Posted By: NTOLERANCE

Performer deep runner porting - 12/28/17 06:05 AM

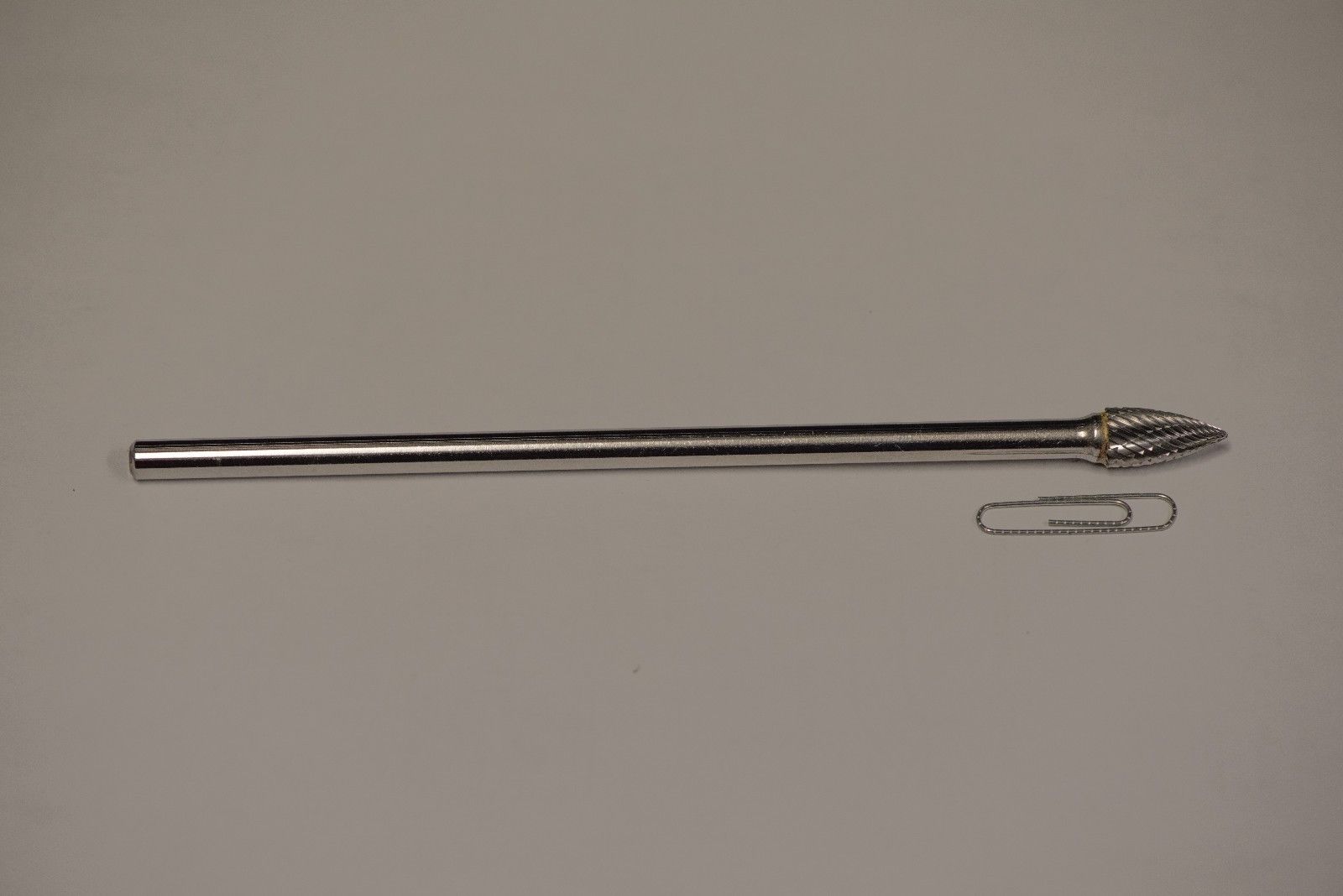

I need to deep port match the runners on a edelbrock performer 318/360 Intake to match the larger ports on my heads

How deep is deep and what tooling would you recommend ?

How deep is deep and what tooling would you recommend ?