Moparts

Ritter Block

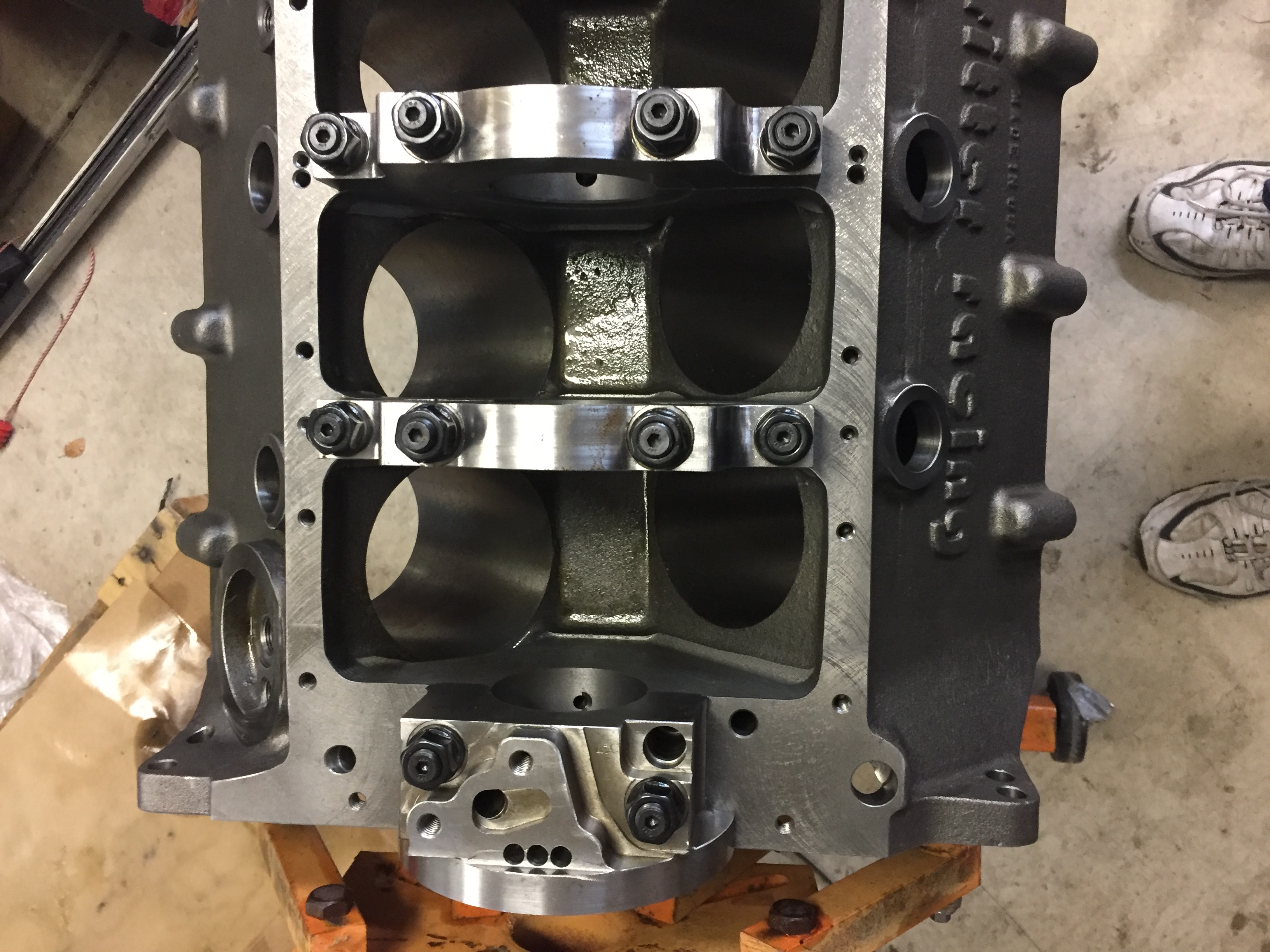

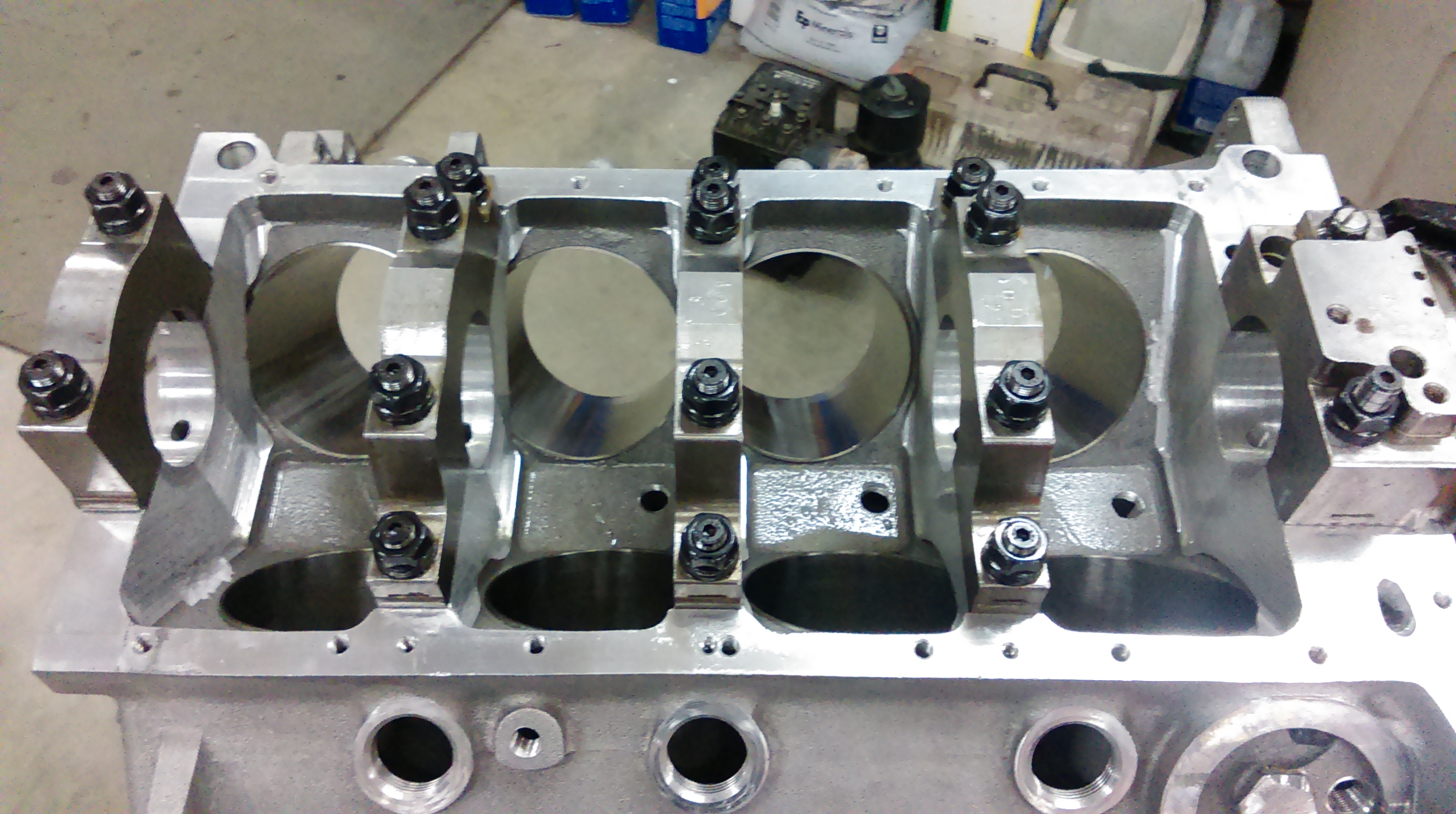

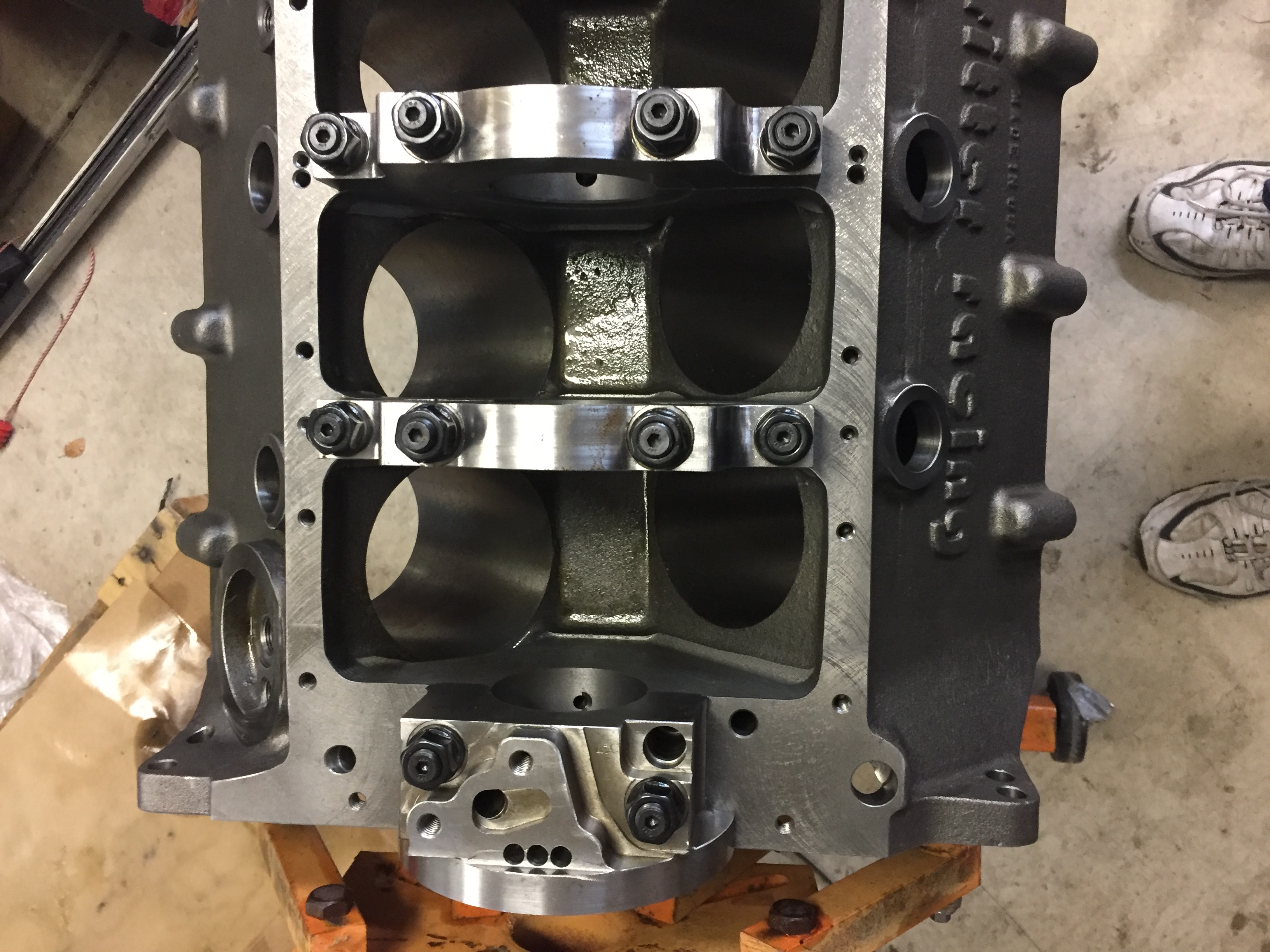

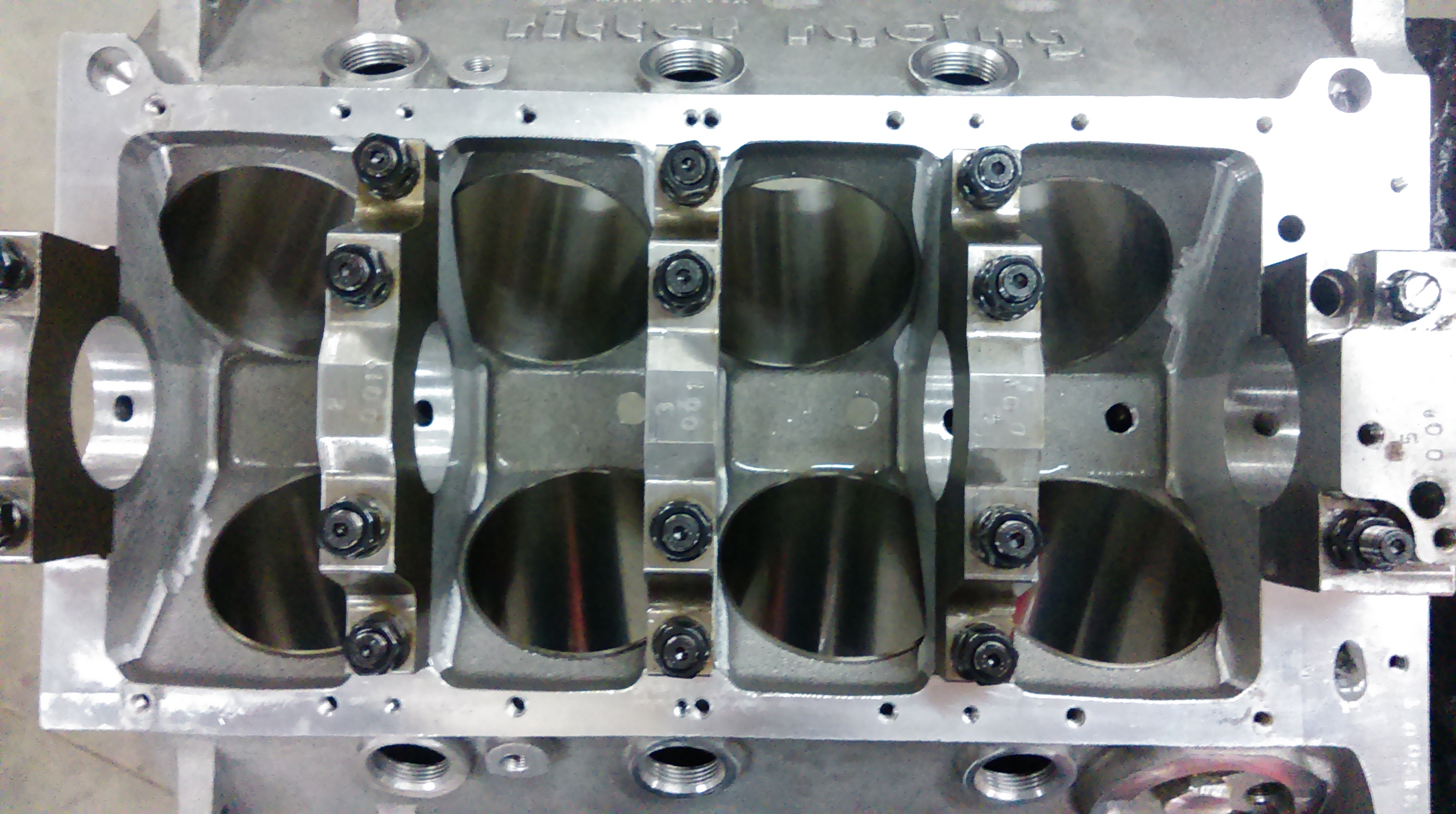

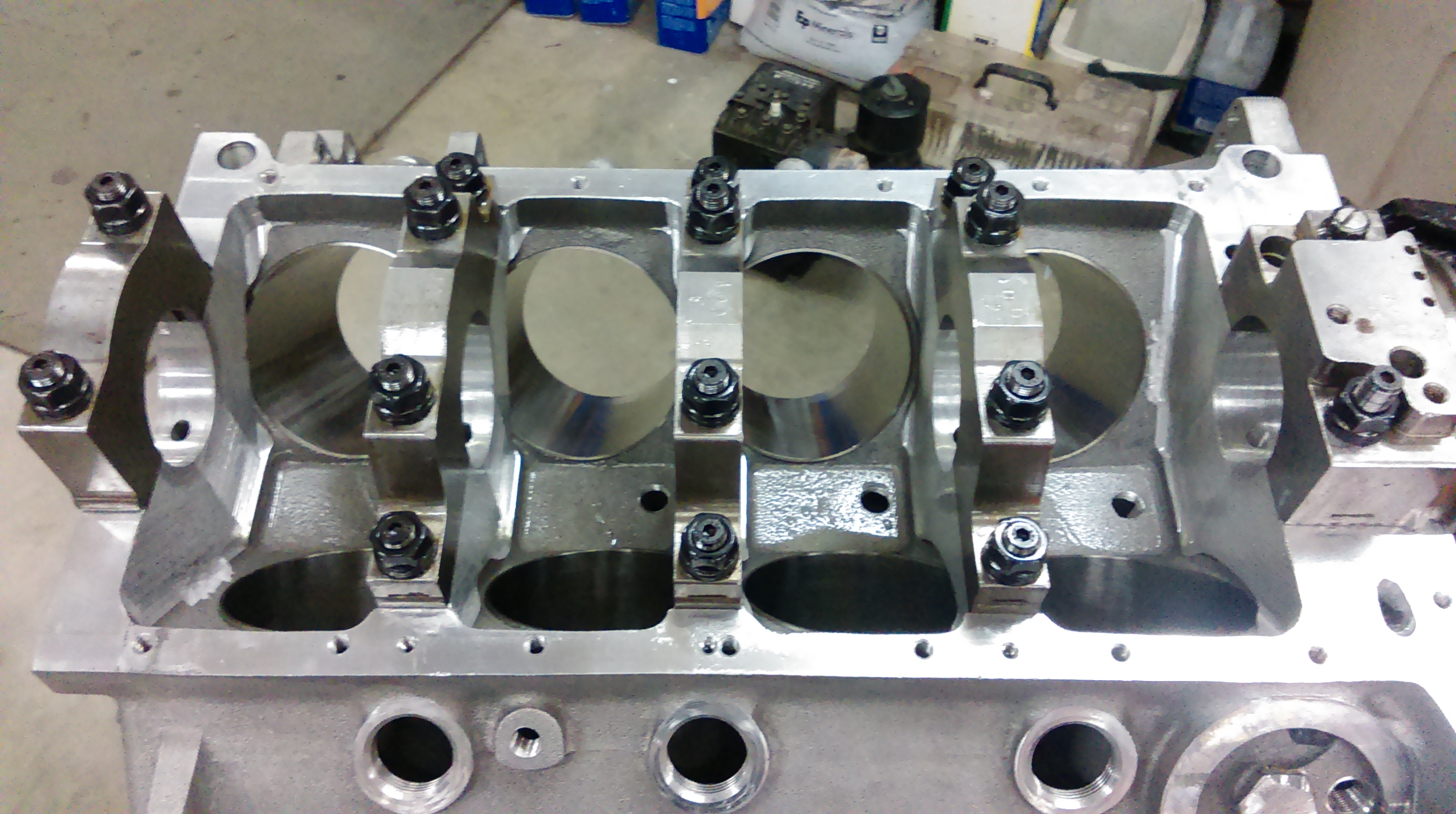

I received two new Ritter Blocks today. From what I can tell these blocks look really good. The casting is real good, even inside the water jacket. All the machine work looks good. It will need the be finish bored and honed, deck surface, and line honed.

