Moparts

Cracked Mains W/ Aluminum Caps

Posted By: 6bblFLASH

Cracked Mains W/ Aluminum Caps - 07/24/15 11:13 PM

Last time I ran the car was September 14.

Fired it yesterday for the 1st time since,,low oil pressure.

Could`nt find any reason. As it built heat it got worse.20lbs.

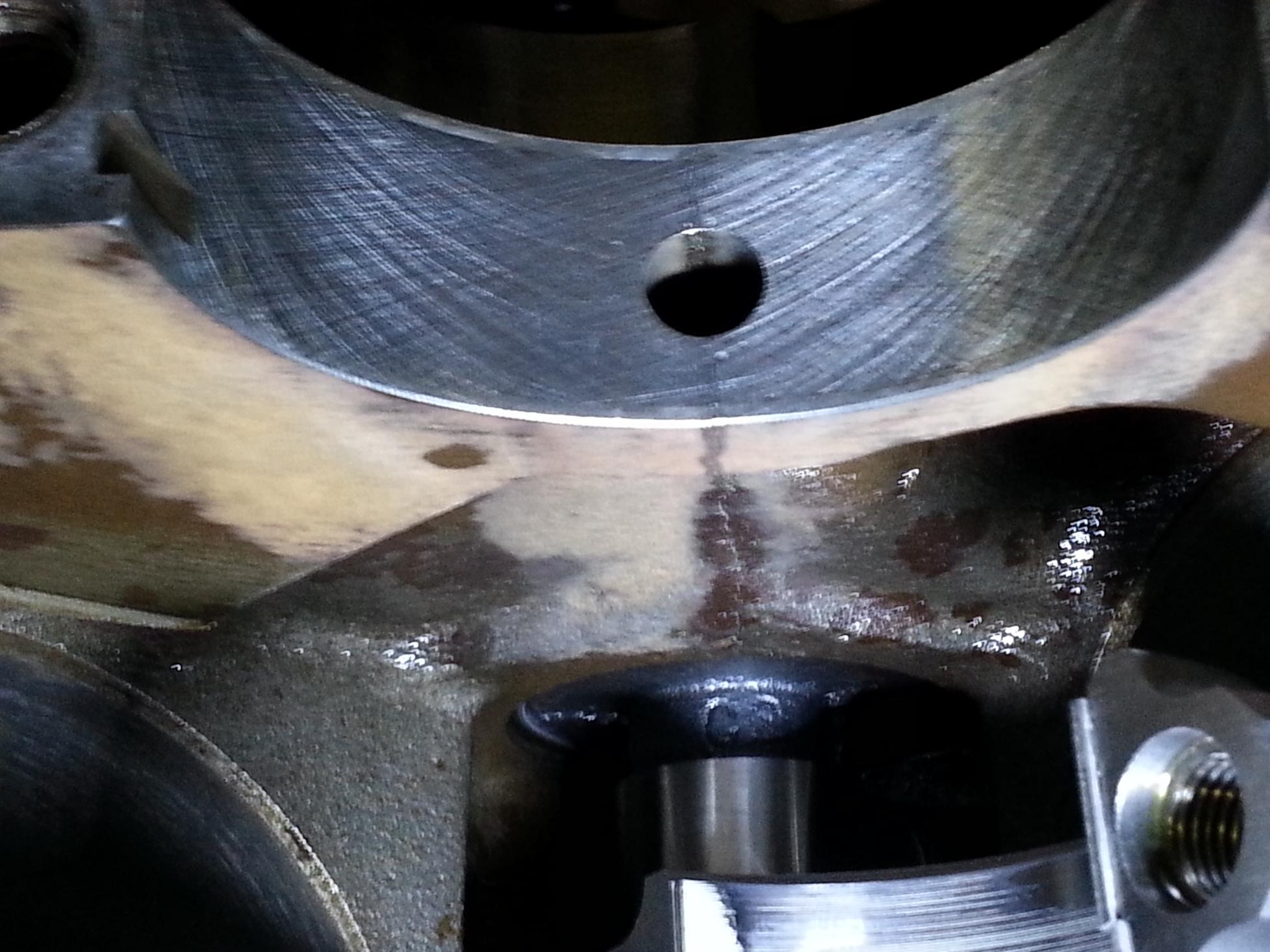

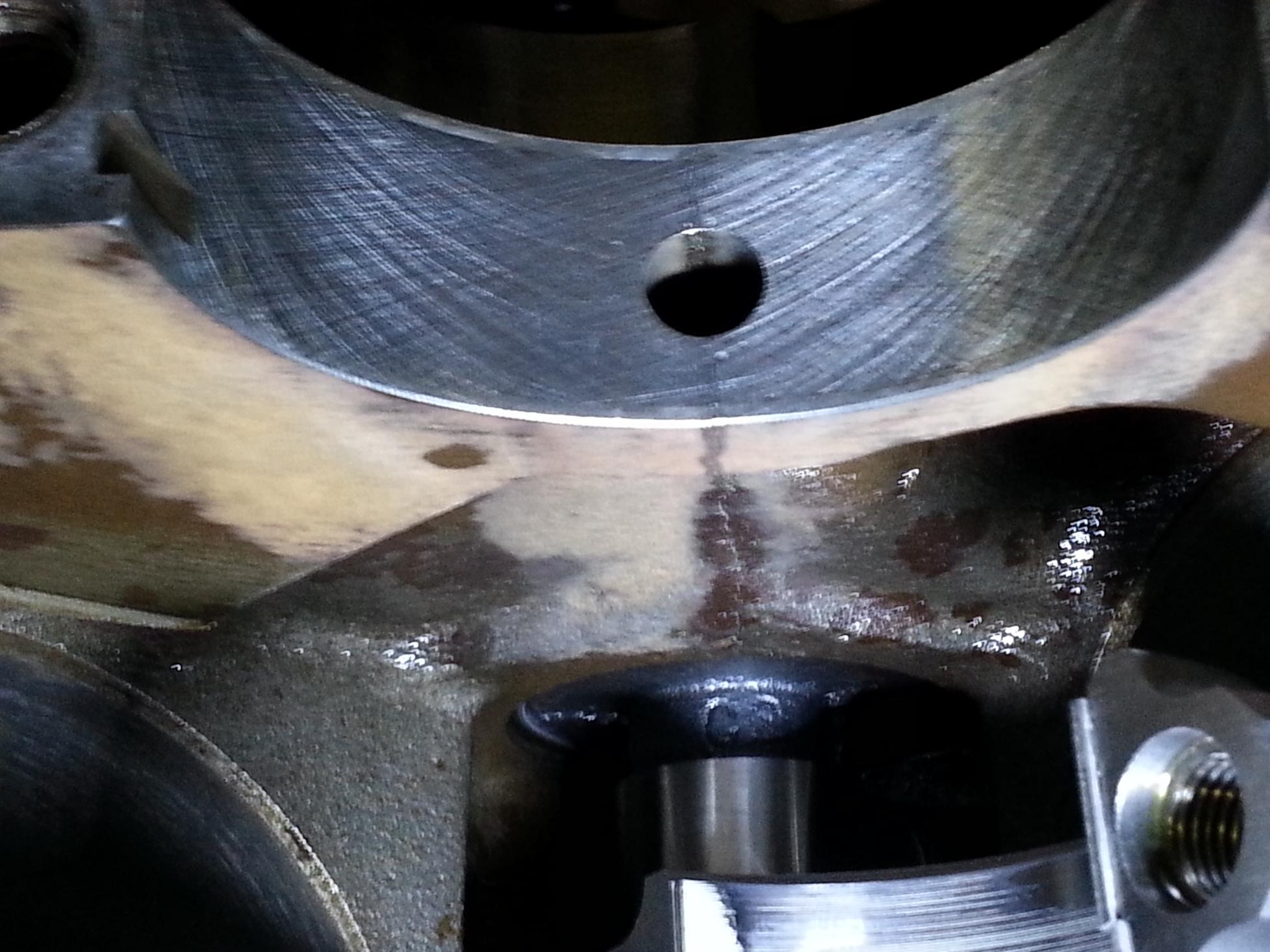

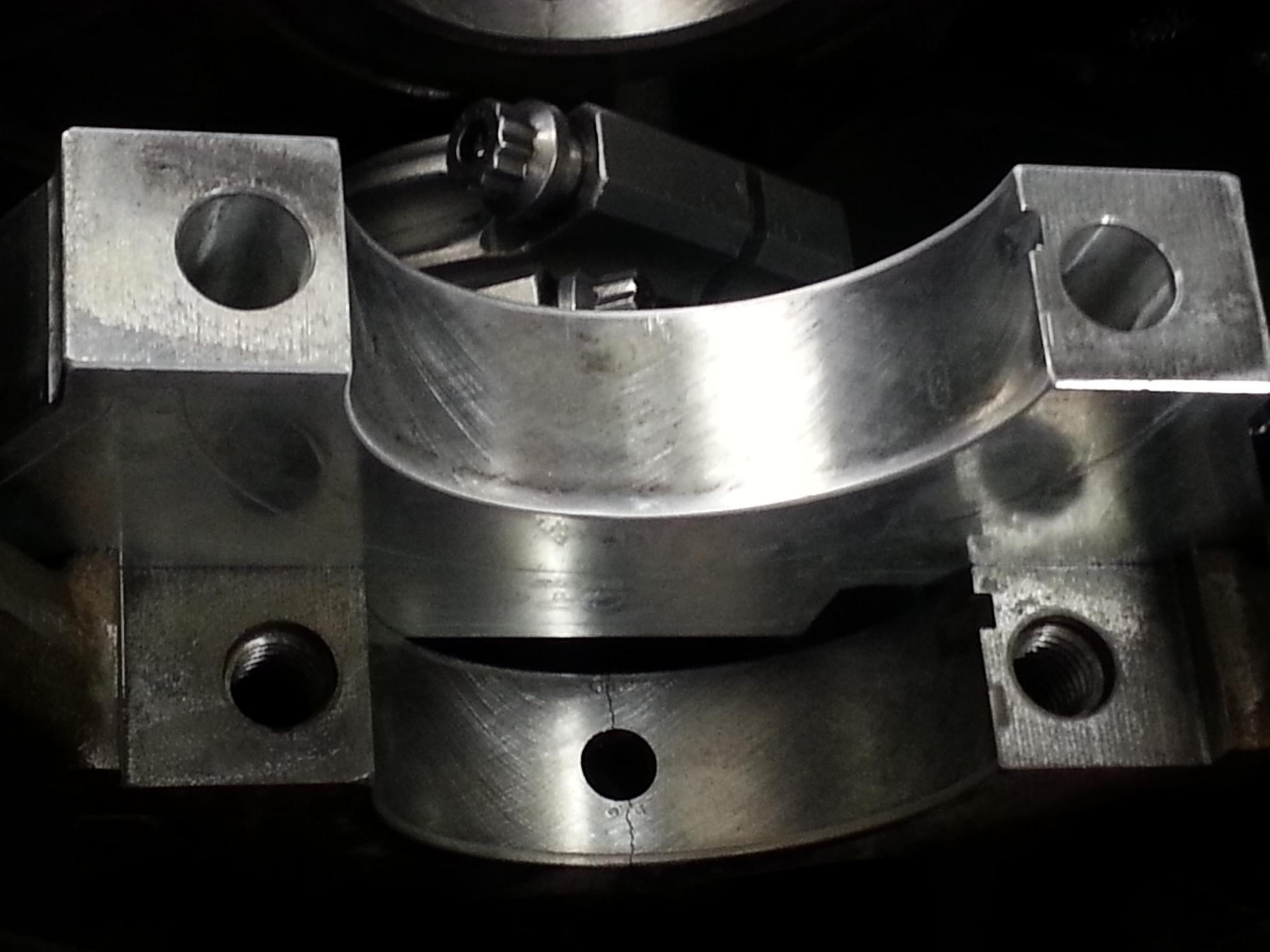

So out it came and this is what I found.

#2-3-4 mains cracked from saddle to cam tunnel.

Machinist says"every motor that Iv`e seen with aliminum caps breaks". Blah blah blah.

So at the 600hp level as I am didn`t expect to see a block crack with good caps.3.75-stroke,.030 over etc.. Estimate 150 passes.

