Moparts

Improving cnc ported heads

Posted By: B3422W5

Improving cnc ported heads - 12/18/17 04:17 AM

Down the road i am thinking about buying a set of cnc smallblock heads.

The "as delivered" numbers seem decent, but not earthshattering.

Can a good head porter typically improve the numbers on a cnc ported head?

I know there are lots of variables.

Posted By: pittsburghracer

Re: Improving cnc ported heads - 12/18/17 04:24 AM

Down the road i am thinking about buying a set of cnc smallblock heads.

The "as delivered" numbers seem decent, but not earthshattering.

Can a good head porter typically improve the numbers on a cnc ported head?

I know there are lots of variables.

I have never had a set of cnc'd heads in my hands that I couldn't improve but you never know what tomorrow may bring

Posted By: Al_Alguire

Re: Improving cnc ported heads - 12/18/17 05:21 AM

Yes...

Posted By: Rob C

Re: Improving cnc ported heads - 12/18/17 05:38 AM

All CNC porting work shouldn’t be a max effort because of the possible and dreaded core shift.

Posted By: Cab_Burge

Re: Improving cnc ported heads - 12/18/17 05:41 AM

If you want the most power later buy the best head you can get at that time

Posted By: polyspheric

Re: Improving cnc ported heads - 12/18/17 06:13 AM

All true.

The CNC surface finish is typically very good but not nearly what an owner would do for himself.

Posted By: B3422W5

Re: Improving cnc ported heads - 12/18/17 06:22 AM

Looking at the new trick flow small block head. They come cnc" street ported", hence ny question.

Posted By: dogdays

Re: Improving cnc ported heads - 12/18/17 11:05 PM

I asked this question a while ago and someone answered thinking I meant smoothing out the ridges left by the cutter. duh! A wet intake port may even benefit from the roughness left by the cutter. That's not where I was going.

I am chagrined by the sheer number of folks, real car people, who keep alive the phrase "ported and polished". In my opinion, the only engine that should be fitted with "ported and polished" heads would run a "3/4 race" cam, or maybe a Purple Shaft!!!

Here's the issue, a good CNC program has to be a one-size-fits-all program. The issue is core shift, casting inaccuracies.

If the cnc program was based on a max ported head, then there would be several heads per batch that would have holes in the port walls.

IMHO: A really good CNC program should be able to get within 5-7% of a pro ported head, meaning 15-21 cfm on a 300cfm CNC head. What do you think of those numbers, pro porters?

R.

Posted By: pittsburghracer

Re: Improving cnc ported heads - 12/18/17 11:38 PM

I'm not a "pro Porter" by any means BUT when you hand port a head you can port the head in a way to work with a customers combo better. No sense reaching for the "high number" when he or she is going to run a 600 lift cam or smaller. You can do different things to the short turn so you get some very nice mid lift numbers earlier so his combo works perfectly. Port CC and valves angles come into play to if its not a fits all, out of the box, here you go cnc'd head.

Posted By: rowin4

Re: Improving cnc ported heads - 12/19/17 02:14 AM

I asked this question a while ago and someone answered thinking I meant smoothing out the ridges left by the cutter. duh! A wet intake port may even benefit from the roughness left by the cutter. That's not where I was going.

I am chagrined by the sheer number of folks, real car people, who keep alive the phrase "ported and polished". In my opinion, the only engine that should be fitted with "ported and polished" heads would run a "3/4 race" cam, or maybe a Purple Shaft!!!

Here's the issue, a good CNC program has to be a one-size-fits-all program. The issue is core shift, casting inaccuracies.

If the cnc program was based on a max ported head, then there would be several heads per batch that would have holes in the port walls.

IMHO: A really good CNC program should be able to get within 5-7% of a pro ported head, meaning 15-21 cfm on a 300cfm CNC head. What do you think of those numbers, pro porters?

R.

I was at a seminar years ago , Jack Roush was the speaker. He talked about porting heads and leaving the intake rough for a wet flow. Thinking back now , I think that was before CNC machines were invented.LOL

Posted By: Cab_Burge

Re: Improving cnc ported heads - 12/19/17 07:44 AM

I know a good shop in SO CA that had ordered a set of very expensive CNC ported Dart BB Chevy heads for a customer for his heads up PSCA car on a unlimited budget, the customer saw the heads and ask about smoothing out the CNC ridges in the intake ports to make them better. That shop had a new Super Flow 600 flow bench at that time so he flowed one port before and afte smoothing it out, no measurable improvements doing that on the flow bench

That may be one of those mods that needs to be done after dyno testing the motor and racing it at the track and then do the smoothing and retest it again with similar weather conditions

Posted By: jwb123

Re: Improving cnc ported heads - 12/19/17 05:53 PM

Just because a head is quote CNC ported, does not automatically make it a good head. Who wrote the program? Did they copy the work of a good head porter, or did they just digitize the head and tell the computer to make it 10% bigger? Maybe the best is to buy the heads and put the CNC money into a good head porter? Also heads are only so thick, once you get them thin, seats start to move around and they can warp or crack much easier. If a vlave seat can not hold air, the porting makes no differance. In my experiance you can make minor improvements in a CNC ported head, but basically it is what it is, no meat left to work with. And just because the ports are bigger it may not flow better or run better.

