Moparts

lifter valley plate for trick flows

Posted By: Jimbo

lifter valley plate for trick flows - 05/03/16 12:07 AM

Just wondering what everyone is using for valley plates for these heads, since there isn't a specific one for the application.

Posted By: DblOJoe

Re: lifter valley plate for trick flows - 05/03/16 01:36 AM

I used the Indy plate with mine. Took a little work with a grinder but it worked. Just used right stuff to fill in the gap.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/05/16 10:24 PM

The problem with using a valley plate is that there isn't any surface area to seal against. The valley plate meets the head on a knife edge. You can fill in the gap with some RTV but I don't know how long it will last.

Posted By: fourgearsavoy

Re: lifter valley plate for trick flows - 05/06/16 01:50 AM

Interesting that Edelbrock hasn't stepped up to the plate yet to make one of these

Hmmm... I wonder if anyone else has one programmed in the CNC file yet

I wish these heads were available when I built my engine

Gus

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/06/16 05:54 AM

The billet valley plates have a taper on the edges since they are designed to fit under an Indy head. When you use them with a standard head such as the Edelbrock or Trick Flow then you end up with a narrow gap between the knife edge and the head. You can fill in the gap with RTV but I think it will leak fairly quickly.

I can think of a couple of possible solutions but I'll have to make the parts myself to fix the issue since nobody else has solved the problem yet.

.JPG)

Posted By: rebel

Re: lifter valley plate for trick flows - 05/06/16 08:12 AM

i did this for my Stage 6 heads. a little bit of sealer when you screw it down & its done.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/06/16 04:43 PM

Yeah that idea works for Stage 6 heads but it doesn't work on Trick Flow heads.

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/06/16 05:51 PM

i did this for my Stage 6 heads. a little bit of sealer when you screw it down & its done.

Are you runnin a pcv valve or a vac pump...............

Posted By: Brian Hafliger

Re: lifter valley plate for trick flows - 05/06/16 06:06 PM

The billet valley plates have a taper on the edges since they are designed to fit under an Indy head. When you use them with a standard head such as the Edelbrock or Trick Flow then you end up with a narrow gap between the knife edge and the head. You can fill in the gap with RTV but I think it will leak fairly quickly.

I can think of a couple of possible solutions but I'll have to make the parts myself to fix the issue since nobody else has solved the problem yet.

If you do I'd buy a few from you...maybe TF would carry them too! Might work well with their MW head when released!

Posted By: 66er

Re: lifter valley plate for trick flows - 05/06/16 06:30 PM

I use an Indy style valley plate with RPM heads. I put Rite Stuff between my intake and the bevelled edge of the plate. There is a fairly large sealing surface in that area. I've been running this way for a couple years with zero leaks.

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/06/16 06:40 PM

I use an Indy style valley plate with RPM heads. I put Rite Stuff between my intake and the bevelled edge of the plate. There is a fairly large sealing surface in that area. I've been running this way for a couple years with zero leaks.

Any pics............

