Moparts

carnage at the dyno

Posted By: mopar dave

carnage at the dyno - 03/01/16 02:30 AM

well today was dyno day and i thought it was going to be a great day, but it didnt turn out that way. engine came apart on the 5th short pull. only had 6000rpm on it at the time. not sure what caused it yet. still have to get it apart for examination. on #8 cylinder eagle H beam broke in the middle of the beam and both 8740 rod bolts are broke as well. looks like it took out 2 pistons the cam and the block. total pile of sh!t. also broke the pick up on the oil pump. looks like ill have to start over. it will be interesting to see what the cause was.

Posted By: BradH

Re: carnage at the dyno - 03/01/16 02:41 AM

Ugh...

Posted By: ahy

Re: carnage at the dyno - 03/01/16 02:43 AM

Ouch... the only consolation is better to find it on the dyno vs in the car.

Posted By: Wedgeman

Re: carnage at the dyno - 03/01/16 02:48 AM

Oh non !!!!!!!!!!!!!!!

What a deception !!

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 02:49 AM

absolutely. the main reason i dynoed it.

https://youtu.be/hgoORq5ryWw

Posted By: Darryls-Demon

Re: carnage at the dyno - 03/01/16 02:59 AM

Very sorry to hear that.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 03:06 AM

it had about 45 minutes on it. put it thru a short break in as well. everything looked good, compression test showed all 8 had 195-200psi. checked plugs twice and got the timing dialed in at 35*. the carb was still fat and a jet change was next. i was using one of my new 750 ultras xp straight out of the box. my 850 had some fat issues in the midrange that we didnt want to mess with.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 03:10 AM

thanks. first time it happened to me. i think this was the 5th engine i put together and the first to explode. the number 8 piston looks like the pin was trying to come out the bottom. ill post some pics at the end of the week when i get it apart.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/01/16 03:10 AM

Does the rod look "sawed off" where it hit the block, or just broken. With both rod bolts broken, my GUESS would be oiling issue or it just broke a rod bolt. Usually when one just breaks a rod, the big end stays on the crank.

Watching video, it didn't really sound to be laboring before it broke. So maybe it just broke a bolt. Even beat all to hell, the bearing should show an oil problem if there was one

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 03:16 AM

no it looks hammered and the rod journal is black. the rod bearings where calico and had the black coating so not sure if thats the coating im looking at or a oiling issue. the dyno operator said he thought the motor was down about 50hp at 6000 compared to what he usually sees. idled real good before every pull. had 55psi oil pressure when it broke.

Posted By: sgcuda

Re: carnage at the dyno - 03/01/16 03:29 AM

Man, sorry to see that. You put a lot of work into that piece. I hope at least the heads are salvageable.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 03:31 AM

just took another look at the rod journal. does look like it got hot. wouldnt the #8 rod journal be the first to get oil?

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 03:34 AM

yeah, i dont have those off yet, but we will see.

Posted By: gregsdart

Re: carnage at the dyno - 03/01/16 03:36 AM

Sorry to hear about the failure!

Posted By: HotRodDave

Re: carnage at the dyno - 03/01/16 03:36 AM

Perhaps the crank was out of round? How do the other bearings look? What brand crank?

Be a good time to upgrade to a magnum block at the least.

Posted By: justinp61

Re: carnage at the dyno - 03/01/16 03:37 AM

Darn Dave, sorry about your engine.

Posted By: Hot 340

Re: carnage at the dyno - 03/01/16 03:39 AM

That is awful. Sorry to see that.

that #8 is usually the first bearing to cook on a sb with oiling issues.

VERY sorry to hear this Dave.

Posted By: Dragula

Re: carnage at the dyno - 03/01/16 03:54 AM

well today was dyno day and i thought it was going to be a great day, but it didnt turn out that way. engine came apart on the 5th short pull. only had 6000rpm on it at the time. not sure what caused it yet. still have to get it apart for examination. on #8 cylinder eagle H beam broke in the middle of the beam and both 8740 rod bolts are broke as well. looks like it took out 2 pistons the cam and the block. total pile of sh!t. also broke the pick up on the oil pump. looks like ill have to start over. it will be interesting to see what the cause was.

Totally sucks, sorry to hear that.

Posted By: madscientist

Re: carnage at the dyno - 03/01/16 04:01 AM

I can't tell from the picks where it got the block. Did it take out a pan rail or something else I missed?

It's hard to say about the oiling and does number 8 get it first. It is technically a constant flow system so once there is pressure if the pump can keep they should all get oil all the time. My experience shows 3 and 4 are the first not to get oil but that is usually about 8000 RPM.

Bad deal for you for sure.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/01/16 04:04 AM

Black crank throw...........it grabbed a bearing.

Main web looks cracked. Possible that happened first. Crank may be broken.

Rod didn't break.......it got sawed off

Posted By: justinp61

Re: carnage at the dyno - 03/01/16 04:36 AM

I can't tell from the picks where it got the block. Did it take out a pan rail or something else I missed?