So prep a new block w/the BCR caps ,,,or a stock block std. stuff.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:14 PM

2

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:15 PM

3

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:16 PM

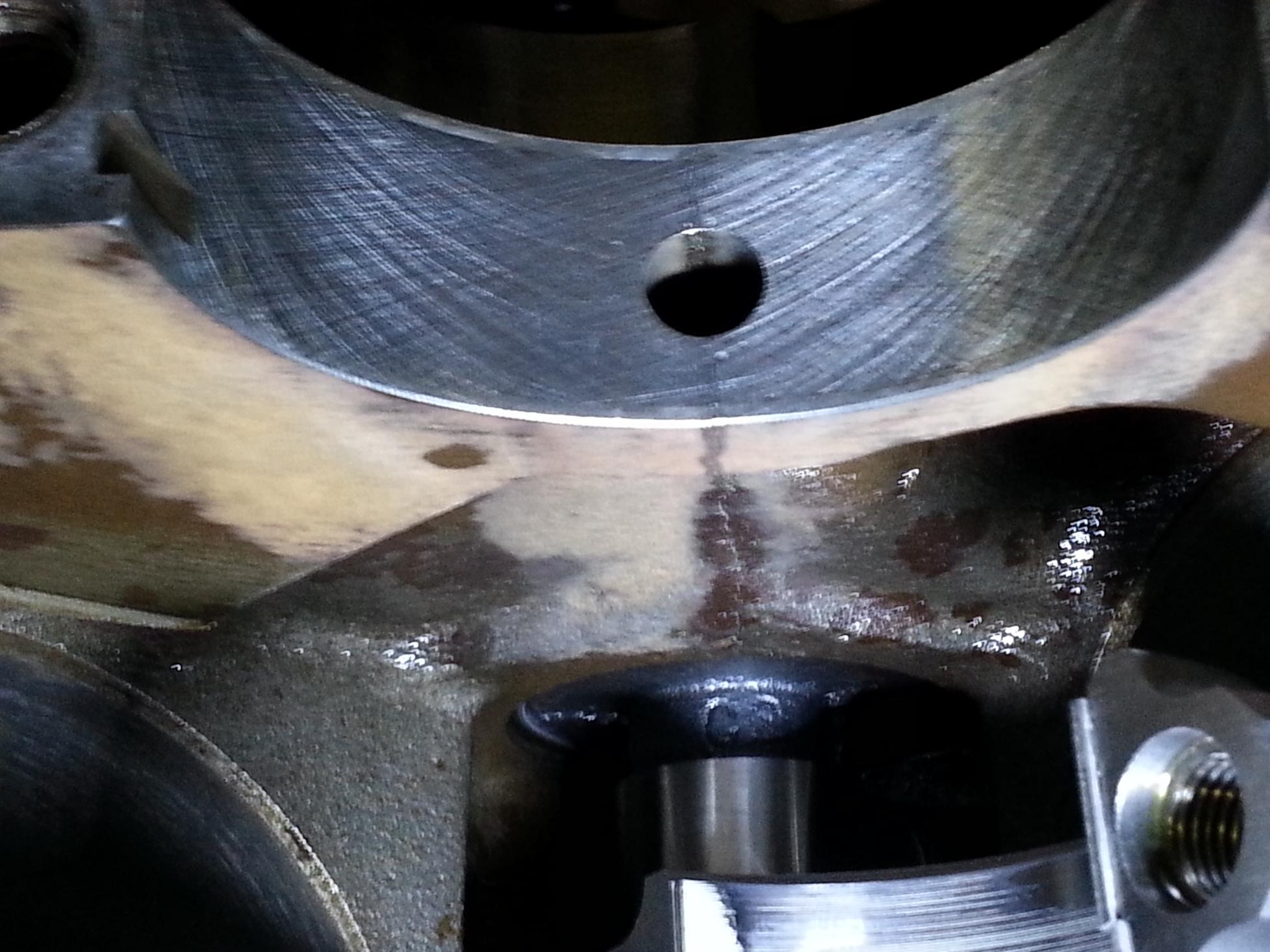

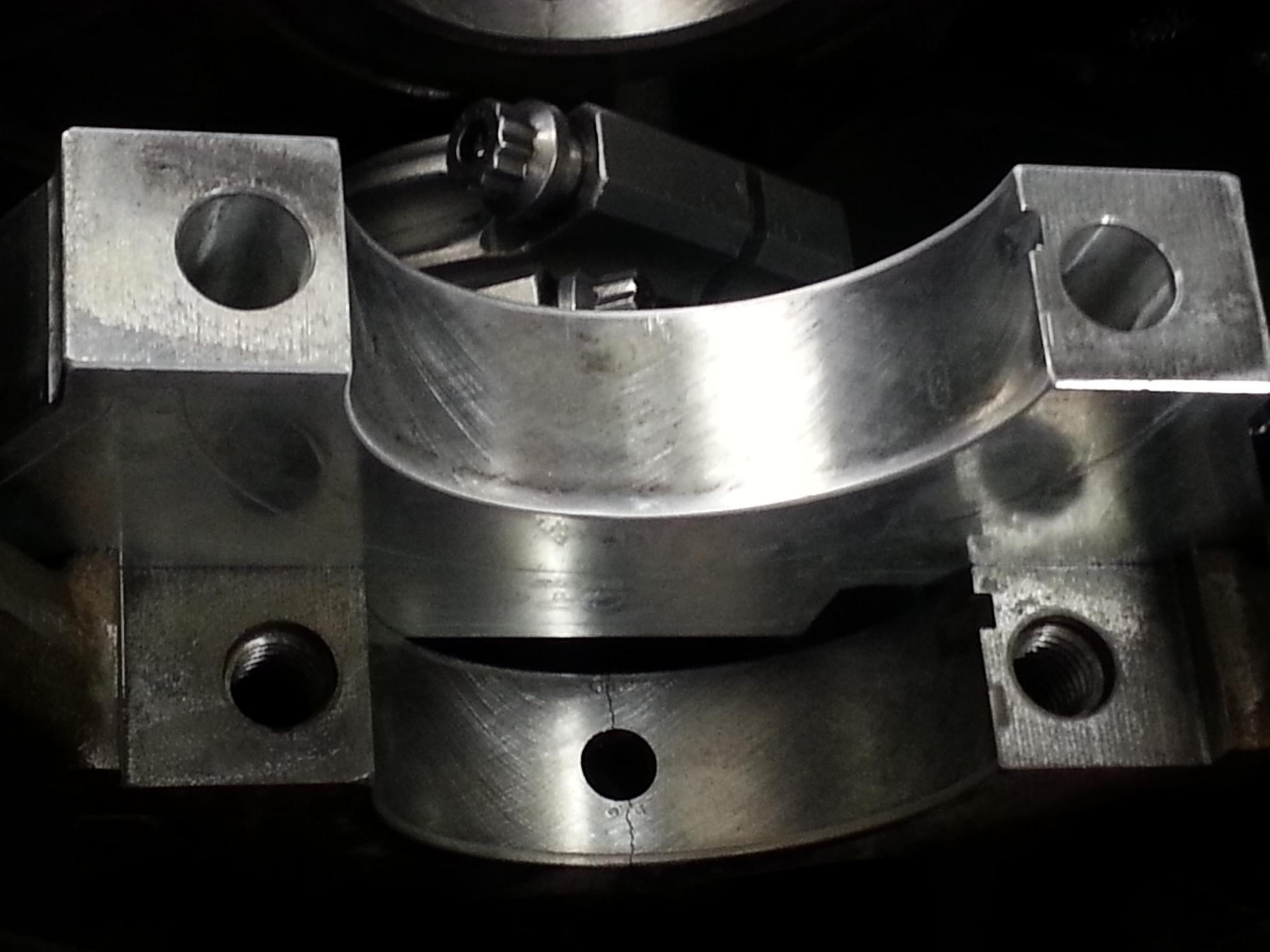

Caps

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:25 PM

Bearings looked/ fit suprisingly good.

3 center main caps were loose,of course and walking.

A little stumped last pass 10.08 normal everything.

fast forward 7/24 busted.

Posted By: DoubleD

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:32 PM

Adding the main caps caps probably helped with doomed block living a little longer.