Posted By: 66er

Re: lifter valley plate for trick flows - 05/06/16 07:00 PM

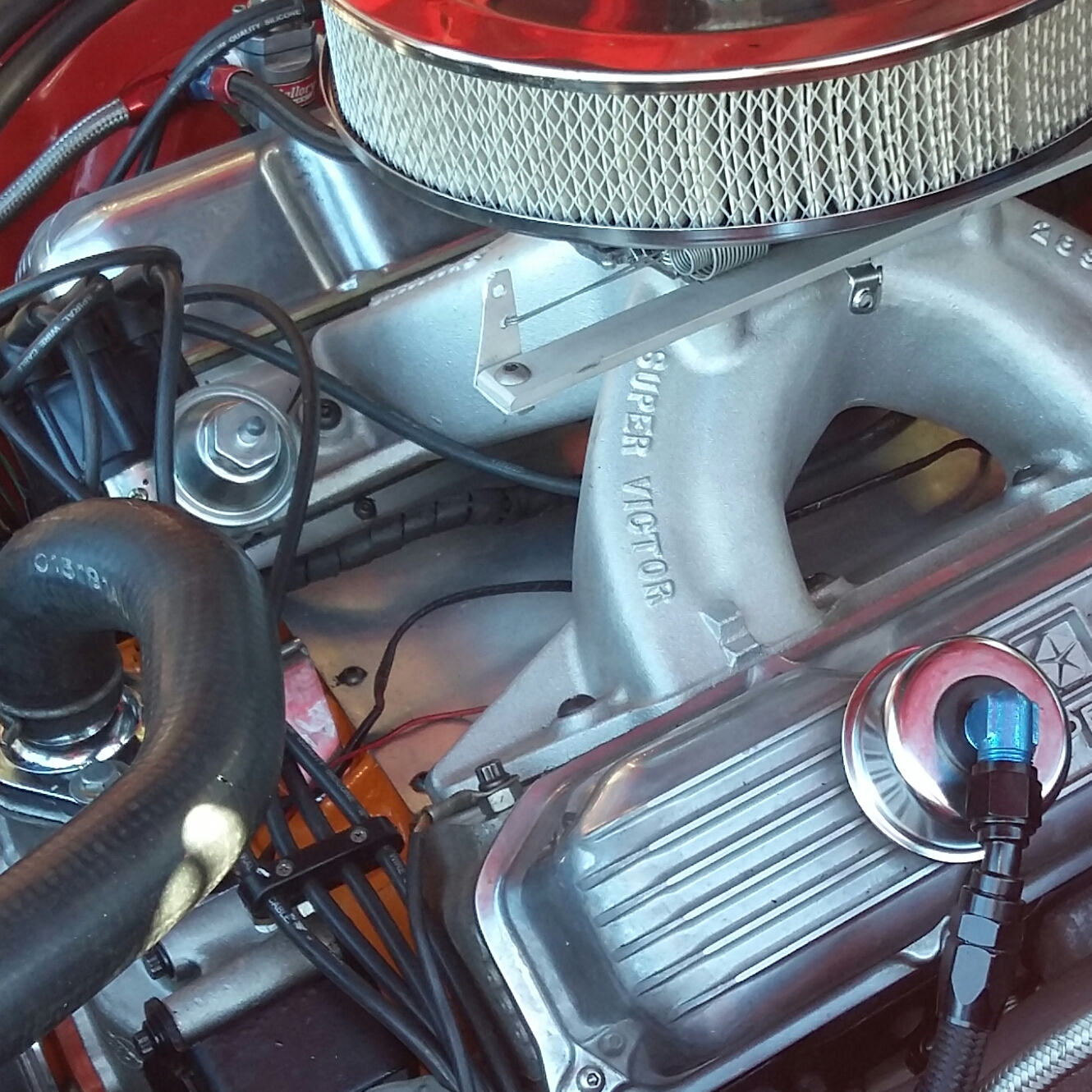

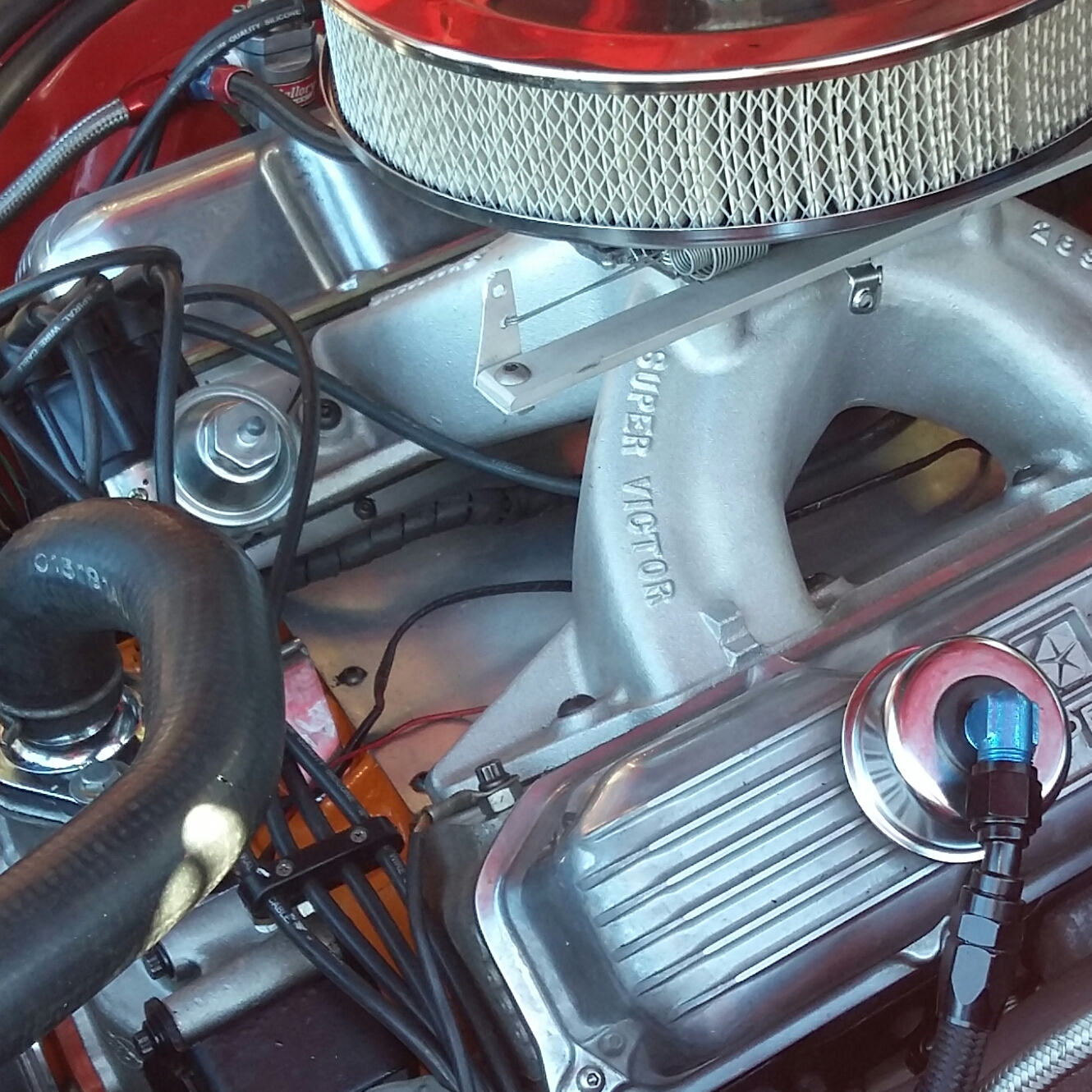

I don't know if you can see it but here's a picture

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/06/16 07:09 PM

Are the ports raised or significantly larger that an oe pan wont work?

I had some stage 6 heads that the ports were raised higher than stock stage 6s. I made a factory style, port encircling pan for that set up. not a big deal for me.

Seems that if a special pan is needed it would be very easy to have made.

I have access to a laser and brake. Let me know if this is something that needs to be on the market.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/06/16 08:04 PM

The billet valley plates have a taper on the edges since they are designed to fit under an Indy head. When you use them with a standard head such as the Edelbrock or Trick Flow then you end up with a narrow gap between the knife edge and the head. You can fill in the gap with RTV but I think it will leak fairly quickly.

I can think of a couple of possible solutions but I'll have to make the parts myself to fix the issue since nobody else has solved the problem yet.

If you do I'd buy a few from you...maybe TF would carry them too! Might work well with their MW head when released!

If the guys at Trick Flow think about the problem at all they'll raise the ports on the MW version. Once the ports are raised and the intake surface extended this whole problem goes away. If they release a set of MW heads with stock port location then they just shoot themselves in the foot since single 4bbl intakes won't fit and the flow will be poor.

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/06/16 09:56 PM

I get the idea thankxxx.............Greg at Superformance made his own and looks good also so I`ll whittle something up............

Posted By: RT540

Re: lifter valley plate for trick flows - 05/06/16 10:02 PM

My old B1BS heads had an alum. bar bolted under the edge of the intake port of the heads that was milled 45 degrees. The bara also had small threaded holes for allen screws.