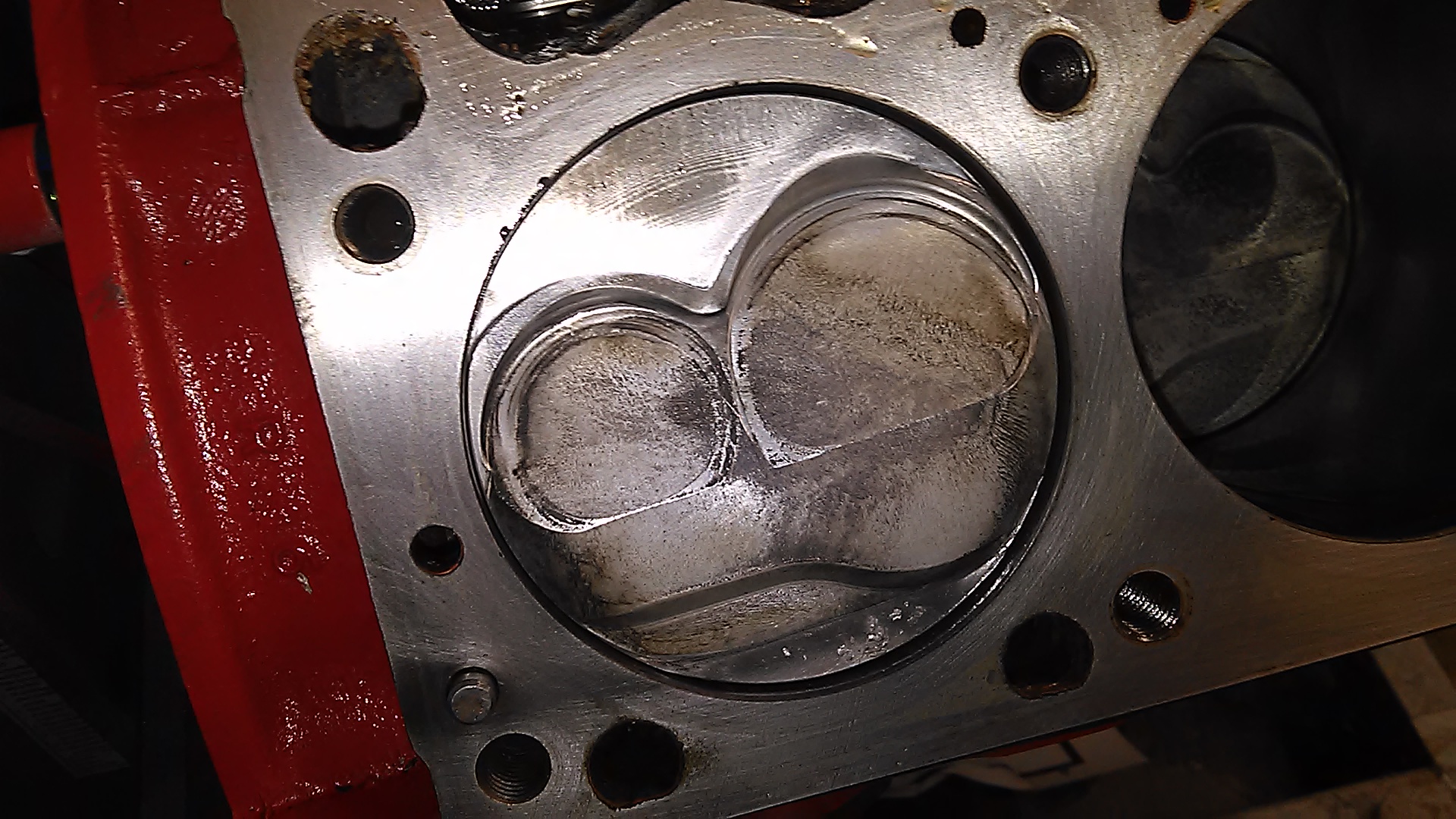

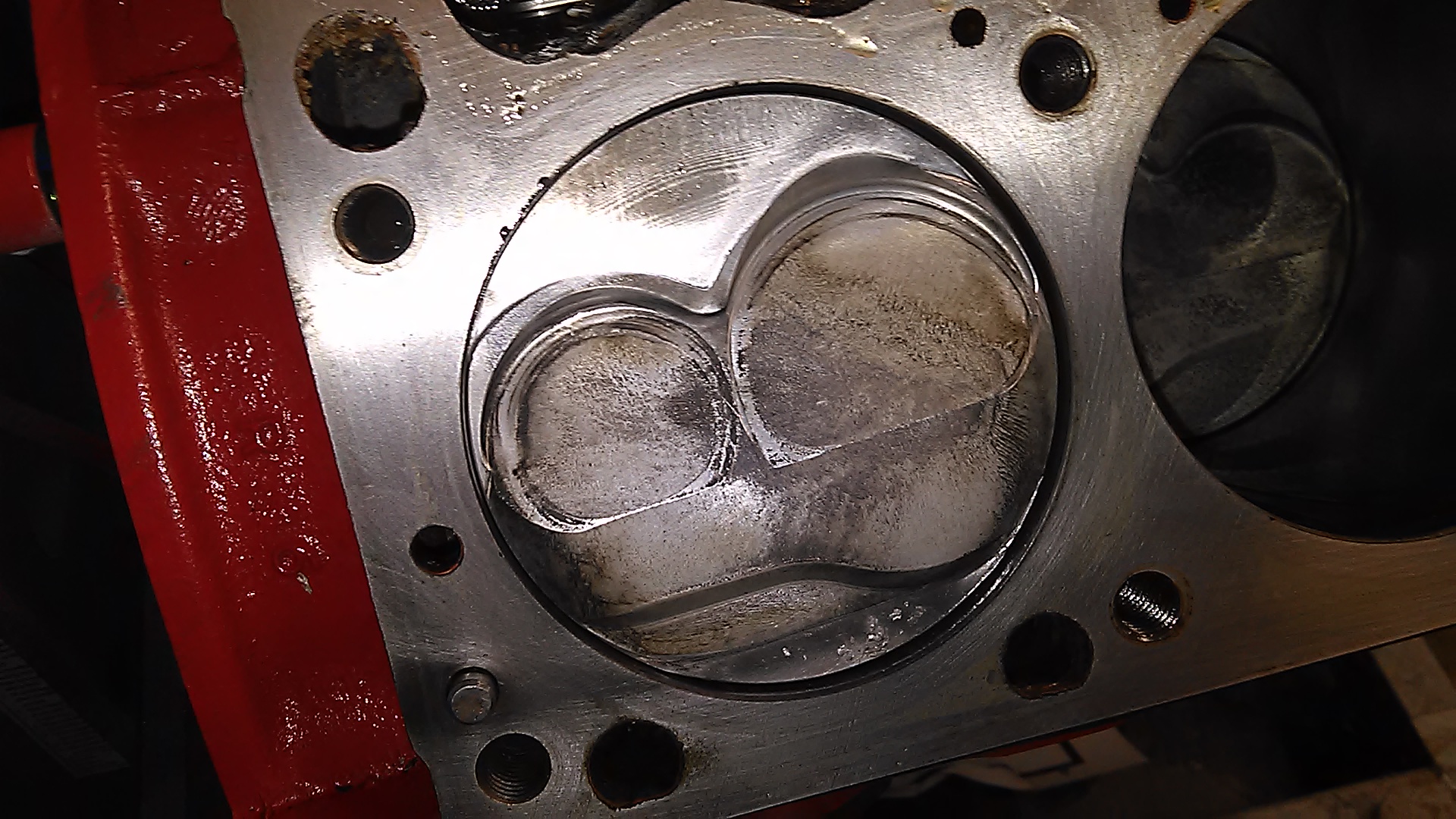

In the first photo, there is a notch in the bottom of the cylinder on the cam side.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 04:47 AM

why is that. i thought that was the first one to get oil?

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 04:50 AM

thats from the rod. put a nice notch in it.

Posted By: Hot 340

Re: carnage at the dyno - 03/01/16 04:56 AM

why is that. i thought that was the first one to get oil?

Im not sure why. Just what ive seen. Ive seen more number 8's jacked up than any of the rest of the journals.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:13 AM

havent looked at the other bearings yet and wont have time til this weekend, but why would #8 get the least oil.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:15 AM

dont make sense. i opened up all those passages. one thing i did do diffently this time was use single groove main bearing. will be going back to a full groove next time for sure.

Posted By: madscientist

Re: carnage at the dyno - 03/01/16 05:22 AM

dont make sense. i opened up all those passages. one thing i did do diffently this time was use single groove main bearing. will be going back to a full groove next time for sure.

I don't think I ever hurt number 8. If all,it did was notch the bores just sleeve it unless you have a bunch of blocks around.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:24 AM

didnt take out the pan rail, but it sure did a number on the bottom of the cylinder. pretty sure the block is toast.

Posted By: 72Swinger

Re: carnage at the dyno - 03/01/16 06:22 AM

I feel for your loss, get it apart, sweep up the mess and get after it again. Only thing that gets you over something like that is a newer better one, just like women.

Posted By: dizuster

Re: carnage at the dyno - 03/01/16 06:38 AM

That sucks man, sorry to see this.

How much rod bearing clearance did it have?

Posted By: Leigh

Re: carnage at the dyno - 03/01/16 10:45 AM

Sorry to hear. Hope things work out for you.

Posted By: Ian

Re: carnage at the dyno - 03/01/16 02:03 PM

sorry to here that dave ,is it a 4340 crank and were they new rods or new rod bolts

Posted By: lewtot184

Re: carnage at the dyno - 03/01/16 02:54 PM

what was the oil system; pan, pick-up, pump?

Posted By: an8sec70cuda

Re: carnage at the dyno - 03/01/16 03:07 PM

Wow, sorry to see this! Hopefully you can salvage the topend and get something going again soon.

Posted By: gregsdart

Re: carnage at the dyno - 03/01/16 03:23 PM

didnt take out the pan rail, but it sure did a number on the bottom of the cylinder. pretty sure the block is toast.

Hopefully the block can be saved? Never done it, but maybe a Diesel engine repair shop might be able to weld up any cracks.

Posted By: Tempest

Re: carnage at the dyno - 03/01/16 03:44 PM

Sucks. Been there (not on dyno) but had one come apart at 7,200. Not much left and just had to start completely over.

Posted By: Roughbird72

Re: carnage at the dyno - 03/01/16 04:31 PM

Sorry to hear this.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:10 PM

a little over .002" (.00225)? and .0033" on mains. only thing I did different was I used a single groove main bearing. the block,crank and rods came from the last build I had and it went 8yrs. that last build had .002 on the mains and rods and never had a issue.

Posted By: 11secdart

Re: carnage at the dyno - 03/01/16 05:17 PM

Sorry to hear it man, I feel your pain I lost one on the dyno about a year ago it didnt break anything but burnt the crank and one rod. It happened on the forth dyno pull and was also down about 50 h.p.. I would have been real upset if it hurt my R3 block as they are almost impossible to find. This is also why I dyno all my motors better on the dyno at the engine builders shop than at the track. It got back together and made even more power and torque than what I expected for what the combo is. I hope you find the problem

And build it even stronger and better.

Posted By: hemi-itis

Re: carnage at the dyno - 03/01/16 05:18 PM

Very painfull to watch

Hope you get something back together soon

Posted By: Streetwize

Re: carnage at the dyno - 03/01/16 05:18 PM

So vey sorry to hear about this, Dave. I know you poured your heart and soul into this one, Please let me know if there's anything I can do to help out my friend.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:19 PM

thanks for the good thoughts guys. once I get it apart and figure what went wrong or what I did wrong I will know what direction to go. I do have a 400 block I have been wanting to do something with. Ian the rods were used but I did have them checked at a shop and new 8740 bolts were used. right now I'm thinking Monty may be correct as it looks like it may have grabbed the bearing broke the bolts and sawed the rod in half. definitely a learning lesson here.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 05:23 PM

hey thanks a bunch man. that's cool. I appreciate all the help guys, thanks. I will not rest til I figure what caused this and I will not be making this mistake again.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/01/16 05:27 PM

Bummer Dave.. I have been in the same boat with

my Rampage.. it didnt blow up but did tear up

the bearings and a little on the crank... good

luck with it

That sucks for sure.

Usually, if there is a wasted bearing and/or a darkened/blackened journal, that's what caused the failure.

Why that happened in your case.......that's what you need to try and figure out.

My friends "good" stocker motor ate a rod bearing on the dyno last fall, and that's a motor that has been run for years, and been on the dyno many many times.

The power was down just a tick and it wasn't repeating as good as it usually does, but that thing uses a Q-jet, and those can be fussy. We did a couple of carb swaps, seemed to be making some progress, and actually got to a point where it made the most it ever had.

We took a break and went for lunch. After we came back and resumed testing the power was down about 15-20hp. The first pull after the motor has sat for a while is usually down a bit but not that much.

Oil pressure seemed a little low after the pull. Loaded the motor to make another pull, TQ looked like it was way down....... And I just shut it off. I knew something had gone away.

Pulled the filter and took it apart(system 1), saw some filings.....we were done.

I don't recall which rod bearing failed, but all the rest of the bearings looked perfect.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 06:26 PM

thanks Mike. i will get it figured out. if the block is scrap i think im gonna start on the 400 block and sell off all my small block stuff.

Posted By: dvw

Re: carnage at the dyno - 03/01/16 06:29 PM

Sorry to hear. Were the rod size checked after the bolt swap?

