Moparts

CNC porting iron heads.

Posted By: 411Dude

CNC porting iron heads. - 07/30/17 11:51 PM

Are there any head porting services that are set up for porting iron Max Wedge 518 heads? Factory or reproduction.

Posted By: PorkyPig

Re: CNC porting iron heads. - 07/31/17 12:52 AM

Not that I've heard of. There are some places that do iron heads, but there probably isn't enough demand for a Max Wedge program to justify the time and money. And just because there might be one doesn't mean it's right for everyone.

Posted By: mopar65

Re: CNC porting iron heads. - 07/31/17 12:54 AM

there is a Guy i think out of Michigan that is CNC porting 906 heads.he might be able to. sorry i cant remember his name, but i can ask my friend what the company's name is.

Posted By: MR_P_BODY

Re: CNC porting iron heads. - 07/31/17 01:14 AM

[quote=mopar65]there is a Guy i think out of Michigan that is CNC porting 906 heads.he might be able to. sorry i cant remember his name, but i can ask my friend what the company's name

Might be Modern Machine in Mich

Posted By: 70AARcuda

Re: CNC porting iron heads. - 07/31/17 01:28 AM

MCH on facebook shows them CNC a 906 head.

Posted By: mopar65

Re: CNC porting iron heads. - 07/31/17 02:20 AM

[quote=mopar65]there is a Guy i think out of Michigan that is CNC porting 906 heads.he might be able to. sorry i cant remember his name, but i can ask my friend what the company's name

Might be Modern Machine in Mich

well that's who i thought my friend was talking about. but i was wrong. My friend was talking about KG Engines, they are out of Ohio

https://www.facebook.com/KG-Engines-830374967004154/

Posted By: 1DGEMAN

Re: CNC porting iron heads. - 07/31/17 02:21 AM

Good luck with MCH. I have a friend that has a set of small block 308's a Victor manifold and special order HS rockers that have been sitting there for a year. Every time he calls about his parts he gets the run around. That is a lot of money to have sitting on some ones shelf. Poor customer service.

Posted By: mr_340

Re: CNC porting iron heads. - 07/31/17 04:59 AM

Good luck with MCH. I have a friend that has a set of small block 308's a Victor manifold and special order HS rockers that have been sitting there for a year. Every time he calls about his parts he gets the run around. That is a lot of money to have sitting on some ones shelf. Poor customer service.

Misery loves company. I have $4k tied up in some aluminum SS Hemi heads for over a year. Bob doesn't even tell me where they are in the queue. A little communication would be nice, a quick e-mail every other month would be nice.

Posted By: Ian

Re: CNC porting iron heads. - 07/31/17 09:46 AM

try hemphill he would have one

Posted By: LaRoy Engines

Re: CNC porting iron heads. - 07/31/17 02:13 PM

The probability of a CNC program for iron Max Wedge is small and the probability of it being better than a hand ported set done by an accomplished porter is even smaller.

Posted By: 370hemi

Re: CNC porting iron heads. - 07/31/17 02:59 PM

KG engines in Ohio 419 806 5870, has a max wedge CNC program for the 906

Posted By: 370hemi

Re: CNC porting iron heads. - 07/31/17 03:06 PM

KG engines in Ohio 419 806 5870 has a max wedge CNC program for the 906

Posted By: polyspheric

Re: CNC porting iron heads. - 07/31/17 03:22 PM

max wedge CNC program for the 906

What?

Posted By: fast68plymouth

Re: CNC porting iron heads. - 07/31/17 04:13 PM

The probability of a CNC program for iron Max Wedge is small and the probability of it being better than a hand ported set done by an accomplished porter is even smaller.

I'd go along with that.

And since the boys at LaRoy Racing seem to love porting iron stuff...... I nominate them !!

Posted By: mopar65

Re: CNC porting iron heads. - 07/31/17 04:34 PM

KG engines in Ohio 419 806 5870 has a max wedge CNC program for the 906

My friend is runing a set of KG CNC ported 906 and told me he is going to get a set of there max wedge CNC ported 906 next. He has been ran 10.40 at 130 in the 1/4 on E85 so far.

Posted By: Cab_Burge

Re: CNC porting iron heads. - 07/31/17 07:41 PM

I seem to remember that the intake gaskets for the M.W. are taller than the 440 are, in other words laying the M.W. gasket over the 440 I can see air between them, no sealing that way

Posted By: fast68plymouth

Re: CNC porting iron heads. - 07/31/17 07:53 PM

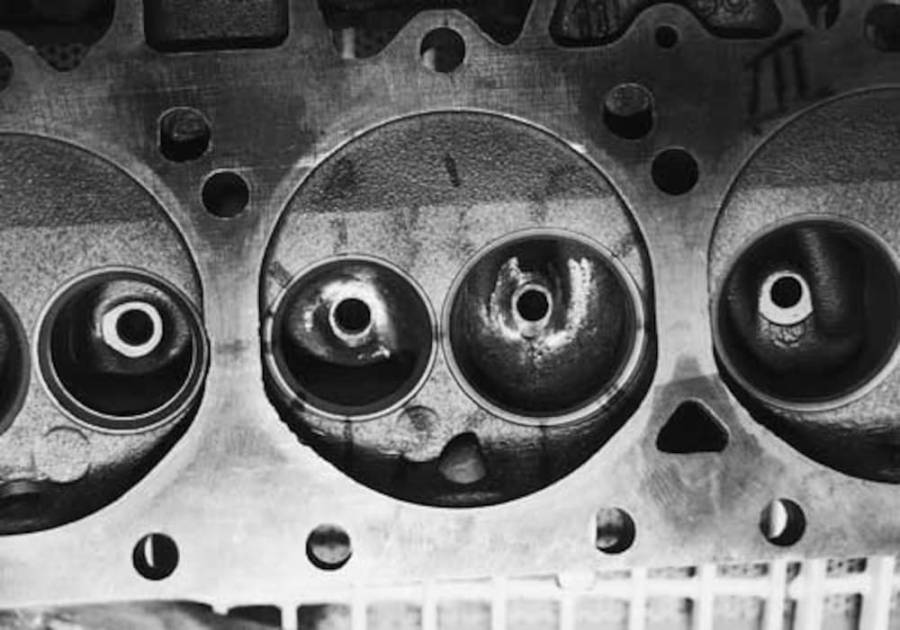

It works like this......