I still have some pics, if anyone would like to see!

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/06/16 10:24 PM

My old B1BS heads had an alum. bar bolted under the edge of the intake port of the heads that was milled 45 degrees. The bara also had small threaded holes for allen screws.

I still have some pics, if anyone would like to see!

Sure.............

Posted By: rebel

Re: lifter valley plate for trick flows - 05/06/16 11:17 PM

i did this for my Stage 6 heads. a little bit of sealer when you screw it down & its done.

Are you runnin a pcv valve or a vac pump...............

neither, i have a catch can it vents into.

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/07/16 01:53 AM

Gotcha............

Posted By: dartman366

Re: lifter valley plate for trick flows - 05/07/16 02:15 AM

The billet valley plates have a taper on the edges since they are designed to fit under an Indy head. When you use them with a standard head such as the Edelbrock or Trick Flow then you end up with a narrow gap between the knife edge and the head. You can fill in the gap with RTV but I think it will leak fairly quickly.

I can think of a couple of possible solutions but I'll have to make the parts myself to fix the issue since nobody else has solved the problem yet.

If you do I'd buy a few from you...maybe TF would carry them too! Might work well with their MW head when released!

Ditto that, I'm going to be needing one my self with the removeable inspection plate.

Posted By: Brian Hafliger

Re: lifter valley plate for trick flows - 05/07/16 02:33 AM

Andy I haven't seen the MW head, so I can't say what they're doing with it but I'm pretty sure they will be casting an intake to go with it....

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/07/16 02:53 AM

I've sent a couple of emails to Trick Flow telling them they need to do a high port version of the head. There is a lot of material there so it should be fairly easy to do. Just move the ports up as they move them out. If they would extend the intake face by 1/2 inch and move the ports up 1/2 inch the head would flow better and they would get rid of the bathtub gasket and all of the associated issues.