You found the most common weak link in stock blocks - That is where they normally will crack - its a bummer but that's the gamble with a stock block.

If you remember Berraducci's hemi - that's the same deal that killed his .005 over stock stroke block. No warning just lost oil pressure one day.

I have had a couple do that - some say any detonation is the problem - some say a bad balance causes it. But I think its just the weak link in Big blocks.

Really Stinks to see that - was this the Cuda?

Posted By: gregsdart

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:32 PM

Gee, I guess according to your machinist my motor shouldn't have lived like it did, aye? 400 block, al caps, 499 cubes, 9.30s at 3,000 lbs, five seasons, sold it to another member here and he hit it with nitrous for a while! Sorry to hear about the breakage, hopefully the next one will hold up much better.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:49 PM

Yep..the Cuda.

Tried getting it out 2 weeks ago..brakes on the truck went out moving the trailer in the driveway...then a funeral.... then this.

My turn I guess....

Posted By: cudaman1969

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:49 PM

Drill the holes insert tube keep on racing, there's a lot of metal side to side on that block, can't see it spreading more.

Posted By: DoubleD

Re: Cracked Mains W/ Aluminum Caps - 07/24/15 11:57 PM

Better days ahead - I am sure!

At least you found it before you drove over the crank!

Posted By: '72CudaRacer

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 12:28 AM

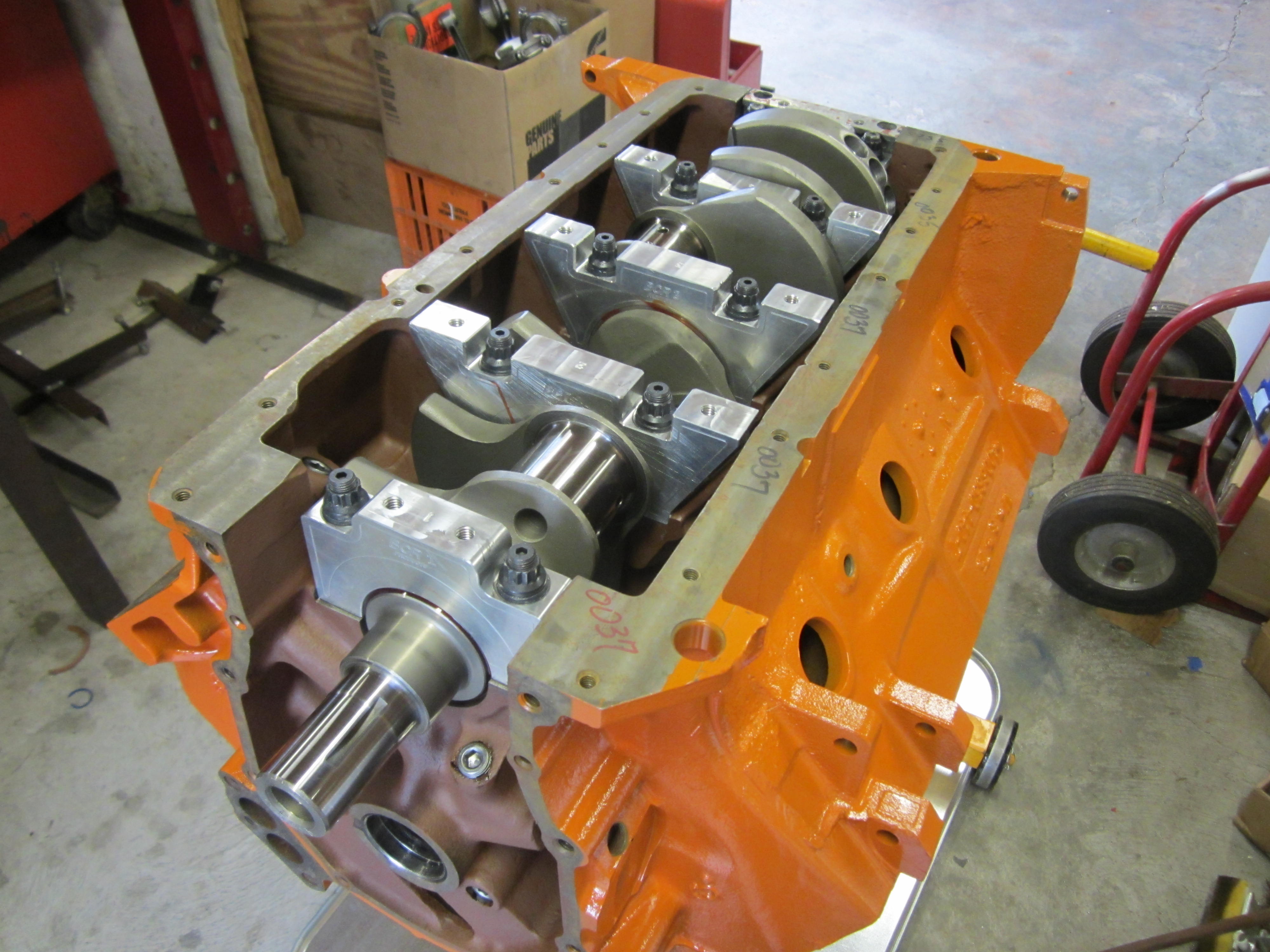

Really NOT what I wanted to see. I just ran my new engine this past weekend. I also went with the BRC alum mains and thick stud girddle set up. Stock stroke (Molnar crank), +.030" Bore, H beam rods, alum heads, mild solid cam. Pretty much the same as yours, except I did find a good block with the thicker main webbs than yours (and my last one block). And yes, I DID almost run over a piece of my crankshaft. I did run over a piece of my block and cut a right rear slick at 100 mph.

To answer your question, I would go back with the BRC set up (it's already bought and paid for!) because I feel like the stock main caps are a "weaker" link than the stock blocks.

Brian Dunnigan

Description: old engine

Posted By: poppaj

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 01:42 AM

Damn, Sorry to here this guys but it wasn't the caps it was the block.

I have seen them live for hundreds of runs or only a pass or two. I like the pre 74' the best if I am going to build one for somebody.

Posted By: nss guy

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 02:30 AM

how many passes on the block?

stock block at 600+ hp maybe 400 passes total, girdle, aluminum caps don't matter.

that's all you going to get, yeah some live longer but..........\

the cracks start appearing then.

so if you get a block that's been raced with 600+ hp for maybe 200 passes and you spend $$$ to rebuild it and upgrade it you still only going to 'safely' get about 200 more passes no matter what

been thru this the last 15yrs

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 03:56 AM

Damn, Sorry to here this guys but it wasn't the caps it was the block.

I have seen them live for hundreds of runs or only a pass or two. I like the pre 74' the best if I am going to build one for somebody.

I'm not blaming the caps or the machine work in any way.

I've been beating on this car 34 years and this is the first block failure.

Didn't expect it to happen in my trailer.

Apparently even ZERO rpm isn't safe!!!

Posted By: super451b

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 05:59 AM

Got 5 years on mine so far. I just have the 2 bolt caps (no girdle )

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 06:23 AM

Just the luck of the draw on a stock block, because you are NOT going to "fix" it, because it can't be fixed. Stock blocks are weak in the main webs and that will never change. Doesn't matter who has done what or how long so and so's lasted. Just is what it is.

Somebody said sleeve it and run it........well you could do that, but eventually what you will "run" is the crank over..........LOL!!!

When I have used alum caps, I prefer the standard two bolt type with no girdle. Many will argue the point, but I think the girdle does more harm than good.

Posted By: SomeCarGuy

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 06:28 AM

I think your machinist sees those failures because an engine with aluminum caps wasnt built to put put around. Not because of the caps.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 08:30 AM

I can clearly see I got away with a potential disaster.

Block was not "fresh" and really have no record of its history.

So now the debate in my head,,,,,lots of empty space for a debate in there....

Low deck or another RB.

I was looking at some of those 383 strokers.

I DO have 3 virgin 383 blocks and 3 virgin 440`s

Don`t want more power,just a little more confidence in my engine....

Opinions

Posted By: sgcuda

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 02:22 PM

I was always told that aluminum rods help act as a shock absorber. Maybe the 440 block will live a little longer at those power levels with aluminum rods and main caps?

Posted By: sr4440

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 02:58 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

Posted By: BSB67

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 03:18 PM

Is this what you are referring too?

70` Cuda`,440 6BBL Jerico,Dana 4.56 Still on 93 Pump Gas 9.87 @ 136.

If so, seems like it might be a bit more than 600 hp?

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 03:19 PM

Sorry to see that. I think you should just stop messing with these money pits and sell me the roller - lol.

In all seriousness though -

1. Do you run stock firing order?

2. If so, can you post up a few photo's of the mating surfaces, both the block and cap of the #4 main.

Thanks.

Posted By: Big Squeeze

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 04:08 PM

Is this what you are referring too?

70` Cuda`,440 6BBL Jerico,Dana 4.56 Still on 93 Pump Gas 9.87 @ 136.

If so, seems like it might be a bit more than 600 hp?

The car must weigh 3,000 race ready.

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 04:19 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

They are cracking for one reason... detonation... to SR4440

31* is a lot on a blower... but other factors also come into

play... fuel, wall thickness.. and cam.. and more... to the

OP... did you put the alum caps on at day 1 of that build and

what was the timing, fuel and cranking pressure

Posted By: AndyF

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 04:57 PM

If you have more 440 blocks and all of your parts are for RB engines then I'd build another 440. You might just think hard about ways to reduce detonation and reduce problems for the bottom end. Aluminum rods might help, double check the balance job on the rotating assembly, careful look at the tops of the pistons and the combustion chambers, double check your AF numbers, etc. You might have a distribution problem and maybe one cylinder is running lean and you don't know it. 6bbl systems are fairly famous for having problems like that.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 05:02 PM

Is this what you are referring too?

70` Cuda`,440 6BBL Jerico,Dana 4.56 Still on 93 Pump Gas 9.87 @ 136.

If so, seems like it might be a bit more than 600 hp?

Yes

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 05:09 PM

Detonation and general abuse are the most likely culprits.

I have proof that #4 cyl has seen detonation over the years.

Flow in the intake is pretty bad on#4.

I`m wanting a bigger cube and less compression like 10.5 or so.

Any opinion on 383 blocks?