Doug

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 06:37 PM

same scenario here. did you figure out the cause?

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 07:33 PM

yes it was checked and I checked the bearing cleances several times. I was alittle concerned with the rod bearing clearances so I called hughes since that's where I bought the calico coated rod bearing. they were not concerned with .002" said run thinner oil. I used gibbs 15/50 because the mains were .0033. the rod bearing is wadded up and hard to read.

Posted By: Leon441

Re: carnage at the dyno - 03/01/16 08:27 PM

Rod and main clearance is a balance of those clearances, the top end oiling and oil weight.

.0033 on the mains is fairly common. Then going .002 on the rod. With aluminum rods fine sense they grow. May have been to tight when considering it's fed from the main. Only #8 is fed from #5 main. Where as the middle journals are feeding two rods each. The rear main wasn't upside down was it? Look at the #5 main bearing.

Posted By: mopar dave

Re: carnage at the dyno - 03/01/16 09:57 PM

I will check that out, but I don't think it was. I'll get it apart Sunday and see if I can make heads or tails out of this mess. Thanks

Posted By: dthemi

Re: carnage at the dyno - 03/02/16 02:20 AM

Sorry man, that gives me a knot in my stomach to see. Hope something can get salvaged.

Like others said, next time use .003 at least on the rods. Better.005, than .002.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 02:40 AM

Standard rod bearing on a 2 under and full groove mains is what I have in mind.

Posted By: dthemi

Re: carnage at the dyno - 03/02/16 02:51 AM

Just personally, I don't like full groove mains. I tried them several times years ago and they never held up, or looked as good as a grooved upper with a solid lower. The HP King bearings have been for me the best at doing the work. they have a ton of taper in them, that will help deal with either a poorly machined, or high power flexing crank.

Posted By: HotRodDave

Re: carnage at the dyno - 03/02/16 03:06 AM

I been studying hard the oiling in my stroker I am building and it seems the full groove would help the rod bearings live longer because they have access to pressurized oil when the cylinder pressure is highest. The 1/2 groove only sends pressurized oil to the rod on the bottom half of the stroke. Weather or not that amounts to a hill of beans under dynamic conditions I could not tell you but it does seem odd they do it that way from the factory.

In order to keep more oil on the crank on mine I drilled smaller oil feed holes in the cam bearings as they are getting fed right off the oil going to the mains. When everything is done right in a SB oiling don't seem to be a big issue from what I have seen. I almost always use standard volume pumps and don't seem to have much issue getting enough pressure.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 03:38 AM

I shouldn't of had this problem. Same block with all oil galleys opened up, same crank and rods. Used full groove on last two builds and didn't have this issue. I use half groove and boom!

Posted By: ProSport

Re: carnage at the dyno - 03/02/16 05:02 AM

Sorry to hear Dave, I know you were excited to get it running and try the TR eventually.

Posted By: WHITEDART

Re: carnage at the dyno - 03/02/16 05:05 AM

Man the is a real bummer. Hopefully the replacement isn't too painful

Posted By: Moparnut426

Re: carnage at the dyno - 03/02/16 05:07 AM

That is NOT what anyone ever wants to see happen on the Dyno.

SUX man!..

Posted By: madscientist

Re: carnage at the dyno - 03/02/16 05:14 AM

I been studying hard the oiling in my stroker I am building and it seems the full groove would help the rod bearings live longer because they have access to pressurized oil when the cylinder pressure is highest. The 1/2 groove only sends pressurized oil to the rod on the bottom half of the stroke. Weather or not that amounts to a hill of beans under dynamic conditions I could not tell you but it does seem odd they do it that way from the factory.

In order to keep more oil on the crank on mine I drilled smaller oil feed holes in the cam bearings as they are getting fed right off the oil going to the mains. When everything is done right in a SB oiling don't seem to be a big issue from what I have seen. I almost always use standard volume pumps and don't seem to have much issue getting enough pressure.

The issue is the oil timing is wrong on these engines. You should have full oil pressure to the rods at 70* ATDC and that is IIRC but it is close to that. That's why a Chevy doesn't need full groove mains. The Chryslers get full oil pressure way before they need it so the full groove mains helps that. Seems to be worse on the SB but it is wrong on both. The higher the engine speed, the worse it gets.

There are only two fixes for the high rpm stuff (unless you get a block that has the oil passage in the correct location).

One is have a crank drilled with the oil hole turned counterclockwise. The other is more complicated. That is the only way I know to correct it.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 05:31 AM

I still haven't given up on the SB yet. I was offered a good 360 block from a member here. Just pay freight. There are a lot of good guys on this forum. I'm interested. I will need a set of rods and 2 pistons a rebalance and a cam. That's doable. I might even have the crank ground for more stroke. Will see. Thanks again guys

Posted By: justinp61

Re: carnage at the dyno - 03/02/16 05:38 AM

Dave you're making me rethink using 1/2 groove mains on my 434. I had to order a set of .001" unders so I have the other grooved half. My rods are 2.00" and the clearances are .0023-.0025" using King aluminum rod bearings and King mains.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 07:26 AM

well, i'm not certain what caused this yet. I will get it apart and examined sunday and go from there. I may change this build up alittle with possible added stroke and more cam.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/02/16 08:26 AM

I wouldn't be so quick blame the mains, or crank needs cross drilled, or anything else. My first thought is it was too tight

Posted By: 1Fast340

Re: carnage at the dyno - 03/02/16 10:07 AM

thanks. first time it happened to me. i think this was the 5th engine i put together and the first to explode. the number 8 piston looks like the pin was trying to come out the bottom. ill post some pics at the end of the week when i get it apart.

Dont forget to look into this.

Would not be surprised if your problems are related to this, rods dont try to pul a pin out of the piston without reason.

Posted By: M_D

Re: carnage at the dyno - 03/02/16 10:09 AM

Obviously it's important to have adequate oil delivery to bearings, and to have proper clearance which will vary depending on the engine and type of usage.

One thing that is often overlooked is the bore of the rod must be round, straight, and sized properly. It's about as important as round and true crank journals and round and straight cylinders. When the bearings are encapsulated in the assembled rod, if the bearing shells are not evenly and tightly contacting the rod bore they can walk around, and they also heat up significantly more because the poor contact between the bearings and rod doesn't transfer heat away from the bearing very well. The bearing shell is then prone to distort from excess heat and lack of support, which usually reduces the oil clearance, which is the beginning of the end.

That may not be what caused your problem, but it's very possible it was. If bearing to journal clearances are on the tight side that's 2 strikes. A lot of rods are honed with methods that are "iffy" and when not done correctly make the bearing bore bell-mouthed. I always inspect and measure the rod bores. On engines that have some run time on them you can look at the contact surfaces on the back of the bearing shells and the bores and see how well they fit.

Posted By: deaks

Re: carnage at the dyno - 03/02/16 10:43 AM

Real sorry to see this Dave, i've put street stuff together but would rather have a motor done by a professional when it's going to see a lot of rpm and has high cost parts.

Mick

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 05:10 PM

Believe me that thought entered my mind when I seen oil gushing from the bottom of the pan. I'll see how I feel about that when its ready for assembly.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 05:12 PM

I will never use another set of used rods.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 05:15 PM

Looking at the broken parts that fell out I think your right. Too tight and not enough oil.

Posted By: Moparnut426

Re: carnage at the dyno - 03/02/16 05:24 PM

There was killer rotating assy on here a few weeks ago. Killer rods, and Killer stroker crank, don't know your cash flow, but it was reasonable.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 05:25 PM

Here's another thing to think about. The last two builds(408) had .002 on rods and mains and never had a failure but had full groove mains.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/02/16 05:36 PM

You said rods were used and new bolts installed. Were big ends checked for size and roundness

Posted By: FastmOp

Re: carnage at the dyno - 03/02/16 05:51 PM

On big blocks there's a wide groove bearing and a narrow groove bearing. Both are full groove. I use the narrow groove.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 07:31 PM

yes they were checked at a machine shop. i checked bearing clearance again before assembly.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 07:32 PM

if i remember right i believe these calico bearings were a narrow bearing. i used a federal mogul main bearing.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 07:35 PM

i'm also second guessing the oil mods as a cause. i have heard the guy that posted those his engine also came apart. not saying thats the cause, but not sure i want to perform those mods on next block.

Posted By: madscientist

Re: carnage at the dyno - 03/02/16 08:04 PM

I doubt that clearance was too tight, but I don't remember what oil you used. I am about ready to fire mine off and it has .0021 on the rods and .0024 on the mains. I'm going to use a 5w30 oil. If yours was too tight I'll be screwed just like you.

I think a lighter grade oil and FGM's and you will be ok.

Posted By: mopar dave

Re: carnage at the dyno - 03/02/16 08:15 PM

joe gibbs xp4 15/50 non synthetic(breakin). like i said last 2 builds had .002 on rods and mains with full groove and using 20/50 amsoil, no issues. i had 100# oil pressure when first fired up, 75 when it got warm and 55 when it let go.