Posted By: Anonymous

Re: CNC porting iron heads. - 07/31/17 08:10 PM

I have seen two wicked set of ported irons--one from Laroy and the other is Mike Duke in Indy--Duke used to do all the "Herb" heads from McCandless--maxed out irons--thing of beauty I will add that the valve job is of supreme importance and I always get more from a real perfect valve job than crazy ported with medium valve job

Actually the valve job is the most over looked thing we all deal with and seem to--- talk about and care about least of all--a REAL mac daddy valve job makes a high performance engine IMO

Duke was King of the perfect valve job on irons

Posted By: 370hemi

Re: CNC porting iron heads. - 07/31/17 08:35 PM

KG engines mills off the raised portion of the intake on the stock head,makes his own cnc valley pan to accommodate gasket sealing on both sides for the taller port

Saw the head at chrysler @ carlisle this year a real nice looking piece of work

Posted By: fast68plymouth

Re: CNC porting iron heads. - 07/31/17 10:47 PM

I have seen two wicked set of ported irons--one from Laroy and the other is Mike Duke in Indy--Duke used to do all the "Herb" heads from McCandless

From what I understand.......Curtis Boggs used to do them for McCandless as well.

Posted By: BradH

Re: CNC porting iron heads. - 07/31/17 11:27 PM

KG engines in Ohio 419 806 5870 has a max wedge CNC program for the 906

My friend is runing a set of KG CNC ported 906 and told me he is going to get a set of there max wedge CNC ported 906 next. He has been ran 10.40 at 130 in the 1/4 on E85 so far.

Unless he MUST run OEM iron heads, there are too many good aftermarket head choices today to bother throwing big $$$ into 50 year old iron passenger car heads.

Posted By: fast68plymouth

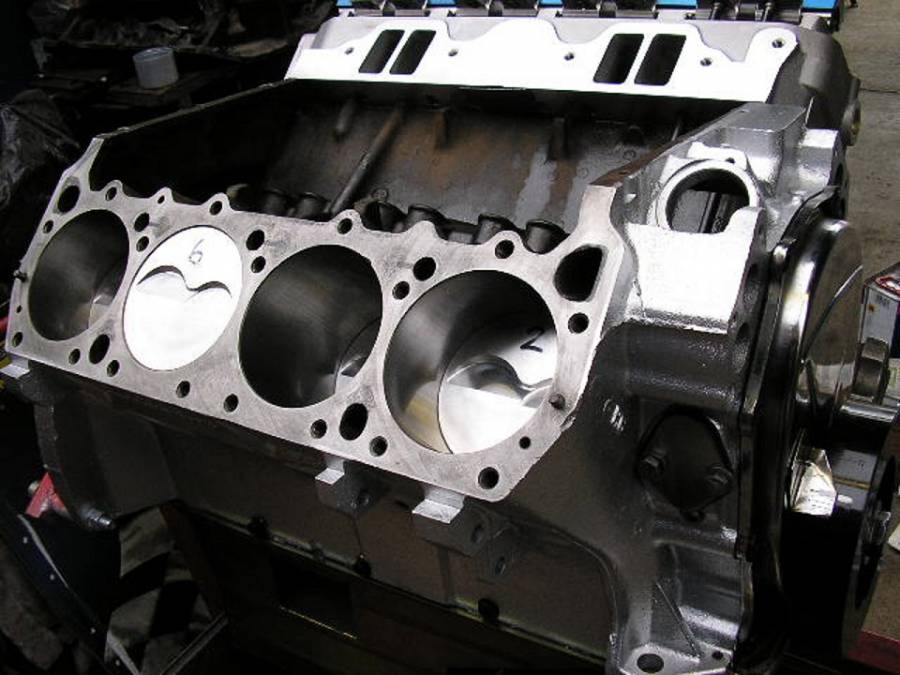

Re: CNC porting iron heads. - 08/01/17 05:12 AM

Posted By: an8sec70cuda

Re: CNC porting iron heads. - 08/01/17 02:16 PM

Given the core shift issues that the factory heads have, wouldn't a CNC ported set tend to be even more crack prone? Going fast w/ stock stuff is cool and all, but at some point it becomes even more of a money pit than racing already is.

Posted By: mopar65

Re: CNC porting iron heads. - 08/01/17 02:27 PM

KG engines in Ohio 419 806 5870 has a max wedge CNC program for the 906

My friend is runing a set of KG CNC ported 906 and told me he is going to get a set of there max wedge CNC ported 906 next. He has been ran 10.40 at 130 in the 1/4 on E85 so far.

Unless he MUST run OEM iron heads, there are too many good aftermarket head choices today to bother throwing big $$$ into 50 year old iron passenger car heads.

Hey Brad how's the new engine build coming along? But yes my friend is tuning in a class that you have to run stock factory blocks and heads. Kind of like the fast class but for poor guys.lol

Posted By: fast68plymouth

Re: CNC porting iron heads. - 08/01/17 04:27 PM

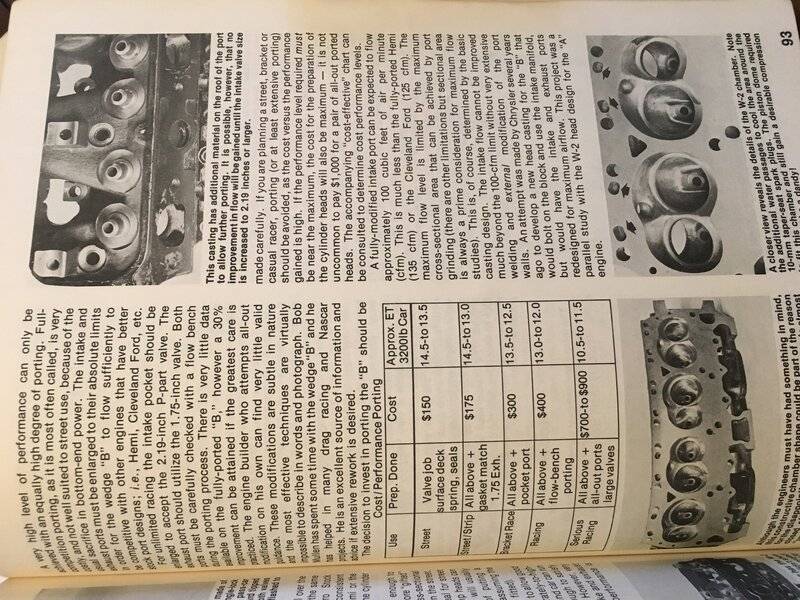

Going fast w/ stock stuff is cool and all, but at some point it becomes even more of a money pit than racing already is.

