Moparts

Frame connectors

Any reason not to use round DOM tubing?

Posted By: CMcAllister

Re: Frame connectors - 06/17/16 04:09 AM

Nope, as long as it's large enough. Many higher end back-half cars (think Super Stock), and 25.whatever cars are done all in round tubing that's integrated into the floor pan. The rectangular tubing has flat sides that make it easier to section and weld into the floor, set cage bars on top of it without having to notch, etc.

Posted By: GY3

Re: Frame connectors - 06/17/16 06:01 AM

2X2 square tubing slid into the rear framerail works well and doesn't interfere with most stock floorpans.

Posted By: jcc

Re: Frame connectors - 06/17/16 06:35 AM

Any reason not to use round DOM tubing?

Yes, if you felt "beam strength" was more of an issue then "torsional strength", round tubing vs square or rectangular?, would not be your first choice. And "DOM" increased cost in this application, has little upside, IMO.

Posted By: gregsdart

Re: Frame connectors - 06/17/16 01:40 PM

2x2 properly welded into the floor pan is way superior in strength to a round tube that isn't. Done right, it also looks like it grew there .

Posted By: CMcAllister

Re: Frame connectors - 06/17/16 05:50 PM

I suppose I should have said "depends" on what else is going on; full chassis, no roll bar or somewhere in between. 1-3/4" 1020 DOM tubing is pretty stout. But if the only thing going in is a set of frame ties, then the added strength and cross section of 2x3 sectioned into the front of the rear frame rail (assuming it's a typical Chrysler product) and the floor and butted up against the rear of the torsion bar crossmember would be a stronger set up. The 2x3 has a much larger cross section and there's just more area to join the floor pan and tubing together. Even with a simple 6 or 8 point, it will be stronger overall. With 2x2, the advantage is less. Keep in mind, it doesn't matter how strong the tie is - if you have it welded in only at the ends of the tie it's better than nothing, but it will flex the sheet metal at the weld before it flexes the stronger tie. Sectioning it into the floor will give the maximum benefit.

Posted By: dogdays

Re: Frame connectors - 06/17/16 06:47 PM

From a design standpoint, metal that is farther out from the neutral axis works harder. As a 2x2 square tube has more material farther away from the axis it is stronger in either torsion or bending. This is a Strengths of Materials, learned from Mr. Ron Apanian back in the day. Anyone else reading this take Strengths from Apanian?

As far as stiffness goes, any steel has approximately the same spring constant or modulus of elasticity as any other. So 1018 and 4340 start bending at exactly the same stress. The difference comes when the bend becomes permanent or yields. The 4340 has a much higher yield strength than 1018.

If welding was perfect then welded tubing would be less expensive, but that long seam seems to have the occasional weak spot. Of course, using a safety factor of 4 or so should cut the stress so that the weld will not fail. Just don't ask me to calculate maximum stress or safety factor for a frame connector!

R.

Posted By: 6PKRTSE

Re: Frame connectors - 06/17/16 06:58 PM

I have round tube under my Challenger tied in with the cage.

Posted By: cudaman1969

Re: Frame connectors - 06/17/16 07:56 PM

I'm planning to run round in my 69 Cuda floor also. One bar at the sill and one next to tunnel with cross bar at the back, sill bar to sill bar then x-ed. Roll bar will set on the sill bars along with side bar. Sill bar will extend to the spring hanger box (stocker no tubbing). All 4130, basicly a cage with no windshield bars (no stupid net). If just tying the frames use 2x2 or 2x3 rec.

Posted By: jcc

Re: Frame connectors - 06/17/16 11:12 PM

From a design standpoint, metal that is farther out from the neutral axis works harder. As a 2x2 square tube has more material farther away from the axis it is stronger in either torsion or bending. This is a Strengths of Materials, learned from Mr. Ron Apanian back in the day. Anyone else reading this take Strengths from Apanian?