Posted By: AndyF

Re: carnage at the dyno - 03/02/16 08:30 PM

I had a big block come apart on the dyno years ago. It had good oil pressure when it spun a rod bearing. We never figured it out exactly but part of the problem in my case might have been poor oil volume. Pressure was high but volume might have been too low. The other issue in my case was tight clearances and heavy oil. I used some 20/50w which might have contributed to the problem. I was also using a fairly inexpensive connecting rod which might have been part of the problem. Hard to say when just one fails. Could be something about that particular rod or it could be something about the oiling to that one rod.

Posted By: HotRodDave

Re: carnage at the dyno - 03/02/16 08:37 PM

I think .002 is fine with high quality machine work but the taper side to side, roundness, big end bore... all need to be very acurate to get away with it consistently. If you machine shop can't deliver very high quality machine work than better to have a little extra clearance.

Posted By: JohnRR

Re: carnage at the dyno - 03/02/16 08:55 PM

joe gibbs xp4 15/50 non synthetic(breakin). like i said last 2 builds had .002 on rods and mains with full groove and using 20/50 amsoil, no issues. i had 100# oil pressure when first fired up, 75 when it got warm and 55 when it let go.

Your oil pressure was a little high, especially at idle, I wonder if you had a restriction somewhere?

Also rule of thumb for oil pressure is 10psi per 1000 rpm , 55psi at 6000 is a little low especially with that thick oil .... but that could have been the bearing going away at that point ?

i'm also second guessing the oil mods as a cause. i have heard the guy that posted those his engine also came apart. not saying thats the cause, but not sure i want to perform those mods on next block.

What oil mods did you do Dave and why not try 10-30. I switched over from 20-50 years ago and my engines love it.

You also may want to step up to SPS2000 (ARP)rod bolts. Cheap insurance.

Posted By: clonestocker

Re: carnage at the dyno - 03/02/16 09:20 PM

yes they were checked at a machine shop. i checked bearing clearance again before assembly.

I was always under the impression that when the bolts were changed the rods got resized.

Posted By: 440Jim

Re: carnage at the dyno - 03/02/16 09:24 PM

yes it was checked and I checked the bearing cleances several times. I was alittle concerned with the rod bearing clearances so I called hughes since that's where I bought the calico coated rod bearing. they were not concerned with .002" said run thinner oil. I used gibbs 15/50 because the mains were .0033. the rod bearing is wadded up and hard to read.

I have run coated bearings that tight without any problems, and at higher RPM. I was running 10W-30 oil, but 15W should have been fine. Mine have all been big blocks with full groove main bearings to improve rod oiling.

Posted By: madscientist

Re: carnage at the dyno - 03/02/16 09:43 PM

It does not matter what the first number is when looking at the grade of an oil. I don't remember off the top of my head but the winter grade is checked at 32* and colder as the number goes lower. He was still using a 50 grade oil. I don't know where Gibbs oil is blended at, but if it is on the high side ( so almost a 60) that oil was too thick for that clearance. The spread for any given grade of oil is very wide. Cheap oils run in huge blends can vary in grade from lot to lot. One lot may grade at the top (almost a 60) and the next lot may be on the low side (almost a 40).

There is a reason some oils are $8.00 a quart and some are $24.00. It pays to spend some time researching who these companies are, what base stocks they are using (probably the LEAST important part of any oil...but the company can save $$$$ using a cheaper base stock), what the additive pack is and where they put the oil in reference to grade.

When you start talking about squeezing down clearances and things like that, or using alternative fuels, it pays to do some research. And get on the phone and talk to themes guys. Every oil guy I have ever spoken to has been very frank about the questions I ask.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 12:34 AM

I think the single groove main and the plugged driver side oil galley contributed to the high oil pressure.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 12:38 AM

I called Gibbs and told them the combo and bearing clearance and they recommended the xp4 15/50. So that's what I used. I have always used a 20/50 because of all the internal leaks. Lifters being the biggest leak.

Posted By: dvw

Re: carnage at the dyno - 03/03/16 12:52 AM

15/50 is only 15 vs 20 when cold. Hot 50 is 50. Personally on non power adder stuff i see no reason not to run 5W30 unless it is a combo that runs a lot of oil temperature.

Doug

Posted By: OUTLAWD

Re: carnage at the dyno - 03/03/16 12:54 AM

Sorry to read this.

It's a shame, I just let a stock bore 360 go for a song because I was tired of looking at it.

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 12:55 AM

I called Gibbs and told them the combo and bearing clearance and they recommended the xp4 15/50. So that's what I used. I have always used a 20/50 because of all the internal leaks. Lifters being the biggest leak.

You can't fault a guy for doing what you are told. I tried to see where that 50 Is supposed to measure at but they don't give it out. Or I just can't find it.

I don't think many other oil companies would call out a 50 for those clearances but I could be wrong.

Posted By: justinp61

Re: carnage at the dyno - 03/03/16 01:03 AM

I had 20-50 VR1 to use in mine but after soaking the roller lifters in it and seeing how thick it was went with Brad Penn break in oil on the dyno. I'll use their 10-30 now that it has been ran.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 01:31 AM

I can tell you this, when using 20/50 hot oil pressure was 15-20 at idle and 55 thru the traps using full groove bearings. I didn't know what to expect for oil pressure on Dyno with single groove and plugged oil galley Dr side. Thought too much would be better than not enough or too low.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 01:35 AM

Oil mods were open up all oil galleys. 1/2 and 5/16 from oil pick up thru main rear cap to plugging the Dr side galley which only feeds the lifter galley.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 01:45 AM

joe gibbs xp4 15/50 non synthetic(breakin). like i said last 2 builds had .002 on rods and mains with full groove and using 20/50 amsoil, no issues. i had 100# oil pressure when first fired up, 75 when it got warm and 55 when it let go.

Dave... those pressures are VERY high for those

clearances... I have never had over 70# cold and

25-30 hot.. when pressure is high you are reducing

the flow.. remember pressure is a restriction in

flow... I use the half groove mains and turn higher

rpms... but I do use .003 and .003 on my clearances

on all my junk... I balance out my oil pressure once

I see what it is both hot and cold... but I wouldnt

make a dyno pull or a pass with the pressure you stated

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 02:09 AM

15W/50 is NOT like straight 50W. Straight 50 is like syrup when it's cold. To put it simply, or at least how it was explained to me, was that multi viscosity oil, the first number is basically the Winter or cold viscosity, with lube qualities of the heavier weight when the motor reaches 212*. For the oil to actually get to the 50W viscosity takes the high temps. This is done with "viscosity modifiers". The cold or Winter viscosity number is based on how hard the oil is to pump through a given orifice at low temps and has to meet pumping pressure requirements based on temps and test orifice size. So what does all that mean? Simply put the 15W/50 oil MUST pass SAE J300 standards of a straight SAE15 to be labeled as such, as well as passing the 50W SAE J300 standard at 212* So that said, based on average dyno room temps and his bearing clearance, no way should 15W/50 be too heavy when cold. Factory motors used to run as tight as his and straight 30 was what most everything came with back then and they weren't grabbing bearings, even in extremely cold temps.

I don't know what caused his issue, but I highly doubt it was the viscosity of the oil, the lack of full groove bearings, or similar.

Of all people, the ones at Gibbs, who he called, should know the characteristics of their oil.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 02:13 AM

15W/50 is NOT like straight 50W. Straight 50 is like syrup when it's cold. To put it simply, or at least how it was explained to me, was that multi viscosity oil, the first number is basically the Winter or cold viscosity, with lube qualities of the heavier weight when the motor reaches 212*. For the oil to actually get to the 50W viscosity takes the high temps. This is done with "viscosity modifiers". The cold or Winter viscosity number is based on how hard the oil is to pump through a given orifice at low temps and has to meet pumping pressure requirements based on temps and test orifice size. So what does all that mean? Simply put the 15W/50 oil MUST pass SAE J300 standards of a straight SAE15 to be labeled as such, as well as passing the 50W SAE J300 standard at 212* So that said, based on average dyno room temps and his bearing clearance, no way should 15W/50 be too heavy when cold. Factory motors used to run as tight as his and straight 30 was what most everything came with back then and they weren't grabbing bearings, even in extremely cold temps.

I don't know what caused his issue, but I highly doubt it was the viscosity of the oil, the lack of full groove bearings, or similar.

I dont care what the viscosity is.. his pressure is

HIGH... pressure is a restriction in flow... PERIOD

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 02:17 AM

I understand that......but some were saying the 15W/50 was like 50W when cold and it is NOT. Would you think straight 15W was too thick given his combo?......No and neither would anyone else and that is the SAE standard that 15W/50 oil MUST meet when cold. My point was that is wasn't the oil that caused the problem.

He said he had .002. Well how was that checked? With plasti-gauge or with mics. And if mics were used, was it only checked 90* from the parting line in a torqued rod, or in several places. The rod could have been out of round, or the crank pin had taper or wasn't round. .002 in one spot, doesn't mean it had .002 everywhere. I still think it was just tight for some reason. If you want to run em tight, that's fine, but it better be right everywhere

I know when I tube the lifter galleys on my small blocks I double and triple check to make sure I redrilled all the needed oil passages and followed the instructions to a T. To make sure I dig out my old mopar manuals just to double-check I didn't forget something.

Posted By: Twostick

Re: carnage at the dyno - 03/03/16 03:30 AM

Is there any way to tell if the coating delaminated?

