Moparts

Grounding for battery in the trunck?

Posted By: gregsdart

Grounding for battery in the trunck? - 01/05/15 04:38 PM

I have had great success running a rear battery and using the cage for a ground for the most part. I ground the heads AND block to the frame, use two 3/8 bolts welded to the frame, one for the electronics and one for the starter circuit.

My question is, for my street dart there is no cage, and I am moving the battery to the back. I am looking for a good way to ground the battery and thought that the same system would work, provided the ground connections are big enough (bolt welded all around the head?)to not create resistance at those points. I would drill a hole in the floor at the subframe area and weld it to the sub. The car has frame connectors. Input?

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/05/15 04:45 PM

Quote:

I have had great success running a rear battery and using the cage for a ground for the most part. I ground the heads AND block to the frame, use two 3/8 bolts welded to the frame, one for the electronics and one for the starter circuit.

My question is, for my street dart there is no cage, and I am moving the battery to the back. I am looking for a good way to ground the battery and thought that the same system would work, provided the ground connections are big enough (bolt welded all around the head?)to not create resistance at those points. I would drill a hole in the floor at the subframe area and weld it to the sub. The car has frame connectors. Input?

Since electricity travels on the exterior of the wire

(and the cage tubing) the cage isnt the best... so they

say.. I have never had any issue doing the same thing

on the cage as you.. and thats the way I set up my

Rampage.. I will tell you how the EFI likes that

ground system.. but I have no doubt its fine

Posted By: Thumperdart

Re: Grounding for battery in the trunck? - 01/05/15 04:46 PM

I have zero issues and 14.7 volts at the hit and running w/my batt. grounds bolted to rear bumper bolts. I have several grounds from engine to firewall, frame etc. I like your ideas though for a cleaner look but mines all hidden anyhow.

Posted By: mopar dave

Re: Grounding for battery in the trunck? - 01/05/15 05:03 PM

I had my trunk mounted battery grounded to the frame right under the battery for years. worked great,no issues. had one of the major ignition box company's tell to ground everything to engine block. so I did using 1ga. multi strand welding cable. now my starter sounds like it labors abit when I first hit the button. i'd ground it as close to the bat. as possible.

Posted By: Just-a-dart

Re: Grounding for battery in the trunck? - 01/05/15 05:05 PM

The last couple of timesI have done this I used a lug with 2 bolts on a small plate with 2 taped holes welded to the frame rail. Put a dab of grease under the lug.

http://www.grainger.com/product/BURNDY-C..._AW01?$smthumb$

Posted By: StealthWedge67

Re: Grounding for battery in the trunck? - 01/05/15 06:00 PM

I've had great success with my setup thus far: 2g ground cable through the trunk floor, and bolted to the frame rail; then a 4g cable from that same spot forward, bolted to the head, and a simple ground strap from that spot back to the firewall.

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/05/15 06:16 PM

I run my ground to the front where my electronics are. ground issues can kill you. I don't think you will find any makers of electronics telling you to use a roll bar or frame as a ground. and yes I have seen people doing it for years. I just choose to do it right..

Posted By: Jeremiah

Re: Grounding for battery in the trunck? - 01/05/15 06:20 PM

I have done it both ways. My red Charger has been running around on the street for ten years with the battery grounded to the rear frame rail. MSD7AL, two step, etc. all function flawlessly.

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/05/15 06:29 PM

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Posted By: tubtar

Re: Grounding for battery in the trunck? - 01/05/15 06:59 PM

I welded a 3/8" bolt to the rear frame rail.......works like a champ.

Multiple grounds from starter and engine block to frame.