I've thrown away a lot of really nice ported OE heads that made pretty good power and the owners were pretty happy with how the cars ran. Some of them I ported, some were ported at other shops.

For big blocks, when they're heavily modified(especially with big intake valves), the two most common places for cracking is across the intake seats into the bowls, and externally under the two center exhaust ports.

Of course, if you're racing in a class where they're required, you don't have a lot of options;

-Port them less(go slower)

-Don't port them at all(go even slower)

-Accept that the heads may not last all that long.

Given the core shift issues that the factory heads have, wouldn't a CNC ported set tend to be even more crack prone? Going fast w/ stock stuff is cool and all, but at some point it becomes even more of a money pit than racing already is.

Probably just the opposite. Most CNC programs are set up on the safe side so they can move product in and out the door. Most hand porters can take a CNC'd head and make vast improvements in flow. I have never had a set of CNC'd heads leave my shop that weren't better and I'm not talking about a few cfm but then again I love playing on the flowbench.

Posted By: fast68plymouth

Re: CNC porting iron heads. - 08/01/17 04:41 PM

I think John could use a nice high effort iron head porting job to help fill up some of his leisure time.

Plus it would be nostalgic........ Bringing back memories of 30 years ago when porting iron was the only option.

I've had a couple sets of iron MW heads in my shop that were ported by a pretty high profile non-Mopar engine builder. These were fairly high effort(high dollar??) jobs, that looked very nice.

One set was some OE 286 heads, the other was the latest version of the 518M heads.

I'll just say that neither set had the kind of flow numbers I've heard that these heads are capable of........ Although they flowed basically the same as what I've gotten out of them with my "normal" port job.

Admittedly....... I'm not into fixing holes...... So I err on the conservative side...... Which means there is some flow left on the table.

I think John could use a nice high effort iron head porting job to help fill up some of leisure time.

I think John has a set of Edelbock small block heads sitting on his bench with .350 off-set rockers waiting for him to pick up the dam grinder again.

Posted By: LA360

Re: CNC porting iron heads. - 08/02/17 10:20 AM

Larry Meaux would be someone I would consider talking to, along with those already mentioned.

Posted By: polyspheric

Re: CNC porting iron heads. - 08/02/17 04:57 PM

Jerry Branch pointed out 50 years ago that "shiny!" is a waste of time, but the customer expects it.

Except to examine symmetry (are the gasket outlines followed accurately? Are all of the left or right-handed ports identical in interior shape? Is the guide exposure the same?), appearance is almost worthless unless you know that the porter has excellent past performance with that casting.

Everything else is just cosmetic.

A CNC program developed for a 906 will do the following on a 518:

1. add 50 hp

2. subtract 50 hp

3. break them

4. no one knows

</rant>

Posted By: mr_340

Re: CNC porting iron heads. - 08/04/17 05:01 AM

Misery loves company. I have $4k tied up in some aluminum SS Hemi heads for over a year. Bob doesn't even tell me where they are in the queue. A little communication would be nice, a quick e-mail every other month would be nice.

I drove up to Detroit this week and met with Bob today. We had a good chat about my heads and he said he would run them next week. I'll post if my engine guy in Tampa gets the heads in the next couple of weeks with a report.

Posted By: HardcoreB

Re: CNC porting iron heads. - 08/06/17 04:27 AM

Going fast w/ stock stuff is cool and all, but at some point it becomes even more of a money pit than racing already is.

I've thrown away a lot of really nice ported OE heads that made pretty good power and the owners were pretty happy with how the cars ran. Some of them I ported, some were ported at other shops.

For big blocks, when they're heavily modified(especially with big intake valves), the two most common places for cracking is across the intake seats into the bowls, and externally under the two center exhaust ports.

Of course, if you're racing in a class where they're required, you don't have a lot of options;

-Port them less(go slower)

-Don't port them at all(go even slower)

-Accept that the heads may not last all that long.

Not to take ANYTHING away from what Dwayne is saying here but, I did epoxy patch a set of heavy ported/milled!!! 906's that were cracked externally below the exhaust ports and that repair held well for a good number of years/passes.

Posted By: fast68plymouth

Re: CNC porting iron heads. - 08/06/17 05:10 AM

Personally, I would never run a bb mopar head with the crack under the exhaust ports that had been repaired that way, in a racing situation.

I've had two motors on the dyno that developed cracks there.

They didn't leak a drop until you started applying a load and making power.......when the head is trying to get lifted off the block, that crack opens up and it's like you turned on a garden hose, with coolant spraying out.

Back out of the throttle.........the flow just stops.

After seeing it first hand on two occasions.........I don't wanna be the guy behind the wheel when it lets go and gets under the tires.

Posted By: 411Dude

Re: CNC porting iron heads. - 08/06/17 11:49 PM

Thanks, all. We are building a "230" block 400 with a de-stroked 383 crank for a class at Bonneville in a roadster. Looking for somebody to set up our max wedge heads. They may not need much work at this cu. in. level but we plan on needing to run the rpms up higher than any super stock wedge so need a max effort creativity on the valvetrain setup. Planning to run Hilborn injection on gas. Dry sump.

Posted By: Bob J

Re: CNC porting iron heads. - 08/07/17 12:38 AM

I hope that you post more on this build

Posted By: CSK

Re: CNC porting iron heads. - 08/07/17 12:45 AM

others may disagree but, a max wedge port is WAY to big for that CID, just my opinion.

Posted By: Cab_Burge

Re: CNC porting iron heads. - 08/07/17 03:57 AM

I know several Mopar sponsored NHRA SS class racers that raced 383 back in the late 1970 and early 1980s, they where shifting them at or above 8400 RPM back then with that technology back then pushing the NHRA rules to the limit

On your deal how long do you get to push the race car before letting out the clutch ?