If it wadded up it only takes a millisecond at speed for the crank to grab the bearing and just a few more to go boom.

Kevin

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 03:34 AM

Well to start with the eagle crank had bad machining on the journals and it showed on the previous build when torn down. The journals were wavie. So my machinest turned all journals and checked rods for out of round. I left that up to him as he has built many circle track engines and has a good rep. He mic'ed the torqued rods and journals and gave me the results which were .00225. I remeasured 90 degrees to parting line on rods and measured journals and found the same measure upon assembly. I used a dial bore gauge and mic. I figured good enough.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 03:44 AM

Good practice to measure rods in 3 places to ensure they are not out of round after you crush the bearing. Also, rod can be perfectly round but big and NOT crush bearing enough. Will measure right at parting line but not sides. Same if rod is small and has too much crush.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 04:10 AM

Dave understand that at just about 70 psi the pump

is blowing off on the by-pass.. thats not flow to

the engine...all the pumps I have checked the by-pass

on blew of real close to 70 psi + or - a small amount..

so all that extra pressure you have will hurt the flow

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 04:39 AM

I see. Mygoal was to have 60-70psi hot at rpm but, It didn't turn out that way.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 04:49 AM

OK. Well I gave all my parts to a machines and had faith he knew what he was doing. He gave me the ok everything is good and I took the parts home and measured bearing clearance for piece of mind and assembled. The guy has a good rep for machining and engine building. I guess ya really don't what quality of work your getting til ya have a failure.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 05:32 AM

OK. Well I gave all my parts to a machines and had faith he knew what he was doing. He gave me the ok everything is good and I took the parts home and measured bearing clearance for piece of mind and assembled. The guy has a good rep for machining and engine building. I guess ya really don't what quality of work your getting til ya have a failure.

I know what ya mean.. I've been there... my one engine didnt

make a 1/8 mile before it let go... luckily it didnt take out

a ton of stuff.. a lifter let go.. that took out 1 head, a

couple of pistons and a cyl bore... a sleeve on the block

with a new head were the big parts.. that was a quick $3500

for that

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 05:50 AM

I understand that......but some were saying the 15W/50 was like 50W when cold and it is NOT. Would you think straight 15W was too thick given his combo?......No and neither would anyone else and that is the SAE standard that 15W/50 oil MUST meet when cold. My point was that is wasn't the oil that caused the problem.

He said he had .002. Well how was that checked? With plasti-gauge or with mics. And if mics were used, was it only checked 90* from the parting line in a torqued rod, or in several places. The rod could have been out of round, or the crank pin had taper or wasn't round. .002 in one spot, doesn't mean it had .002 everywhere. I still think it was just tight for some reason. If you want to run em tight, that's fine, but it better be right everywhere

You dont pick an oil based on the winter grade number unless you are running in sub freezing temps.

Viscosity is based on oil temp.

His oil acted like a 50 grade oil when at operating temp.

That seems heavy for his clearance.

I don't use Gibbs so I can't say why they picked a 50 grade oil. I would have used a quality 30 grade.

The oil timing is off on these engines. At the speed the OP is turning he needs a full groove bearing to get oil to the rods on time, or close to it.

The only fixes for high RPM (over 8k) are have a crank drilled to the correct oil timing, but I have never had it done.

Or, you have to bring the oil to the crank in a different place to correct the timing.

And that is a whole nother thread.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 05:55 AM

im not going to do that but how do you know where to put the holes in the crank?

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 06:01 AM

ok, so let me get this part cleared up. with bearing clearance at .003 on main and rod with full groove mains what would you suggest for oil viscosity in this combo?

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 06:05 AM

im not going to do that but how do you know where to put the holes in the crank?

Forget that crap... SB mopars have been turning HIGH

rpms for YEARS with normal cranks.. the most I ever

did on the crank was elongate the oil hole some.. you

can do that with a file or have the crank grinder do it

(they know what I'm saying on that).. but its just the

slot across the oil hole.. as I said before.. I have been

9600 rpm and its still together.. and I sure dont do anything

magic

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 07:30 AM

im not going to do that but how do you know where to put the holes in the crank?

You have to have it done when the crank is made. I heard that one from a known Comp guy who did PST and dabbled in PS. I didn't do mine that way. But I'm not about to go into the detail of how I fixed mine because it would take an hour to type. If you really want to know, PM me and I'll do it that way.

Mr. Pbody would be one of the only guys I know that can turn a SBM that tight on regular oil timing. Very few guys do it in the first place. Even fewer do it with any level of success.

As for oil, I only know one brand. I wouldn't want to tell you a grade for any other oil. Like I said, there is more to oil than base stocks. It's like how they grade an oil. It can pass as a 50, but it might test on the high side of the grade and almost be a 60. You can't tell the difference, but the engine can. So it is very brand specific.

I may spend some time tomorrow and see if I can find the actual specs of the oil you used. If I can find that, I can see where they blend the oil as far as grade goes.

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 07:32 AM

im not going to do that but how do you know where to put the holes in the crank?

Forget that crap... SB mopars have been turning HIGH

rpms for YEARS with normal cranks.. the most I ever

did on the crank was elongate the oil hole some.. you

can do that with a file or have the crank grinder do it

(they know what I'm saying on that).. but its just the

slot across the oil hole.. as I said before.. I have been

9600 rpm and its still together.. and I sure dont do anything

magic

You can't correct the oil timing with file. And the oil timing is off, by a mile. All you need to do is stand a sbc next to a sbm. Even Ray Charles can see the timing is off. And you need the cranks too.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 04:01 PM

OK . in the past combos I used 20/50 brad Penn,valvoline and 15/50 amsoil with .002 on mains and rods and never had an issue.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 04:30 PM

im not going to do that but how do you know where to put the holes in the crank?

Forget that crap... SB mopars have been turning HIGH

rpms for YEARS with normal cranks.. the most I ever

did on the crank was elongate the oil hole some.. you

can do that with a file or have the crank grinder do it

(they know what I'm saying on that).. but its just the

slot across the oil hole.. as I said before.. I have been

9600 rpm and its still together.. and I sure dont do anything

magic

You can't correct the oil timing with file. And the oil timing is off, by a mile. All you need to do is stand a sbc next to a sbm. Even Ray Charles can see the timing is off. And you need the cranks too.

I'm not trying to correct anything.. it just give

it more area for the oil once its out of the hole

to hold oil.. I bought a old PS truck crank and that

is what was done to it.. then I had another turned

down and they did it for me

Posted By: GTX MATT

Re: carnage at the dyno - 03/03/16 04:52 PM

Factory motors used to run as tight as his and straight 30 was what most everything came with back then and they weren't grabbing bearings, even in extremely cold temps.

I don't know what caused his issue, but I highly doubt it was the viscosity of the oil, the lack of full groove bearings, or similar.

Not that I know anything but this is what I was thinking reading through this thread, I'd reject the idea that it was too tight, too thick oil, etc. I'd think it was too out of round, was starved for oil, or simply didn't have .002 clearance...

I wouldn't want a 50 weight in an engine with .002 clearance, but people put 50 weight in tight engines all the time. Or engines that they have no idea what the clearances are, factory stuff, etc. I've put 50 weight in old worn out oil burners, who knows what the clearances were, but I wound them up tight and it was never an issue. Maybe they were just loose. But if 50 weight with .002 clearance was an issue that was going to grenade a lot of engines we'd be hearing about it a lot more often...

Posted By: 1Fast340

Re: carnage at the dyno - 03/03/16 05:00 PM

How comon is it that a bearing/oiling isue tries to pul the pin out of a piston?

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/03/16 05:06 PM

How comon is it that a bearing/oiling isue tries to pul the pin out of a piston?

I cant say that both would even be related .. if the

pin doesnt get oil they tend to seize the piston and

then end up spinning a bearing

Posted By: justinp61

Re: carnage at the dyno - 03/03/16 06:11 PM

I'm thinking after the rod bolts broke the crank hit the rod and caused the damage to the piston. I don't think the carnage started with the wrist pin.

Posted By: 440_Offroader

Re: carnage at the dyno - 03/03/16 06:12 PM

How comon is it that a bearing/oiling isue tries to pul the pin out of a piston?

I cant say that both would even be related .. if the

pin doesnt get oil they tend to seize the piston and

then end up spinning a bearing

So perhaps this was a wrist pin failure? The rod bearing failure being a secondary result?

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 06:15 PM

This engine has an Eagle crank. While I have not compared a SBC and a SBM Mopar crank from Eagle, I would imagine that Eagle uses the same "high speed oiling" arrangement in all their crankshafts, regardless of brand of motor. The way a crank is made, you can move the timing "some" but it isn't a huge amount. So while it may be true that factory Chevy and Mopar cranks may differ in timing, I would think aftermarket cranks are drilled the same. Would be easy to find out........all you have to do is ask them.

BUT........that isn't the problem here. SB Mopars been running for years with factory drilled cranks.

As far as the oil, some need to read up on how multi viscosity oils are rated, tested and really work. The oil in question here would not have taken on the viscosity characteristics of 50W until the oil temp reached 212*. And anybody who has ever drained some HOT, even straight 50 from a motor, knows at that temp, it is not all that thick

Posted By: Al_Alguire

Re: carnage at the dyno - 03/03/16 06:37 PM

Looks to me like you had a clearance issue, or the crank journal or rod big end was out of round. Don't see a big mystery here, lack of oil film on that rod...