They never responded to my emails so I doubt they'll take the advice but it would make the head an even bigger winner. Standard intakes would still bolt on, they would just be raised up a slight amount. The port would be the same size but it would be a straighter shot to the valve rather than an S shape like it is now.

But regardless of what they do, I have a solution for the valley tray issue. I have a design ready to get cut and should have parts on my engine to test before too long.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/09/16 09:03 PM

I have the new parts designed and on order. Might be a week or so before I have them in my hand for test fitting. I'm pretty sure this new design will solve the problem.

Posted By: fast68plymouth

Re: lifter valley plate for trick flows - 05/09/16 09:30 PM

In the overall scheme of things, IMO the TF heads are closest in execution to the old Bulldog heads.

The first version of those also had std height ports, but after enough clamering from users they finally changed to a slightly raised/extended runner, eliminating the need for the OE valley pan gasket.

Hopefully, TF will follow suit and offer them like that as well.

It would just make it a better head.

Posted By: RT540

Re: lifter valley plate for trick flows - 05/10/16 06:42 AM

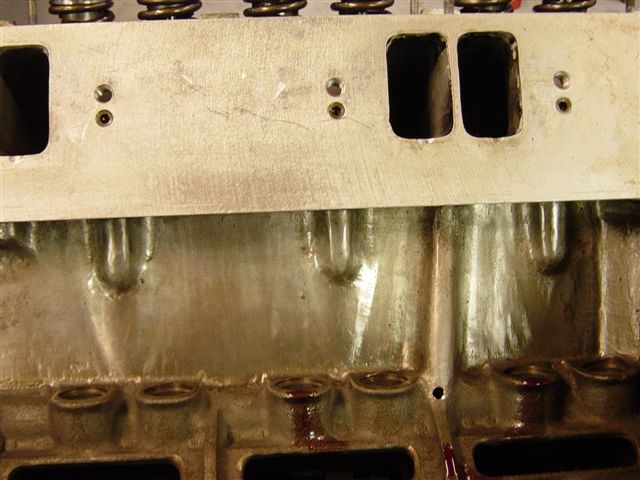

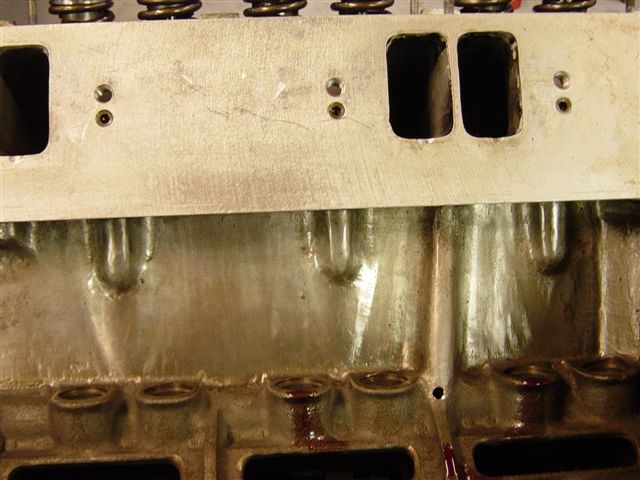

My old B1BS heads had an alum. bar bolted under the edge of the intake port of the heads that was milled 45 degrees. The bara also had small threaded holes for allen screws.

I still have some pics, if anyone would like to see!

Sure.............

Here´s the pict.

Can´t take credit, as the heads came this way when I bought them.

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/10/16 04:56 PM

Very clever..............

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/14/16 10:48 PM

The billet valley plates have a taper on the edges since they are designed to fit under an Indy head. When you use them with a standard head such as the Edelbrock or Trick Flow then you end up with a narrow gap between the knife edge and the head. You can fill in the gap with RTV but I think it will leak fairly quickly.

I can think of a couple of possible solutions but I'll have to make the parts myself to fix the issue since nobody else has solved the problem yet.

If you do I'd buy a few from you...maybe TF would carry them too! Might work well with their MW head when released!

Here is the solution I'm working on. I need to tweak this design a little more and then I think it is ready to try on the dyno. I just made some aluminum "bat wings" which I can then glue a pair of gaskets to. The bottom of the aluminum inner gasket is bent up so it can be sealed with RTV to the valley plate. Should be simple and bulletproof.

.JPG)

.JPG)

Posted By: fast68plymouth

Re: lifter valley plate for trick flows - 05/15/16 12:58 AM

How thick are the new plates?

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/15/16 01:34 AM

I really dig all the stuff you make. Really. But why would you not just make that a simple factory style tub? Seems overly complex for a simple problem, and much more expensive. Also more leak potential with no upside. Am I missing something?