The reason I'm asking is the cam and getting the motor up to RPM that it will start to pull good before wind resistance gets in the mix

Posted By: dwayne welder

Re: CNC porting iron heads. - 08/07/17 09:05 PM

TheMax Wedge head is to big for that application it won't make any torque or rev up fast!!!

Posted By: HotRodDave

Re: CNC porting iron heads. - 08/07/17 11:27 PM

They are no bigger than the apache head on a 6.4. Send em to someone who knows those heads and let em at em. Try to keep some material in the exhaust port to keep it from cracking and cam apropriately. A max wedge head is just fine if you build the rest of the motor/car to match the RPM range.

Posted By: sasquatch

Re: CNC porting iron heads. - 08/07/17 11:53 PM

It should work and work well. The big bore (4.340) short stroke will be great.

How is it the Chevy guys can run 500Plus cfm heads on there stuff and we somehow cannot run heads that will NEVER see 350 on ours? I would be curious to see your rule package as to what your allowed. I know that some of the Classes out on the salt can result in some interesting packages. I used to work on a guy who ran a 291 cid Desoto hemi out there years ago. Different and neat.

Todd

Posted By: MR_P_BODY

Re: CNC porting iron heads. - 08/08/17 12:12 AM

I use to run a destrokes 383.. was a HIGH rpm

engine.. I shifted it a 9800 rpm(4 speed car)

in a 2900# with me Valiant ... it was more of

a square block for the aerodynamics... I used

a set of home ported max wedge heads on it with

a tunnel ram

Posted By: mr_340

Re: CNC porting iron heads. - 08/08/17 01:04 AM

Thanks, all. We are building a "230" block 400 with a de-stroked 383 crank for a class at Bonneville in a roadster. Looking for somebody to set up our max wedge heads. They may not need much work at this cu. in. level but we plan on needing to run the rpms up higher than any super stock wedge so need a max effort creativity on the valvetrain setup. Planning to run Hilborn injection on gas. Dry sump.

I'm thinking that you should get some B1 heads and turn the RPMs up. I don't think you will need the torque as you probably will be spinning in the salt from what I was told from a friend that ran a NASCAR Ford 358 in a B/SR tying to top 200 MPH. Maybe use a 5-speed transmission or maybe a 6-speed with OD to get top end? Sounds like a fun project.

Posted By: AndyF

Re: CNC porting iron heads. - 08/08/17 02:17 AM

Thanks, all. We are building a "230" block 400 with a de-stroked 383 crank for a class at Bonneville in a roadster. Looking for somebody to set up our max wedge heads. They may not need much work at this cu. in. level but we plan on needing to run the rpms up higher than any super stock wedge so need a max effort creativity on the valvetrain setup. Planning to run Hilborn injection on gas. Dry sump.

If you need a super low profile billet dry sump pan I have one. I built it for a project but do not need it anymore. It should help you get the engine as low as it will go in roadster.

.JPG)

