Posted By: justinp61

Well Darn!!! problem found - 04/13/19 10:18 PM

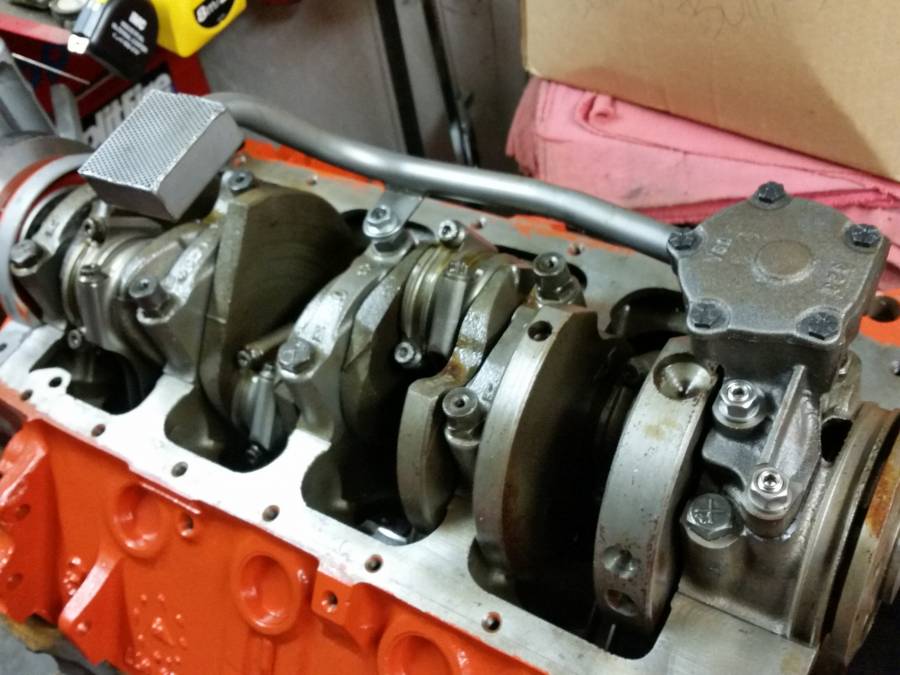

Today I was changing the oil in my Dart and after it all drained out I cut a slim strip of a clean rag and pit it on a wire to reach in the drain plug hole and wipe the bottom of the pan. I didn't find anything alarming but what I did find is that the pick tube is loose in the (SB) oil pump. When I put it up for the winter the oil pressure was still 60 psi hot at cruise and 30 psi at idle so I don't think anything is hurt. The engine will have to come out so I can fix it. I'm thinking that I'll fab some sort of tab to one of the main studs to prevent this from happening again, plus I'll check the bearings while the pan is off. I've built several small blocks over the years and never had this issue.