Posted By: Bad340fish

New Transmission Struggle thread - 09/29/19 09:11 PM

Hopefully someone else can learn from this. I am pretty frustrated with it at the moment.

I moved from a 15 year old flawlessly working 727 to a 904 last summer. Mainly to find a little more ET and help fit a trans shield to be legal without chopping up the tunnel. I used one of my Dad's transmissions that had been sitting idle for awhile, it worked, and it didn't leak but it was real soft on the 2-3 shift. We had another 904 rebuilt, and it worked good, did drag week with it, set new best ETs etc. The only thing I really didn't like about it was the 2-3 shift was kind of soft(compared to the 727) but that could have been high expectations for a stock 904(cheetah VB and A&A spring pack only mods) behind a 550-600HP 416. I freshened up the top end of the motor over the summer and was just busy and lazy so I didn't get it running until a month or two ago. When I fired it I had a transmission leak and it turns out the converter snout was cracked.

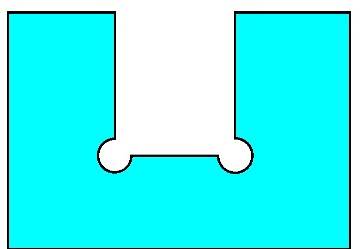

I pulled the transmission, removed the front pump to change the converter bushing and decided to keep going even though I had no trans building expirience. I pulled the high gear drum out and the clearance was in spec and nothing had been overheated, the forward clutch was way looser than spec but also showed no signs of slippage. While I had it out I had decided to use this Brand new but very old A-1 trans brake valve body. I drilled the hole in the front piston per the instructions and put 5 red clutches and Kolene steels from A&A in as well as new seals on the piston. Off the top of my head the clearance was .65-070 for that clutch pack. I did the same clutches and steels for the forward clutches, and the spec setup to A-1s instructions .045 I believe. I replaced any seal or ring I came across from a kit I bought from A&A. I adjusted the front and rear bands to spec and I felt it all went together well and I didn't have any worries. I also plugged the stock vent and moved it to the tail housing.

As posted in another thread I put it in yesterday and it ran through the gears on stands(not ideal I understand) but reverse was wonky and didn't give me a good feeling. I had a fuzzy memory when i came to how i adjusted the low reverse band so I pulled the pan and checked that, i was confident it was right so I changed the valve body back to my trusty Turbo Action Cheetah. Initially things looked good, reverse engaged, everything worked on the stands etc. Test drive time-failed! Reverse 1st and 2nd work fine, high gear is slow to engage but letting off the throttle it will go in and feels solid once its there. And its leaking out of the bell housing.......pissed!

I will pull the trans again in a few weeks but I am not certain what to look for. I used a known good converter, new pump bushing, new seal. I was extra careful to make sure I greased up the new seals on the high gear piston. Is that hole I drilled in the direct apply piston causing the problem? Is it a band adjustment deal? Reverse works just fine so the clutch pack works.

My only thought is the ancient A-1 valve body instructions told me to drill a hole in the piston for high gear. I am also using the A&A spring pack for the direct clutch and maybe those two mods don't work together? But it sure doesn't have any problem engaging reverse?

There is a race the first weekend in November that I normally do well at so I might just put my 727 back in for that event because the car clearly doesn't want a 904 lol.

My almost 6 year old boy rode around the neighborhood with me for the test drive. He obviously sensed I was frustrated and commented "I dunno Dad.....maybe you just need to change more parts?" I am sure he is right!

I moved from a 15 year old flawlessly working 727 to a 904 last summer. Mainly to find a little more ET and help fit a trans shield to be legal without chopping up the tunnel. I used one of my Dad's transmissions that had been sitting idle for awhile, it worked, and it didn't leak but it was real soft on the 2-3 shift. We had another 904 rebuilt, and it worked good, did drag week with it, set new best ETs etc. The only thing I really didn't like about it was the 2-3 shift was kind of soft(compared to the 727) but that could have been high expectations for a stock 904(cheetah VB and A&A spring pack only mods) behind a 550-600HP 416. I freshened up the top end of the motor over the summer and was just busy and lazy so I didn't get it running until a month or two ago. When I fired it I had a transmission leak and it turns out the converter snout was cracked.

I pulled the transmission, removed the front pump to change the converter bushing and decided to keep going even though I had no trans building expirience. I pulled the high gear drum out and the clearance was in spec and nothing had been overheated, the forward clutch was way looser than spec but also showed no signs of slippage. While I had it out I had decided to use this Brand new but very old A-1 trans brake valve body. I drilled the hole in the front piston per the instructions and put 5 red clutches and Kolene steels from A&A in as well as new seals on the piston. Off the top of my head the clearance was .65-070 for that clutch pack. I did the same clutches and steels for the forward clutches, and the spec setup to A-1s instructions .045 I believe. I replaced any seal or ring I came across from a kit I bought from A&A. I adjusted the front and rear bands to spec and I felt it all went together well and I didn't have any worries. I also plugged the stock vent and moved it to the tail housing.

As posted in another thread I put it in yesterday and it ran through the gears on stands(not ideal I understand) but reverse was wonky and didn't give me a good feeling. I had a fuzzy memory when i came to how i adjusted the low reverse band so I pulled the pan and checked that, i was confident it was right so I changed the valve body back to my trusty Turbo Action Cheetah. Initially things looked good, reverse engaged, everything worked on the stands etc. Test drive time-failed! Reverse 1st and 2nd work fine, high gear is slow to engage but letting off the throttle it will go in and feels solid once its there. And its leaking out of the bell housing.......pissed!

I will pull the trans again in a few weeks but I am not certain what to look for. I used a known good converter, new pump bushing, new seal. I was extra careful to make sure I greased up the new seals on the high gear piston. Is that hole I drilled in the direct apply piston causing the problem? Is it a band adjustment deal? Reverse works just fine so the clutch pack works.

My only thought is the ancient A-1 valve body instructions told me to drill a hole in the piston for high gear. I am also using the A&A spring pack for the direct clutch and maybe those two mods don't work together? But it sure doesn't have any problem engaging reverse?

There is a race the first weekend in November that I normally do well at so I might just put my 727 back in for that event because the car clearly doesn't want a 904 lol.

My almost 6 year old boy rode around the neighborhood with me for the test drive. He obviously sensed I was frustrated and commented "I dunno Dad.....maybe you just need to change more parts?" I am sure he is right!

![[Linked Image]](http://i221.photobucket.com/albums/dd90/miradaus/Snapbucket/car%20stuff/728277F1-49D2-4ACF-BA9F-7F6AB9E31BD4_zps41tfnst0.jpg)