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/17/21 03:21 PM

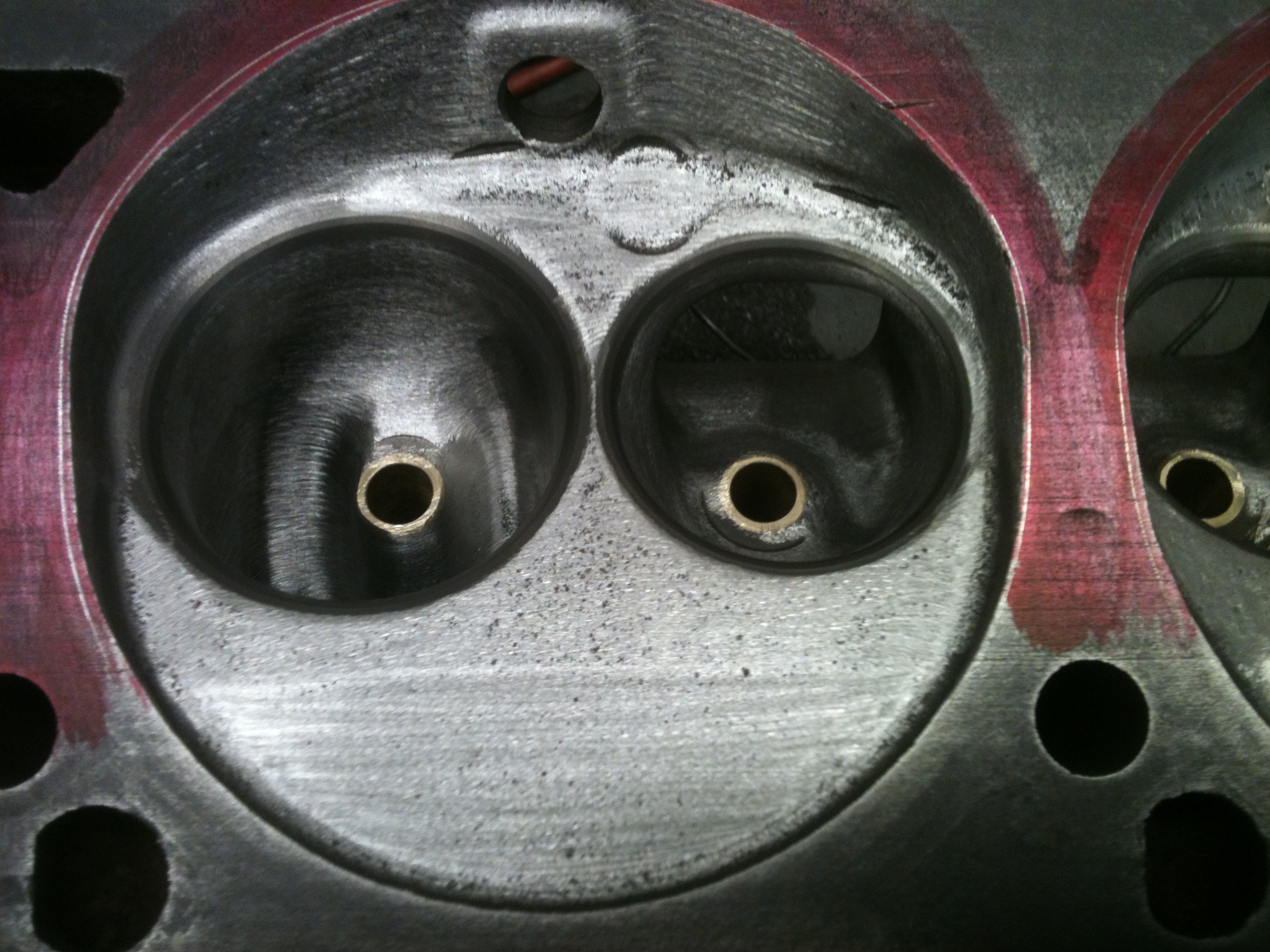

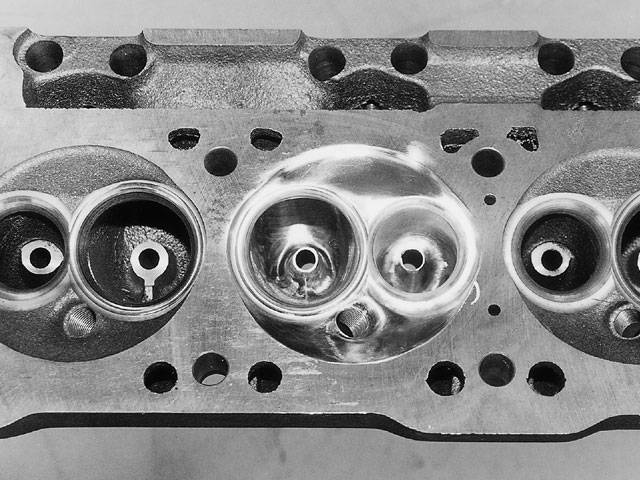

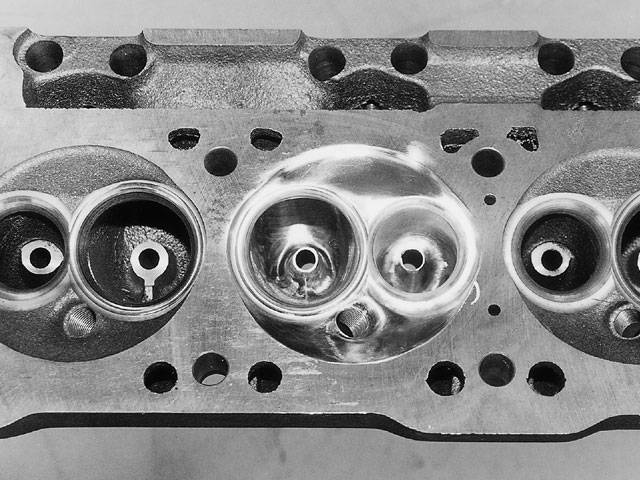

Wonderful head work there fast68!

Guess they is later smog castings?

I'm going for 2.225 intakes and 1.84 exhausts myself...

Posted By: fast68plymouth

Re: CNC porting iron heads. - 10/17/21 09:52 PM

Those are a set of 346’s.

2.14/1.81

I did work on a set of the repro 518-M’s last year though.

I’ve never had a set of original 518’s in my shop, so I can’t say how similar they are to the -M versions.

But I can tell you this........ both the intake and exhaust ports on the 518-M’s are shaped nothing like the early 286 heads.

Posted By: Max Weg

Re: CNC porting iron heads. - 10/18/21 10:42 AM

I race a fairly fast Max Wedge Superstock car, the first lite weight Plymouth shipped in 64 (in SS/EA I have ran 9.39 at 141), I developed my own engine program as their have not been any SS Max Wedges go this fast. I cross the Stripe at Sea Level at around 8700rpm, I did everything on the heads myself and I have done both original 518 and 518M heads, you have to know which ones to pick. The exhaust side does not need much work but to make 800hp the intake Port needs lots of creative work. Good luck with your Project and be selective on who you use.

Max Weg

Posted By: cudaman1969

Re: CNC porting iron heads. - 10/19/21 01:03 AM

I race a fairly fast Max Wedge Superstock car, the first lite weight Plymouth shipped in 64 (in SS/EA I have ran 9.39 at 141), I developed my own engine program as their have not been any SS Max Wedges go this fast. I cross the Stripe at Sea Level at around 8700rpm, I did everything on the heads myself and I have done both original 518 and 518M heads, you have to know which ones to pick. The exhaust side does not need much work but to make 800hp the intake Port needs lots of creative work. Good luck with your Project and be selective on who you use.

Max Weg

And they say big blocks won’t turn! I bet it sounds sweet up top, I had one back in the 70s, a whole nuther sound.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/19/21 08:33 AM

Many thanx for the quick replies Guys!

The port work and pictures are truly AWESOME!

Very interesting your comment on 518 to 286 Max Wedge ports?

I am fortunate to have a set of 62 286 heads and the ports are awesome lol.

There were a lot of trick iron headed 440's here in the 80's and 90's.

But the evolution of Aluminum has pretty much 'killed them off'...

For me I want to run in a kinda 'Superstock' set-up with a six-barrel on my 71 GTX.

Its a Canadian car with 346 heads and the engine is BLUE?

The car was raced in the 90's and has succumbed to rust issues.

After a 20 year resto I want to get her back out, with another 440 or 511.

Sold all my Ali heads but have a few 'old school irons' laying around lol.

Gonna practice on some ex Jensen sixpack 902's for now with a 3/8 inch manifold spacer.

ps, my old 452ci iron-engine used to rev to 7200, would have gone more but I didn't want to wreck an ex 69 SP Superbee block, (now back in the car)!

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/19/21 01:53 PM

Just watched Nick on YT running the 520cube 71 GTX engine.

It has answered a lot of questions real quick for me!

Don't use a stock intake or stock exhausts lol...

But the real question is?

How good or bad 'are' the Stealth heads...

Can I 'out-port' them with iron???

We did buy a set back in 2005 and fitted them on a 543 engine with high compression.

It was pretty new stuff back then and I think it ran high tens in a street car (65 Coronet).

I would be happy with 11's with my homeported 902's and 511 cubes.

Start with an Edelbrock Torker and then hopefully an iron six-barrel...

Posted By: ZIPPY

Re: CNC porting iron heads. - 10/19/21 02:08 PM

I use to run a destrokes 383.. was a HIGH rpm

engine.. I shifted it a 9800 rpm(4 speed car)

in a 2900# with me Valiant ... it was more of

a square block for the aerodynamics... I used

a set of home ported max wedge heads on it with

a tunnel ram

It might be a post from 4 years ago, but I wasn't around for it, so I'm gonna say......