Posted By: AndyF

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 05:37 PM

440 blocks are usually stronger than 383 blocks but 400 blocks might be better than either. Hard to say really with any certainty. This stuff is all 40+ years old.

More cubes and less compression might be the ticket. A 4.25 crank in a 440 builds a 505. With 6.80 or 7.10 rods you have a super nice bottom end and plenty of room for a dished piston to get you to 10.5 compression. You can change the gearing and run lower engine speed while still having the same basic power and same ET.

Posted By: ProSport

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 05:52 PM

Many years ago when I was just learning, someone told me that if I want to make it live I needed to go with a 400 block with aluminum caps and no girdle. So I tried it, and made 9 second passes for about 7 years, then ran that same type of combo in another 9 second car for 5 years. Everyone has their own opinions, I'm just telling you what worked for me. I don't know why, but all my friends that have blown up their motors over the years, have all been RB blocks. But alot of guys here on Moparts run them every weekend.

Posted By: sr4440

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 06:32 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

They are cracking for one reason... detonation... to SR4440

31* is a lot on a blower... but other factors also come into

play... fuel, wall thickness.. and cam.. and more... to the

OP... did you put the alum caps on at day 1 of that build and

what was the timing, fuel and cranking pressure

I am sorry, 31 was on my NA junk. I think we were around 21-22 with 10 PSI of boost on the blower.

Joe

Posted By: John_T_Brown

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 07:26 PM

If you have more 440 blocks and all of your parts are for RB engines then I'd build another 440. You might just think hard about ways to reduce detonation and reduce problems for the bottom end. Aluminum rods might help, double check the balance job on the rotating assembly, careful look at the tops of the pistons and the combustion chambers, double check your AF numbers, etc. You might have a distribution problem and maybe one cylinder is running lean and you don't know it. 6bbl systems are fairly famous for having problems like that.

+1

The major problem with stock block main problems are with balance, anything that disrupts that (bob weight, fuel mixture, timing, etc.) will cause the bottom end to do ugly things.

Here is an excellent article on the subject

Engine Balance

Posted By: Cab_Burge

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 07:43 PM

All three RB blocks(1 426 M.W., two 440) I've seen up until now that cracked the main webs where under #1 and #3 cylinders up towards the cylinder walls

I've seen other GM blocks crack the mains like the one pictured here, me thanks that is mainly weakness in the castings and design

Posted By: viperblue72

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 09:54 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

They are cracking for one reason... detonation... to SR4440

31* is a lot on a blower... but other factors also come into

play... fuel, wall thickness.. and cam.. and more... to the

OP... did you put the alum caps on at day 1 of that build and

what was the timing, fuel and cranking pressure

I am sorry, 31 was on my NA junk. I think we were around 21-22 with 10 PSI of boost on the blower.

Joe

A 400 block is a different ball game. Much more rigid block.

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/25/15 10:29 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

They are cracking for one reason... detonation... to SR4440

31* is a lot on a blower... but other factors also come into

play... fuel, wall thickness.. and cam.. and more... to the

OP... did you put the alum caps on at day 1 of that build and

what was the timing, fuel and cranking pressure

I am sorry, 31 was on my NA junk. I think we were around 21-22 with 10 PSI of boost on the blower.

Joe

Years ago I ran a 383 block but with a destroked engine

that turned some high rpm...everything was light and

it was a tunnel ram.. I measured EGT on all cyls just

to see if the flow balance was decent... that engine

lasted till I sold the car and it was still running..

of course this was before the 400 blocks

Posted By: JohnRR

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 07:16 PM

I can clearly see I got away with a potential disaster.

Block was not "fresh" and really have no record of its history.

So now the debate in my head,,,,,lots of empty space for a debate in there....

Low deck or another RB.

I was looking at some of those 383 strokers.

I DO have 3 virgin 383 blocks and 3 virgin 440`s

Don`t want more power,just a little more confidence in my engine....

Opinions

I would say build a low deck , but get a 400 ... this is coming from the guy that is building 383's, but if you go with a 440 use a late block .

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 08:02 PM

My advice would be to buy a good block........which would likely eliminate the chance of you being here in a 150 more passes with the same type pictures, asking for opinions on what to do.

You guys can talk about detonation, balance and all this other stuff. Doesn't change the fact that the blocks are weak there and any 30 year old block to be used as a race block is a serious crap shoot. Even if it is out of your one owner, 67 model grandma car that only has a few thousand miles and never driven over 30mph............Still don't mean a damn thing..........it's a stock block.

Posted By: Al_Alguire

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 08:09 PM

Agree the only true solution is an aftermarket block. That is another can of worms for sure. Best bandaid IMO is aluminum caps, aluminum rods, and keep the bobweight as low as possible. Low deck in generally considered stronger than a tall deck deal and will be a lighter bobweight. Detonation will certainly speed up the demise of either one for sure. So your choice. Spend the money on a stock block and cross your fingers or pony up for an aluminum block as that is all that's out there except for those of us hoarding steel ones

Posted By: Cab_Burge

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 08:11 PM

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 08:57 PM

Lots of ideas to ponder,,,,, thanks for the advise.

Simple math is an aftermarket block is out of the question.

Last 5 years I`ve probably only made 100 passes.

Only go zero to 5 times a year anymore.

In all likelyhood it will be summer 2016 before it makes another pass.

I have the stuff already to build the same+.030 block,crank etc...

Want something better.........

Like the idea of a 400 stroker more cubes less compression.

I`ll get some pictures of the parting line

Posted By: madscientist

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:13 PM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:26 PM

Heres the #4 main/cap pictures Jerry K. asked for.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:27 PM

another

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:37 PM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

I totally understand your point,but thats kind-of a D--k comment.

Am I to undertstand I drive a car to work with rust on it not realizing they sell rust-free ones?

WHO races wore-out junk if they can afford new stuff?

"Just buy a new one"

Sorry,,,that just kinda chaps my a--z

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:40 PM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

What the hell is a P car block.... I've hear of P blocks

(performance) but never heard of P car blocks

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:58 PM

I would be interested in knowing what the max timing was on the blocks that cracked. the reason i ask is i run 843HP (corrected) on my 400 (aluminum caps and griddle) and we put a blower on one and made 1240 hp but kept cracking upper cylinder walls (that block was cross bolted and had a griddle on it also) I run 31 degrees of timing.

Joe

You must have been running some HIGH octane fuel for 31*

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 09:59 PM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

I totally understand your point,but thats kind-of a D--k comment.

Am I to undertstand I drive a car to work with rust on it not realizing they sell rust-free ones?

WHO races wore-out junk if they can afford new stuff?

"Just buy a new one"

Sorry,,,that just kinda chaps my a--z

Why is that a d&^k comment and why does it chap your azz. He wasn't trying to be cute, only stating absolute facts. You are making a good bit more power than a P (passenger) car block was ever intended to make, not to mention they are all nearly 40 years old and have been through no telling what, BEFORE you ever get hands on it to make a race car motor out of it. It may have had the hell beat out of it long before you ever saw it. His point is and we all keep talking about it.........chances are VERY good, that if you build what you had, you will likely get similar results. SO, options are, buy a better block, or lower the potential of that happening again, by reducing stress on the factory block, which generally means reducing the power level.

I am sure you already know what you SHOULD do, so no need to get upset when somebody gives you that advice, because it's not what you want to hear. You obviously have the option to use a stock block again, all he is saying is don't be surprised when you break another one. And how many stock block motors does one build, before the good block would have been cheaper in the long run

I have made over 1000hp on stock blocks before and have broken several as well, but that was a long time ago, when choices were VERY limited. Knowing what I know NOW and the results I have personally had, my stock block builds will be limited to not much more than warmed over street/strip stuff. I just don't care to invest the money, time and effort into something I can't depend on. Don't matter if a 100 guys come on here and say how their so and so Hp stock block motor has been living for a 100 years. That is not MY experience and now, obviously not yours either

Posted By: Sport440

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 10:18 PM

[quote=madscientist]Some

What the hell is a P car block.... I've hear of P blocks

(performance) but never heard of P car blocks

Ive got a P Block, Im thinking production block. Yep, got a few of those.

Edit, yep or Passenger car block, whichever he means.

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 10:18 PM

The BIG thing about blocks from the way back years is the NICKLE

content... the stuff we ran back years ago was like jello... look

at the ring ridge you use to have.. you could never pull a piston

without a ridge reamer... now with the high nickle blocks I dont

even own a ridge reamer any more... they havent changed the design

just what they make them out of

EDIT

Thats for the explanation on the P... never thought about

that... just the P for the performance aspect

Posted By: Old School

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 10:52 PM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

That's all good, and I agree! But, aftermarket blocks for us mopar guys are not just sitting on part supply shelves. Plus their are not many choices.

Sometimes it comes down to availability and reasonable cost.....

Posted By: tex013

Re: Cracked Mains W/ Aluminum Caps - 07/28/15 11:56 PM

That's all good, and I agree! But, aftermarket blocks for us mopar guys are not just sitting on part supply shelves. Plus their are not many choices.

Sometimes it comes down to availability and reasonable cost.....

this for me sums up the main issues .

I am about to start a 440/505 stroker build aiming for 600/625FWHP for my street/strip daily driver . It's even tougher for block choices here in Oz .

Tex

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 04:29 AM

Some how we have gotten to the point where guys making 600 real HP (as the OP says he is) don't think they need an aftermarket block. Not only is reliabilty down using P car blocks so is your HP. Your tune up window is significantly reduced, so a minor tuning error will cost you big time.

If you can't afford/want an aftermarket block, think about a reduction in HP and RPM. What you are using was never designed to have done to it what you are doing. All the tricks in the world won't help that.

That's all good, and I agree! But, aftermarket blocks for us mopar guys are not just sitting on part supply shelves. Plus their are not many choices.

Sometimes it comes down to availability and reasonable cost.....

We all understand that and that is part of the dilemma of being a Mopar guy........but you drop several thousand prepping a stock block with the machine work, caps, girdles, whatever your bandaids are to fix it and it still cracks within a couple hundred passes or less. It's all up to each individual whether they are willing to gamble or not. Some last, many don't

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 07:39 AM

I sent madscientist a PM.

My responce was out of line,I`m a bit sore about the situation.