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 07:46 AM

More pics

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 07:47 AM

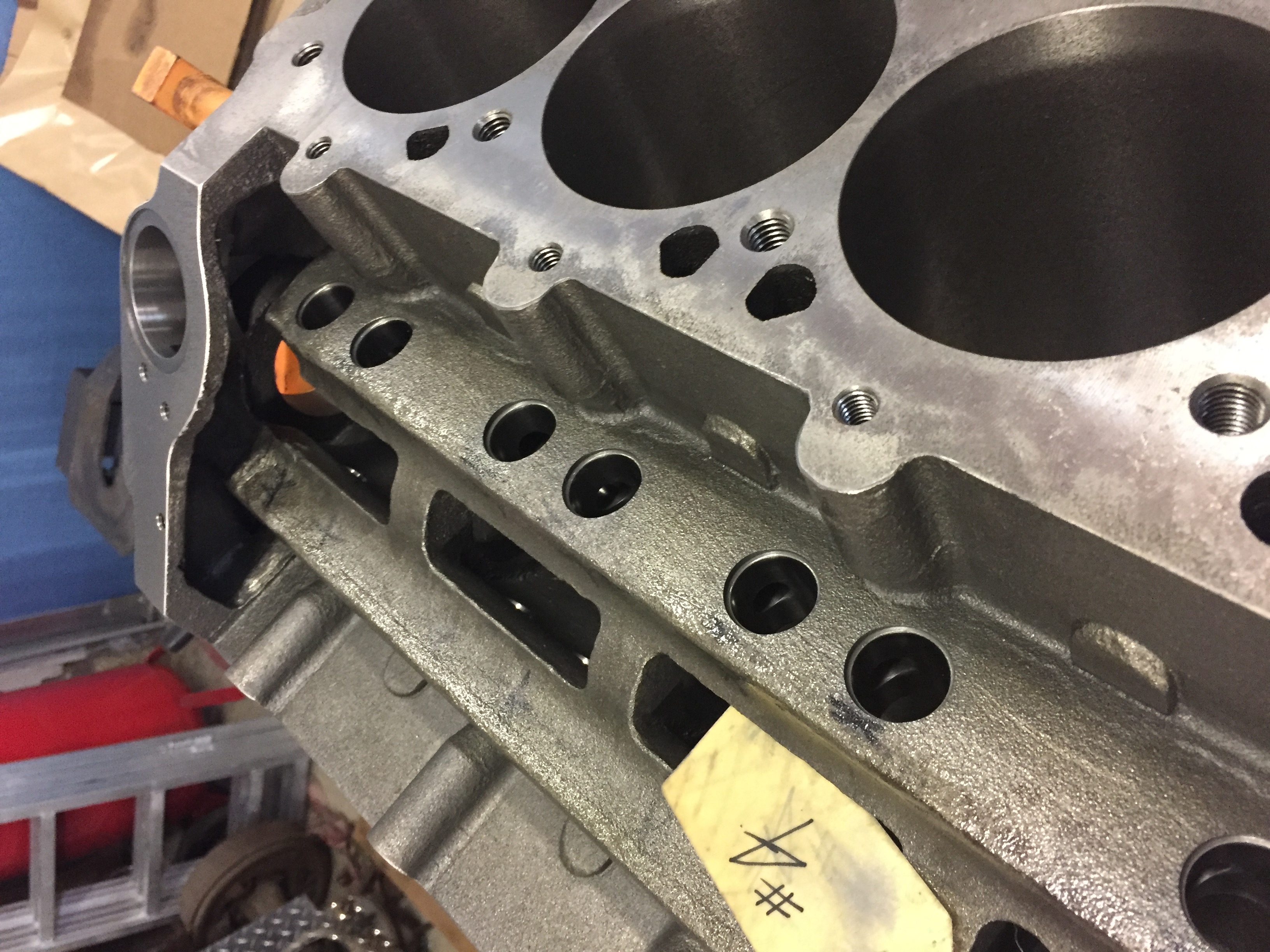

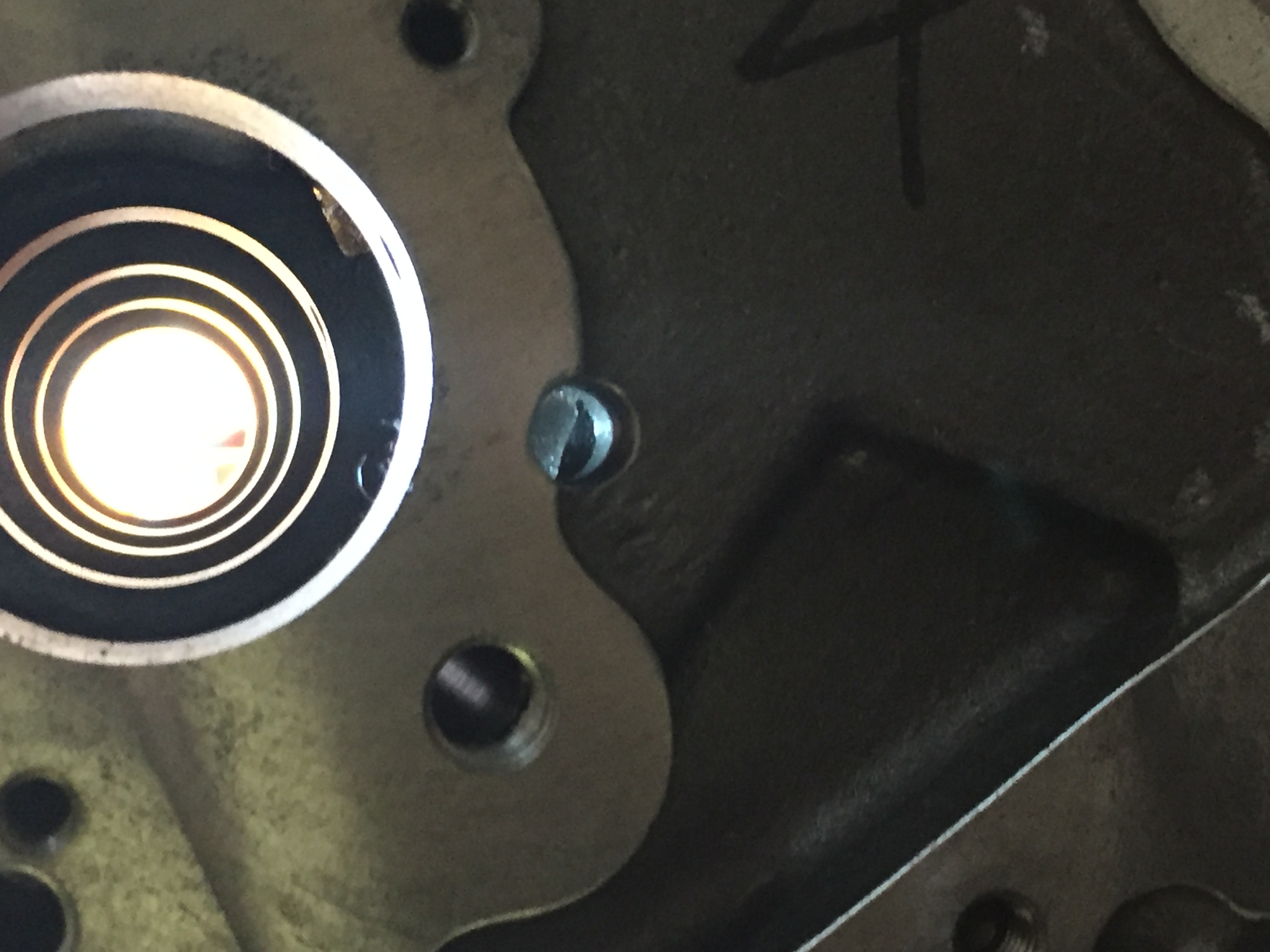

Lifter Valley

Posted By: RAY1969CARS

Re: Ritter Block - 02/16/18 07:55 AM

How much was it

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 08:00 AM

Right around $3000.00

Posted By: RAY1969CARS

Re: Ritter Block - 02/16/18 08:01 AM

How much do you anticipate the machine work to cost ???

Posted By: justinp61

Re: Ritter Block - 02/16/18 12:59 PM

Where does the oil return from the cam/lifter area?

Posted By: ric3xrt

Re: Ritter Block - 02/16/18 01:21 PM

That looks real nice, what kind of power do you think it could handle?

Posted By: racerx

Re: Ritter Block - 02/16/18 03:19 PM

Those look nice

3000. bucks make it look even better.

Posted By: 340Cuda

Re: Ritter Block - 02/16/18 04:26 PM

That's good news!

I have wanted him to succeed with this project.

Please keep us posted on these builds.

Bill

Posted By: 340Cuda

Re: Ritter Block - 02/16/18 04:29 PM

That's good news!

I have wanted him to succeed with this project.

Please keep us posted on these builds.

Bill

Posted By: WHITEDART

Re: Ritter Block - 02/16/18 05:38 PM