Posted By: polyspheric

Re: Improving cnc ported heads - 12/19/17 06:12 PM

heads are only so thick, once you get them thin, seats start to move around

This^^^

Vizard reported on intake valves that didn't seat properly because the seat itself moved laterally when hot. The cure: weaken the valve head so it bends to conform. !!!

Posted By: fast68plymouth

Re: Improving cnc ported heads - 12/19/17 06:49 PM

IMO, if the pre/post reworking of the CNC job isn't accompanied by a pre/post dyno session, you can't really quantify what you did.

Then, if it is better, by how much? And what did that gain cost?

Posted By: Porter67

Re: Improving cnc ported heads - 12/19/17 06:59 PM

Maybe vs trying to squeeze every last bit out of a head with the risk of going thin or jacking the casting, short life span, ect, unless restricted by class rules why not just start or jump to the next best/better head?

Vs all the costly tricks/time/money in a edelbrock or a knockoff of it making the jump to the new victors, even ootb but looked over dont seem so bad to me.

Posted By: B3422W5

Re: Improving cnc ported heads - 12/19/17 07:04 PM

Again, talking about the as delivered " street port" cnc the new trick flows will come with

Posted By: Porter67

Re: Improving cnc ported heads - 12/19/17 07:05 PM

You are correct, I should of read a bit more/further back... sorry.

Posted By: pittsburghracer

Re: Improving cnc ported heads - 12/19/17 07:18 PM

Again, talking about the as delivered " street port" cnc the new trick flows will come with

Sometimes it comes down to WHO ported the head that the cnc’d Port was copied from. Anyone can Port a head and some guys call a buff & shine porting.

Posted By: polyspheric

Re: Improving cnc ported heads - 12/19/17 10:32 PM

CNC is not a program that analyzes port efficiency, or determines ideal port characteristics, that's CFD (and few of us can afford it).

CNC is the xerox of porting. It can never be better than the manual porting done on the original modified head to be used as a model.

How to:

1. have a highly rated and successful porting service do a common casting*

2. do an A > B dyno test, then a track test (especially for mph, not ET)

3. digitize the head using multi-axis probes

4. the computer program creates instructions to direct cutting tools to follow the contours identified in 3.

* you may see someone attempt to use a CNC program developed from a specific casting on a different casting... because they interchange on the same engine.

DON'T.

Posted By: polyspheric

Re: Improving cnc ported heads - 12/19/17 10:38 PM

There may be differences in result quality between 2 different programs and 2 different CNC fixtures from the same (already ported) head.

How is that possible?

One takes smaller readings with the probe, at more angles, then uses more passes and smaller cutters at more axes (hours longer to complete).

In some castings (not all) the difference may be significant, especially with small ports and 3 dimensional curves.

Posted By: WHITEDART

Re: Improving cnc ported heads - 12/19/17 11:50 PM

if it makes you feel any better.. I am yet to see a c&c head flow as good as they're advertised.. most head companies these days r more into selling a flow number...

Posted By: polyspheric

Re: Improving cnc ported heads - 12/20/17 03:34 AM

Larry Widmer very strong on CFM numbers are less important than velocity at the right lift, producing best transitional horsepower (only shows up on an RPM per second dyno).

Posted By: moparx

Re: Improving cnc ported heads - 12/20/17 04:43 PM

There may be differences in result quality between 2 different programs and 2 different CNC fixtures from the same (already ported) head.

How is that possible?

One takes smaller readings with the probe, at more angles, then uses more passes and smaller cutters at more axes (hours longer to complete).

In some castings (not all) the difference may be significant, especially with small ports and 3 dimensional curves.

this

something i learned over my 42+ year machining career dealing with castings, both virgin and finished/repaired, although dealing with natural gas transmission meters instead of cylinder heads. also, different cutters most definitely affect flow, sometimes in mysterious ways, such as the helix difference in same sized end mills used in contour cutting.