My bad

Posted By: cudaman1969

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 08:41 AM

Just curious, how was the engine-trans supported? Especially with a manual trans. I would say a lot of external forces being applied to this engine to go along with the internal ones. Bob Glidden wouldn't use a engine stand to build his engines because it would stress it differently then the machining was done. He built them vertically setting on the flywheel, but heck, what did he know about engines. One thing I would do on the next block is have it stress relived in an oven since you don't know how many cycles it's been through.

Posted By: gregsdart

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 11:13 AM

I am surprised more guys don't look into center weighted cranks. They will reduce stress on a stock block, (a lot)and that combined with a low deck 400 block and a light rotating assembly ought to really live well, within reason. Add a good tune and keep the revs down would be the way I go if I couldn't afford to go with an aftermarket block.

Posted By: dogdays

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 07:25 PM

Just what I was going to say.

People get all excited about external balancing an engine, yet any V8 without center counterweights is balancing the inner four cylinders externally, as the balance is mostly in the outer four.

I bet we'd be amazed at the bending stresses on the crankshafts.

R.

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 07:32 PM

Just what I was going to say.

People get all excited about external balancing an engine, yet any V8 without center counterweights is balancing the inner four cylinders externally, as the balance is mostly in the outer four.

I bet we'd be amazed at the bending stresses on the crankshafts.

R.

I can tell you this for a fact......Donovan aluminum block 738 with a Bryant billet crank, ATI damper and the crank sensor set at a .045 gap will flex the crank snout enough to touch the trigger wheel and kill the motor on the chassis dyno.......LOL!!! Did it last week twice before I found it.....LOL!!!.......And NO, there is no runout on the trigger wheel causing it. It just moves that much and that is WITHOUT the nitrous activated

Posted By: madscientist

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 07:45 PM

No apology required.

Just wish there was a way to make it better, other than me dipping into my vast fortune, casting my own blocks, and selling them at a loss so we could get the MoPar car count up

That would assume several things...the first being my vast fortune.................

Posted By: Jeremiah

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 10:18 PM

So...are you guys saying that my aluminum main capped 511" CNC Victor motor isn't going to live with the 200 shot?

Should we be starting a pool? '78 Cordoba block, Jerry's caps, no fill.

Posted By: madscientist

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 10:21 PM

So...are you guys saying that my aluminum main capped 511" CNC Victor motor isn't going to live with the 200 shot?

Should we be starting a pool? '78 Cordoba block, Jerry's caps, no fill.

Nope. We are saying you are asking to break a block in relatively few runs.

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 07/29/15 10:57 PM

So...are you guys saying that my aluminum main capped 511" CNC Victor motor isn't going to live with the 200 shot?

Should we be starting a pool? '78 Cordoba block, Jerry's caps, no fill.

What kind of power and rpm are you planning... dont get

crazy on the timing

Posted By: StricNine

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 02:14 AM

So...are you guys saying that my aluminum main capped 511" CNC Victor motor isn't going to live with the 200 shot?

Should we be starting a pool? '78 Cordoba block, Jerry's caps, no fill.

It'll be fine if the Cordoba came with soft Corinthian leather seats.

Posted By: sixpackgut

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 04:57 AM

The solution

Build a 600hp Gen 3.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 06:59 AM

The solution

Build a 600hp Gen 3.

That is EXACTY what I`m researching...

Care to give the run down and basic price/parts to get where you are at.??

Heres what I have figured out:

Reliable isn`t AFFORDABLE

Affordable isn`t RELIABLE

So neither is PRACTICAL

Posted By: Jeremiah

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 08:05 AM

Well, in the case of failure I just budget an extra short block...until we bought another car for it lol.

I'll start another thread with pool info once we get ready for dyno day.

Posted By: MoparBilly

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 08:07 AM

You detonate it, you break it.

Impossible to build a detonation proof engine, so everyone wants to blame the stock block instead of their aggressive tune-ups.

Between my Dad, 3 brothers and I, we've raced for 25 years, and beat on over 35 B and RB engines and never, NEVER cracked a main web...not once! Split cylinder walls, yes, broke LY rods, yes, all kinds of other carnage, sure...but no main web damage.

Current engine in my brother's 3300lb street strip Gremlin is a non filled 440 with stock caps and ARP studs, stock 440 crank, h-beam rods, icon pistons 10.5 to 1, solid cam with Indy-1 heads and two big shot plates. 8.87-149 at 16 degrees of timing and C-12. He wasted two sets of pistons with fuel delivery issues, and claims the cap walk chaffing is "significant", but it has two drag weeks, thousands of street miles and a 100 runs on it.

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 08:26 AM

^^^^^^^So you appear to be saying that ALL these people who break blocks and have over the years, apparently have no clue what they are doing.......Interesting point of view

Posted By: MoparBilly

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 03:51 PM

EXACTLY!! Thanks for clarifying it so well, Monte...wait a minute, no, no...that's not what I meant. I see what you did there...I think.

I'd say they know what they are doing, trying to wring every bit of horsepower and ET out of a given combination, and that usually puts them on the ragged edge of detonation. That's the game we play, and the line you can't step over is a moving target depending on components in and on the block, the weight it's pulling, the fuel used, and the weather conditions on that day (not the weather they had on the day it ran it's best number).

There is a story about a guy taking a motorcycle licensing test who was instructed to ride up to a white line and stop as close as he could get to it, as if it was a brick wall.

He stopped four feet from the line, and the instructor commented, "That's as close as you can get?" The rider shot back, "If that's a brick wall, that as close as I want to be!!"

I know there is a line where stock blocks break, I don't think it's 600 horsepower.

I know there is a point where all the bandaids you put on a stock block to allow you to ride closer to that line stop making sense as well. I like aluminum caps, but I've never purchased or installed a girdle.

Posted By: sixpackgut

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 04:47 PM

The solution

Build a 600hp Gen 3.

That is EXACTY what I`m researching...

Care to give the run down and basic price/parts to get where you are at.??

Heres what I have figured out:

Reliable isn`t AFFORDABLE

Affordable isn`t RELIABLE

So neither is PRACTICAL

I have a 426 but 6.1 blocks are hard to find.

so a stroker 5.7, eagle heads with valvesprings, stock rockers, cam 600/250 range, good pushrods, the knockoff drag pack intake with porting would get you there.

with my 426, I shift at 6800 with 3.55 gears and cross at 6100. I just put 4.10s in though. and I'm 150-200 lbs heavier than your at.

Steff spun his pretty hard but his engine is a 400 but is heavier than me and runs the same number as us.

Posted By: pittsburghracer

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 07:50 PM

I now have a Keith Black block but this is how I look at it. It costs me less than 400 dollars to prep a 440 block and that includes cleaning and boring. I install my own cam bearings, block prep, and assembly so that keeps costs down. My first 440's ran hundreds of high 9's-10.40's and only cracked and broke stock forged cranks. When I bought my 2500 pound daytona it ran 9.0's-9.20's for years with zero issues other than cranks showing cranks on 3 year rebuilds. When I built my 440source 500 inch engine it ran 8.60's-8.90's with the only other upgrade being 440source billit main caps. When I tore the engine down for rebuild after 275 (8 second) passes I found that the block was cracked. No water or and other sign of it being cracked. This engine even hit 8500rpm at the line once when it destroyed a set of 4.30 9 inch ford gears. I never have used or will use concrete in one of my engine blocks. I have another 440source 512 cubic inch assembly sitting here that will be running 8's again in my other Duster soon. For the peanuts I spend if I get 250 runs out of a block I will be happy as heck. But being diapers are so cheap now it will probably be wearing one.

Posted By: Cab_Burge

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 08:48 PM

Find a decent 400 block and do the same thinhgs as your doing to the 440 block and never look back or have any regrets on using a stock block

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 09:06 PM

Well, I can't prep any block for $400. Because by the time you have it bored, honed, cleaned, decked, main housing bores checked, line honed for alum caps(which I use), deburr it, cam bearings, plugs, chase threads, etc, you have well over $400 into it. Sure, you can do a lot of that yourself, but time is time and is not free. Whether you do it, or pay someone to do it, still requires all the same work and my time is worth something.

You might say, well I won't deck it. You could do that, but most stock blocks are terribly inconsistent from side to side, front to rear and lifter side to outside. I won't even build a stock type replacement without squaring it. Same on the line hone. I have yet to check one that met MY standards and if you put caps on, it's a must.

These days power is EASY to make. A mild cam, some decent alum head and stroker kit or not, a 600hp motor is nothing. That's EASY and most want more. So you have some nice alum heads, a 512 rotating assy, with a pretty healthy cam and get it together and think "I should really run this real easy, because I have a stock block". Whats the point in buying the GOOD parts if you can't use them to their potential. Most guys just don't think that way. We want all we can get and is generally the point of building a "good" motor.

Stock block is just a crap shoot, always has been, always will be.

Using Billy's example above. At the weight of the Gremlin, the ET and speed, they make about 900HP on both kits. So if each plate is 150ish, they are around 600hp on motor. Will that live for thousands of street miles and two Drag Weeks......sure it will. He says it has 100 track passes. OK, were those 100 passes ALL on two kits at the 900HP level.......probably not. You take that thing to the track EVERY weekend and every hit you make is on the jug on two kits, I am betting it's life would be pretty short.

Now I am NOT trying to discourage ANYBODY from building a stock block motor. It's your money and you can do as you wish. But you screw one together it makes well over 600hp, you should not be in the least bit surprised when you knock the main webs out of it.

Posted By: HotRodDave

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 09:09 PM

I am no expert but that looks like a 75 or older block with the thin webs, if you don't want to go to the 400 than at least get a 77-78 block with the thicker webs.

Posted By: madscientist

Re: Cracked Mains W/ Aluminum Caps - 07/30/15 09:27 PM

Well, I can't prep any block for $400. Because by the time you have it bored, honed, cleaned, decked, main housing bores checked, line honed for alum caps(which I use), deburr it, cam bearings, plugs, chase threads, etc, you have well over $400 into it. Sure, you can do a lot of that yourself, but time is time and is not free. Whether you do it, or pay someone to do it, still requires all the same work and my time is worth something.

