had a scored roller biu other than that they looked fine to me.

The pictures don't do it justice. Some of the grooving is quite deep - more than just a light catch with a fingernail. I might try to measure it in the lathe with an indicator. I would not feel good about reusing this cam. My buddy called it a "tomato stake".

Knowing what I know today I don't like my choice of oil either. I believe that I was skidding the rollers on the cam because of one or more variable's. I think it may be a combination of oil and maybe spring pressure.

My biggest thing is to make sure that the new motor cam does not experience any issues..............

Posted By: Cab_Burge

Re: Why did my Cam Fail???? - 12/11/19 04:24 AM

If you can feel those marks it needs to be fix before running it again.

I'm sure that this motor is not a wedge, correct?

The valve train on a 426 Hemi motors need a lot better parts (than a B, RB or SB motor)as far as the pushrods, valve springs. keeper and retainers to make the valve train stay stable above 6000 RPM

Posted By: markz528

Re: Why did my Cam Fail???? - 12/11/19 11:35 AM

If you can feel those marks it needs to be fix before running it again.

I'm sure that this motor is not a wedge, correct?

The valve train on a 426 Hemi motors need a lot better parts (than a B, RB or SB motor)as far as the pushrods, valve springs. keeper and retainers to make the valve train stay stable above 6000 RPM

It is a wedge.

Posted By: gregsdart

Re: Why did my Cam Fail???? - 12/11/19 11:53 AM

A cracked crank will do that and worse. Mine ran well right up until I drove over the rod bearings and related parts!

Posted By: fbs63

Re: Why did my Cam Fail???? - 12/11/19 11:54 AM

I have had 2 customers lose roller cams and hurt lifters using synthetic oil. 1 used Mobile 1 and one used Valvoline synthetic. I recommend Penn grade (Brad Penn) or Penzoil 25-50 racing oil.

Posted By: HardcoreB

Re: Why did my Cam Fail???? - 12/11/19 01:07 PM

I'm going to go against some the the grain here and say that cam is compromised and likely 'soft'. The cam in the pic that Fast posted LOOKS GOOD TO ME TOO but, it looks differently 'worn' in my eyes. My buddy bought a solid roller cam from Comp about 6 years ago and the core color between lobes was black like seen. It wiped out in the same manner in a very short time. They all used to be 'copper' color from what i remember until relatively recently. The one solid roller i bought new from Comp around that same era WAS 'copper'. I'm not sure if that is a reflection of the parent cam metallurgy or just heat treat. His newest cam is 'copper color' but was bought from Crane about 4 years ago and has over 3x the use on it so far and looks fine under all same conditions. And for what it's worth his newest cam has a significant increase in lobe intensity.

Posted By: fbs63

Re: Why did my Cam Fail???? - 12/11/19 01:36 PM

Usually the copper color cores are billet and the black cam cores are cast.

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/11/19 03:05 PM

There are no cast roller cores for BB Mopars.

Copper color between the lobes is 8620 material.

Black between the lobes is usually 5150 material.

The heat treat goes deeper on the 5150, which allows for more manipulation for putting a wider variety of lifts and LSA’s on the core.

Both are steel billet.

Posted By: fbs63

Re: Why did my Cam Fail???? - 12/11/19 03:44 PM

I've had some hydraulic rollers I would swear were cast.

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/11/19 04:45 PM

For a BB Mopar?

Cast cores used with roller lifters are made of a different material than what is used with flat faced tappets.

AFAIK, there are no SADI cores(ductile iron, the material used for roller lifters) made to fit BB Mopars.

Posted By: INTMD8

Re: Why did my Cam Fail???? - 12/11/19 05:21 PM

My biggest thing is to make sure that the new motor cam does not experience any issues..............

I wouldn't personally run a 5150 core with those specs.

You would have better reliability out of an 8620 core but of course need to make sure spring pressure and everything else in the valvetrain is correct.

JMO

Posted By: HardcoreB

Re: Why did my Cam Fail???? - 12/11/19 05:27 PM

There are no cast roller cores for BB Mopars.

Copper color between the lobes is 8620 material.

Black between the lobes is usually 5150 material.

The heat treat goes deeper on the 5150, which allows for more manipulation for putting a wider variety of lifts and LSA’s on the core.