That's a really cool car, Mike. Love it. Thanks for the pic.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/19/21 02:23 PM

4 years is a 'blink' in Mopar time!

I still feel like its the mid 80's (to me), so little time/money and so much to do...

It was always our 'mantra', got to be an all iron engine and normally aspirated!

But I'm still looking for an Aluminum MP hemi head, please Zippy lol...

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/19/21 02:27 PM

Back to iron 440 heads!

Best size of valves is my next question?

I have 2.225 intakes and 1.84 exhausts...

Am I over-valved???

We always spent a week on Intake porting and a day on exhausts...

Now we know better...

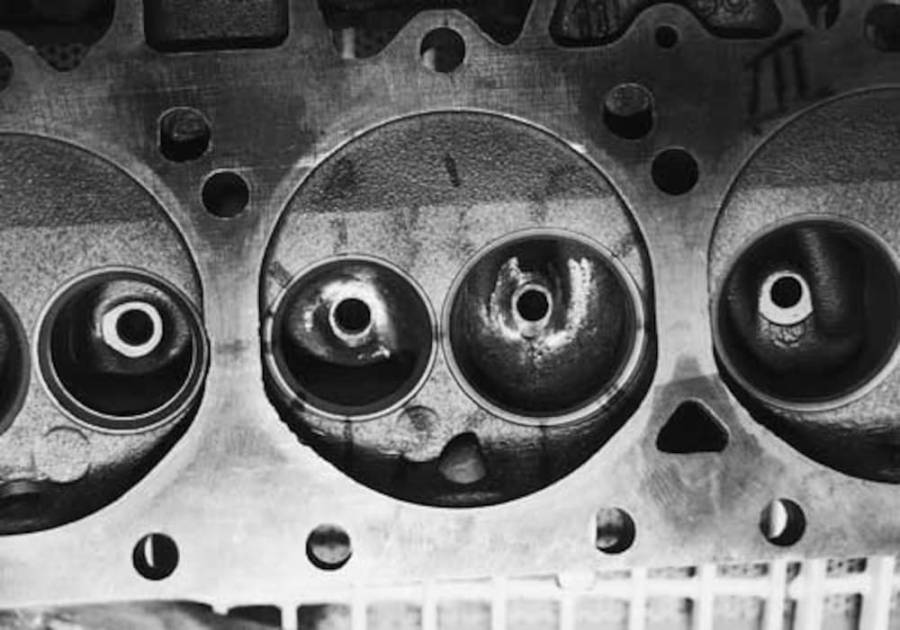

Best iron head exhausts I have ever seen...

Posted By: CSK

Re: CNC porting iron heads. - 10/19/21 02:39 PM

Just watched Nick on YT running the 520cube 71 GTX engine.

It has answered a lot of questions real quick for me!

Don't use a stock intake or stock exhausts lol...

But the real question is?

How good or bad 'are' the Stealth heads...

Can I 'out-port' them with iron???

We did buy a set back in 2005 and fitted them on a 543 engine with high compression.

It was pretty new stuff back then and I think it ran high tens in a street car (65 Coronet).

I would be happy with 11's with my homeported 902's and 511 cubes.

Start with an Edelbrock Torker and then hopefully an iron six-barrel...

The Stealths can be ported to flow better than a ported iron head with much less work , I have the Super Stealths that I ported to Max Wedge on my 512 street car, they quit making them they use .650 offset intake rockers, My junk runs pretty good for what it is, small cam, 9.7 compression, if you want the stock looking head with straight spark plugs they can be made to flow pretty good for a NON raised port head.

Posted By: fast68plymouth

Re: CNC porting iron heads. - 10/19/21 03:17 PM

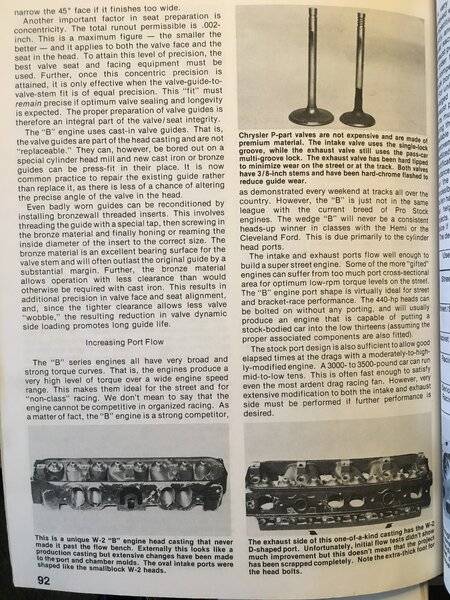

Best iron head exhausts I have ever seen

Actually, there isn’t all that much done to those ports. Just some basic clean up and smoothing.

The 518-M exhaust ports are pretty good as cast ...... especially the later versions.

Posted By: Chargerfan68

Re: CNC porting iron heads. - 10/19/21 10:07 PM

Best iron head exhausts I have ever seen

Actually, there isn’t all that much done to those ports. Just some basic clean up and smoothing.

The 518-M exhaust ports are pretty good as cast ...... especially the later versions.

On the 906 and 346, etc…., what was the reason for the big intrusion sticking out on one side of the exhaust port? I see those 518 heads do not have that at all.

Posted By: fast68plymouth

Re: CNC porting iron heads. - 10/19/21 10:38 PM

The area filled in on one side of the ex port in the OE heads is to facilitate more coolant capacity in the head.

There is a corresponding mild bulge in the adjacent intake port.

Apparently that’s less of a concern to the aftermarket head designers. They’re going for the flow instead.

Posted By: polyspheric

Re: CNC porting iron heads. - 10/19/21 10:38 PM

A straight valve size comparo doesn't cover what's happening. The ports function at violently different pressures: .74 psi WOT vacuum in the intake manifold, perhaps 7 psi vacuum in the cylinder near TDC, vs. 70 psi pressure in the cylinder when the exhaust valve cracks open.

Opening the exhaust even a few degrees earlier helps a weak port.