You might say, well I won't deck it. You could do that, but most stock blocks are terribly inconsistent from side to side, front to rear and lifter side to outside. I won't even build a stock type replacement without squaring it. Same on the line hone. I have yet to check one that met MY standards and if you put caps on, it's a must.

These days power is EASY to make. A mild cam, some decent alum head and stroker kit or not, a 600hp motor is nothing. That's EASY and most want more. So you have some nice alum heads, a 512 rotating assy, with a pretty healthy cam and get it together and think "I should really run this real easy, because I have a stock block". Whats the point in buying the GOOD parts if you can't use them to their potential. Most guys just don't think that way. We want all we can get and is generally the point of building a "good" motor.

Stock block is just a crap shoot, always has been, always will be.

Using Billy's example above. At the weight of the Gremlin, the ET and speed, they make about 900HP on both kits. So if each plate is 150ish, they are around 600hp on motor. Will that live for thousands of street miles and two Drag Weeks......sure it will. He says it has 100 track passes. OK, were those 100 passes ALL on two kits at the 900HP level.......probably not. You take that thing to the track EVERY weekend and every hit you make is on the jug on two kits, I am betting it's life would be pretty short.

Now I am NOT trying to discourage ANYBODY from building a stock block motor. It's your money and you can do as you wish. But you screw one together it makes well over 600hp, you should not be in the least bit surprised when you knock the main webs out of it.

And this is the real problem^^^^^^^^^^^. When I was growing up, every one and their mother had a 500 HP SBC and they did NOT. Today, the blocks are 30 plus years older, cams/induction/ignition/chassis/tires/fuel systems are all better. Where as you could screw together a decent 350-375 HP small block or a decent 500-525 HP big block, now you can do 500 plus small blocks and 600 HP big blocks all day long, screwing half of it up. RPM's are higher, strokes are longer, R/S ratios are WAY less so the blocks see more stress than ever. And we haven't even began to discuss power adders.

I know guys are building big HP crap on P-car blocks all the time. There are times when I do it, but I whine like a girl because I know its a grenade with the pin pulled.

I guess we no longer respect HP numbers the way we (at least I)did. We are lucky today because of what was done 34/40/50 years ago, by guys who developed ideas and products that allow us to absolutely kill it in power making.

I always like to ask the customer the question this way: if we bought a Pro Stock engine and drive line and put it in your 8.50 car, will your 8.50 car magically run 6.60's??? No, because the chassis won't take the HP, TQ, RPM etc. It's too flexible.

It's the smae scenario with a block. It needs to be solid or it will flex. The it will crack and fail.

Posted By: cudatom

Re: Cracked Mains W/ Aluminum Caps - 07/31/15 02:51 AM

Hi Dennis sorry to see the damage. We've known each other since the late 70's and you have always seemed to get the most out of your combos.

So if it was me I would stick w/what you have. You only had 150 runs on the combo in 5 yrs. Hopefully you will be able to get it out more often but if not in 5 yrs we will be around 60. Hope to still be doing this but who knows.

I would bump your octane up a little to eliminate any detonation. Beaver Petroleum which is in Waco is close by. They have 110 and 112 at the pump. Mix some in w/your 93 and get the octane up to 96-98. Yeah I know its nice to say its a pump gas motor(technically it still would be pump gas) but at this point in our lives we start thinking twice about those large outlays of cash(yeah says the dumb A that is trying to put 2 cars together now Lol). I know you will get it going again, you always have and I look forward to seeing the Cuda at the track again.

Good Luck Dennis

Tom

Posted By: cudaman1969

Re: Cracked Mains W/ Aluminum Caps - 07/31/15 06:55 PM

"It's the smae scenario with a block. It needs to be solid or it will flex. The it will crack and fail."

_________________________

Do you really think any block doesn't flex? Even a solid moves. Heat up a bar to 150 degrees, mic it, let it set in freezer awhile ,mic again.

I guess we throw away all of our 440-400 blocks because the "powers that be" have said 600 hp is the limit. Now we just go buy the 5 grand nonexistent blocks laying around. I have zero money in mine so after 1grand machining I got maybe 200 runs so I do each one till I get up to that 5 grand block(plus the machine work it has to have). So that's a thousand runs to how many does the big money block have in it. Any real race engine is a ticking time bomb. So cost effective, don't think so

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 07/31/15 07:09 PM

Thanks Tom....

More than likely it will be another RB.

Like you said how much longer does it need to last?

440 is the cheapest by far.....

Posted By: pittsburghracer

Re: Cracked Mains W/ Aluminum Caps - 07/31/15 07:43 PM

The way I look at it you can spend thousands on a stock block or spend as little as possible. My 8 second combo is still being used by a member in his street car so it is still going strong. If you make a lot of HP it IS going to break if you race it often, NO MATTER WHAT. No band-aids will stop that. Some of the guys saying you have to do this and you have to do this haven't had their car running for years claiming they can't afford it. No kidding. Use good gas, be careful with the timing, and don't rev the heck out of it. The little gained is just not worth it.

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 03:06 PM

Heres the #4 main/cap pictures Jerry K. asked for.

Would it be safe to assume this is the worst of the five at the mating surface?

Either way, the evidence doesn't support detonation as the bore is too clean and brite, I would lean more towards inherent casting stress and harmonics.

What does the rod bearing shells look like on the back sides? brite or dark? are they still snap fit or do they drop out of the rods and caps?

Detonation can obviously kill parts, but its also going to leave a good bit of evidence behind, we haven't even discussed piston decks, ring lands, chamber coloring and so on.......lol

I would forge on with the RB block for your objectives, just make sure the balance is done by a reputable shop, keep the balance neutral and if you can swing it ($) switch to a 4/7 & 2/3 swap cam, one of the best kept secrets for reducing harmonics, the cores are not cheap but it is good insurance.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 03:42 PM

Interesting info Jerry.

All the bearings fit tight,no loss of crush.

However when it comes to detonation "hammering" the bearings that has not always been my experience.

I have 8 pistons out of my boosted 440 streetcar that pushed the ring lands down,all the bearings were fine.

On the 440 in question I collapsed the ring lands and dished the piston top from detonation on #4 piston a few years ago[different block} and the bearings were fine in that one too...

I have torn down engines that have lost all the crush and the bearings are curled against the crank...

I can only assume there is different levels and conditions surronding detonation damage.

Can anyone explain how you hammer/deform a piston and not see it in the bearings??

Must be something I`m not looking for...

Posted By: HardcoreB

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 03:58 PM

Just my opinion but I'd redo another stock block. Get good sonic numbers on the bores, aluminum caps, make sure you have a good balance and BALANCER (ATI or ?). Ditch the 6-pac intake OR fix the distribution issues validated with port EGT's. Build it with good quench and keep it out of detonation. I think it will live well in your current HP level. I agree with MoparBilly/Pittsburg racer etc.

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 05:50 PM

I probably didnt phrase that the best....as you have seen yourself detonation can produce a variety of side effects...all pending on the root cause.

My position on your conditions is that it is not detonation. Detonation will not crack a block without significant other evidence/conditions occurring.

Number 4 chatter is a given when things are less than optimal....and that is evident in the photo....my questions where what else are you seeing in conjunction with that?

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 06:15 PM

I probably didnt phrase that the best....as you have seen yourself detonation can produce a variety of side effects...all pending on the root cause.

My position on your conditions is that it is not detonation. Detonation will not crack a block without significant other evidence/conditions occurring.

Number 4 chatter is a given when things are less than optimal....and that is evident in the photo....my questions where what else are you seeing in conjunction with that?

I will post more pictures later of piston tops,combustion chambers.

What else would you like to see?

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 06:18 PM

Anything abnormal.....

at the track right now on my phone and about to get real busy....will look tomorrow am at what you have