Posted By: Ian

Re: Improving cnc ported heads - 12/23/17 01:10 AM

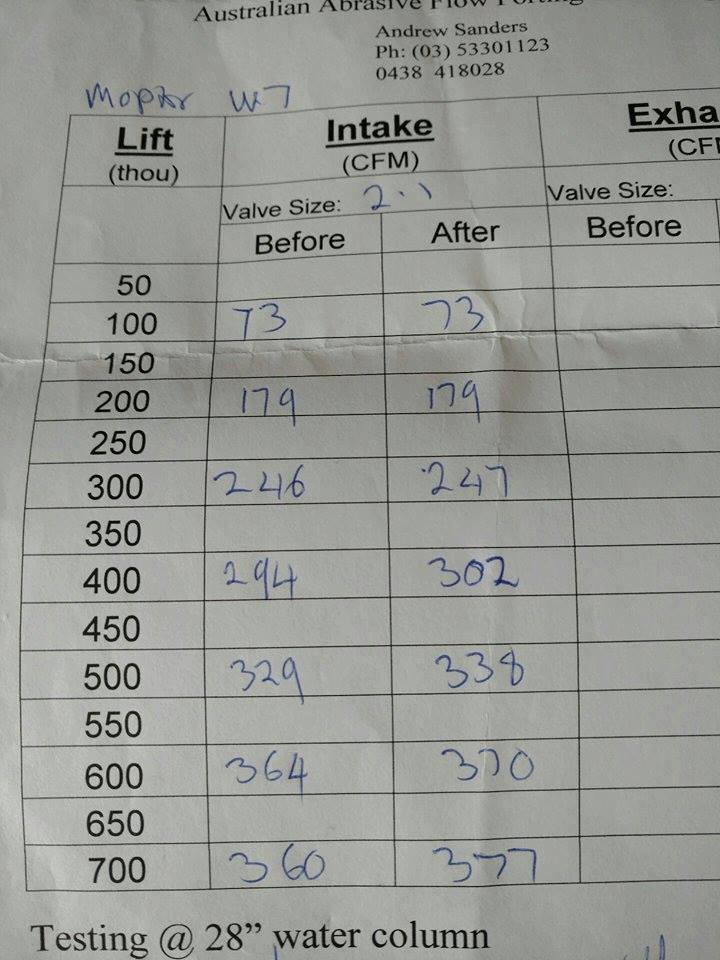

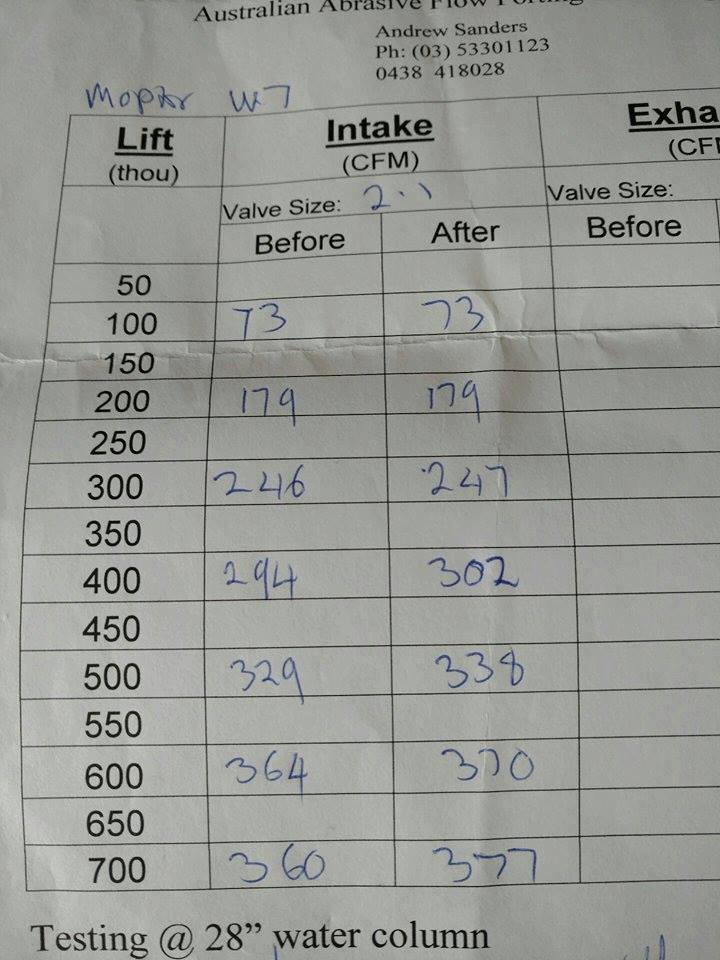

a cnc head is a good start and most of the time a lot cheaper than a hand port but in most cases you can always do a little more here is a flow sheet my w7 cnc head and after i ported it

Posted By: Cab_Burge

Re: Improving cnc ported heads - 12/23/17 03:27 AM

Where both test done on the same machine and in similar weather conditions?

Posted By: Ian

Re: Improving cnc ported heads - 12/23/17 03:42 AM

Where both test done on the same machine and in similar weather conditions?

same day 2 hrs apart same port same bench mate

Posted By: Cab_Burge

Re: Improving cnc ported heads - 12/23/17 07:53 AM

Where both test done on the same machine and in similar weather conditions?

same day 2 hrs apart same port same bench mate

Posted By: Crizila

Re: Improving cnc ported heads - 12/24/17 05:12 AM

heads are only so thick, once you get them thin, seats start to move around

This^^^

Vizard reported on intake valves that didn't seat properly because the seat itself moved laterally when hot. The cure: weaken the valve head so it bends to conform. !!!

Vizard reading his weegie board again. Anyone who does this needs a frontal lobotomy.