Posted By: mopar dave

drill speed when performing oil mods - 05/10/15 06:03 AM

what drill speed works best when doing oil mods on cast iron block? don't want to break any drill bits.

Posted By: ademon

Re: drill speed when performing oil mods - 05/10/15 07:16 AM

I always use a fast speed with little pressure on cast iron but never did the oil mods to a block.

Posted By: NEVjr

Re: drill speed when performing oil mods - 05/10/15 07:28 AM

go slow, dont use oil, drill pilot hole, then one size smaller than final size, then final size. the key is lots of straight steady pressure

Posted By: MR_P_BODY

Re: drill speed when performing oil mods - 05/10/15 02:47 PM

I dull down the bit slightly.. that way it wont try to bite..

when the bite bites is when they break.. also.. iron cuts easy

thats why they tend to bite

Posted By: mopar dave

Re: drill speed when performing oil mods - 05/10/15 03:41 PM

ok, thanks guys. slow speed and easy steady pressure. got it.

Posted By: mopar dave

Re: drill speed when performing oil mods - 05/10/15 03:42 PM

also, don't know what size the main feeds are, but will be starting with a 1/4" bit then to 9/32" final size.

Posted By: BSB67

Re: drill speed when performing oil mods - 05/11/15 02:52 AM

9/32" drill and some WD-40. Don't know the rpm, just use what felt right. It drills pretty easy.

Posted By: NEVjr

Re: drill speed when performing oil mods - 05/11/15 03:33 AM

9/32" drill and some WD-40. Don't know the rpm, just use what felt right. It drills pretty easy.

if you use oil or lube, it tends to make the cuttings into lapping compound and makes the hole oversized, do it dry if the hole is dimension critical