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 08:37 PM

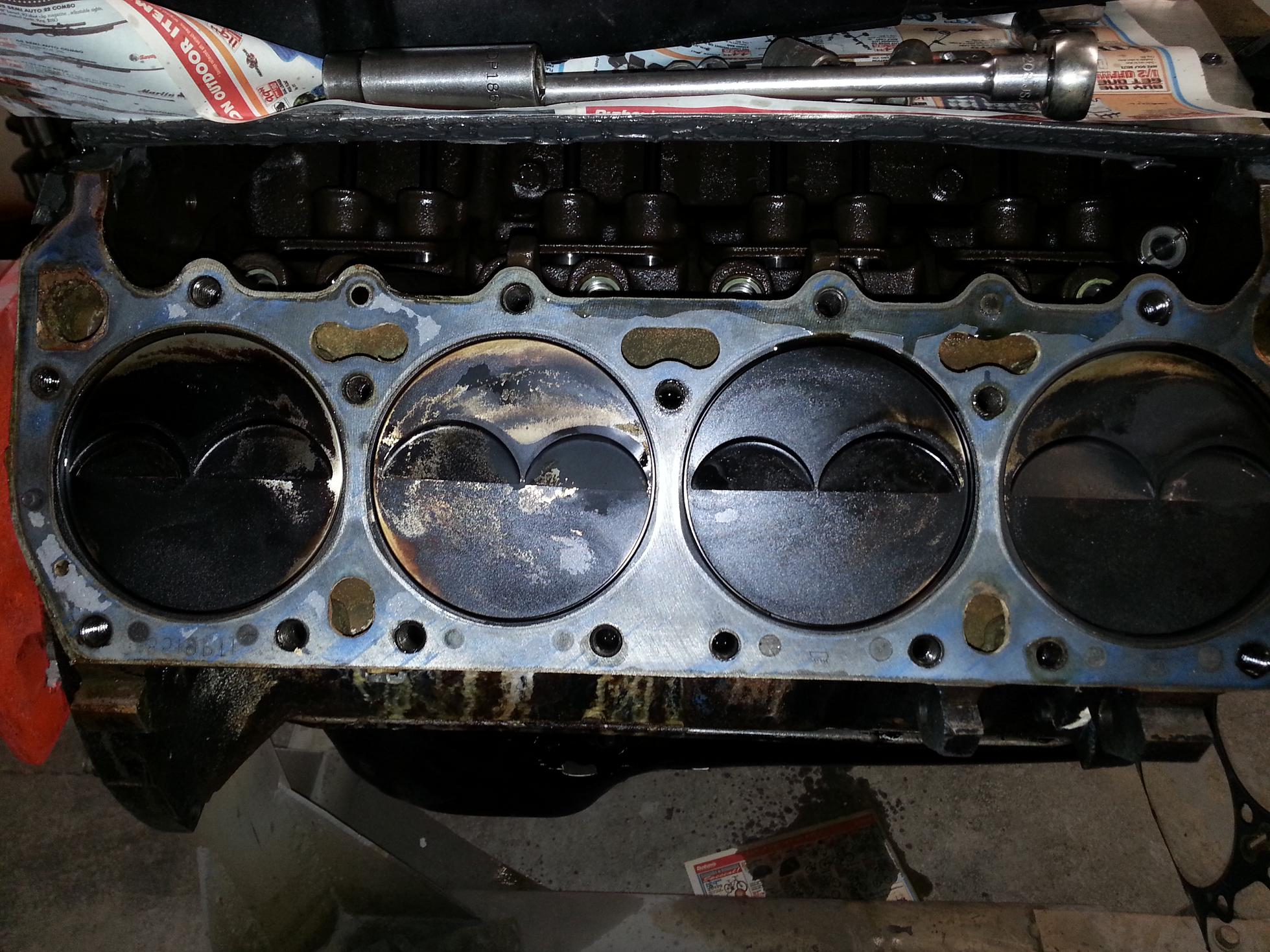

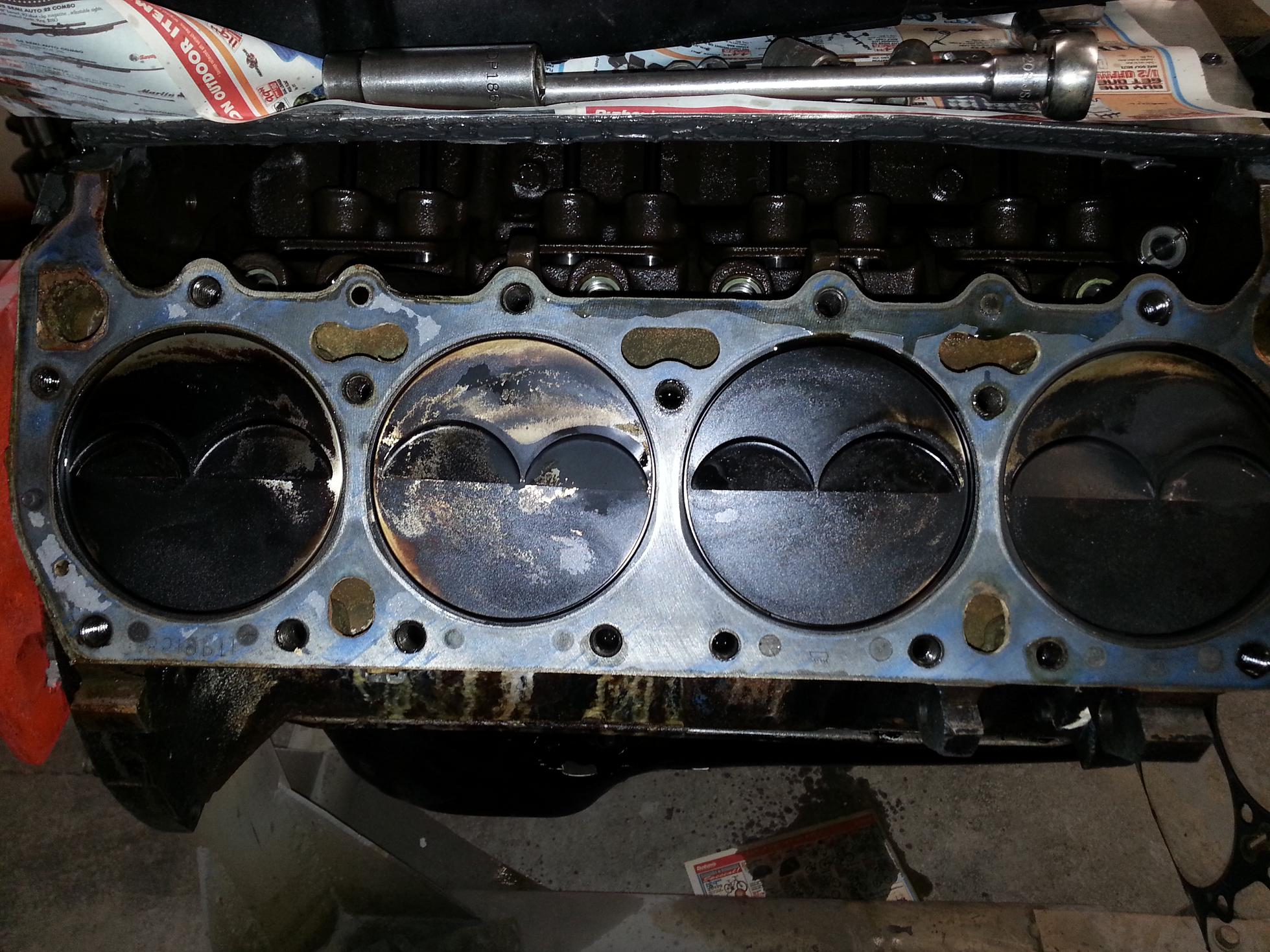

#4 Chamber

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 08:39 PM

piston

Posted By: TRENDZ

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 09:31 PM

Are you running it with fuel from your 2 stroke weed whacker?

Posted By: MR_P_BODY

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 09:42 PM

Is that a COMPLETELY filled block?

You can see that the distribution is all wrong

Posted By: Sport440

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 09:43 PM

That speckling look your pics are showing are sure signs of detonation. Also looks like your burning allot of oil witch promotes detonation. The One chamber pic doesn't look nearly as bad as the pistons, but seems to show some slight speckling as well.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 10:31 PM

P-Body,no block is filled to the top of the core plugs.

Trendz,no 2-stroke !

Sport, oily look is probably from the winterizing. Engine was only run maybe 5 minutes since put in storage last fall. I put Stabil in each carb. thru the vent and fog the engine.

When started all that stuff is still in there.

Never smoked,used oil. Plugs were fine last time checked.

Who knows what the piston tops would look like after a run

Posted By: Jeremiah

Re: Cracked Mains W/ Aluminum Caps - 08/01/15 11:29 PM

Perhaps the intake ports were sucking oil and causing the detonation and black piston top issue?

Did the plug have a dark side on the porcelain?

Did you post a picture of the intake ports or can you?

Thanks for sharing I am learning lots of good stuff from this thread!

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 07:46 AM

That motor is NOT sealed up at all and number 4 is oiling pretty bad..........or at least a good bit worse than the others. Pistons don't look like that because you ran some stabil through it. It's not sealed very well. And is it me, or are the valves seriously sunk in that chamber. Are they all like that?

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 03:08 PM

Clearly you have some issues going on in the photos above. I’m not a fan of filling these blocks as they are venerable to begin with and then you compound the problem with growth and shrink cycles from the thermal dynamics. That will focus the stress in the areas that can move and gray iron is weak to begin with.

IMO…..I would do another build using a stock block as I don’t believe your power level is anywhere near a problem. Don’t fill it, use ARP studs on the mains, and have them in place with all the machining processes, specifically when line boring, cylinder finishing and decking (if done). Use aluminum caps if you think they help….but FWIW….I never have used them and for the same reason as I don’t fill (thermal growth dynamics). The #4 hole may look worse because it detonates the least….IDK…..the carbon on #6 looks like some of it may have been “blasted” out…..lol

You deal is pumping a lot of oil…..maybe detonation has contributed to the rings not sealing and is some of the culprit there, pull the pistons and closely inspect the ring faces and piston lands, that should disclose more. Now that we know your block has been filled and you didn’t disclose any bad news with the other main caps/mating surfaces…..I further do not believe it was detonation that cracked the block. Start fresh, make things right and it should live…. BTW…..who did the valve job? , maybe you should take your stuff elsewhere?….lol….it can defiantly make more grunt than it did….lots of low hangin’ fruit on that tree….lol

Did I understand you are using a stock six pack intake? If so, ditch it and find the wieand or build one similar, as mentioned, it’s not the hot set up for even distribution at upper RPM….another potential source of detonation.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 05:32 PM

Ok, thanks for all the free info.

The carbon is soft ,comes off with fingernail.

Heads are "as shipped" from Muscle-Motors 1999. Guides are good but those spring pockets hold alot of oil. Maybe the seals can`t keep up?

I not so sold on the rings/pistons not doing their job.

It makes good power for a "junk" motor....

6bbl intake that isn`t any good

.590 MP cam that is obsolete

Stage^6 heads that were never any good

.030 3.75 440 runs into the 9`s @ 3,050lbs.

I will look for the source of the oil,and start FRESH,no block filler, and see what I get........

Posted By: FastmOp

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 06:54 PM

I use hardblock and won't run a stock block without it. Hardblock is magnetic because it's designed to heat and expand and contract like cast iron.

Oil causes Detonation, nuff said.

You have more oil then I like. I would check everything that controls it.

Sounds like the heads might need seals and oil drans if u can.

Your intake might need a surface cut if it's letting oil in around the heat crossover. I try to block all that crap.

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 09:53 PM

Not trying to be a smart azz here.......but whether you are "sold" on it or not, that motor is NOT sealing. It pumps a lot of oil and that doesn't come from the seals. That is by the rings. The bores are either too big, not straight, not round, the rings just never seated.......or all of the above. If it was sucking oil in the ports, it would smoke. By the rings, not so much.

The pistons that are "somewhat" clean near the top, that is just a function of the quench and where it makes enough heat to burn the oil off. Number 4 is cold. That cylinder makes no power.

The motor could have ten or 1000 passes. Carbon is black, but it's dry. Oil is wet and shiny..........that's what I see.

Opinions are like..........well you know........and everybody has one, but I am a firm believer in both alum caps and hard block in cast iron motors. Obviously ALL the machine work has to be done AFTER the pour. Factory cylinder walls can be thin. The hard-block is to KEEP THE BORES ROUND. They don't stay round, it will NEVER seal

And those heads are in SERIOUS need of some new valve and a decent valve job. Can't be any margin there and they are WAY deep

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/02/15 10:11 PM

Not trying to be a smart azz here.......but whether you are "sold" on it or not, that motor is NOT sealing. It pumps a lot of oil and that doesn't come from the seals. That is by the rings. The bores are either too big, not straight, not round, the rings just never seated.......or all of the above. If it was sucking oil in the ports, it would smoke. By the rings, not so much.