Definitely appear to be nice castings.. I can see several things that have changed for the good just in the photos that you've shown... what are your plans for these motors what cylinder heads.. and will you be Machining these yourself.. also I wish you the best of luck and if I can help you in any way give me a shout

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 05:58 PM

Whitedart,

Thanks for the offer on help, I’m going to need it.

Anyway these are both going to be stroker W9 deals

1.) 468cid, Brett Miller W9’s, 4.250” Stroke x 4.185” Bore

2.) 451cid, Brett Miller W9’s, 4.100” Stroke x 4.185” Bore

I’m going to have a Shop do the machine work (Bore, hone, Line hone, deck) and I have no idea what it will cost.

Power-I believe by looking these over that they can handle whatever you want to throw at them. ProCharger, Turbo, Supercharger, Nitrous you name it.

The two I’m building are N/A 48* carburated.

Posted By: RMCHRGR

Re: Ritter Block - 02/16/18 06:01 PM

What is the lifter angle and deck height on these?

Woops, you beat me to it, 48*.

Posted By: onig

Re: Ritter Block - 02/16/18 06:11 PM

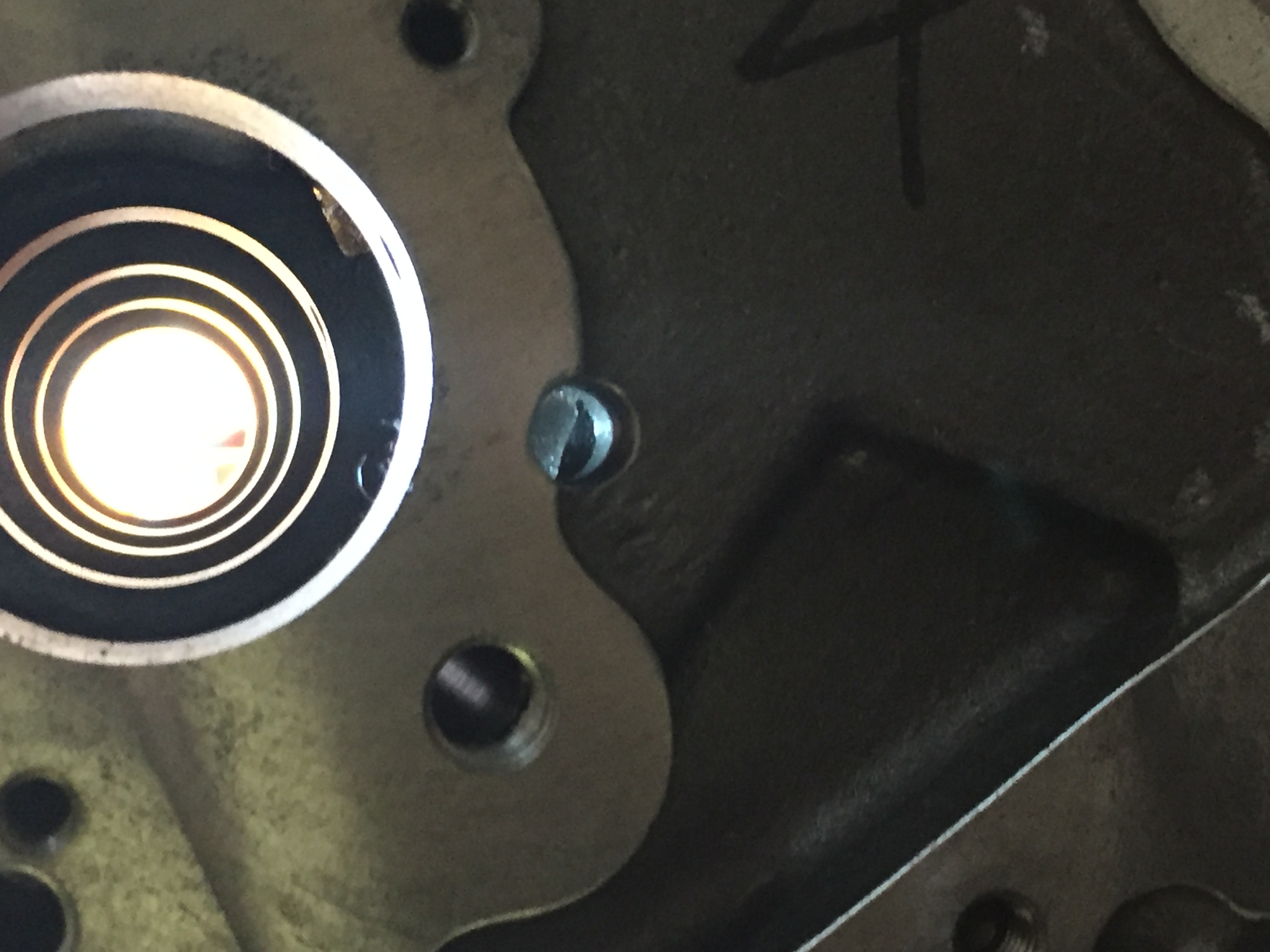

What are the three holes beside the oil pump mounting on the rear main cap?

Posted By: BradH

Re: Ritter Block - 02/16/18 06:15 PM

I haven't seen the phrase "pressure test" used, yet. Given the Ritter block's history, wouldn't that be a must-do operation before doing any machine work to one?

