This will be part science experiment AND the heads are expected to be used on a live engine. "When" depends upon which century they get finished.

Ideally, they'd be done in time to do a swap w/ the current heads on my RB 452 to see what's what. Otherwise, they'll be tested on my RB 451 build that will eventually replace the RB 452 that's been through multiple rebuilds / freshen-ups over the years.

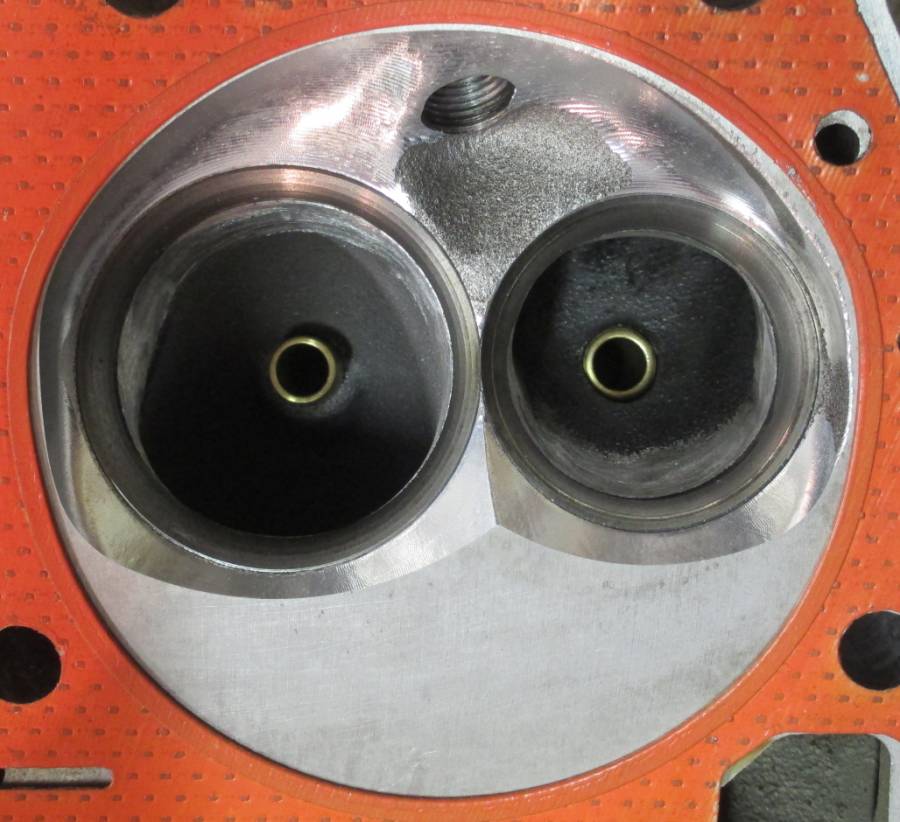

The current heads' chambers being opened up to gasket line as shown is the result of Hughes Engines CNC chamber program, which I had Hughes do after getting the heads from Brian at IMM (member ou812).

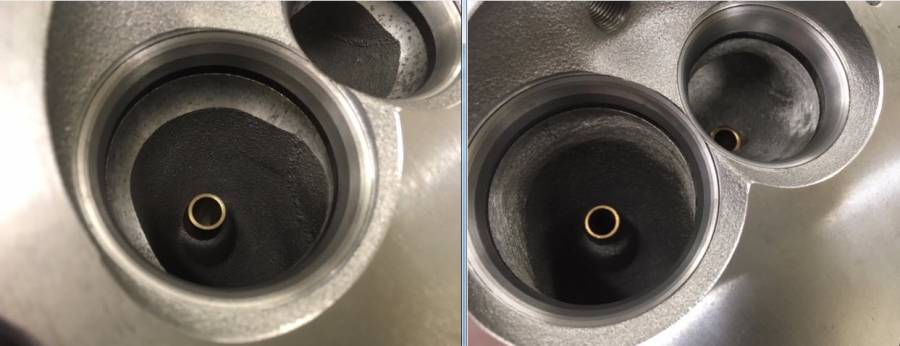

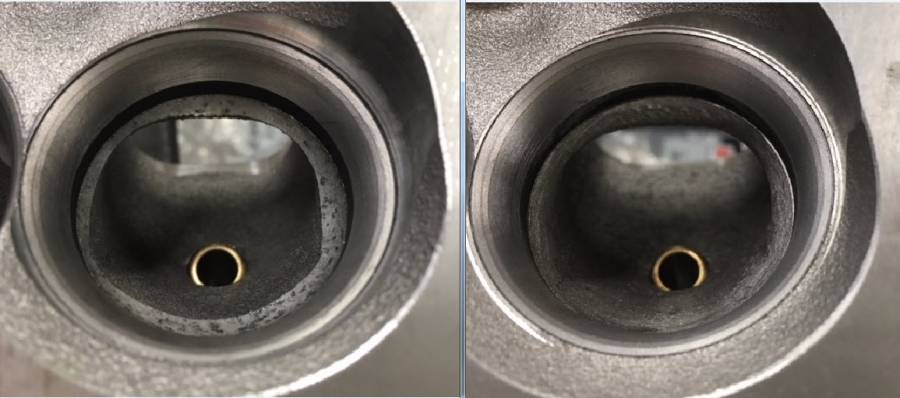

I'd prefer to not have any overhang at all, if possible, but won't know how far to take it until I finally get around to porting & flow-testing. One hypothesis about why the current heads back up starting about .750" is because this CNC'd chamber program takes too much out between the intake valve and the adjacent bore, as well as removes too much material from the plug-side of the chamber (too concave). So, that's where the "science experiment" part of this factors in. Also, I've never notched the top of my blocks' bores, so maybe this is one of those scenarios where the head is "happier" if the chamber is pushed out a bit beyond the bore, as long as the bore is notched to eliminate the resulting ledge.

There are a couple of beliefs I've seen debated on engine tech forums such as SpeedTalk. One is (basically) that improving the area below the curve of the peak valve lift is the goal, even if the port stalls or backs up (flows less) at lifts higher than the cam being used. The other is that having a port that is more stable across the lift curve and continues to increase in flow well after the peak valve lift will help power across the RPM range, even if the flow #s that fall under the valve lift curve aren't as good as a head that fits into that first category.

My current head seems to fit pretty well into that first category w/ solid flow #s, but backs up starting around .100" above peak valve lift. My desire for the second set of heads is to come up w/ something that fits into that second category. An apples-to-apples comparison of both sets of heads would be very interesting... well, at least to a few(?) people.