Posted By: radar

Edit: 727 is out and apart- here’s what I found - 03/29/19 05:16 AM

Howdy fellas

I’m getting a little more seat time in my hotrod and it’s becoming obvious that something isn’t right in my transmission. If you didn’t see my earlier thread I couldn’t get any gear at first because I had installed the pickup/ filter extension for the deep pan 180° out and wasn’t building line pressure.

I’m a little bummed I have more work to do but doing it is the best way to learn right? I’m hoping I can describe my symptoms and say what I’m thinking based on my very limited understanding of the 727, and get confirmation or correction & guidance from all you 727 experts.

-atf level good

-shifter synchronized/indexed properly

-cable style theottle pressure lever adjusted for WOT and fitted with a return spring

-tf2 kit installed

-2400 holeshot converter

-1 manual works great

-2 manual same

-D shifts quickly through 1-2 at low throttle, hangs on to 1 longer with more gas, never seems to shift into 3rd/direct

-R sometimes shifts and works good, sometimes acts like neutral, sometimes bang bang bang jerks you backward hard and shudders

I’m not sure if I ever had 3rd or not but it just never seems to go into cruising gear. I have a 512 motor and 3.21 sure grip so second gear will do 60mph pretty easy. Around my neighborhood and some bigger streets it does a really nice footbrake burnout (instant smoke) and breaks loose the tires at 30mph if I mash it a little. So I guess it must have some pressure and the rear clutches working?