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 06:35 PM

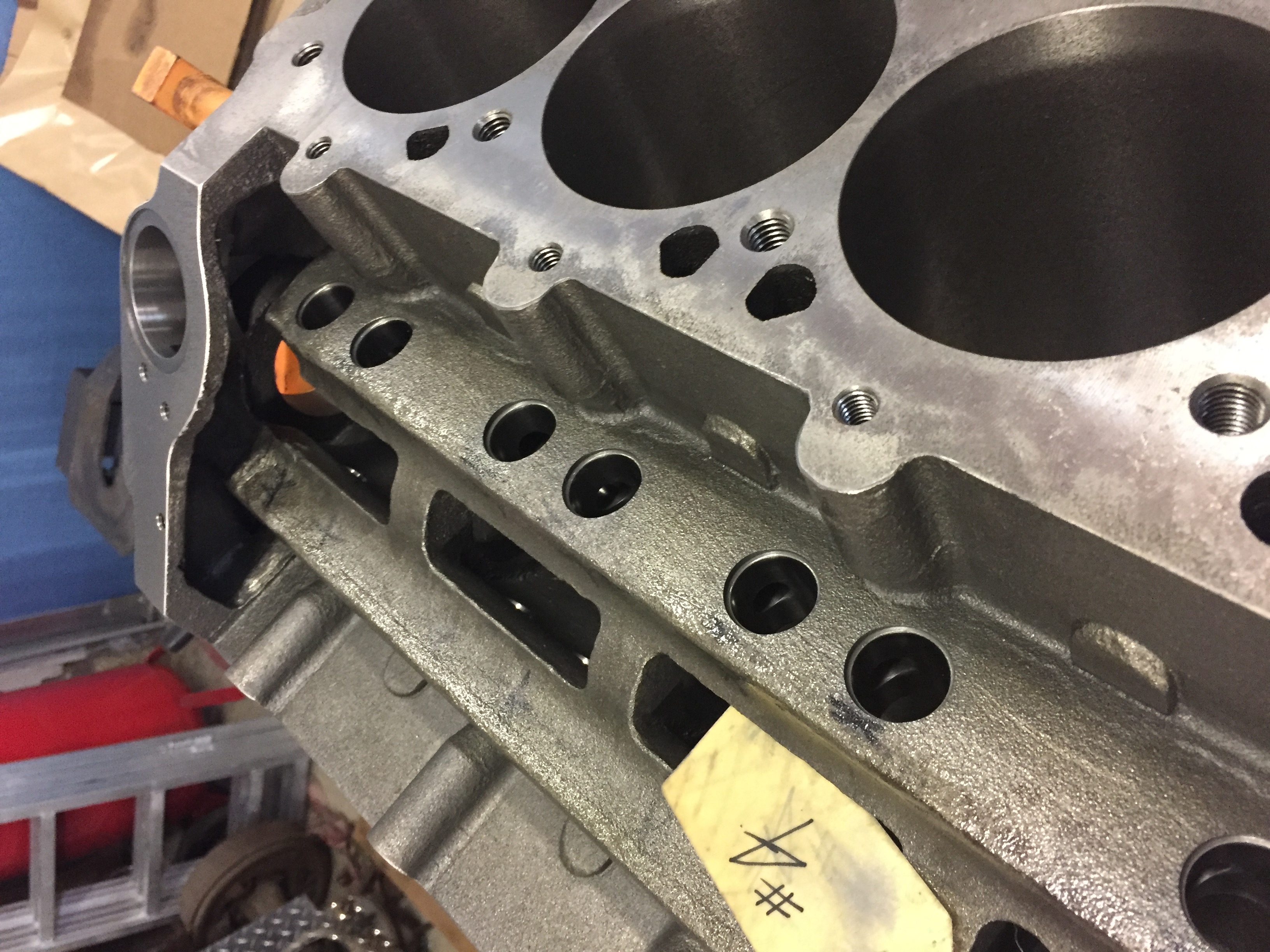

Where does the oil return from the cam/lifter area?

It returns the front bay through a drilled hole that goes to the timing chain area and the other bays by a hole in the rear that returns to the oil pan area. What I mean by bays is the cam bearing saddles kind of create a bay in between each cam bearing saddle.

#2 through #5 have a channel that directs flow to the rear.

I'll try and take a picture this weekend.

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 06:37 PM

I haven't seen the phrase "pressure test" used, yet. Given the Ritter block's history, wouldn't that be a must-do operation before doing any machine work to one?

That is the very first step.

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 06:37 PM

What is the lifter angle and deck height on these?

Woops, you beat me to it, 48*.

9.600" Deck height

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 06:39 PM

I haven't seen the phrase "pressure test" used, yet. Given the Ritter block's history, wouldn't that be a must-do operation before doing any machine work to one?

Where did the older ones have problems? What should I be looking for, any idea?

Man those look GREAT and thanks for sharing. Looks like things may slowly be turning around for the Mopar guys wishing to step up their race programs.

Posted By: madscientist

Re: Ritter Block - 02/16/18 06:44 PM

What are the three holes beside the oil pump mounting on the rear main cap?

On a factory cap there is a slot there. It's to get oil out of the back side of the main IIRC. With out going out and looking at a cap I'm going off memory.

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 06:46 PM

What are the three holes beside the oil pump mounting on the rear main cap?

On a factory cap there is a slot there. It's to get oil out of the back side of the main IIRC. With out going out and looking at a cap I'm going off memory.

Posted By: BradH

Re: Ritter Block - 02/16/18 06:57 PM

I haven't seen the phrase "pressure test" used, yet. Given the Ritter block's history, wouldn't that be a must-do operation before doing any machine work to one?

Where did the older ones have problems? What should I be looking for, any idea?

Good question... all I know is the words "Ritter" and "porosity" seemed to go hand in hand on other posts about those blocks.

Posted By: Bad340fish

Re: Ritter Block - 02/16/18 07:51 PM

I believe WhiteDart would be a wealth of information in that area.

Posted By: WHITEDART

Re: Ritter Block - 02/16/18 08:57 PM

Verify.. every bolt hole is in the correct location and proper angle.. verify both the coolant side and oil side of every Passage.. if you're doing a Max effort deal verify the correct angle on every lifter.. hours were all over the place.. actually had to increase the lifter diameter to correct the issue.. oil drain backs definitely going to need to be improved.. if you were doing a wet sump

. But like I stated earlier from what I can see they definitely look better

Posted By: WHITEDART

Re: Ritter Block - 02/16/18 08:59 PM

On another note I'm not saying it's mandatory.. but I think bushing the lifters is a smart move with the way that he has drilled the oil Galley through the center of the lifter bore.. it's very easy to get in a situation where the lifter uncovers the oil Passage

Definitely keep us informed how these progress.

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 09:48 PM

Verify.. every bolt hole is in the correct location and proper angle.. verify both the coolant side and oil side of every Passage.. if you're doing a Max effort deal verify the correct angle on every lifter.. hours were all over the place.. actually had to increase the lifter diameter to correct the issue.. oil drain backs definitely going to need to be improved.. if you were doing a wet sump

. But like I stated earlier from what I can see they definitely look better

I'll do all these things along with bushing the lifter deal, killing two birds with one stone. Kent Ritter suggested the bushing the lifter bores for a max deal. The machining done on the blocks I have has extremely nice lifter bores right now, not sure about angles but they all look real good.

Posted By: justinp61

Re: Ritter Block - 02/16/18 10:13 PM

Where does the oil return from the cam/lifter area?

It returns the front bay through a drilled hole that goes to the timing chain area and the other bays by a hole in the rear that returns to the oil pan area. What I mean by bays is the cam bearing saddles kind of create a bay in between each cam bearing saddle.

#2 through #5 have a channel that directs flow to the rear.

I'll try and take a picture this weekend.

Thanks.

Posted By: WHITEDART

Re: Ritter Block - 02/16/18 10:45 PM

With the Limited oil return on the Block if you're doing a wet sump I would also recommend external drain Backs from the head to the oil pan this enables air to come up so oil can go down in other locations

Posted By: Biginchmopar

Re: Ritter Block - 02/16/18 11:13 PM

With the Limited oil return on the Block if you're doing a wet sump I would also recommend external drain Backs from the head to the oil pan this enables air to come up so oil can go down in other locations

Let me ask this, wet sump, what about drilling holes from the cam tunnel valley to the crankshaft, I know, I know, windage, it's an issue but is it really on a deal were you're not looking for every last HP?