As far as stiffness goes, any steel has approximately the same spring constant or modulus of elasticity as any other. So 1018 and 4340 start bending at exactly the same stress. The difference comes when the bend becomes permanent or yields. The 4340 has a much higher yield strength than 1018.

If welding was perfect then welded tubing would be less expensive, but that long seam seems to have the occasional weak spot. Of course, using a safety factor of 4 or so should cut the stress so that the weld will not fail. Just don't ask me to calculate maximum stress or safety factor for a frame connector!

R.

The issue above not mentioned here or by me in my earlier reply, frame connectors have multiple stresses imparted on them, and to the op's question, tension would care less what shape the member, and compression forces would be best with round, and as large as physically allowable. Not sure that a 2x2 square tube compares favorably to a 2" round tube from a strictly torsional standpoint, comparing equal weight per ft materials, although it has greater material farther from the neutral axis you mentioned. Correct me if I am mistaken. Your comment on "welded tubing", is indeterminate to me, most of our typical tubing is welded, including DOM. All of this has been covered on moparts ad infinitum. What has never been proven or even narrowed down, is exactly what forces are at play with the frame connectors, and in what applications are they notably different.

Posted By: polyspheric

Re: Frame connectors - 06/18/16 06:25 AM

The greatest load in racking (angular twisting of the chassis by application of power, in which the axle planes are no longer parallel) is bending in the vertical plane. More height increases stiffness, which is why rectangular frame connectors are taller than they are wide.

Welding through the floor makes it a structural member, otherwise it's a big tin playing card.

Compare the frame rails of 1/2 ton and 1 ton trucks - the height difference is huge.

Making the tunnel taller is a key element in small sports cars - it's not just to clear the driveshaft. Taller door sills also helps, see my article here:

http://victorylibrary.com/mopar/frame.htm

Posted By: Monte_Smith

Re: Frame connectors - 06/18/16 07:01 AM

The cheapest tubing is cold rolled ERW(Electric resistance welded). It is generally made from 1010 steel.

DOM is made from 1020 or 1026 steel, is also cold rolled and ERW on the seam. The difference is, the flash weld is completely removed on the tubing is cold drawn over a mandrel (DOM). It is a MUCH higher quality tube from both the steel quality and the forming process. Strongest and most dimensionally accurate mild steel, welded seam tubing you can buy.

.120 wall DOM will pass a sonic test in the bends. Rarely will .120 ERW pass, that is why most cheap kits come with .134 wall tubing.

The round is more than adequate for frame connectors

Posted By: jcc

Re: Frame connectors - 06/18/16 03:28 PM

The greatest load in racking (angular twisting of the chassis by application of power, in which the axle planes are no longer parallel) is bending in the vertical plane. More height increases stiffness, which is why rectangular frame connectors are taller than they are wide.

Welding through the floor makes it a structural member, otherwise it's a big tin playing card.

Compare the frame rails of 1/2 ton and 1 ton trucks - the height difference is huge.

Making the tunnel taller is a key element in small sports cars - it's not just to clear the driveshaft. Taller door sills also helps, see my article here:

http://victorylibrary.com/mopar/frame.htm I question the "bending" comment in the first sentence. In maybe a full cage car, I might see the Frame connector seeing bending loads when seeing power induced twisting, besides expected tension/compression, but in our unibody cars, with the stiffest item being the added frame connectors, I'm thinking torsional twist is the bigger stress.

Your informative link worth reading, has one IMO extremely important point, often ignored or overlooked and worth repeating, and in design should be followed closely:

"every effort should be made to attach the rear of the connector directly to the forward end of the rear spring support structure (spring hangar box, trailing arm pivot, &c.). The forward end of the connector should approach the lower control arm mount as closely as possible."

Posted By: CMcAllister

Re: Frame connectors - 06/18/16 06:32 PM

How it is installed is much more important than sizes and shapes. Welding a 4' long tube, regardless how stiff it is, to sheet metal at both ends without supporting what is in the middle, will do more flexing of the weld areas at the ends than it will to stiffen the entire unibody structure. Will it help if you decide you don't want to cut the floor? Yes. But it's not as effective.