So, only one rod bearing didn't like the oil? The other bearings look good?

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 07:14 PM

OK . in the past combos I used 20/50 brad Penn,valvoline and 15/50 amsoil with .002 on mains and rods and never had an issue.

The only way to know for sure is to have what you were using tested. Like I said, the oil grading system is very wide. You can buy a 50 that is very close to a 40 or it can be very close to a 60 or anywhere in between.

I tried to find numbers for the oil you were using and I can't. I may call them and see what I can find.

Posted By: GTS340

Re: carnage at the dyno - 03/03/16 07:18 PM

125 replies and quicktree hasn't stopped in to bestow his knowledge yet...something is wrong!

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 07:20 PM

This engine has an Eagle crank. While I have not compared a SBC and a SBM Mopar crank from Eagle, I would imagine that Eagle uses the same "high speed oiling" arrangement in all their crankshafts, regardless of brand of motor. The way a crank is made, you can move the timing "some" but it isn't a huge amount. So while it may be true that factory Chevy and Mopar cranks may differ in timing, I would think aftermarket cranks are drilled the same. Would be easy to find out........all you have to do is ask them.

BUT........that isn't the problem here. SB Mopars been running for years with factory drilled cranks.

As far as the oil, some need to read up on how multi viscosity oils are rated, tested and really work. The oil in question here would not have taken on the viscosity characteristics of 50W until the oil temp reached 212*. And anybody who has ever drained some HOT, even straight 50 from a motor, knows at that temp, it is not all that thick

We at least need to use the correct terminology. There is no such thing as a multi viscosity oil. They are multi grade.

Again, the oil timing is way off.that isn't the issue hear, just try to help people learn. As RPM goes up, the more the timing issues show up.

What the oil acts like drawing it is irrelevant. It pumps and resists flow like a 50 or it wouldn't be graded a 50.

EDIT: I have looked at Eagle cranks. And Scat cranks. They have the oil holes in the factory Chrysler location. That means the oil timing is off. If you want to argue oil timing and how critical it is, take it up with David Nickens. I had several long discussions with him. He isn't stupid.

Posted By: HotRodDave

Re: carnage at the dyno - 03/03/16 07:35 PM

A SBC is not an excercise in good oiling to follow, they got some messed up junk coming down from the cam then to the lifters and then the crank gets the left overs but somehow they live for a while, that is why they like to use high volume pumps and such to ensure enough pressure is left over from everything else to keep the crank lubed. Sure a SBM has timing issues but based on the guys like p-body and others and the SBC guys with that crappy oiling set up turning serious RPM it just don't matter. Centrifugal force is going to keep the oil flowing out of the crank toward the rod bearing even when the pressure is blocked for a split second.

I don't think he had a oil quality or viscosity problem, I have seen guys running 20-50 in brand new cars that come with VERY tight clearance and it don't hurt em, I run 0-20 in all my cars anymore and no engine trouble that did not exist when I bought the car. It was something wrong with the machining, out of round, too much taper, twisted crank...

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 07:44 PM

That's simply not true. It IS multi viscosity and that is accomplished by VIIs which stands for "Viscosity Index Improvers". Grades or weights of oil are defined by their viscosity. Multi weight oil HAS to pass both SAE J300 test parameters for which it is advertised to be. In this case the oil has to pass BOTH 15W cold tests and 50W hot tests to be classified as such.

Below is from Bel-Ray

The SAE designation for multi-grade oils includes two viscosity grades; for example, 10W-30 designates a common multi-grade oil. The first number '10W' is the viscosity of the oil at cold temperature and the second number is the viscosity at 100 °C (212 °F). The two numbers used are individually defined by SAE J300 for single-grade oils. Therefore, an oil labeled as 10W-30 must pass the SAE J300 viscosity grade requirement for both 10W and 30, and all limitations placed on the viscosity grades (for example, a 10W-30 oil must fail the J300 requirements at 5W).

Posted By: Monte_Smith

Re: carnage at the dyno - 03/03/16 07:56 PM

A SBC is not an excercise in good oiling to follow, they got some messed up junk coming down from the cam then to the lifters and then the crank gets the left overs but somehow they live for a while, that is why they like to use high volume pumps and such to ensure enough pressure is left over from everything else to keep the crank lubed. Sure a SBM has timing issues but based on the guys like p-body and others and the SBC guys with that crappy oiling set up turning serious RPM it just don't matter. Centrifugal force is going to keep the oil flowing out of the crank toward the rod bearing even when the pressure is blocked for a split second.

Wasn't referring to the ENTIRE SBC oiling system, only how the crank is drilled. The crank is drilled to provide crank pin oiling at 60 before "max load" on crank pin.

Posted By: dvw

Re: carnage at the dyno - 03/03/16 08:01 PM

What I think not everybody understands about multi-grade is that warm 50wt will flow easier than cold 15wt. But cold 15wt flows easier than cold 50wt, the same is true when theyre warm. You need enough film strength and clearance to prevent metal to metal contact. If parts flex even more clearance is required. The thinner the oil the higher the flow at a given clearance and temperature. More flow equals better cooling of the part. Higher temp equally thinner oil, too thin or hot and you lose load capacity. It's all a balancing act. My theory in this case is either the clearance tightened up or we had lack of flow, providing nothing broke at the onset. The temp and film strength would be the same for the other 7 rods. Maybe after teardown we'll find a obstructed rod feed galley, other rods that are out of round or a spun #5 main? I still like thinner oil and more clearance, but doubt if 50wt or if it had actual .002" clearance caused this failure. My 2 cents

Doug

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 08:04 PM

Amen brother!

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 08:24 PM

That's simply not true. It IS multi viscosity and that is accomplished by VIIs which stands for "Viscosity Index Improvers". Grades or weights of oil are defined by their viscosity. Multi weight oil HAS to pass both SAE J300 test parameters for which it is advertised to be. In this case the oil has to pass BOTH 15W cold tests and 50W hot tests to be classified as such.

Below is from Bel-Ray

The SAE designation for multi-grade oils includes two viscosity grades; for example, 10W-30 designates a common multi-grade oil. The first number '10W' is the viscosity of the oil at cold temperature and the second number is the viscosity at 100 °C (212 °F). The two numbers used are individually defined by SAE J300 for single-grade oils. Therefore, an oil labeled as 10W-30 must pass the SAE J300 viscosity grade requirement for both 10W and 30, and all limitations placed on the viscosity grades (for example, a 10W-30 oil must fail the J300 requirements at 5W).

I get this Monte. One time they say viscosity and then they say grade. Viscosity is temperature referenced. Grade is what they are rated at. If you take a 50 and measure it at ambient it will be closer to the winter grade number. But the viscosity is related to temp. At 212* a 50 is a 50. At 240* it's still a 50, but its viscosity is much thinner. Still a 50 though.

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 08:28 PM

A SBC is not an excercise in good oiling to follow, they got some messed up junk coming down from the cam then to the lifters and then the crank gets the left overs but somehow they live for a while, that is why they like to use high volume pumps and such to ensure enough pressure is left over from everything else to keep the crank lubed. Sure a SBM has timing issues but based on the guys like p-body and others and the SBC guys with that crappy oiling set up turning serious RPM it just don't matter. Centrifugal force is going to keep the oil flowing out of the crank toward the rod bearing even when the pressure is blocked for a split second.

Wasn't referring to the ENTIRE SBC oiling system, only how the crank is drilled. The crank is drilled to provide crank pin oiling at 60 before "max load" on crank pin.

Exactly, and maybe I wasn't clear enough. Monte says it's 60* degrees where the oil is timed at. The point is at the exact time, the oil hole in the crank had damn well better be lined up with the feed hole in the block so Full oil pressure is going to the rods. On a SBC these two holes are lined up at the right time. On the Chrysler they are not. It's a big deal as the RPM's go up. That is all I am saying.

Posted By: madscientist

Re: carnage at the dyno - 03/03/16 08:35 PM

A SBC is not an excercise in good oiling to follow, they got some messed up junk coming down from the cam then to the lifters and then the crank gets the left overs but somehow they live for a while, that is why they like to use high volume pumps and such to ensure enough pressure is left over from everything else to keep the crank lubed. Sure a SBM has timing issues but based on the guys like p-body and others and the SBC guys with that crappy oiling set up turning serious RPM it just don't matter. Centrifugal force is going to keep the oil flowing out of the crank toward the rod bearing even when the pressure is blocked for a split second.

I don't think he had a oil quality or viscosity problem, I have seen guys running 20-50 in brand new cars that come with VERY tight clearance and it don't hurt em, I run 0-20 in all my cars anymore and no engine trouble that did not exist when I bought the car. It was something wrong with the machining, out of round, too much taper, twisted crank...

I'm sorry but you are wrong. I can't say it any nicer than that. If you rely on centrifugal force to oil the rods, you will kick out 'two rods. Usually 3-4 go first.

How many small block molars have you built that made horsepower over 8000 rpm? I have done it. Many say they have. I know I have. I know the results. They are not good. You MUST fix the oil timing issue or it will fail.