I believe on a wet sump I would do a lot more work on oil return. I'll do that on one of the engines I'm going to build because it will be wet sump. I will look into all options but putting hole into the cam tunel to the crankshaft area would help. It might also help to return oil from the valley even though it is open in the back.

I will keep you guys posted.

Posted By: DavidDean

Re: Ritter Block - 02/17/18 12:16 AM

Thanks for the post ! I injured my R-3 block a couple of weeks ago. This looks like a good option.

Posted By: TRENDZ

Re: Ritter Block - 02/17/18 03:35 AM

So, what’s the deal with the r3 blocks? Jegs lists a 9.025 deck 48 degree dry sump block for $2900. Says it will ship on the 23rd of this month. Is this not really available? Or is it just an undesirable configuration?

As for the ritter blocks... what ever became of the xr block that accepted the p7 heads/ cam?

A tall deck aliminum version of that would be absolutely fantastic to get your hands on.

Posted By: Jason B

Re: Ritter Block - 02/17/18 06:37 AM

We did exactly that... we opened up the cam tunnel to increase drain back. We are going to run a similar setup as White Dart using a Daily wet sump.

White Dart is a great source of help and information. I will be starting a thread as soon as ours starts going back together! Hopefully will be posting pictures in a few weeks good luck and if you need any help let us know.

Posted By: J_BODY

Re: Ritter Block - 02/17/18 04:17 PM

So, what’s the deal with the r3 blocks? Jegs lists a 9.025 deck 48 degree dry sump block for $2900. Says it will ship on the 23rd of this month. Is this not really available? Or is it just an undesirable configuration?

It it's the P4876381AB block they show nothing at any warehouse or in dealer inventory.... JEGS has been famous for this. It's been awhile since I've searched part numbers but the last time I found a couple odd ball 59 degree and one or two 48 degree blocks in dealer inventory. Brett texted me part numbers to check here and there and I actually located a block in dealer inventory fairly close to his place. funny how that works out

...and fwiw that block listed also makes you go in search of the hard to find "Arrow" timing cover (was $400+ new), or belt drive.

Posted By: J_BODY

Re: Ritter Block - 02/17/18 04:21 PM

P4876381AB is also listed on Jegs website, but again, none in any warehouse or dealer inventory.

Posted By: 340Cuda

Re: Ritter Block - 02/17/18 05:27 PM

I have ordered Mopar Performance parts from Jeg's and others only to fairly quickly get an email back, "Sorry we don't have any of these, they have been discontinued and cannot get them".

Also the big demand seems to be for tall deck (9.56) 59 degree blocks, not many out there.

Posted By: Biginchmopar

Re: Ritter Block - 02/18/18 02:04 AM

Where does the oil return from the cam/lifter area?

First pic is the rear of the block

Second pic is the chanel under each cam journal

Third pic is the front of the block (timing chain area)

Posted By: Biginchmopar

Re: Ritter Block - 02/18/18 02:08 AM

I have check ever head bolt hole, the lifter bores and angle, all the cam bores and main bores, so far everything checks out.

I’ll pressure check it at the machine shop before we deck, bore and hone and line hone.

Posted By: Biginchmopar

Re: Ritter Block - 02/18/18 02:13 AM

Posted By: Bad340fish

Re: Ritter Block - 02/18/18 03:10 PM

Thank you for sharing

Posted By: Just-a-dart

Re: Ritter Block - 02/18/18 05:16 PM

Did you bolt a timing cover to it?

Set a head gasket and check if it would seal and if the water passages line up?

I would also screw studs in it and see if the heads can go on

I have witnessed Shilohs (whitedart) problems and hope yours is trouble free.

Posted By: onig

Re: Ritter Block - 02/18/18 05:21 PM

Curious, how did you check the lifter angles?

Posted By: Biginchmopar

Re: Ritter Block - 02/18/18 07:52 PM

Curious, how did you check the lifter angles?

I used some lifters and did some measurements. I’ll reconfirm these once I get them to the shop with the fixture that we use to do lifter bushings.

Posted By: Biginchmopar

Re: Ritter Block - 02/18/18 07:55 PM

Did you bolt a timing cover to it?

Set a head gasket and check if it would seal and if the water passages line up?

I would also screw studs in it and see if the heads can go on

I have witnessed Shilohs (whitedart) problems and hope yours is trouble free.

Not yet, but I will soon (timing cover)

Studs and heads yes, gasket no

Posted By: CMcAllister

Re: Ritter Block - 02/18/18 09:46 PM

On another note I'm not saying it's mandatory.. but I think bushing the lifters is a smart move with the way that he has drilled the oil Galley through the center of the lifter bore.. it's very easy to get in a situation where the lifter uncovers the oil Passage

I'm not familiar with these and this may be a dumb question, but if the lifter bores interrupt the galley 100% and you bush them and block the galley, how is the crank oiled? Right side conventional and left side drilled through the center?

Posted By: Biginchmopar

Re: Ritter Block - 02/19/18 03:42 AM

On another note I'm not saying it's mandatory.. but I think bushing the lifters is a smart move with the way that he has drilled the oil Galley through the center of the lifter bore.. it's very easy to get in a situation where the lifter uncovers the oil Passage

I'm not familiar with these and this may be a dumb question, but if the lifter bores interrupt the galley 100% and you bush them and block the galley, how is the crank oiled? Right side conventional and left side drilled through the center?

These blocks have priority oiling to the mains. The lifter bushings I’m going to use will have groves on the outside to pass excess oil by.

Posted By: 69 lawndart

Re: Ritter Block - 02/20/18 12:00 AM

That's what I did with mine.

Posted By: RylisPro

Re: Ritter Block - 02/20/18 01:18 AM

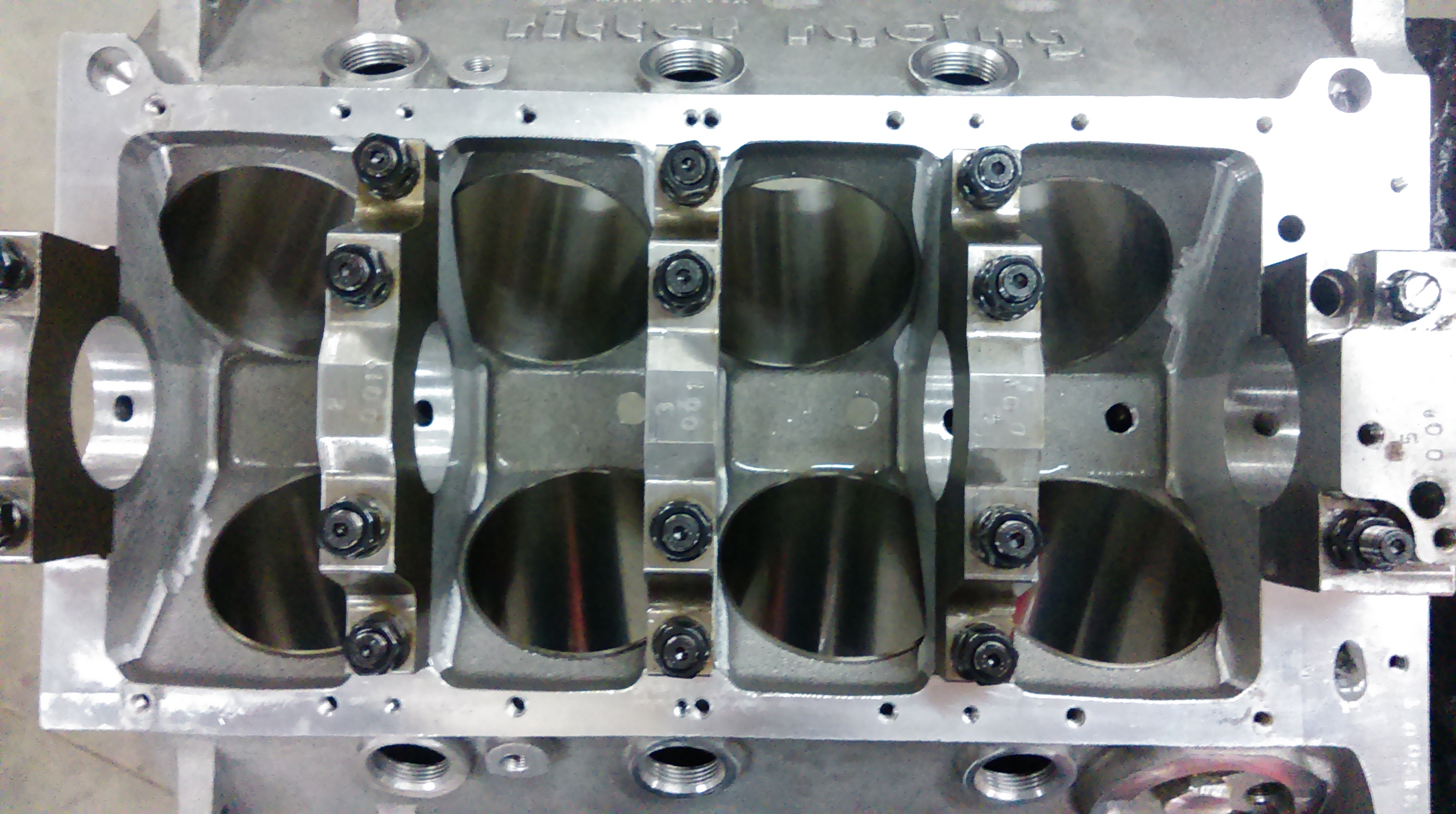

I know that the OP's block is cast iron due to the unthreaded freeze plug ports and lack of sleeves. Is your block above aluminum?