Both are steel billet.

Yes, his was a steel billet but likely (99.99%) it was as Fast said 5150 base. I vaguely remember him saying that Comp would offer him no $break$ for a replacement and they did say that the 8620 SHOULD have been HIS request for his application AND would be a $ upcharge verses the 5150 cores.

Posted By: second 70

Re: Why did my Cam Fail???? - 12/11/19 05:45 PM

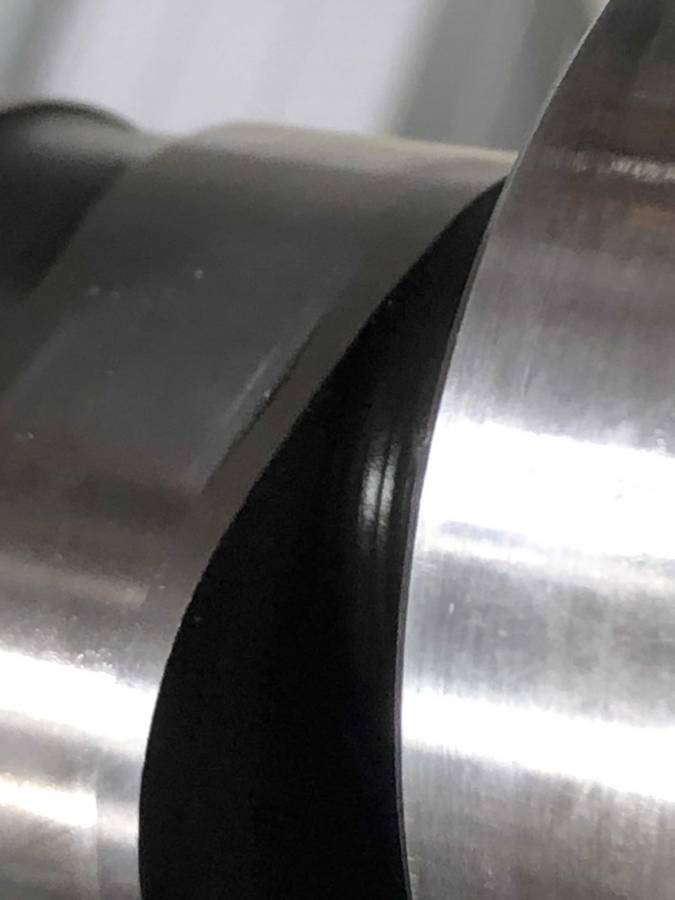

Here's mine after 10 years on the street with Mobile 1 Yes it is a copper core.

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/11/19 06:05 PM

I haven’t had any problems with the 5150 cores.

That’s what most of the BB Mopar cores are these days.

They simply don’t always have 8620 cores that are suitable for every combination.

And if they do, they’re usually more $$$.

Unless Marks cam looks way worse in person than in the pics...... I still say it looks pretty normal to me.

Posted By: n20mstr

Re: Why did my Cam Fail???? - 12/11/19 07:40 PM

Is BES ok with reusing that cam? Maybe now is the time to let him spec your new one ?

Posted By: BradH

Re: Why did my Cam Fail???? - 12/11/19 07:47 PM

I'm DOOOOOOOOOOOOOOOOOOOOOOOOOOOOMED!!! I have a BLACK CORE CAM!!!

( Hee hee!

)

Posted By: Cab_Burge

Re: Why did my Cam Fail???? - 12/11/19 10:00 PM

I've had some hydraulic rollers I would swear were cast.

Years ago, early to mid 1970s, I had two Isky solid rollers that I'm sure where cast core camshafts also

None bought since from any other company

Posted By: CSK

Re: Why did my Cam Fail???? - 12/11/19 10:19 PM

I'm DOOOOOOOOOOOOOOOOOOOOOOOOOOOOMED!!! I have a BLACK CORE CAM!!!

( Hee hee!

)

NOOOOOOOOOOOOOOOOOOOOOOOO,, dont take it apart & start over

Posted By: markz528

Re: Why did my Cam Fail???? - 12/12/19 01:24 AM

Is BES ok with reusing that cam? Maybe now is the time to let him spec your new one ?

The cam is being replaced. New one is on its way. That was always the plan.