Posted By: cudaman1969

Re: CNC porting iron heads. - 10/20/21 01:14 AM

I know I’ll get beat up for this but we always found good power with stock size intake valve and the max wedge exhaust (1.88) just mild bowl work under the seat. Never could understand why it was said they wouldn’t help. Maybe what poly said, 70 psi

Posted By: Max Weg

Re: CNC porting iron heads. - 10/21/21 10:19 AM

I race a fairly fast Max Wedge Superstock car, the first lite weight Plymouth shipped in 64 (in SS/EA I have ran 9.39 at 141), I developed my own engine program as their have not been any SS Max Wedges go this fast. I cross the Stripe at Sea Level at around 8700rpm, I did everything on the heads myself and I have done both original 518 and 518M heads, you have to know which ones to pick. The exhaust side does not need much work but to make 800hp the intake Port needs lots of creative work. Good luck with your Project and be selective on who you use.

Max Weg

And they say big blocks won’t turn! I bet it sounds sweet up top, I had one back in the 70s, a whole nuther sound.

Yes it does!! It has a very flat power curve from 6800 to 8700 and could spin higher but there is no need. The biggest thing is crankshaft stability so a 2 bolt block does not like it, therefore a crossbolted conversion is required. The 518M heads latest version Exhaust Ports can be made to flow almost to good. With creative work on the intake ports you can make a stock port size with a 2.08" intake valve flow over 330cfm. And support North of 800hp na.

Max Weg

Posted By: ChrgrCuda

Re: CNC porting iron heads. - 10/21/21 11:31 AM

Ok I will be the Big Dummy in the conversation. So is the 518M head a Max Wedge head?

Posted By: Max Weg

Re: CNC porting iron heads. - 10/21/21 11:35 AM

Yes it is the replacement head for the Original 518 Max Wedge Stage 3 head.

Max Weg

Posted By: A727Tflite

Re: CNC porting iron heads. - 10/21/21 12:48 PM

I race a fairly fast Max Wedge Superstock car, the first lite weight Plymouth shipped in 64 (in SS/EA I have ran 9.39 at 141), I developed my own engine program as their have not been any SS Max Wedges go this fast. I cross the Stripe at Sea Level at around 8700rpm, I did everything on the heads myself and I have done both original 518 and 518M heads, you have to know which ones to pick. The exhaust side does not need much work but to make 800hp the intake Port needs lots of creative work. Good luck with your Project and be selective on who you use.

Max Weg

And they say big blocks won’t turn! I bet it sounds sweet up top, I had one back in the 70s, a whole nuther sound.

Yes it does!! It has a very flat power curve from 6800 to 8700 and could spin higher but there is no need. The biggest thing is crankshaft stability so a 2 bolt block does not like it, therefore a crossbolted conversion is required. The 518M heads latest version Exhaust Ports can be made to flow almost to good. With creative work on the intake ports you can make a stock port size with a 2.08" intake valve flow over 330cfm. And support North of 800hp

Max Weg

How many versions of the 518M and how do you identify them?

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 01:33 PM

This now opens a HUGE can of worms in my mind!

Why did they not just carry on reproducing the 1964 max wedge head into the 70's???

I know you are gonna say ''because we had the HEMI'' but that's a very expensive and specialist engine...

Why go through years of Bigblock heads, 516, 915, 906, 236, 902 213, 452 blah, blah, blah...

440 max wedge would have worked better as the 413 bore was way too small for the MW heads.

426 solved some of them head to cylinder problems.

What about a 400 max wedge, how good would that have been?