If so that is so cool! I had always wanted an all aluminum small block Mopar!

Posted By: 69 lawndart

Re: Ritter Block - 02/20/18 04:56 AM

Yes sir it is.

Posted By: SCATPACK 1

Re: Ritter Block - 02/20/18 07:07 AM

With the Limited oil return on the Block if you're doing a wet sump I would also recommend external drain Backs from the head to the oil pan this enables air to come up so oil can go down in other locations

Let me ask this, wet sump, what about drilling holes from the cam tunnel valley to the crankshaft, I know, I know, windage, it's an issue but is it really on a deal were you're not looking for every last HP?

I believe on a wet sump I would do a lot more work on oil return. I'll do that on one of the engines I'm going to build because it will be wet sump. I will look into all options but putting hole into the cam tunel to the crankshaft area would help. It might also help to return oil from the valley even though it is open in the back.

I will keep you guys posted.

What about drilling a 1/4 inch hole next to each main saddle. That way any oil that drains back would be down the side of the main saddle and not splashing around too much. Would require holes drilled next to #2, #3, and #4 mains.

HAH.

Never mind, i see you already handled the oil drain issue. Treed again.

Posted By: LA360

Re: Ritter Block - 02/20/18 09:30 AM

They certainly look better, the rear cap is markedly improved.

I have a couple of XR2 blocks for P7 heads, they're earlier blocks. Once I've recovered from a recent surgery, I'll be measuring them. I have a feeling the lifter bores are out of position, based on my initial inspections.

Posted By: Cab_Burge

Re: Ritter Block - 02/20/18 08:12 PM

I know that the OP's block is cast iron due to the unthreaded freeze plug ports and lack of sleeves. Is your block above aluminum?

If so that is so cool! I had always wanted an all aluminum small block Mopar!

Be careful of what you wish for

N/A iron blocks, even super charged, will run faster than the same parts in a aluminum block in the 1/4 mile in the same car weighing the same

But the car won’t weight the same. Lol.

Posted By: Cab_Burge

Re: Ritter Block - 02/20/18 08:18 PM

Certain heads up classes out here have minimum weights

Posted By: J_BODY

Re: Ritter Block - 02/20/18 08:26 PM

Certain heads up classes out here have minimum weights

....so you'd prefer not to put the weight where YOU want it?

Posted By: CMcAllister

Re: Ritter Block - 02/20/18 08:51 PM

I know that the OP's block is cast iron due to the unthreaded freeze plug ports and lack of sleeves. Is your block above aluminum?

If so that is so cool! I had always wanted an all aluminum small block Mopar!

Be careful of what you wish for

N/A iron blocks, even super charged, will run faster than the same parts in a aluminum block in the 1/4 mile in the same car weighing the same

Which means they make more power. Ive been told by engine guys that you need to "get after" an aluminum block combination more so than an iron block. And then there's the extra expense. Some of us have a finite budget and want to spread it around past one engine or one car.

Posted By: Cab_Burge

Re: Ritter Block - 02/21/18 03:52 AM

Certain heads up classes out here have minimum weights

....so you'd prefer not to put the weight where YOU want it?

The car I'm talking about had ballast on the front bumper with the aluminum block, they moved it from there and move it further back to keep the front to rear ratio % the same for traction, they had to add over 400 lbs. to the car make the minimum weights

I wish I could afford to build a car like that, but I'm not

Posted By: Biginchmopar

Re: Ritter Block - 02/21/18 08:14 PM

The reason I didn't go with Aluminum is bore size, I believe the Aluminum Ritter Block is limited to 4.120 bore.

Look at the main caps between mine and the aluminum block , the front is the same but the rest are different. Maybe a change for the better? Rear cap is way better now.

Posted By: DavidDean

Re: Ritter Block - 02/21/18 08:40 PM

Is the Ritter block Siamese ?

Is the max bore size 4.250 ?

Posted By: Biginchmopar

Re: Ritter Block - 02/21/18 08:42 PM

It is Siamese and I think they say 4.220"

Posted By: Al_Alguire

Re: Ritter Block - 02/21/18 08:51 PM

Well you cant argue wanting the biggest bore possible as bore is HP. But weight is also a factor, any idea what the weight difference between the two are? Just curious

Posted By: WHITEDART

Re: Ritter Block - 02/21/18 09:15 PM

About 100lb

Posted By: Al_Alguire

Re: Ritter Block - 02/21/18 09:33 PM

So in my mind you would need to be able to making enough power to overcome the weight difference to justify the extra weight. Why I have chosen aluminum BB's over the iron brethren. The big difference is the weight difference is larger but the bore potential is the same. BUt that is the logic behind why the Vette has an aluminum SB in it, but we are not limited to a smaller bore because of that choice.

Posted By: Biginchmopar

Re: Ritter Block - 02/21/18 11:22 PM

All out race car deal I would go Aluminum.

This thing is getting there quick, at least the engine part.

Posted By: LA360

Re: Ritter Block - 02/22/18 02:43 AM

The Ritter block in it's aluminium form is the same casting as the iron version. It's not a specific pattern, I'm not even sure if they've allowed for the different shrinkage rates of the two materials.

I'd want to see some more material in the casting, ribs etc. That's just a personal preference of mine. I think for most of us, the weight saved in an aluminium block is more of a benefit. Those chasing every last piece of HP, in a car they have to add ballast too, you'd go Iron.

A lot of guys go with aluminum for ease of repairing the block when all heck break loose. Lots of junk mega blocks still laying around

Posted By: DavidDean

Re: Ritter Block - 02/22/18 04:33 AM

It’s too bad the max bore size of the aluminum is 4.120. Does any one know the price ?

Posted By: 69 lawndart

Re: Ritter Block - 02/22/18 04:42 AM

Mine is 4.155", I would say 4.185" is about max bore, I think the prototype aluminum block is 4.185". There is a lot of material around the cylinders in this block. I was told that the castings were the same. The weight on mine is 107 lbs. with sleeves and main caps. I need to add for a NA motor.

Posted By: RylisPro

Re: Ritter Block - 02/22/18 05:07 AM

All good Cab!

You want an aluminum block for track days and road racing. I got an all aluminum Gen3 instead. 600hp at the crank is plenty scary enough when going around a corner!