I wish I had never mentioned oil timing because it is off topic to the OP. But I felt it was relevant. There are many busted blocks from oil timing issues. The OP didn't have that issue.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 08:49 PM

I know one thing, it ran out of the pan like water.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 08:50 PM

I will know sunday when i get it apart. dont have all my tools here.

Posted By: HotRodDave

Re: carnage at the dyno - 03/03/16 09:16 PM

Dave did not have a problem turning 9000, he had a problem at a much lower RPM where engines have lived a loooong time without fixing the oil timing issue. My comment about centrifugal force was just speculation on how they live at 6000-7000 RPM.

Don't worry about bringing it up, I was the one who steped in it not you.

Posted By: v cummins

Re: carnage at the dyno - 03/03/16 09:38 PM

Not a oil prob. part failure or clearance prob.

either way it be junk know. hope you can save as much as you can.

Posted By: mopar dave

Re: carnage at the dyno - 03/03/16 10:13 PM

Me too. I think the block is saveable as long as its not cracked but I will be using a different block next build.

Posted By: Streetwize

Re: carnage at the dyno - 03/03/16 11:02 PM

You guys also got to remember the first fire up of a new motor generates a lot of heat as all the parts "get introduced" to one another, even when everything is precisely machined and fitted. Those tighter .002" Main clearances (as Monte correctly points out) means that you have much less margin of error on any high .0001 or tight spots. Also the 360 has a bigger main diameter than even a 440 so bearing speed and heat is higher, so combining that with a tight clearance is something to watch carefully....even under normal non stroker loads. Also....I don't think most people realize how much things move around inside a cast iron block, and how much side loading comes into play when you load a motor up. I'm assuming a motor like that was line honed? I have to suspect somewhere the (too tight on too tight) 'tolerance stack' might have bit you. More oil clearance (say .003 vs .002 )also means more (50%) hydraulic cushion around the crank as well as more volume passing through with less restriction, it also allows the oil to wick away more heat. The other key component to oil (other than friction reduction) is also it's surfactant (surface cooling) qualities.

Again, I'm so sorry to hear about this.

Posted By: mopar dave

Re: carnage at the dyno - 03/04/16 12:46 AM

Thank you. That's behind me now and I'm in the process of building a better engine. I can salvage some of it. Do you think I can reuse my piston rings? Mahle 1mm steel rings, 45 minutes run time.

Posted By: justinp61

Re: carnage at the dyno - 03/04/16 12:52 AM

Dave, what was the oil temp before it let go?

Posted By: Monte_Smith

Re: carnage at the dyno - 03/04/16 12:52 AM

Assuming the notch in the cylinder is the only block damage.......sleeve that hole, get a rod and piston.....fix crank and carry on. If the crank is standard now, grind it .010 and get some more clearance

Posted By: madscientist

Re: carnage at the dyno - 03/04/16 12:59 AM

Assuming the notch in the cylinder is the only block damage.......sleeve that hole, get a rod and piston.....fix crank and carry on. If the crank is standard now, grind it .010 and get some more clearance

I agree. Use as many parts as you can. A .010/.010 or a .030/.030 crank is just as strong as it is standard.

You can reuse the Pistons if they don't have a bunch of junk in the skirts and I would reuse the rings if they pass the eye test.

A sleeve in a bore is not a bad thing. In my time I have set literally hundreds of sleeves. Zero issues.

Save what you can.

When I have my cranks ground I always tell them .011, .021, .031, ect ect. Its always worked for me.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/04/16 01:18 AM

That's what I was going to say. Don't just tell them "grind it .010". Tell them to grind it to where YOU want it. You do that by measuring the main housing bores and rods with bearings installed and torqued. Get those sizes and then have the crank ground to the number that gives the clearance you want.

If your crank grinder says he can't get it that close.....find another one that can

Posted By: madscientist

Re: carnage at the dyno - 03/04/16 01:44 AM

I always say .0005 under minimum. Then I size the rods and main line for the clearance I want.

Posted By: mopar dave

Re: carnage at the dyno updated - 03/04/16 03:35 AM

Removed the heads today. Not sure I found the issue, but I did find a issue. Both intake and exhaust valve touching the piston on #8 only. Now I did check VP clearance but on 1 and 2 cylinder only(.130) on both. I did check deck height on all cylinders and I had .005 in the hole on all. The valves have not been checked but do not look bent.

Posted By: mopar dave

Re: carnage at the dyno - 03/05/16 08:22 PM

Now if you remember from my build posts I used a .030 head gasket on pass side and a .036 on the Dr side to get the compressions equal. Do you think the piston could of hit the valves after the rod broke?

Posted By: justinp61

Re: carnage at the dyno - 03/05/16 08:30 PM

Now if you remember from my build posts I used a .030 head gasket on pass side and a .036 on the Dr side to get the compressions equal. Do you think the piston could of hit the valves after the rod broke?

Yes if none of the other pistons on that side show any signs of valve contact. The only other explanation is that the #8 rod was long.

Posted By: HotRodDave

Re: carnage at the dyno - 03/05/16 08:35 PM

Once the bearing clearance went away and the rod let go it smacked the head and valves, that is not the cause of the issue. If it was you would have only hit the head as you had way more clearance from the valves, the damage to the head/valves is a result not a cause.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/05/16 08:49 PM

When the rod broke, piston stopped moving, rest of motor did not. Valves opened against a stationary piston that was at the top of bore........or as cap was coming apart, rod got "long" and smacked head. Either way, affect, NOT cause

Posted By: mopar dave

Re: carnage at the dyno - 03/05/16 10:03 PM

Kinda what I thought. Looks like something was in the cylinder. Left marks on the piston and head. I'll know more tomorrow.

Posted By: HotRodDave

Re: carnage at the dyno - 03/05/16 10:13 PM

I see what you are talking about. Maybe the extra load on the bearing from sticking something between the head and piston caused too much load for the oil film and made the bearing grab.

Posted By: v cummins

Re: carnage at the dyno - 03/05/16 10:28 PM

The good news is the heads of the valves are still there and you save the head.

Posted By: Monte_Smith

Re: carnage at the dyno - 03/05/16 10:49 PM

Did the piston hit the plug? That could explain the marks on piston if it knocked the strap off or broke the porcelain.

Would have to be something really big to hit the piston hard enough to hurt a bearing. That's very minor, whatever got up there

Posted By: mopar dave

Re: carnage at the dyno - 03/05/16 11:42 PM

First thing we did after the failure was pull all the plugs. They all looked good. Don't see any indication Of piston hitting the head. Something was in there but hard saying what.

Posted By: justinp61

Re: carnage at the dyno - 03/06/16 12:32 AM

What I see looks like the valves shaved some of the piston out in the radius of the valve reliefs. Like the piston was cocked in the bore when they hit it.

Posted By: mopar dave

Re: carnage at the dyno - 03/06/16 12:59 AM

OK maybe that's it. Do you think wiseco would build me 2 pistons or will I have to buy another set of 8? A member here is sending me a 73 360 block with the 4 bolt main conversion short fill line honed and a 4.040 bore. If I can get just 2 pistons made I can get this back together pretty quick at low cost. If I have to buy a whole set I will start on my big block project.

Posted By: dvw

Re: carnage at the dyno - 03/06/16 02:05 AM

As Monte said there is almost always valve to piston contact when the rod breaks. Replace those valves. How does the #5 main look? no need to buy an entire set of pistons. two will probably be a little more costly per piston.

Doug

Posted By: roadhazard

Re: carnage at the dyno - 03/06/16 02:33 AM

Sorry to see the carnage

Yes, your going to be replacing some valves also.

Posted By: BigBlockMopar

Re: carnage at the dyno - 03/06/16 02:42 AM

Is the piston still loose in the bore? What's the ringgap?

Any damage marks on the cylinder wall from a possible piston seize?

I've once seen an engine where the camshaft had broken in half, piston ringlands were cracked and the rod was broken with some crank/bearing damage.

The shop who put the engine together thought they had gotten a badly cast cam and tried to go after the cam company.

What they didn't (want to) see was that they had built the engine with too little ringgap clearence, which caused that particular piston start to seize up high in the bore, causing excess stress on the bearing for a while and finally snapping off the rod and bolts as the remains got pulled down by the crank, and while that happened, the still rotating cam was trying to open the valves, which broke because the valves were blocked by the stuck piston.

Its hard to believe what can happen to some of these engines. My Friend bought a chevy small block (short block) from a well know Ohio Company and He made 2 passes on a test n tune and on the 3rd one I ran over to the fence at half track to watch. He heated his tires and before he could stage his headlights went out and they pushed him off the track. We thought at first his battery died and it shut off but I did some checking and it was locked up. The piston EXPLODED. They wanted the engine back for an investigation and the piton parts were sent to the manufacture. I read the 6-8 page report and it came down to dirty engine assembly work. They sent him a new short block and its going on its third season.

Posted By: mopar dave

Re: carnage at the dyno - 03/06/16 03:23 AM

I don't see any marks on the cylinder wall. Pistons moves with ease. Ring gaps were .020 and .024. Yeah if I can get 2 matching pistons I will put this back together. I would think $100 ea. They were a total custom deal.

