Posted By: Jeremiah

Wire/Groove Around Combustions Chamber on Heads - Why? - 11/01/17 04:01 PM

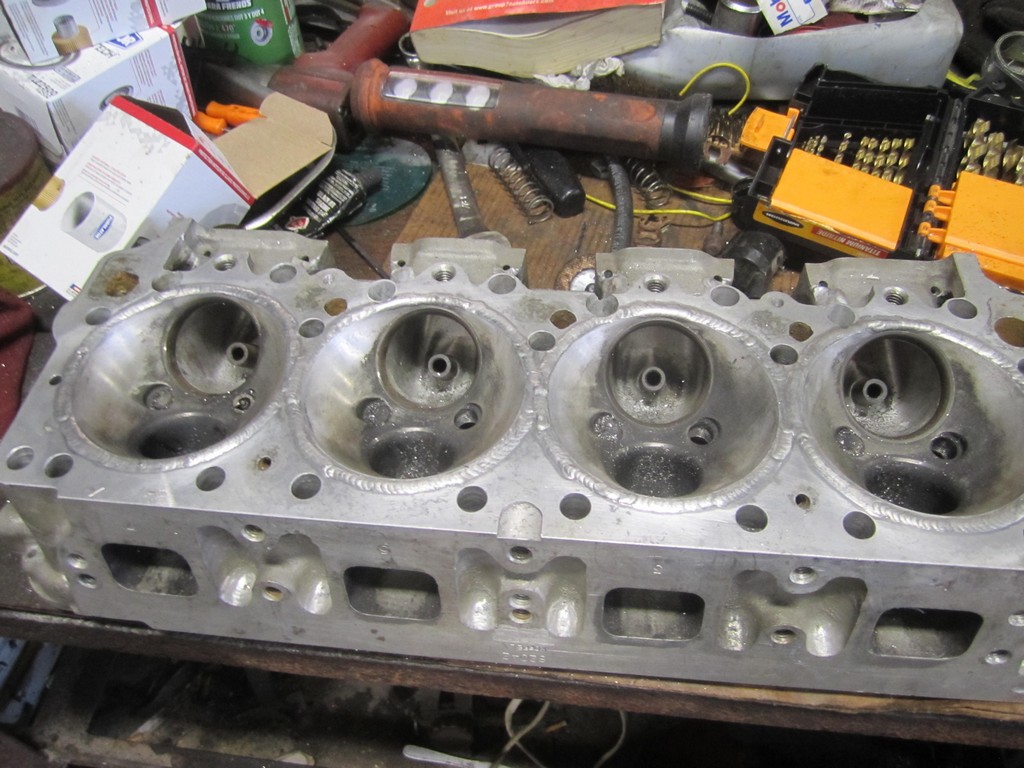

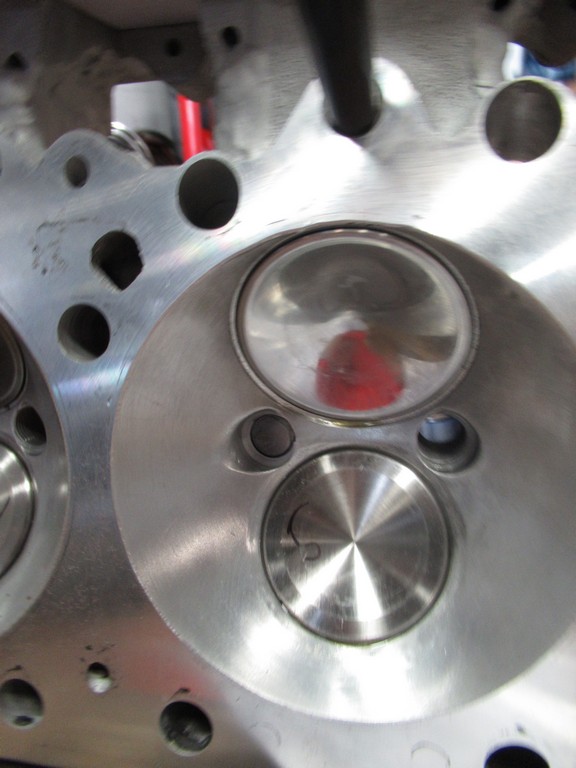

Other than a ton of boost is there any reason why one would run a groove/wire around the combustion chambers? I am looking at a set of -1's and typically use MLS gaskets on stuff like this.

I'd appreciate any insight. Also, are there any revisions of the -1's to watch out for? These particular heads are ported with no flow number or other data which is also making me nervous. Either way I think I'm going to do our other 511 for the black '66 Charger with -1's and a paired rocker setup instead of another shaft setup. We had considered doing up another set of Victors but the price of used -1's with good rockers makes them very attractive even with the associated risk.

I'd appreciate any insight. Also, are there any revisions of the -1's to watch out for? These particular heads are ported with no flow number or other data which is also making me nervous. Either way I think I'm going to do our other 511 for the black '66 Charger with -1's and a paired rocker setup instead of another shaft setup. We had considered doing up another set of Victors but the price of used -1's with good rockers makes them very attractive even with the associated risk.