Posted By: Monte_Smith

Re: Frame connectors - 06/19/16 07:22 PM

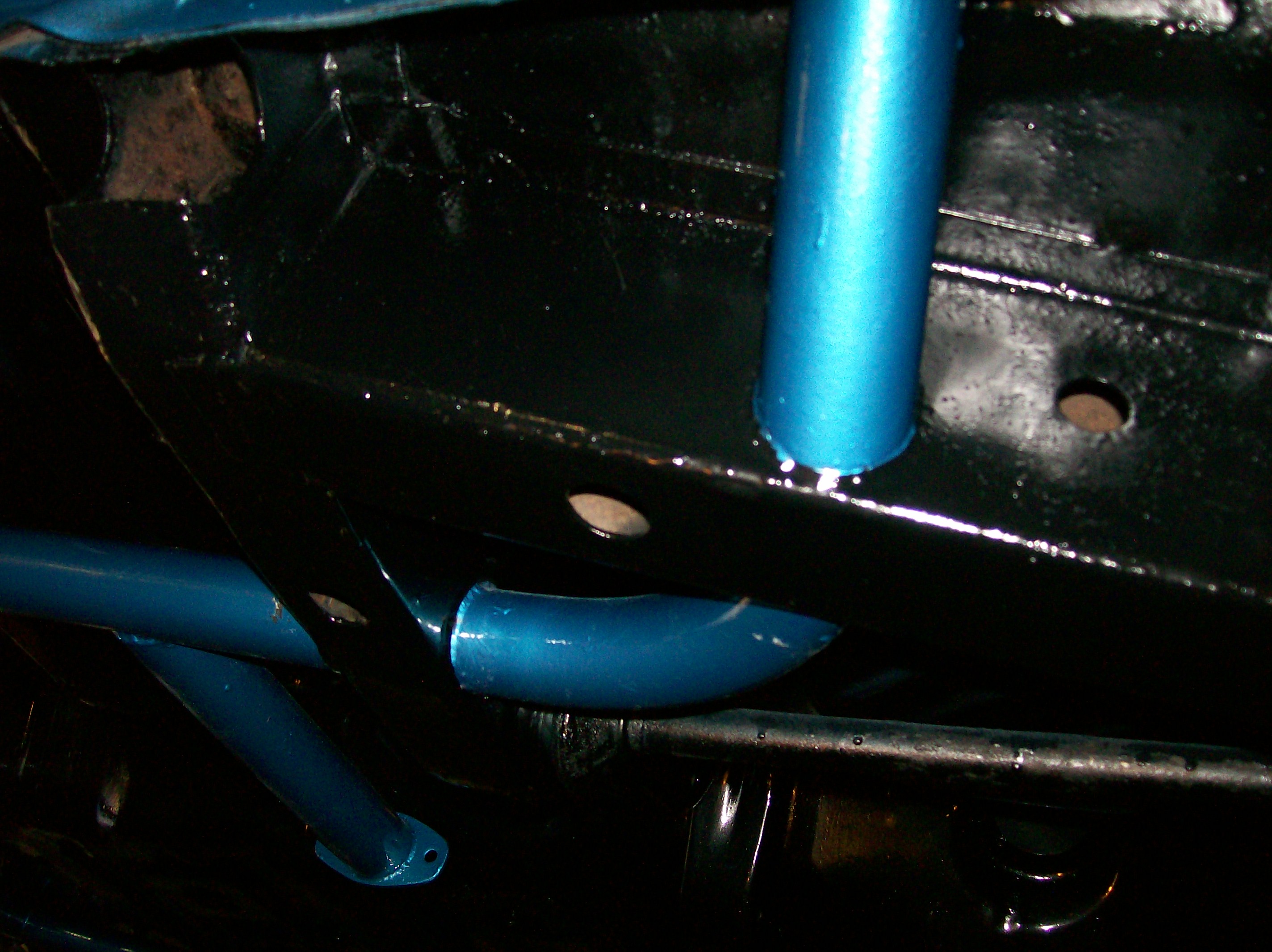

You don't have to sink it in the floor for it to work well, you just have to do it right. I cut a hole in the front of the rear rail and also a hole in the torsion bar crossmember that goes all the way through. The frame tie actually sticks into both the rear rail and the front rail a bit. Then the hole I cut into the backside of t-bar crossmember, to gain access, is plated over and welded to tie as well. You also plug weld tie inside front and rear rails. You weld floor to frame tie wherever it hits

Posted By: DrCharles

Re: Frame connectors - 06/20/16 06:18 PM

This may be a dumb question, but you're talking about

round tube (going all the way through the torsion bar crossmember), right?

Could this be done with 2x3 1/8-wall box tubing also? The way I usually see it installed is with a 2x6" piece of 1/8" plate welded to the box tubing and then the plate welded to the rear side of the crossmember...

Sounds like a big hunk to cut out though.

Posted By: jcc

Re: Frame connectors - 06/20/16 07:05 PM

Not sure what the OP's exact plan was, in my case, when possible, especially when floor pans were removed, I addressed this transfer stress forward issue by adding internal gussets, as needed, inside the TB crossmember where the FC attach. I'd be hesitant to think cutting out big chunks would be best solution, in the big picture.

Posted By: cudaman1969

Re: Frame connectors - 06/20/16 07:37 PM

This may be a dumb question, but you're talking about

round tube (going all the way through the torsion bar crossmember), right?

Could this be done with 2x3 1/8-wall box tubing also? The way I usually see it installed is with a 2x6" piece of 1/8" plate welded to the box tubing and then the plate welded to the rear side of the crossmember...

Sounds like a big hunk to cut out though.

Right, just welding to the crossmember is not strong by itself, if tied to the floor pan, much stronger. Have to remember the sills and tunnel are supporting in the same way, just not tied as good. Welding all the seams, instead of spot welds, would help. Enough flexing(after 50 years) they get loose.

Posted By: DrCharles

Re: Frame connectors - 06/20/16 07:47 PM