Posted By: cudaman1969

Re: carnage at the dyno - 03/06/16 04:27 AM

Check that rod journal for heat cracks before using the crank again

Posted By: mopar dave

Re: carnage at the dyno - 03/06/16 05:16 AM

Adney Brown with be getting the crank.

Posted By: madscientist

Re: carnage at the dyno - 03/06/16 05:18 AM

Glad you can save the engine with minimal costs.

Posted By: HardcoreB

Re: carnage at the dyno - 03/06/16 11:53 PM

Wow Dave, sorry to see the failure.

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 01:08 AM

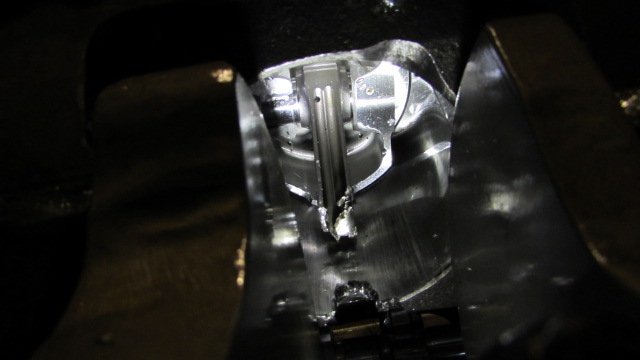

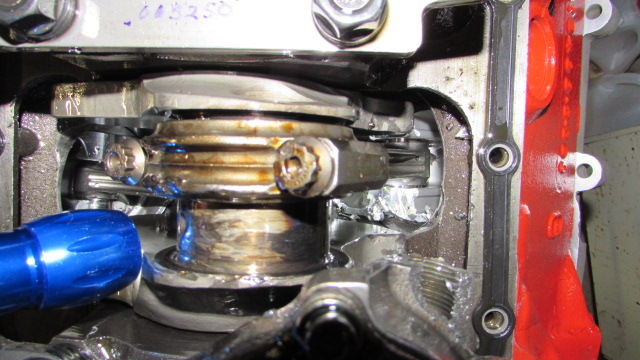

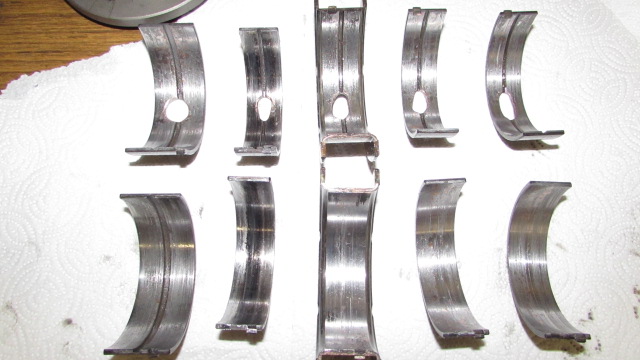

yeah, but i'm hoping to get something together soon. I dis assembled the short block today. All bearings were starved for oil. Removed plugs in the block and all oil galleries are clear. All bearings were in their proper places and everything was tight. I was scratching my head trying to figure what went wrong. the pick up had 1/4" of clearance from the bottom of pan. I thought maybe the purolator oil filter was the issue, but dont think so. I took the oil pump apart and found what looked like a bur riding against the pressure valve. If it was holding that shut not sure enough oil would get thru. heres some pics

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 01:10 AM

I slid a red electrical prob in there so you can see the bur.

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 01:12 AM

Any ideas? Im ready not sure what caused all the trouble here.

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 01:14 AM

with all the oiling mods i shouldn't of had this issue.bearing clearances were plenty. looks like the rear suffered the worst.

Posted By: WO23Coronet

Re: carnage at the dyno - 03/07/16 01:42 AM

No expert here (not even a novice) but all those bearings look like they were starving for oil. You could have a blockage somewhere?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 02:18 AM

maybe someone can school me on how these oil pump pressure valves operate.

Posted By: GTS340

Re: carnage at the dyno - 03/07/16 02:22 AM

with all the oiling mods i shouldn't of had this issue.bearing clearances were plenty. looks like the rear suffered the worst.

Are you sure ALL of the shavings from all your oiling mods got flushed out of galleys and passages? Did you hot tank and flush/brush clean after doing the mods?

Posted By: justinp61

Re: carnage at the dyno - 03/07/16 03:20 AM

I'm guessing from the photos you posted that the rod bearings start with #1 on the left and the mains start with #1 on the right? What exactly did you do to the block?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 03:54 AM

correct on the bearing orientation. opened up all 1/2" and 5/16" oil gallery. plugged dr oil gallery on #1 main. this was done before the block went to the shop and it did get a cleaning there. their is a plug in the large oil gallery under the rear cap. what is the proper orientation for that plug? how is it possible to have 75psi oil and not get enough oil to bearings?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 03:57 AM

I also ran brushes and compressed air threw every gallery before i assembled it. that block was clean no doubt.

Posted By: justinp61

Re: carnage at the dyno - 03/07/16 04:25 AM

correct on the bearing orientation. opened up all 1/2" and 5/16" oil gallery. plugged dr oil gallery on #1 main. this was done before the block went to the shop and it did get a cleaning there. their is a plug in the large oil gallery under the rear cap. what is the proper orientation for that plug? how is it possible to have 75psi oil and not get enough oil to bearings?

Dave IIRC the plug is driven into the block between the passages from the pump and the main feed passage. If it was driven to far it could stop or restrict flow to anything past the #5 main. The cup side should be facing down. I suppose if it isn't driven in deep enough it could restrict flow to the #5 main.

If you remove the threaded plug from under the oil filter and shine a light in the port you shouldn't be able to see the plug.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/07/16 04:33 AM

correct on the bearing orientation. opened up all 1/2" and 5/16" oil gallery. plugged dr oil gallery on #1 main. this was done before the block went to the shop and it did get a cleaning there. their is a plug in the large oil gallery under the rear cap. what is the proper orientation for that plug? how is it possible to have 75psi oil and not get enough oil to bearings?

Dave... didnt you say you had 100 psi in your

early post... anything over 70 is just getting

dumped back.. it doesnt go through the block..

and your pic of the relief valve.. I'd bet that

happened after it came apart.. a piece hung that

valve open.. have you looked at that chunk yet

Posted By: qwkmopardan

Re: carnage at the dyno - 03/07/16 04:34 AM

Assuming the notch in the cylinder is the only block damage.......sleeve that hole, get a rod and piston.....fix crank and carry on. If the crank is standard now, grind it .010 and get some more clearance

If the crank is std grind it .011 U.S. and get some more clearance.

I agree with streetwise, the stacked size variances got this engine. The thickest bearing wound up in the smallest rod on the largest journal on the crank.

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 04:34 AM

did that and did not see the plug. the cup points to the bottom of the block. would their be any possible way the oil pump valve could cause low oil flow but still show high pressure?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 04:36 AM

yeah Mike, 100psi on start up, 75 warm and 55 when it came apart.

Posted By: wyoming

Re: carnage at the dyno - 03/07/16 04:38 AM

If it was stuck open you would have low pressure

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 04:39 AM

well, then if the mains had .0033" why do they show signs of low oil? doesnt seem like they would have got hurt at all.

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 04:40 AM

what would happen if it was stuck closed?

Posted By: qwkmopardan

Re: carnage at the dyno - 03/07/16 04:46 AM

what would happen if it was stuck closed?

Your oil pressure gauge would be be pegged high and blow up the oil filter.

Posted By: qwkmopardan

Re: carnage at the dyno - 03/07/16 04:56 AM

Are you sure the pick-up tube didn't un screw and sit on the bottom of the pan?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 04:58 AM

ok, so that rules out the oil pump.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/07/16 04:58 AM

did that and did not see the plug. the cup points to the bottom of the block. would their be any possible way the oil pump valve could cause low oil flow but still show high pressure?

Nope.. no way... unless your gauge is reading real

high.. check it for calibration/accuracy

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 05:02 AM

yes, in fact the pickup was knocked off the oil pump breaking the pump when the failure accured.

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/07/16 05:05 AM

yes, in fact the pickup was knocked off the oil pump breaking the pump when the failure accured.

The pick up cant come unscrewed.. the crank would hit

it.. and you say it broke the pump at the pick up.. so I

would assume the rod did that.. you also say it had pressure

when it let go.. correct

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 05:11 AM

yes, looks like a rod hit it. 55psi when it let go.

Posted By: justinp61

Re: carnage at the dyno - 03/07/16 05:12 AM

You had a ton of oil pressure and you spun the #8 rod bearing, all the bearings look oil starved. IMO your clearances were to tight.

Out of curiosity, did you pull the valve covers after it went down? Was there much oil laying the heads?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 05:15 AM

they may have been on the tight side on the rod, but the mains had plenty. why would they show signs of low oil?

Posted By: MR_P_BODY

Re: carnage at the dyno - 03/07/16 05:17 AM

yes, looks like a rod hit it. 55psi when it let go.

The 55 psi when it let go rules out the pick up

and pump

Posted By: justinp61

Re: carnage at the dyno - 03/07/16 05:19 AM

they may have been on the tight side on the rod, but the mains had plenty. why would they show signs of low oil?

They were tight too. How did you set up your bore gauge?

Posted By: mopar dave

Re: carnage at the dyno - 03/07/16 05:23 AM