All of this is brought up with the greatest respect... Really.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/15/16 02:12 AM

How thick are the new plates?

I used 0.032 aluminum. So with a pair of the Superformance paper gaskets the stack up is 0.062 which is what I need for this combo. Actually a perfect stackup might be an 0.015 on the bottom and a 0.030 on the top side for a 0.075 total height. I'll have to play around with it a little bit to get a perfect port alignment.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/15/16 02:14 AM

I really dig all the stuff you make. Really. But why would you not just make that a simple factory style tub? Seems overly complex for a simple problem, and much more expensive. Also more leak potential with no upside. Am I missing something?

All of this is brought up with the greatest respect... Really.

Sorry, I don't understand your question. It isn't simple to tool up a factory style tub. I already had a valley plate sitting on the shelf so these little bat wings are easy to make.

It would be great if someone tooled up a factory style tub for fully ported heads but I'm not holding my breath.

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/15/16 02:29 AM

A single flat piece of aluminum with two bends and port holes. There is no need for the "tub" stamping.

The inspection style plates are only needed for heads that hang over the valley surface.

I understand that if you have one of these plates, that you may want to use it. I just see a heavier, more complex, more expensive part with more leak potential.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/22/16 03:17 AM

I tweaked the design a little bit and got it really close. I think I can ahead and run these. Just a little RTV on the bottom side where it seals to the valley plate and then some grease on the gaskets and it should seal up nice. I was really struggling getting the ports in the bathtub gaskets to line up with the fully ported TF heads.

.JPG)

.JPG)

Posted By: Moparteacher

Re: lifter valley plate for trick flows - 05/22/16 06:40 AM

That looks like it would work to seal factory iron heads to the valley plate as well. What do you think?

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/22/16 06:58 PM

Yes, the same trick should work or ported iron heads or Edelbrock/Stealth heads. I could also easily make the port size in the aluminum portion a custom size if I was doing something crazy like making a raised port Trick Flow head.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/22/16 08:17 PM

Here is the other idea that I'm working on. You can overlap two of these. The overlap area is more than an inch so I'm thinking that a thin coat of RTV would make a pretty good seal. The aluminum is only 0.030 thick so it gets really flimsy in the center but it should work okay for a drag motor.

.JPG)

.JPG)

Posted By: dartman366

Re: lifter valley plate for trick flows - 05/22/16 08:42 PM

on the second design, my only concern would be is if you were using a vac pump which I am planning on doing,maybe the rtv and 3 or 4 sheet metal screw's down the center would do the trick,, I like the first design for my application by using an Indy or Mancini center plate with inspection cover, that should seal better with the cast frame and the sheet stock having the break close to the sealing area for stiffness, both would work good if a vac pump were not used.

Posted By: CSK

Re: lifter valley plate for trick flows - 05/22/16 08:43 PM

Here is the other idea that I'm working on. You can overlap two of these. The overlap area is more than an inch so I'm thinking that a thin coat of RTV would make a pretty good seal. The aluminum is only 0.030 thick so it gets really flimsy in the center but it should work okay for a drag motor.

I need this in Max wedge ports!!!!!

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/22/16 11:05 PM

Why not one piece? make the ports standard size, and leave material around the ports for end user fitment.

Posted By: BradH

Re: lifter valley plate for trick flows - 05/22/16 11:56 PM

Why not one piece? make the ports standard size, and leave material around the ports for end user fitment.

Since you don't like his design, why not try building something yourself, instead of complaining about what Andy's coming up with on his own? You already described what you'd like to see made.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/23/16 12:34 AM

The two piece design is adjustable. I can build a one piece design for my own engine but I wouldn't sell it as a product since I'd get an endless stream of complaints. People build engines with blocks that have been decked or with different head gaskets or with heads that have been milled but then blame me when the valley tray doesn't fit.

The two piece design has slots so it can slide back and forth to adjust for different deck heights, different head gasket thicknesses and different cylinder head heights.

.JPG)

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/23/16 01:57 AM

Why not one piece? make the ports standard size, and leave material around the ports for end user fitment.

Since you don't like his design, why not try building something yourself, instead of complaining about what Andy's coming up with on his own? You already described what you'd like to see made.

I have made what I describe. That's my whole point. It is very easy if you have the equipment. From the parts he's shown, its obvious that he could make one.

I was trying to stay out of the selling aspect, but if someone needs one made just pm me.

All I would need is a couple of simple measurements for anything that is not factory deck ht.

Posted By: BradH

Re: lifter valley plate for trick flows - 05/23/16 03:17 AM

Why not one piece? make the ports standard size, and leave material around the ports for end user fitment.