Posted By: Biginchmopar

Re: Ritter Block - 02/27/18 07:40 PM

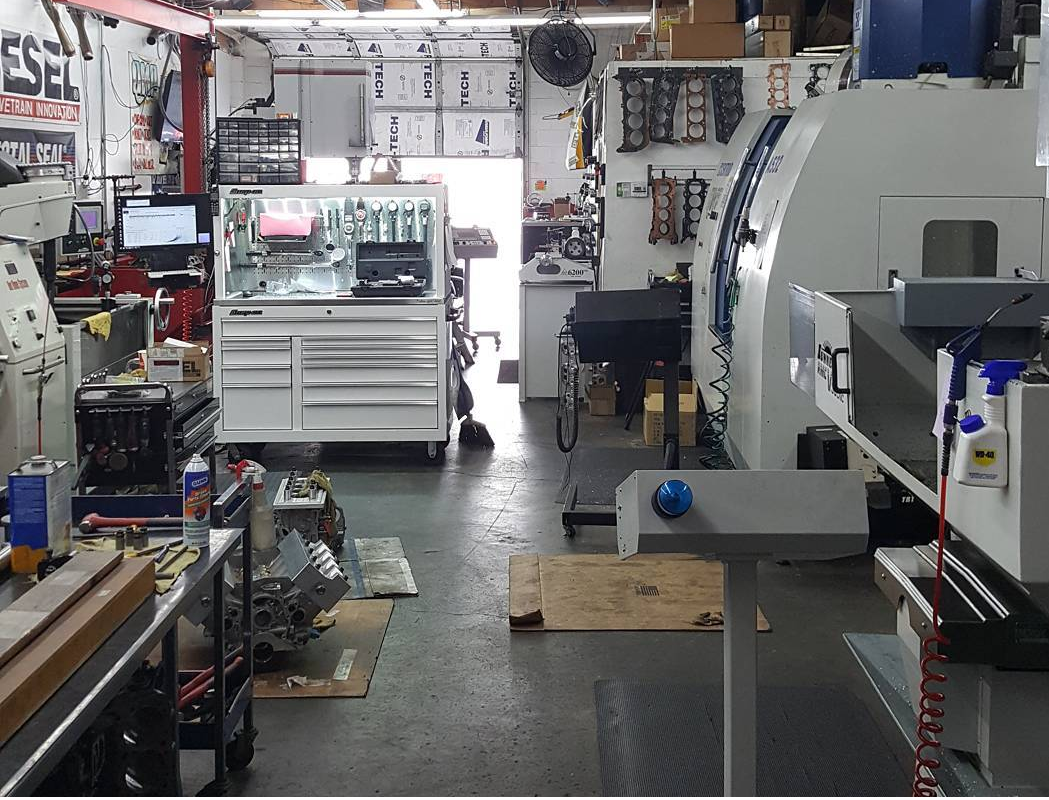

Just a quick update. After making a few calls and talking to the guys that are way deep into these small blocks, I have decided to take the block to Quarter Mile Performance (QMP) is Southern California. They have all the tools to do what I want plus they have already worked on a few of these blocks in the past so we will get their opinion as well.

These are all good things and I'll share what we find when it is finished being machined.

Posted By: Biginchmopar

Re: Ritter Block - 02/27/18 09:35 PM

We did exactly that... we opened up the cam tunnel to increase drain back. We are going to run a similar setup as White Dart using a Daily wet sump.

White Dart is a great source of help and information. I will be starting a thread as soon as ours starts going back together! Hopefully will be posting pictures in a few weeks good luck and if you need any help let us know.

Thanks Jason!

I'll be in touch for sure, lots of little details need to be addressed.

Posted By: Al_Alguire

Re: Ritter Block - 02/27/18 09:43 PM

Hard to go wrong with the QMP crew

Posted By: WHITEDART

Re: Ritter Block - 02/28/18 12:05 AM

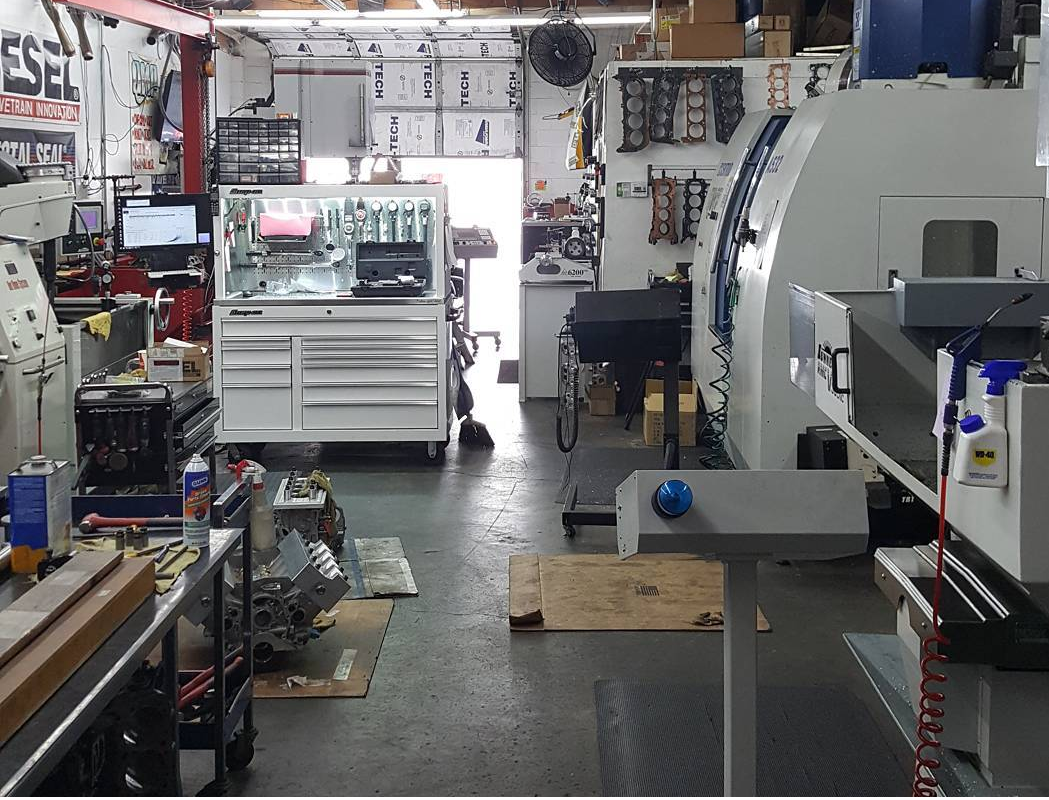

I'm going to say good choice.. it will require some patience because they are very busy but I assure you it will be worth the wait.. when you get their since you're a paying customer ask for a tour of the shop.. you will be surprised at the names on blocks and boxes of parts that you see.. everything from shops that say they do everything in house to maybe even some top 10 Pro Stock teams. I know you had some other options on block transportation.. but definitely worth a field trip

Posted By: WHITEDART

Re: Ritter Block - 02/28/18 02:10 AM

A sneak peek inside qmp North

Posted By: WHITEDART

Re: Ritter Block - 02/28/18 02:11 AM

And for those that know about honing

Posted By: LA360

Re: Ritter Block - 03/02/18 12:34 AM

And for those that know about honing

They made a substantial investment (around $100K) in their honing equipment. Definitely a higher end machine shop

Posted By: WHITEDART

Re: Ritter Block - 03/02/18 12:45 AM

And for those that know about honing

They made a substantial investment (around $100K) in their honing equipment. Definitely a higher end machine shop

I think you meant to say hone head and diamonds

.. and actually I think that was only for the old head and stones.

They have substantially better stuff than that now.. I think if you have a Target temperature that you can operate the Motor Inn he can hone the block at that temperature..

Posted By: Thumperdart

Re: Ritter Block - 03/02/18 12:56 AM

Hard to go wrong with the QMP crew

I would of given Pettis a call unless Jason doesn't have the experience w/those.........

Posted By: Leon441

Re: Ritter Block - 03/02/18 02:48 AM

So one guy say's he thinks the aluminum XR2 will only go 4.1" bore. And everyone repeats it.

There is no reason this block in aluminum can't go at least 4.185". After all the other aluminum blocks with this bore space go 4.185".

Posted By: Biginchmopar

Re: Ritter Block - 03/06/18 05:53 AM

I said I wasn't sure about bore size, I remember asking Kent and I don't remember what he said exactly but I know for a fact he didn't say it would go 4.185"

I'm not saying it won't go 4.185' but I took his word on it.

Posted By: LA360

Re: Ritter Block - 03/06/18 09:34 AM

And for those that know about honing

They made a substantial investment (around $100K) in their honing equipment. Definitely a higher end machine shop

I think you meant to say hone head and diamonds

.. and actually I think that was only for the old head and stones.

They have substantially better stuff than that now.. I think if you have a Target temperature that you can operate the Motor Inn he can hone the block at that temperature..

Yes,I should have been more specific, or used a word like accessories :-p Unlike regular stones and honing heads, One head does one bore size. It all adds up rather quickly!

Posted By: WHITEDART

Re: Ritter Block - 03/06/18 04:44 PM

So one guy say's he thinks the aluminum XR2 will only go 4.1" bore. And everyone repeats it.

There is no reason this block in aluminum can't go at least 4.185". After all the other aluminum blocks with this bore space go 4.185".

the question that comes to mind.. is he referring to the block that is sleeved or unsleeved.. I know in the beginning he was selling unsleeved blocks and recommended people use the spray in liner.. I would imagine with a good quality sleeve maybe like a interlocking Darton set up you could get 4.200.+ but I have never physically seen an aluminum block