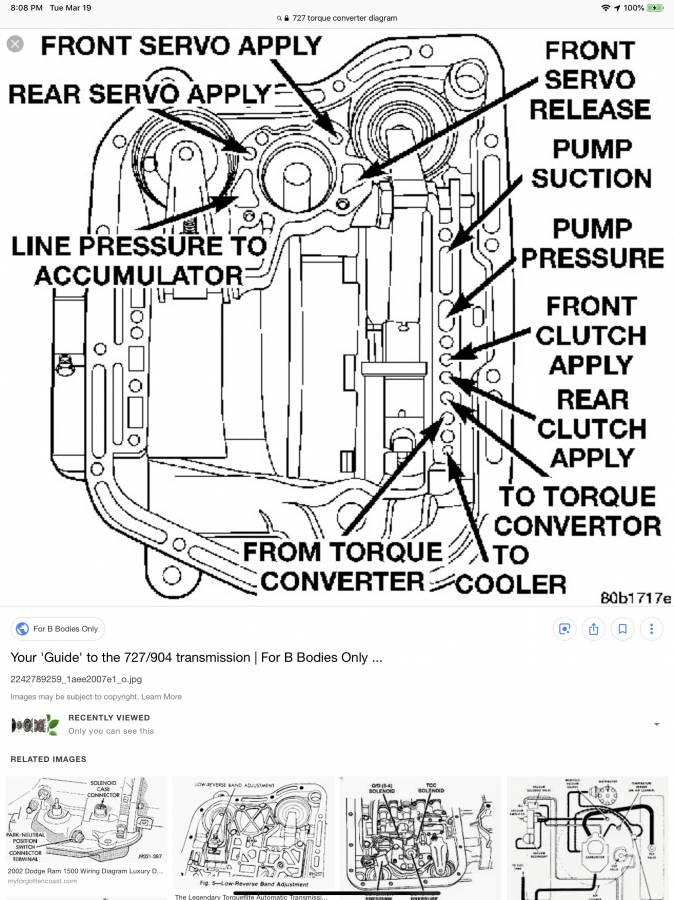

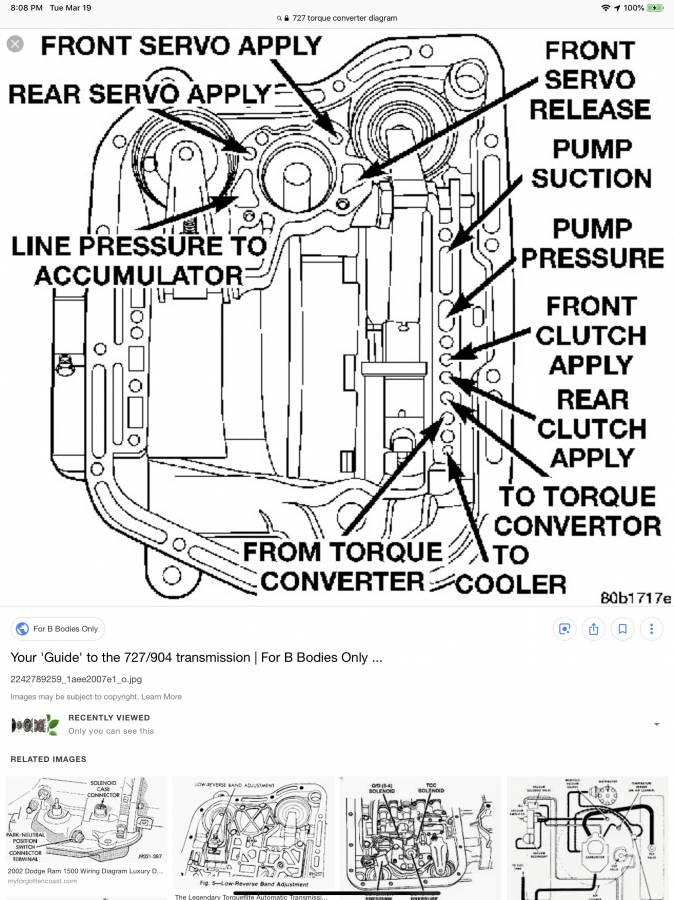

So since the front clutch seems to be the one thing that reverse and 3rd have in common, and reverse has a mich higher line pressure, I’m thinking the piston is not sealing? Or something is amiss there.

Should I go ahead and buy some pressure gauges? What is an affordable option and do I have ro cobble together a 727 tool or two with hoses long enough to see from safely not under the car? 100 & 300 psi guages right? Links or advice mich appreciated.

Should I assume that it is the front clutch that is causing this or is it possible that the problem is in my valve body- possibly a swapped or backward shaft or a check ball causing this? Band adjustment?

Should I go straight to an air check on the front clutch? What am I looking for and am I on the right track trying to fix it?

If I keep finding problems I’m really gonna be an expert soon haha

Thanks for y’alls time and patience

Radar

I’m getting a little more seat time in my hotrod and it’s becoming obvious that something isn’t right in my transmission. If you didn’t see my earlier thread I couldn’t get any gear at first because I had installed the pickup/ filter extension for the deep pan 180° out and wasn’t building line pressure.

I’m a little bummed I have more work to do but doing it is the best way to learn right? I’m hoping I can describe my symptoms and say what I’m thinking based on my very limited understanding of the 727, and get confirmation or correction & guidance from all you 727 experts.

-atf level good

-shifter synchronized/indexed properly

-cable style theottle pressure lever adjusted for WOT and fitted with a return spring

-tf2 kit installed

-2400 holeshot converter

-1 manual works great

-2 manual same

-D shifts quickly through 1-2 at low throttle, hangs on to 1 longer with more gas, never seems to shift into 3rd/direct

-R sometimes shifts and works good, sometimes acts like neutral, sometimes bang bang bang jerks you backward hard and shudders

I’m not sure if I ever had 3rd or not but it just never seems to go into cruising gear. I have a 512 motor and 3.21 sure grip so second gear will do 60mph pretty easy. Around my neighborhood and some bigger streets it does a really nice footbrake burnout (instant smoke) and breaks loose the tires at 30mph if I mash it a little. So I guess it must have some pressure and the rear clutches working?

So since the front clutch seems to be the one thing that reverse and 3rd have in common, and reverse has a mich higher line pressure, I’m thinking the piston is not sealing? Or something is amiss there.

Should I go ahead and buy some pressure gauges? What is an affordable option and do I have ro cobble together a 727 tool or two with hoses long enough to see from safely not under the car? 100 & 300 psi guages right? Links or advice mich appreciated.

Should I assume that it is the front clutch that is causing this or is it possible that the problem is in my valve body- possibly a swapped or backward shaft or a check ball causing this? Band adjustment?

Should I go straight to an air check on the front clutch? What am I looking for and am I on the right track trying to fix it?

If I keep finding problems I’m really gonna be an expert soon haha

Thanks for y’alls time and patience

Radar