The pistons that are "somewhat" clean near the top, that is just a function of the quench and where it makes enough heat to burn the oil off. Number 4 is cold. That cylinder makes no power.

The motor could have ten or 1000 passes. Carbon is black, but it's dry. Oil is wet and shiny..........that's what I see.

Opinions are like..........well you know........and everybody has one, but I am a firm believer in both alum caps and hard block in cast iron motors. Obviously ALL the machine work has to be done AFTER the pour. Factory cylinder walls can be thin. The hard-block is to KEEP THE BORES ROUND. They don't stay round, it will NEVER seal

And those heads are in SERIOUS need of some new valve and a decent valve job. Can't be any margin there and they are WAY deep

All good points Monte, I don`t claim to be an "expert",but I ain`t a novice either.

I will pull some pistons soon and post what I find.

I`ll wager a dirty sock that #4 has damaged ring lands again.

I had too much clutch in the early days and loaded the motor too hard.

Ran it the same way for many years.

Never had an issue till I tried a 2-step,,then a 4-spd.

Live and learn

Posted By: cudaman1969

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 01:44 AM

Do you have a mid plate attached to frame and elephant ears on front? Or does engine hang from trans mount to the ears? Full cage? What type trans, clutch, rear tires? Just trying to get a feel of the shock loads to stand the car up like that. Does it do it every time? Good looking car by the way, one of my favorites.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:45 AM

Do you have a mid plate attached to frame and elephant ears on front? Or does engine hang from trans mount to the ears? Full cage? What type trans, clutch, rear tires? Just trying to get a feel of the shock loads to stand the car up like that. Does it do it every time? Good looking car by the way, one of my favorites.

Thank you...been my baby for 34 years.

No midplate

Basically "3" point mount 2 at the front 1 rear.

Everything but the halo-bar. Everthing is tied together.

Jerico DR4,4.88 Dana,14x32 MT stiffwall.

Without the wheeliebars it would go vertical.

Thats what 50/50 weight distribution will do with a torqy motor.

The 4 speed is not going back in and is for sale....

Posted By: AndyF

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 07:50 PM

You might want to consider changing engine shops.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:50 PM

Piston/rings #4

Rings are free and side clearance OK.

Thought I would find damage.

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:52 PM

Another

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:54 PM

Bore

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:56 PM

#4 rod

Posted By: madscientist

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 08:59 PM

Wow the bore looks rough. Especially for a moly ring.

Posted By: Thumperdart

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 10:26 PM

I see what looks like oil which requires more fuel to burn which means LEAN which leads to detonation............

Posted By: unknown

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 10:49 PM

Im not sure if its just the picture, but im not seeing a good cross hatch on that honing job ????

Posted By: Sport440

Re: Cracked Mains W/ Aluminum Caps - 08/03/15 10:54 PM

Piston/rings #4

Rings are free and side clearance OK.

Thought I would find damage.

That bore does look a little rough. Id like to see what your ring gaps are measuring at now. They may be on the loose side.

Your combo is running good being in the nines, at 3050# with the .mp 590. But it could be running 9.7,s IMO like ProSports old mp 590 3150# combo was running if she were to be sealed up abit.IMO

Posted By: cudaman1969

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 12:15 AM

Reason I asked about the mounting points, quite a few years back my good friend had a 64 Dodge Hemi light weight with the 4 speed, kept missing shifts, not every time but a lot. Different guys tried thinking it was him, same thing. Checked it all, couldn't put a finger on it till someone said its flexing, engine-trans. Had ears in front and just trans mount, so they put the mid plate in and no more missed shifts. Also was eating rod and occasionally main bearings, this got better too so I'm thinking the engine was flexing along with the bell and trans. Never proved it outright but worth some thought. Oh and with the mid plate he left the trans mount bolts loose. Good luck on your next build, if you're happy with those times keep the same parts. There will always be someone faster and someone slower, just keep having a good time. I never had a car that would stand up like that, I imagine it's quite a thrill.

Posted By: Jerry Kathe

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 12:24 AM

The discoloration above the oil ring on the piston is extreme. Its getting combustion leakage past both compression rings and oil from the other side. Its not sealed and I don’t believe it ever was. The cylinder finish was incorrect for these rings, plain old cast rings would have worked better. Do you know the cylinder/piston sizes yet?

I get opinions will vary and every body has one Monte….but a few key points here based on the photos and circumstances of what the OP presented.

1. It turns out to be only a 446….in no way is power killing that block with those heads and that cam.

2. The photos do not support enough evidence of detonation damage to crack this block. Detonation will leave some physical damage to other key parts if it has the energy to crack a block.

3. Filling a gray iron block and filling a nickel, ductile fortified cast block yields different results, gray iron is about the worst casting material out there for high stress.

4. Filling to the bottom of the freeze plug does squat for strengthening the cylinder and helping ring seal….the top ~2” is what needs the help. That low fill isn’t helping with ring seal or making power in any way……but what it is doing is reducing the ability for this thing to flex/move…..inducing stress failure.

5. Hard block is a good product…but read line 4 again……

6. This thing evidently cracked when fired up from winter storage….pretty sure the power/load wouldn’t make the grade for any type of detonation to occur – lol. Thermal change when fired up from winter storage, possibly at a quick rate is what I believe cracked this block.

7. Aluminum caps ain’t where it’s at……but we can leave that as my opinion only……

6bblFLASH; You have several issues here to work with and make significant improvements if you so choose, but honestly – I would simply start fresh with a good block and go to a reputable shop specializing in PERFORMANCE machine work. The precision is worth the cost. I agree, It DID perform well for the components involved and even considering the other issues, I think it will probably surprise you when its all fixed. This probably doesn’t need mentioned….but make sure those pistons are not dimensionally damaged. You may find some rolled skirts, if you do, don’t match bore the new block to those pistons, start with all new stuff, cheaper in the long run.

Good luck, maybe see you around the Ohio area.

Posted By: AndyF

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 01:23 AM

Umm, hate to be rude but that inside of that motor looks horrible! That valley area looks like it came out of a '75 Vega or an old Checker cab. Better check your evac system since I don't think it is working.

Posted By: Thumperdart

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 01:57 AM

The discoloration above the oil ring on the piston is extreme. Its getting combustion leakage past both compression rings and oil from the other side. Its not sealed and I don’t believe it ever was. The cylinder finish was incorrect for these rings, plain old cast rings would have worked better. Do you know the cylinder/piston sizes yet?

I get opinions will vary and every body has one Monte….but a few key points here based on the photos and circumstances of what the OP presented.

1. It turns out to be only a 446….in no way is power killing that block with those heads and that cam.

2. The photos do not support enough evidence of detonation damage to crack this block. Detonation will leave some physical damage to other key parts if it has the energy to crack a block.

3. Filling a gray iron block and filling a nickel, ductile fortified cast block yields different results, gray iron is about the worst casting material out there for high stress.

4. Filling to the bottom of the freeze plug does squat for strengthening the cylinder and helping ring seal….the top ~2” is what needs the help. That low fill isn’t helping with ring seal or making power in any way……but what it is doing is reducing the ability for this thing to flex/move…..inducing stress failure.

5. Hard block is a good product…but read line 4 again……

6. This thing evidently cracked when fired up from winter storage….pretty sure the power/load wouldn’t make the grade for any type of detonation to occur – lol. Thermal change when fired up from winter storage, possibly at a quick rate is what I believe cracked this block.

7. Aluminum caps ain’t where it’s at……but we can leave that as my opinion only……

6bblFLASH; You have several issues here to work with and make significant improvements if you so choose, but honestly – I would simply start fresh with a good block and go to a reputable shop specializing in PERFORMANCE machine work. The precision is worth the cost. I agree, It DID perform well for the components involved and even considering the other issues, I think it will probably surprise you when its all fixed. This probably doesn’t need mentioned….but make sure those pistons are not dimensionally damaged. You may find some rolled skirts, if you do, don’t match bore the new block to those pistons, start with all new stuff, cheaper in the long run.

Good luck, maybe see you around the Ohio area.

You have some very valid points and obviously there`s no load at idle as you "lol"..........that`s a no brainer cos the damage was already done. I was testing at Fontana a few years ago and ran a 10.03 w/my tune up and for giggles went w/Holleys wacked tune up and boom....17.1 afr`s and slowed to 10.50 just like that w/no piston damage we could see. "lol"

Posted By: 6bblFLASH

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 05:18 AM

Umm, hate to be rude but that inside of that motor looks horrible! That valley area looks like it came out of a '75 Vega or an old Checker cab. Better check your evac system since I don't think it is working.

.

Must be the way it photographed with the sun glare.

Couldn't be any cleaner.

Posted By: Sport440

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 06:05 AM

Umm, hate to be rude but that inside of that motor looks horrible! That valley area looks like it came out of a '75 Vega or an old Checker cab. Better check your evac system since I don't think it is working.

.

Must be the way it photographed with the sun glare.

Couldn't be any cleaner.

I will back you up on this, Some of the pics look dark oil stained but, others show Clean as can be. Its the lighting, im sure.

The lighting from the crank side , super clean. The lighting from the intake valley is dark and looks pretty dirty. Put some light on it and Im sure it will look just as clean as the crank side.

Posted By: Monte_Smith

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 06:22 AM

I agree that the motor is not sealed and likely never was. And number 4 is the worst offender. The rings also appear glazed. Maybe the picture, but the hone job looks terrible and also there is some scuffs in the cylinder where the skirts have been touching off. That could be from two things......One, it's either just TOO big and the pistons are rocking in the bore.......or two, the oil contamination is diluting the fuel charge so much that it is killing the octane rating and rattling the motor. A motor that is oiling will NOT need more fuel. It will need less fuel because it is making no power because of the blowby.

Posted By: Thumperdart

Re: Cracked Mains W/ Aluminum Caps - 08/04/15 05:02 PM

Maybe I`m wrong Monte on this one but my junk was pullin oil through the valley pan and the afr`s were goofy and it was down on power so I jetted up and it ran smoother and the afr`s showed it was richer.............