Since you don't like his design, why not try building something yourself, instead of complaining about what Andy's coming up with on his own? You already described what you'd like to see made.

I have made what I describe. That's my whole point. It is very easy if you have the equipment. From the parts he's shown, its obvious that he could make one.

I was trying to stay out of the selling aspect, but if someone needs one made just pm me.

All I would need is a couple of simple measurements for anything that is not factory deck ht.

Pics?

Posted By: ozymaxwedge

Re: lifter valley plate for trick flows - 05/23/16 03:27 AM

Hey Andy, I love your work and have used plenty of your tricks so I'm not being picky ok.

I made a ali valley tray for some 516 heads that I was using on the track years ago, the problem I had was the thin (1.2 mm about .050)tray broke it' seals on the front and rear of the engine because of vibration. I think your idea will need the flat bars each end and you will need to look at the join. Cheers Al

Posted By: moparx

Re: lifter valley plate for trick flows - 05/23/16 01:08 PM

The two piece design is adjustable. I can build a one piece design for my own engine but I wouldn't sell it as a product since I'd get an endless stream of complaints. People build engines with blocks that have been decked or with different head gaskets or with heads that have been milled but then blame me when the valley tray doesn't fit.

The two piece design has slots so it can slide back and forth to adjust for different deck heights, different head gasket thicknesses and different cylinder head heights.

would there be a stiffening of the two piece if you incorporated a 90*flange approximately 3/8" into the lifter valley on the lower piece ? notching for the china walls of course. or would this be of little benefit ?

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 05/23/16 01:20 PM

I don't have pics of the part not on the engine. The engine had the intake ports moved up .750", so no off the shelf pan would work.

I'm not digging on Andy. His stuff is all top notch, and were I building another BB, he would be on speed dial. I just look for the simplest solution.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/23/16 05:47 PM

The two piece design is adjustable. I can build a one piece design for my own engine but I wouldn't sell it as a product since I'd get an endless stream of complaints. People build engines with blocks that have been decked or with different head gaskets or with heads that have been milled but then blame me when the valley tray doesn't fit.

The two piece design has slots so it can slide back and forth to adjust for different deck heights, different head gasket thicknesses and different cylinder head heights.

would there be a stiffening of the two piece if you incorporated a 90*flange approximately 3/8" into the lifter valley on the lower piece ? notching for the china walls of course. or would this be of little benefit ?

That actually seems like a good idea. By turning one edge down you would make the part stiffer.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/25/16 04:23 AM

Posted By: Brian Hafliger

Re: lifter valley plate for trick flows - 05/25/16 06:00 AM

The two piece design is adjustable. I can build a one piece design for my own engine but I wouldn't sell it as a product since I'd get an endless stream of complaints. People build engines with blocks that have been decked or with different head gaskets or with heads that have been milled but then blame me when the valley tray doesn't fit.

The two piece design has slots so it can slide back and forth to adjust for different deck heights, different head gasket thicknesses and different cylinder head heights.

How about one for me??

Posted By: tex013

Re: lifter valley plate for trick flows - 05/25/16 08:42 AM

didn't Hughes or someone have a 2 piece tray ? was a lot of complaints of leakage at overlap . that may be the hardest area to seal ?

maybe the folded edge will help this by being stiffer . maybe have a threaded bar spot welded to the plate rather than use sheet metal screws at least then they wont tear out

Tex

Posted By: moparx

Re: lifter valley plate for trick flows - 05/25/16 01:39 PM

didn't Hughes or someone have a 2 piece tray ? was a lot of complaints of leakage at overlap . that may be the hardest area to seal ?

maybe the folded edge will help this by being stiffer . maybe have a threaded bar spot welded to the plate rather than use sheet metal screws at least then they wont tear out

Tex

that's a good idea tex. maybe, with a "captured" bar instead of spot welding the aluminum. you could still put a stiffening bend in the middle, but have a couple of extra "tabs" down the length that could simply be folded over the bar, holding it in place. don't know what kind of equipment andy has to facilitate this arrangement though. sounds just like an engineer. take a simple idea and complicate it a bunch, then require extensive special equipment to manufacture. write up comprehensive, complicated instructions for installation and use, then set up exclusive marketing networks to distribute.

still a good idea though ! what ever andy decides, it will be a great product.

Posted By: RT540

Re: lifter valley plate for trick flows - 05/25/16 02:05 PM

For my B1 heads, there was a gap to fill, when the block was heavy milled, so I made these bars from alum.sheet metal. My intake is O-ringded and easy to lift of to get access under.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/25/16 04:39 PM

The two piece design is adjustable. I can build a one piece design for my own engine but I wouldn't sell it as a product since I'd get an endless stream of complaints. People build engines with blocks that have been decked or with different head gaskets or with heads that have been milled but then blame me when the valley tray doesn't fit.

