Posted By: radar

Ate a couple lifters-edit: added a carnage video - 03/13/19 08:38 PM

Howdy moparts

I finally started breaking in my fresh 400/512 that’s been built for a while. Everything went good for a few minutes until I heard a rattle and shut it down. Turns out the last two bolts on my rocker shaft were coming loose. What was shocking was that #7 exhaust pushrod was too short to touch the rocker once I tightened the shaft.

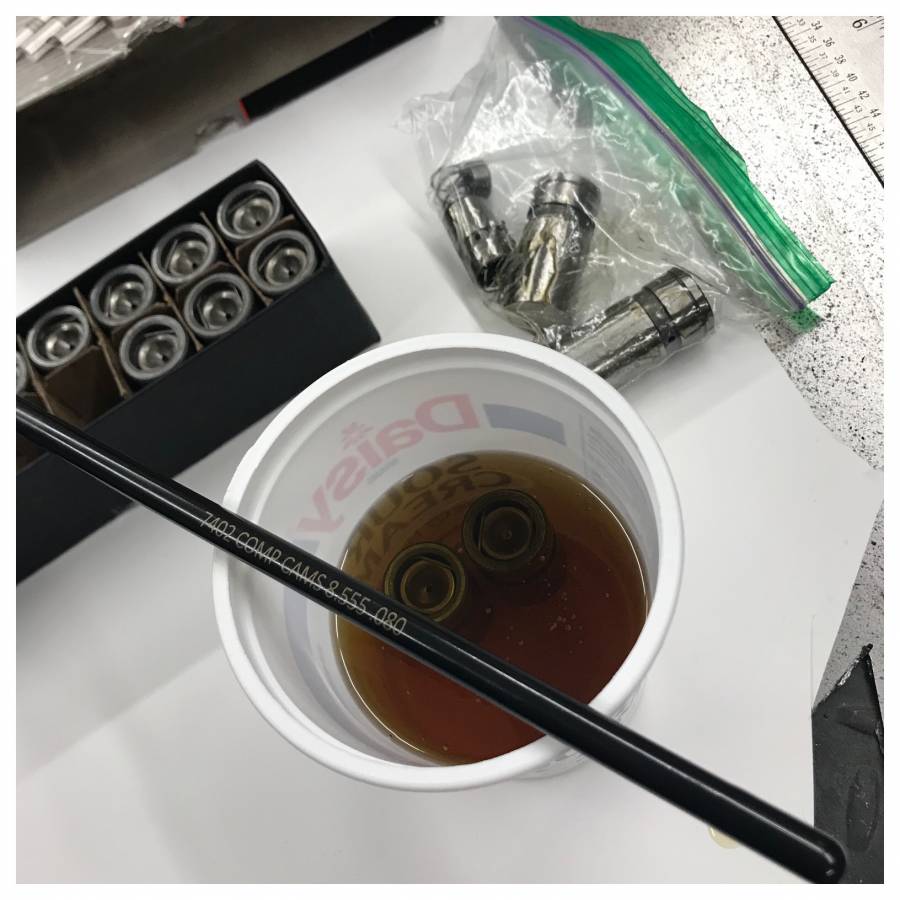

It’s my first big block and wow what a pleasure to work on. With no water in the intake I had the valley open inside 30 mins. #7 exhaust lifter puked its piston and the little pierced sheetmetal piece underneath was ripped in half. #7 intake had its piston stuck cocked in the lifter bore. Both lifters still looked brand new on the bottoms as does the cam so I just ordered replacements. I was only a couple minutes into fire up and break in before it let go and no pieces fell thru to the pan so I think I dodged the bullet on this one and it will just be a small setback.

Is that a normal thing to have happen when rockers let go? This is stock stamped rockers and a .507” hft cam, no crazy pressures or anything. I half expected to find a whole lifter ejected into the valley I don’t see why this would have broken like this?

Thanks!

Radar in Philly

I finally started breaking in my fresh 400/512 that’s been built for a while. Everything went good for a few minutes until I heard a rattle and shut it down. Turns out the last two bolts on my rocker shaft were coming loose. What was shocking was that #7 exhaust pushrod was too short to touch the rocker once I tightened the shaft.

It’s my first big block and wow what a pleasure to work on. With no water in the intake I had the valley open inside 30 mins. #7 exhaust lifter puked its piston and the little pierced sheetmetal piece underneath was ripped in half. #7 intake had its piston stuck cocked in the lifter bore. Both lifters still looked brand new on the bottoms as does the cam so I just ordered replacements. I was only a couple minutes into fire up and break in before it let go and no pieces fell thru to the pan so I think I dodged the bullet on this one and it will just be a small setback.

Is that a normal thing to have happen when rockers let go? This is stock stamped rockers and a .507” hft cam, no crazy pressures or anything. I half expected to find a whole lifter ejected into the valley I don’t see why this would have broken like this?

Thanks!

Radar in Philly