Thanks cudaman. I realize it'd be stronger welded to the floor pan everywhere, but there is considerable disagreement (over on FABO, for example) as to just how

much stronger...

http://www.forabodiesonly.com/mopar/threads/sub-frame-connectors-please-build-them-correctly.286631/What I really want to know is, could I cut a 2x3" hole in both the front and rear sides of the t-bar crossmember and slide the box tubing all the way through and weld both sides (as Monte recommended with the round tube)? Again, that would definitely be stronger than a plate connection to only the rear face of the crossmember, but will it be

enough stronger to complicate the installation that way.

Posted By: cudaman1969

Re: Frame connectors - 06/20/16 10:21 PM

Thanks cudaman. I realize it'd be stronger welded to the floor pan everywhere, but there is considerable disagreement (over on FABO, for example) as to just how

much stronger...

http://www.forabodiesonly.com/mopar/threads/sub-frame-connectors-please-build-them-correctly.286631/What I really want to know is, could I cut a 2x3" hole in both the front and rear sides of the t-bar crossmember and slide the box tubing all the way through and weld both sides (as Monte recommended with the round tube)? Again, that would definitely be stronger than a plate connection to only the rear face of the crossmember, but will it be

enough stronger to complicate the installation that way.

Are you lining up the tubing with the front frame and rear frame? If so, yes do that. I attach to the frames by going through the crossmember. Just cut out a section of floor over the frame and crossmember then notch and set the tubing down into the frame and x member (back too). More work but you know it's welded strong and will be no flex. Then you have a full frame from front to back, not just a connector. Easier to weld up top too

Posted By: jcc

Re: Frame connectors - 06/20/16 11:58 PM

This cutting the huge percentage wise holes in the TB crossmember seems to ignore the main purpose of the crossmember's function, and effectively weakens it, to gain stiffness of the FC. The TB crossmeber is ALWAYS taking load, except when on jackstands or wheelstand when airborne. The FC does not. I would strongly suggest thinking this solution, at this scale (size of holes), over very carefully, as it is hard to reverse. I mentioned and others have mentioned alternative solutions.