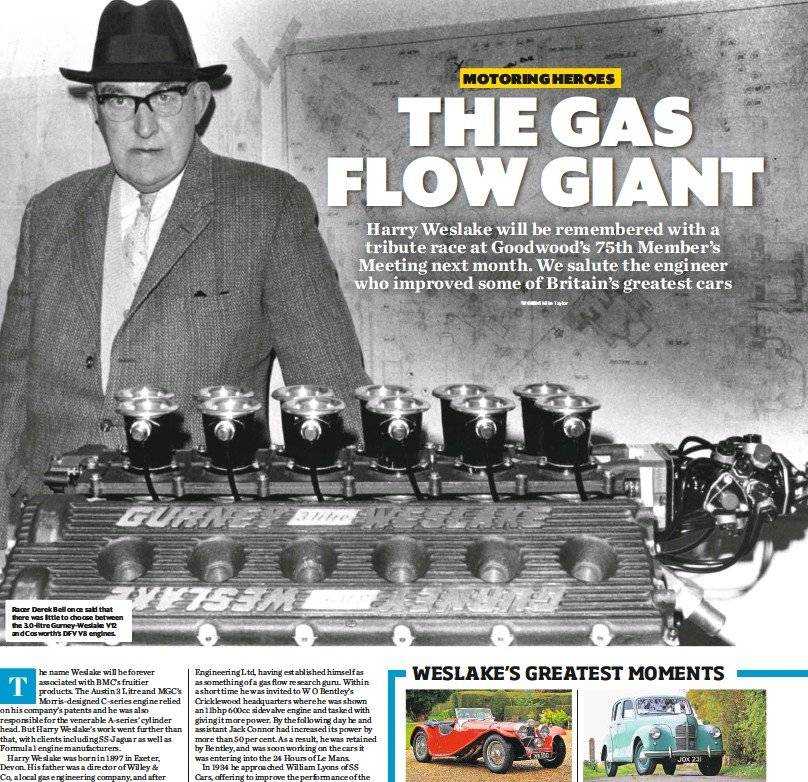

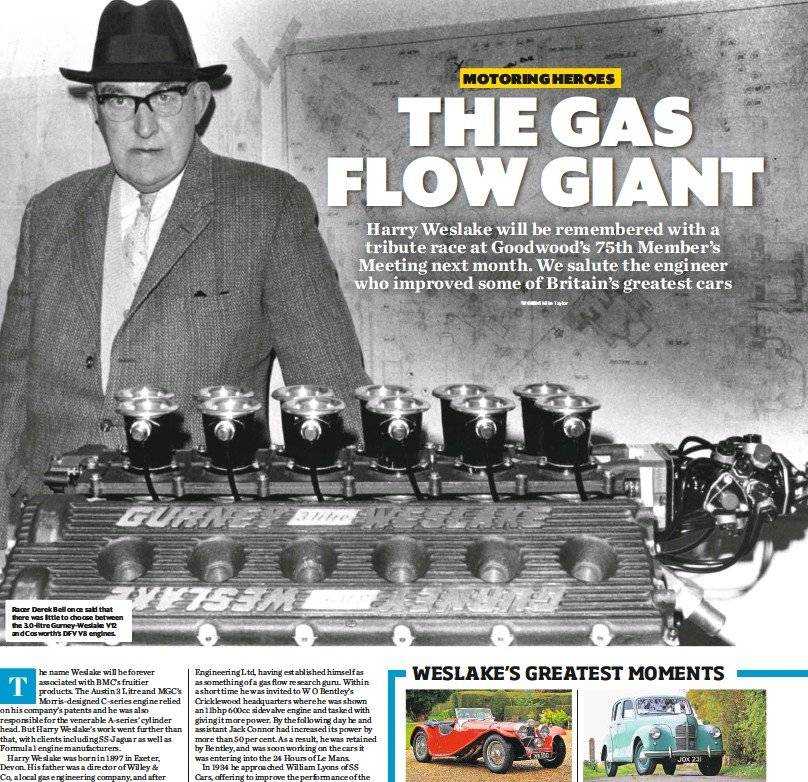

And what about these W1 heads from Weslake???

Bigblock OVALPORTS and D-PORTS, WITH HEAT-CROSSOVER.

Why were they not followed up too???

2.250 intakes and 1.80 exhausts with offset intake rockers

A pile of unique 'one off' items castings and forgings, never to be seen again! (until now) lol...

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 01:38 PM

Plus the extra cooling holes around the plugs 'as per 452 motorhome heads' too.

I did run this engine in the 90's at the famous 'Santa Pod raceway' UK.

But the valves were way too short for any 'meaningful' camshaft use, best was a 509 DC hydraulic.

Then I found out the valves had been 'remade' by a previous owner at standard 440 length which was 0.250 too short!

So now I have had some longer valves made so I can use 2.000'' valves springs and a 0.650 roller.

Folks have been wanting to know what flow they have?

Don't actually know this fact as all the paperwork was lost when Weslake Engineering 'shut-down'.

I guess around 300cfm's as they are 'rough cast' and will need some port work to get the best outta them?

The rumour was they were in 'hemi-territory' as a replacement when the Hemi got banned in Nascar?

The Wingcars and other issues of the early 70's put paid to much of mother Mopars development work...

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 01:52 PM

Some info can be found in the Mopar Performance book of the late 70's by Larry Schreib.

Two sets of Big-Block development heads sent to the World famous Weslake Engineering in the late sixties.

One set is featured in the book, the other set is still here in the sunny County of Kent UK...(the garden of England)

They got 'BAD PRESS' and then forgotten for 50 years...(how sad)

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 02:02 PM

maybe even more interesting?

No Intake was ever made, so a STR was modded to work...

Sand-cast Nascar carb 1969 only, makes the domi M1 look small lol.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 02:40 PM

Posted By: fast68plymouth

Re: CNC porting iron heads. - 10/21/21 02:41 PM

Cool stuff.

Seems like pics of those heads pop up on line every few years.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 02:50 PM

Hi fast 68,

That's me ''just getting them out there'' lol...(nearly 40 years, kept in my Dungeon).

Dick Landy and Don Garlits both wanted the ex Weslake Dyno engine, but not enough money (yet) to coax them back across the Atlantic...

Posted By: ChrgrCuda

Re: CNC porting iron heads. - 10/21/21 02:51 PM

Would it be fair to say that if the Max Wedge head design would have continued, that the horrible flat standard 4 barrel iron intake would have also had to be improved/redesigned to take advantage of the Max Wedge head flow?

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/21/21 02:54 PM

Too true!

Victor Edelbrock said to me ''you got the Sixpack manifold, what more do you need''?

Posted By: cudaman1969

Re: CNC porting iron heads. - 10/21/21 08:09 PM

The max wedge heads were lost when the building burned that had the patterns-molds late 60s if I remember right. Racing was the only reason ANY of those heads were made .

I remember seeing a proposal, appeared to be real, to use 6pack short blocks and manifolds with Max Wedge

heads in a Demon to target a SS class. (D I think).

DC saw it as a way to get the supply of MW heads replentished.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/22/21 10:14 AM

Mother Mopar dropped the ball with the W series heads!

When Steve Dulcich reviewed them in 2001 at Westech, he was 'blown away'...

50 years ago they had the castings already made and ready to go!

Calling them 'ECONO' probably made folks wince and feel under-whelmed.

No heat-crossover for the small-block W2 though?

The W1 Big-block was a viable replacement for the 915 head of 1967.

Instead we got the 906 and all the other non descript offerings...

Posted By: HotRodDave

Re: CNC porting iron heads. - 10/22/21 04:57 PM

It really would not have taken much for the factory to bolt em on, surely they could have been made to pass emission regs of the day? Same with the magnum R/T head, actually they would have been even easier as there is nothing else needs to be different to put em on and surely with the much improved injector targeting MPG and emissions are improved (they no longer squirt into the side of the port)... I suspect they didn't use the magnum R/T in production because they were big inning the new hemi development and wanted as drastic of an improvement over the magnum as possible when they introduced them.

Posted By: A727Tflite

Re: CNC porting iron heads. - 10/22/21 05:15 PM

I remember seeing a proposal, appeared to be real, to use 6pack short blocks and manifolds with Max Wedge

heads in a Demon to target a SS class. (D I think).

DC saw it as a way to get the supply of MW heads replentished.

Hoover and Koffel put a package together that my friend raced.

Started out as a destroked 361 with Maxie heads on it, single 4 barrel, 4 speed in Super Modified.

Around 75 I think.

Posted By: Gtxxjon

Re: CNC porting iron heads. - 10/23/21 09:11 AM

Obviously the 906 was a first generation SMOG head!

After that they flattened the 346 port and copied the small-block '915-J' head intake and fitted the 'Huber Hump' (that's what Vizard called it).

Vizard and Dulcich did much work on the iron heads in 98 and 99 as a SWANSONG methinks?

The 21st Century has been the Aluminum revolution for Big-blocks!

The 493ci 'Torque Monster' built by Nick up in Canadia has opened my eyes to Big-blocks again!

650 pounds feet of torque is hemi beating stuff...

Hope that guy has got an 18 spline BOX!!!

Nice 346 port work by Vizard, he was talking 270cfm's (on a good day) lol