Posted By: Stanton

Re: drill speed when performing oil mods - 05/11/15 03:29 PM

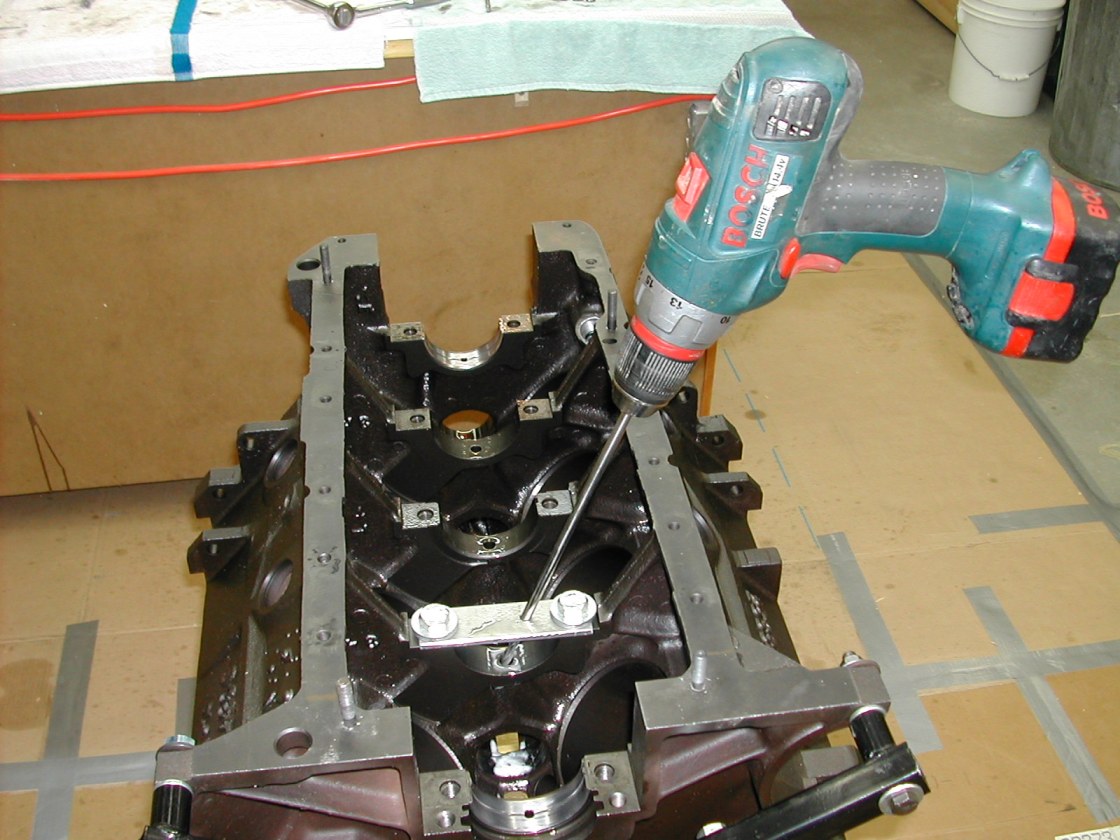

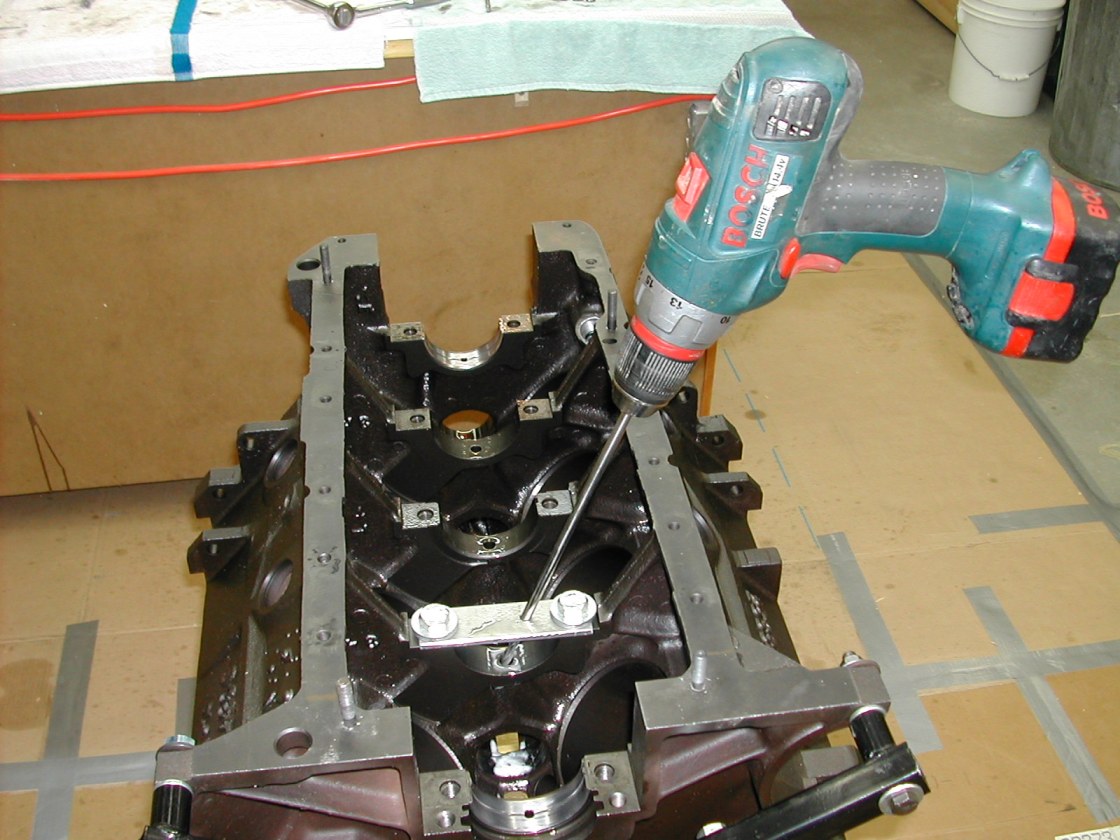

Back in the '70's we didn't have a variable speed drill. A Black and Decker and a long bit that I bought at a hardware store did just fine - no pilot holes, no lube, etc.. Two years ago I used the same bit in a new B&D drill with no pilot holes and no lube and again, no problems. Keep it simple! One thing I would suggest ... a low-power cordless will stop before the bit snaps if it jams. Use a big powerful drill and the potential to snap the bit just increased!

I imagine I could ten blocks in the time it took to make that guide plate !!!

Posted By: mopar dave

Re: drill speed when performing oil mods - 05/11/15 03:45 PM

ok, good points. I will be careful with drill speed and no lube.

Posted By: pittsburghracer

Re: drill speed when performing oil mods - 05/11/15 03:59 PM

Don't make a bigger project out of this than it really is. I drilled mine and shoved 2 pieces of house water line in it, peened it with a rounded of scrap lifter (then I found the old peening tool that came in my Ed Hamburgers kit I bought years ago), drill your oiling hoes, enlarge the ones you want bigger, drill and tap the front to block off the other side, and wash,wash,wash to flush everything out. I may have skipped a step or two but the book walks you thru nicely and I still refer to it every time I do one as one missed step could get VERY expensive. Just DON"T forget to drill the holes thru the tube after you have it installed. Trial fit your lifters to make sure the tube has been peened sufficiently.

Posted By: mopar dave

Re: drill speed when performing oil mods - 05/11/15 04:20 PM

going to block drivers galley at 1 main, but will not be tubing pass. side. opening up main galleys as well as the 1/2" galleys. that's it.