Posted By: cudaman1969

Re: Frame connectors - 06/21/16 06:27 AM

This cutting the huge percentage wise holes in the TB crossmember seems to ignore the main purpose of the crossmember's function, and effectively weakens it, to gain stiffness of the FC. The TB crossmeber is ALWAYS taking load, except when on jackstands or wheelstand when airborne. The FC does not. I would strongly suggest thinking this solution, at this scale (size of holes), over very carefully, as it is hard to reverse. I mentioned and others have mentioned alternative solutions.

So you cut holes-whatever and not weld them back to the new tubing (box or round)?? The x member is SPOT welded to the sill and SPOT welded to the front frame, now a tube is laid into the x member, welded all around, and the x member is weaker? I'm sure some person can botch this up with sloppy welds-poor fitment but done properly it will be stronger.

Posted By: jcc

Re: Frame connectors - 06/21/16 02:17 PM

Yes the crossmember is weaker, but my concern is more with larger holes and their shape, like the 2x3 already mentioned, any hole makes it weaker, even when the cut out is welded 100%, unless the intersecting member has its own internally added gusset, the point being, bigger hole is worse. Whether the decrease in strength is acceptable, is why people drive fords, chevys, and mopars.

Posted By: A/MP

Re: Frame connectors - 06/21/16 04:50 PM

I can understand that cutting front and rear holes in the front member is stronger if you have a new chassis. If we are speaking of factory steel that is 50+ years old, I'd say no. I don't like hanging pipe just off the back side if the crossmember. After looking at bolt on frame connectors, I built a flange that gives me some beef to hang that connector while I also tie it directly, at that point, to the crossmember. Then I pick up a few more good tacks where the flange meets the crossmember, about 2-3" right and left. For my next build, I will fabricate a U channel that I will slip over the crossmember with welds on both sides. This should strengthen the crossmember. It will then place stress where the frame connector is attached. I never believed that the factory sheet metal and tubing was ever that great. Add 50+ years of stress and rust and then add heat from your welds and it just adds the to weakness of the steel in general. So whatever bracing that you can do to force the load over a longer distance, is in my opinion, a better solution.

Posted By: Monte_Smith

Re: Frame connectors - 06/21/16 05:25 PM

This cutting the huge percentage wise holes in the TB crossmember seems to ignore the main purpose of the crossmember's function, and effectively weakens it, to gain stiffness of the FC. The TB crossmeber is ALWAYS taking load, except when on jackstands or wheelstand when airborne. The FC does not. I would strongly suggest thinking this solution, at this scale (size of holes), over very carefully, as it is hard to reverse. I mentioned and others have mentioned alternative solutions.

You could take a hole saw and cut holes all through the TB crossmember and not weaken it. You could also do the same to your front frame rails and 2x3 subframe connectors and not weaken them in the direction they are designed to support. This is simple engineering principles. The purpose of the TB crossmember is to hold the front of the car up. That's where the springs(torsion bars) mount. The bars are basically trying to twist that crossmember out of the car in a vertical motion. Since they can't twist the crossmember out, they push the car up. Drilling holes will not effect the strength of that crossmember in a vertical plane.

Plus when I say I cut holes, I do it for a purpose. I cut a hole right behind the front frame rail and actually insert my tubing up INTO to the front frame rail and plug weld it, plus plate it inside the TB crossmember, as well as plating the outside where the tubing enters. All this actually ties the frame connector TO the front frame, which is the point of the entire exercise.