Posted By: ZIPPY

Re: Why did my Cam Fail???? - 12/12/19 02:07 PM

If it's still straight and otherwise in good shape, might be a nice one to regrind, if there's

enough meat there in the right places to create a different profile.

Posted By: markz528

Re: Why did my Cam Fail???? - 12/12/19 11:56 PM

Looked at it some more tonight.

It’s the worst on the opening side. At max lift not too bad and gets worse on the closing side but not as bad as the opening side. Base has no marks.

The worst groove is 0.0008 inches - so almost a thousandths. I actually thought it would be worse.

The worst ones have pretty significant burrs.

Posted By: A727Tflite

Re: Why did my Cam Fail???? - 12/13/19 12:51 AM

Have you compared the width of the contact portion of the roller wheel versus the edges of the contact patch on the lobe?

Posted By: markz528

Re: Why did my Cam Fail???? - 12/13/19 01:27 AM

Have you compared the width of the contact portion of the roller wheel versus the edges of the contact patch on the lobe?

I have not but it looks to be pretty much the width of the roller.

Posted By: markz528

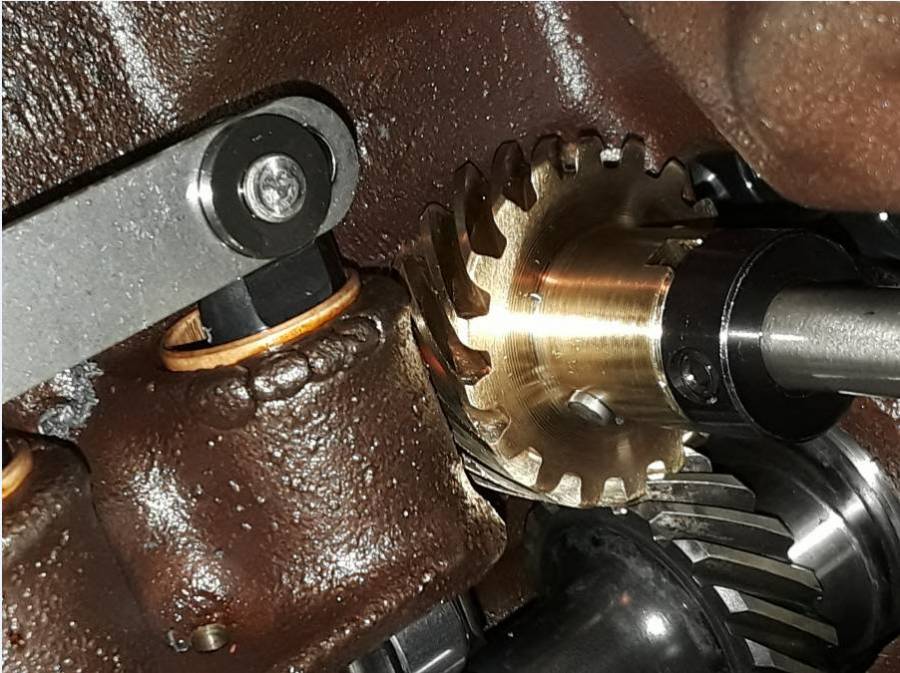

Re: Why did my Cam Fail???? - 12/13/19 03:07 AM

Posted By: Cab_Burge

Re: Why did my Cam Fail???? - 12/13/19 06:29 AM

it looks like one side of that lifter is hitting the cam lobe before the other side, it looks like it is loosing contact with the lobe after max lift

I would replace (or have them rebuilt with new wheels, axles and bearings) all the lifters off of the lobes that look like that

Posted By: BradH

Re: Why did my Cam Fail???? - 12/13/19 02:35 PM

Somewhat from out of left field...

- Rocker brand & ratio?

- Pushrod length, diameter & wall thickness?

- Did you find the spring specs and any info on how they were installed?

Speaking strictly as an amateur bystander, I'm wondering if the opening & closing flanks are showing the result of insufficient valve train control, or a lubrication issue.

Posted By: fast68plymouth

Re: Why did my Cam Fail???? - 12/13/19 03:13 PM

Still looks totally normal to me.

The more pics I see the more normal it looks.

All 16 lobes on the cam I posted the pic of have the same impressions on the opening side, in the area where the big change in velocity and pressure angle occurs.