The two piece design has slots so it can slide back and forth to adjust for different deck heights, different head gasket thicknesses and different cylinder head heights.

How about one for me??

You want a one piece design or a pair of the two piece? I can send you some prototype parts if you want. Some fitting may be required......

Posted By: dartman366

Re: lifter valley plate for trick flows - 05/26/16 02:01 AM

Andy, when you get these sorted out and ready for sale please let me/us know, I was telling Doug my engine machinist about your idea and he thought the 2 piece would work well with the cast valley covers giving a shelf to seal with rtv and make a lot cleaner look.

Posted By: AndyF

Re: lifter valley plate for trick flows - 05/28/16 05:57 AM

I cut out a stiffener for the center of the valley. I'll probably just glue it to the plate and call it good.

.JPG)

Posted By: Thumperdart

Re: lifter valley plate for trick flows - 05/28/16 06:01 AM

I like it.............

Posted By: tex013

Re: lifter valley plate for trick flows - 05/28/16 09:01 AM

Tex

Posted By: 9SecRoadRunner

Re: lifter valley plate for trick flows - 05/29/16 01:21 AM

I didn't read all the posts so I'm not sure if this has been suggested, But what I did was get some sheet gasket material, cut out my own intake gaskets leaving an extra 3/8" on the bottom, then I scored it along that extra 3/8" and folded up making like an "L" shape along the bottom, it sat right on the indy plate ... a little sealer and it worked (so far).....

Posted By: AndyF

Re: lifter valley plate for trick flows - 06/13/16 09:46 PM

I ended up making some one piece valley plates as well as reinforcement plates for the center. I'll probably give this a try on the dyno.

.JPG)

.JPG)

Posted By: 72Swinger

Re: lifter valley plate for trick flows - 06/13/16 10:01 PM

For my B1 heads, there was a gap to fill, when the block was heavy milled, so I made these bars from alum.sheet metal. My intake is O-ringded and easy to lift of to get access under.

just an FYI, if that bung in the valley pan is a breather or vacuum pump it will blow oil out by the quart. Been there done that, it won't work.

Posted By: RT540

Re: lifter valley plate for trick flows - 06/14/16 07:04 AM

The AN10 bung have a 90° elbow with a pickup for the last dry sump stage, as I have a 6-stage pump.

Lifter area is sealed of in the center.

Posted By: 72Swinger

Re: lifter valley plate for trick flows - 06/14/16 08:37 AM

The AN10 bung have a 90° elbow with a pickup for the last dry sump stage, as I have a 6-stage pump.

Lifter area is sealed of in the center.

Good, it will get plenty of oil there.

Posted By: AndyF

Re: lifter valley plate for trick flows - 07/03/16 08:39 PM

I think this is the combo that I'm going to use (although I could change my mind again). This is a solid valley plate made from 0.250 aluminum. The plate is beveled on the edges and then I made up a pair of aluminum "bat wings" that will RTV to the bevel on the plate. I'm going to glue paper gaskets to each side of the bat wing.

.JPG)

Posted By: dartman366

Re: lifter valley plate for trick flows - 07/04/16 02:08 AM

Andy, when you get this system ready for sale let me know, I am interested in useing this set-up.

Posted By: AndyF

Re: lifter valley plate for trick flows - 07/04/16 06:52 AM

I can sell you the same parts that are in the picture. I have extra valley plates and bat wings on hand. Just shoot me a PM. If you already have an Indy valley plate then I can sell you just the bat wings. I have solid valley plates for B blocks only. The RB plates that I have on hand have the inspection cover machined in them so they are more expensive.

Posted By: sgcuda

Re: lifter valley plate for trick flows - 07/04/16 04:05 PM

Like mentioned before, there are so many variables as far as head milling, block milling, port size and location, wouldn't it be best to just tig an aluminum plate to the bottom of the intake and seal the ends with RTV like a small block?

Posted By: AndyF

Re: lifter valley plate for trick flows - 07/04/16 11:23 PM

Welding on a plate might work for a guy who only has one intake manifold but it isn't a good solution for me. I have a bunch of intake manifolds to test so I need a "bolt on" solution.

Posted By: AndyF

Re: lifter valley plate for trick flows - 07/06/16 04:21 AM

With the bat wing design I now have very good port alignment. Can't see all of it but what you can see by looking down the runner lines up exactly with the port in the head.

Might be good for a little extra power. I was at 715 last time on the dyno so we'll see what she does this time.