Frame ties do exactly THAT. They tie the front and rear frame rails together...........so to properly DO that, the tie needs to actually attach TO the front frame rail, not the backside of a sheetmetal crossmember welded behind it. As I said, I run the tie inside the front rail, but I have seen guys bring the tubing through the TB member and weld it to a plate on the side of front frame rail, where it kicks out

Posted By: CMcAllister

Re: Frame connectors - 06/21/16 05:55 PM

Drilling or cutting a hole through a piece of tube or box, passing a piece of tube or box of proper strength through it and welding both sides is much preferred (to me anyways) to just welding something to the side of the main member. Especially if it is subject to flex. It acts as a reinforcement to the main member rather than flexing and maybe cracking it at the weld. Done all the time, suspension mounts, weight bars, anything substantial or heavy enough to crack the piece it's being attached to.

Posted By: cudaman1969

Re: Frame connectors - 06/21/16 08:14 PM

This cutting the huge percentage wise holes in the TB crossmember seems to ignore the main purpose of the crossmember's function, and effectively weakens it, to gain stiffness of the FC. The TB crossmeber is ALWAYS taking load, except when on jackstands or wheelstand when airborne. The FC does not. I would strongly suggest thinking this solution, at this scale (size of holes), over very carefully, as it is hard to reverse. I mentioned and others have mentioned alternative solutions.

You could take a hole saw and cut holes all through the TB crossmember and not weaken it. You could also do the same to your front frame rails and 2x3 subframe connectors and not weaken them in the direction they are designed to support. This is simple engineering principles. The purpose of the TB crossmember is to hold the front of the car up. That's where the springs(torsion bars) mount. The bars are basically trying to twist that crossmember out of the car in a vertical motion. Since they can't twist the crossmember out, they push the car up. Drilling holes will not effect the strength of that crossmember in a vertical plane.

Plus when I say I cut holes, I do it for a purpose. I cut a hole right behind the front frame rail and actually insert my tubing up INTO to the front frame rail and plug weld it, plus plate it inside the TB crossmember, as well as plating the outside where the tubing enters. All this actually ties the frame connector TO the front frame, which is the point of the entire exercise.

Frame ties do exactly THAT. They tie the front and rear frame rails together...........so to properly DO that, the tie needs to actually attach TO the front frame rail, not the backside of a sheetmetal crossmember welded behind it. As I said, I run the tie inside the front rail, but I have seen guys bring the tubing through the TB member and weld it to a plate on the side of front frame rail, where it kicks out

Exactly, what I was trying to say and what I do, you said it much better.

Posted By: jcc

Re: Frame connectors - 06/21/16 08:50 PM

"You could take a hole saw and cut holes all through the TB crossmember and not weaken it. You could also do the same to your front frame rails and 2x3 subframe connectors and not weaken them in the direction they are designed to support. This is simple engineering principles."

Whatever.

Posted By: @#$%&*!

Re: Frame connectors - 06/22/16 06:18 AM

I'm with you, JCC. And instead of casually stating "engineering principles" I actually went to engineering school for 7 years...

Posted By: Monte_Smith

Re: Frame connectors - 06/22/16 08:37 AM

Well then, how about explaining how a few holes in a piece of 2x3 tubing radically weakens it on the vertical plane, when you have it standing up. I am all ears

Posted By: moparx

Re: Frame connectors - 06/22/16 01:34 PM

Well then, how about explaining how a few holes in a piece of 2x3 tubing radically weakens it on the vertical plane, when you have it standing up. I am all ears

then welding said "passing through" tubing to both sides plus adding reinforcement plates to both sides as well. i'm not picking sides here. in over 50 years of playing, plus 42 1/2 years of machining stuff for a living, i have seen text book "proper principals" fail miserably and "hill billy engineering" succeed way beyond anything should be allowed to do going against "proper practices.

Posted By: Monte_Smith

Re: Frame connectors - 06/22/16 04:53 PM

This isn't hillbilly engineering. This is the same principle that means a truss is just as strong as a solid beam in some instances.