Anyone got a pic of a typical drag race roller cam, that’s been run with typical drag race spring pressures for 100 or more passes that doesn’t have those marks on the opening side?

Let’s see some pics and specs.

.0008

Give me a break. 😂

Lmao

Posted By: moparacer

Re: Why did my Cam Fail???? - 12/14/19 03:17 PM

I have a Bullet cam that looks just like that. And it eat a lifter and screwed it up....I could take some pictures and you wouldn't be able tell them from yours. When I first switched from a solid to a roller in my big block it was even worse. We sent the cam back to Bullet and they checked the hardness and it was ok, reground it, I put it back in and it did it again. I ended up upping the spring pressure and it helped, but I don't think I ever totally eliminated it. Since then I have been through several different lifter styles, cams and even blocks and it has always done it to some extent. I have to pull the engine and go through it here shortly and its got a few hundred passes on it and I bet there is some evidence of it still doing it.

I would like to know what the issue is if anyone ever figures it out. I have a theory that it might be related to the roller diameter, lobe profile and the geometry of the lifter bores, but that is just a guess.

Posted By: EchoSixMike

Re: Why did my Cam Fail???? - 12/16/19 12:32 AM

I'd guess the lifter bores are not parallel to the cam, looks as if one side of the lifter is biased and it's not travelling flat on the cam, so you have an unequal impact loading where the lash gets taken up, that's displacing a small amount of cam metal. All that said, I'd put it on the crank polisher and I'd bet it looks like new, Lord only knows some of the stuff racers have crammed back into blocks "for one more run." S/F....Ken M

Posted By: A727Tflite

Re: Why did my Cam Fail???? - 12/16/19 01:57 AM

I'd guess the lifter bores are not parallel to the cam, looks as if one side of the lifter is biased and it's not travelling flat on the cam, so you have an unequal impact loading where the lash gets taken up, that's displacing a small amount of cam metal. All that said, I'd put it on the crank polisher and I'd bet it looks like new, Lord only knows some of the stuff racers have crammed back into blocks "for one more run." S/F....Ken M

I can’t remember the last time I saw lifter bores parallel to the cam.

Posted By: DrCharles

Re: Why did my Cam Fail???? - 12/16/19 02:00 AM

I'm pretty sure you know he meant "perpendicular"

Posted By: A727Tflite

Re: Why did my Cam Fail???? - 12/16/19 02:51 AM

I'm pretty sure you know he meant "perpendicular"

Aww come on - it was supposed to be funny.

Posted By: EchoSixMike

Re: Why did my Cam Fail???? - 12/17/19 09:56 AM

Yeah, my brain was trying to pick between square and perpendicular and my hands typed parallel. The point remains. S/F....Ken M

Posted By: 66coronet

Re: Why did my Cam Fail???? - 12/17/19 01:24 PM

My two thoughts on this.

One - how many passes were on the valve springs? Were they allowing the lifters to bounce/skid? I change valve springs every winter. It just seems like cheap insurance to me. My cam is not as aggressive though. 683/683 284/288@.050

Two - I run heavy oil and an additive. I use Lucas 20w50 and comp cams break in lube with every oil change. Maybe I am giving up hp and et by doing this, but I have been 9.45 @140 in NSS trim weighing 3585. Light weight oils just are not worth it to me.

Posted By: HardcoreB

Re: Why did my Cam Fail???? - 12/17/19 02:26 PM

Appears like the lifter wheels are concave/crowned causing a localized edge loading. The material transfer of the cam may be from both the lifter wheel and some cam combined. if the 'chamfer' cut on the wheel was done AFTER the face of the roller was ground this could create these conditions OR... Also, someone mentioned they have tried different lifters...it's LIKELY those different lifters use wheels from the same manufacturer.

Posted By: A727Tflite

Re: Why did my Cam Fail???? - 12/17/19 02:43 PM

Yeah, my brain was trying to pick between square and perpendicular and my hands typed parallel. The point remains. S/F....Ken M

We have seen this “wear” for years, in blocks with bushed lifter bores, and using quality oils back in the 70’s.

Thoughts back then were the lifters we’re rotating against the guide bars, valve spring issues, pushrod deflections.

Point remains, based on seeing this for that long, it’s nothing to get worried about.