.JPG)

Posted By: AndyF

Re: lifter valley plate for trick flows - 07/30/16 04:37 AM

I sent the valley plate back to the shop for a little weight reduction.

.JPG)

Posted By: ozymaxwedge

Re: lifter valley plate for trick flows - 07/30/16 04:56 AM

NICE, I need to put in more effort with my intake alignment.

Posted By: moparx

Re: lifter valley plate for trick flows - 07/30/16 01:39 PM

I sent the valley plate back to the shop for a little weight reduction.

how much does that weigh now ? good looking for sure !

Posted By: sgcuda

Re: lifter valley plate for trick flows - 07/30/16 02:40 PM

That weight reduction makes it look like a whole different component. Very nice, Andy.

Posted By: AndyF

Re: lifter valley plate for trick flows - 08/15/16 03:35 AM

Now that I have the other head back from machine shop jail I can go back to mocking up the options. The one piece valley cover I built ended up fitting perfectly but I still think I'll go with the 3 piece setup. Here is the one piece. Port match is perfect.

.JPG)

.JPG)

Posted By: AndyF

Re: lifter valley plate for trick flows - 08/15/16 03:38 AM

Here is the 3 piece setup with a solid valley cover and then the pair of batwings. I like this solution better since I can move the batwings around to get the alignment that I want and then just lay a bead of RTV down to seal things up. This solution will also work with different deck heights and different head gasket thicknesses.

.JPG)

.JPG)

Posted By: AndyF

Re: lifter valley plate for trick flows - 09/10/16 05:29 AM

The bat wing design passed the dyno test with flying colors. We made a bunch of dyno pulls without any issues and we made multiple intake swaps. The intake just lifts off without any issue and does not damage the gaskets. So the gaskets can be re-used multiple times.

.JPG)

Posted By: BCFKody

Re: lifter valley plate for trick flows - 09/10/16 05:49 AM

Hi Andy! It appears that you glue (gasgacinch?) the gaskets to both sides of the bat wings, and then spread a little grease (white lithium) on the gaskets so they won't stick. Correct??

Posted By: AndyF

Re: lifter valley plate for trick flows - 09/10/16 05:16 PM

Yep. I use contact cement to glue the gaskets to the aluminum bat wing and then smear some white grease on the intake face of the gasket.

Posted By: AndyF

Re: lifter valley plate for trick flows - 10/28/16 06:58 PM

I decided to move the breather to the valley plate so I had a #12 bung welded to the plate and then used a Peterson breather. I think this will work better than the valve cover mounted breather that I was using.

.JPG)

Posted By: tex013

Re: lifter valley plate for trick flows - 10/29/16 01:26 AM

Andy ,

would this 3 piece plate work with 440 Source heads ?

Tex

Posted By: AndyF

Re: lifter valley plate for trick flows - 10/29/16 02:07 AM

Sure but it is really only needed with a fully ported head. If the heads are unported then the standard bathtub gasket should work just fine.

Posted By: TRENDZ

Re: lifter valley plate for trick flows - 10/29/16 02:22 AM

Trying to be helpful... The valley breather is a tough nut to crack. A lot of oil in suspension there. You need a large amount of well thought out baffling to succeed. Also, with any breather, the larger the inner diameter of the exit tube, the lower the velocity. Velocity is the common culprit of oil escaping from breathers.

Posted By: AndyF

Re: lifter valley plate for trick flows - 11/11/16 05:09 AM

I now have solid valley plates for RB blocks. I had a bunch of people ask me to make them so I went ahead and ran a batch. If you want one you can order it from Hughes or Mancini Racing. Part number is AR300A. Don't forget the A on the end. The AR300 is the two piece cover, the 300A is the one piece version.

.JPG)

Posted By: OUTLAWD

Re: lifter valley plate for trick flows - 11/11/16 02:37 PM

Looks Great Andy! How did the valley breather work out?

Are the Batwings also available? Standard and/or MW port?

Posted By: AndyF

Re: lifter valley plate for trick flows - 11/11/16 06:03 PM

I haven't run the engine with the valley breather yet. I'm in the middle of complete engine re-shuffle with my 470 engine turning into two different 470 engines.

I do have batwings on hand in both the std port as well as the MW port size. I haven't tried the MW port size on an engine yet myself but I've sold some to folks who gave me a thumbs up on the fitment. There are a lot of different MW port sizes floating around as well as different gasket sizes so it wasn't a perfect one-size-fits all solution.

Posted By: Skeptic

Re: lifter valley plate for trick flows - 11/11/16 06:27 PM

It will be interesting to see how the new TF270s will fit into the "MW" port size arena.

Posted By: Cab_Burge

Re: lifter valley plate for trick flows - 11/11/16 06:45 PM

What are "Bat wings" ?