Posted By: Cab_Burge

Re: Grounding for battery in the trunck? - 01/05/15 07:08 PM

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/05/15 07:18 PM

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

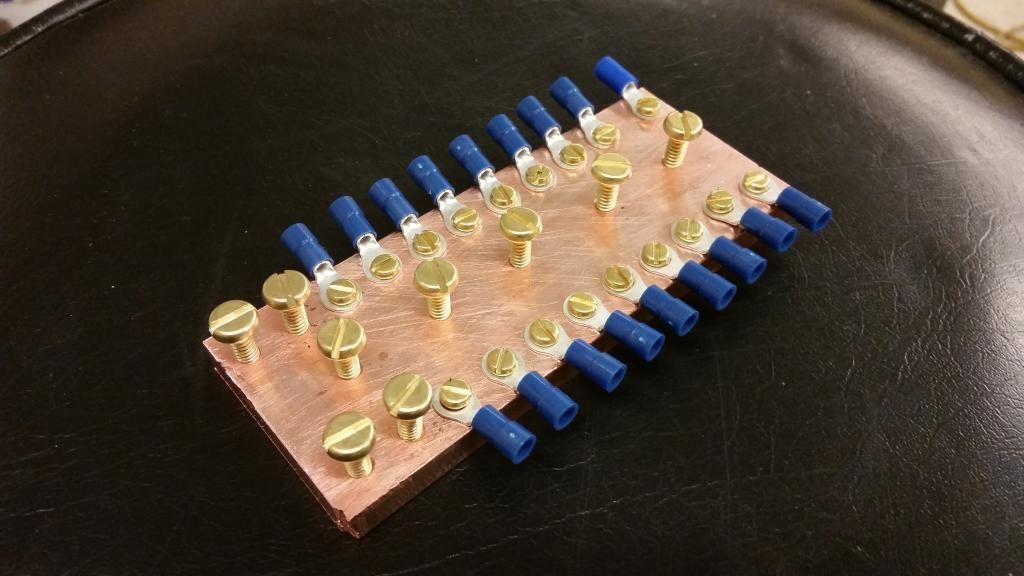

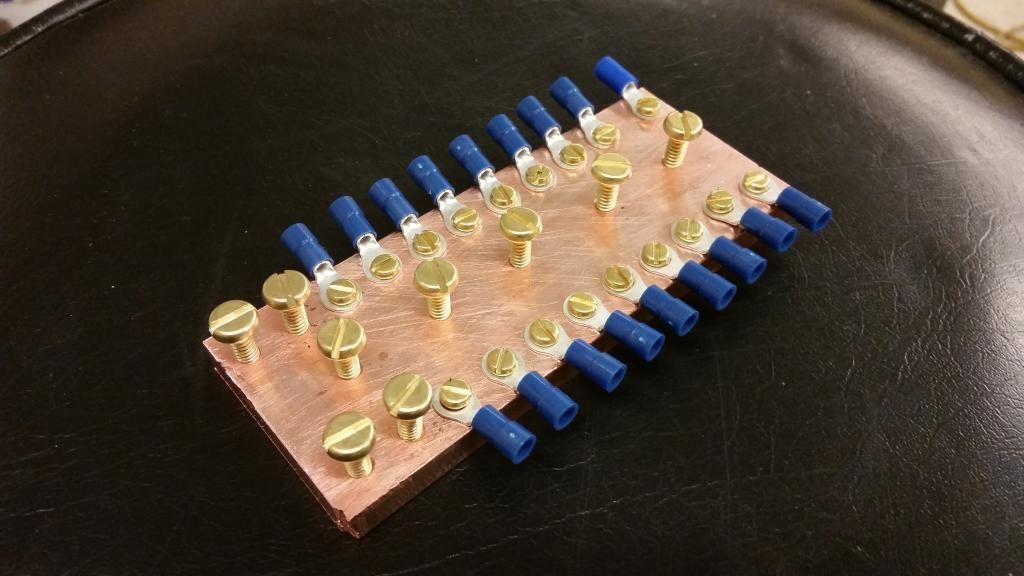

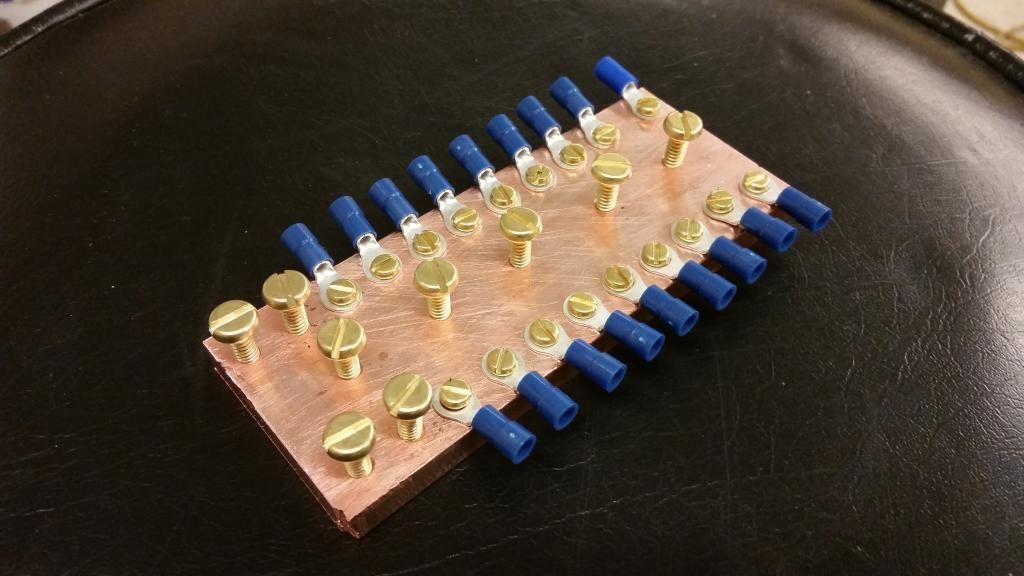

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Posted By: dartman366

Re: Grounding for battery in the trunck? - 01/05/15 08:06 PM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

this is they way I did it back in the day and it still functions correctly, I had run the main ground from the battery to the frame then ran a 08 ground wire to the buss and ran all my grounds to that,,engine,electronics etc.

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/05/15 11:16 PM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

but the individual circuit voltage loss between the 2 systems is negligible, and just not practical in most instance's. Use the frame or 1000 feet of wire? I could see it for some "highly sensitive" circuits, but to run a fan, water pump, or a fuel pump, etc., not needed.

but the individual circuit voltage loss between the 2 systems is negligible, and just not practical in most instance's. Use the frame or 1000 feet of wire? I could see it for some "highly sensitive" circuits, but to run a fan, water pump, or a fuel pump, etc., not needed.

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/05/15 11:21 PM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

exactly, thats the way I do them also

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/05/15 11:22 PM

Quote:

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

but the individual circuit voltage loss between the 2 systems is negligible, and just not practical in most instance's. Use the frame or 1000 feet of wire? I could see it for some "highly sensitive" circuits, but to run a fan, water pump, or a fuel pump, etc., not needed.

but the individual circuit voltage loss between the 2 systems is negligible, and just not practical in most instance's. Use the frame or 1000 feet of wire? I could see it for some "highly sensitive" circuits, but to run a fan, water pump, or a fuel pump, etc., not needed.

not really but you can do it that way if you like.

Posted By: dvw

Re: Grounding for battery in the trunck? - 01/06/15 12:37 AM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Lets look at a new Charger or Challenger. Battery in the trunk, tons of components that are Can Bus based. Cars are even sent to the lab to check for radio and magnetic interference. Guess where the ground connects? Frame rail next to the battery. What do you think?

Doug

Posted By: NOM36

Re: Grounding for battery in the trunck? - 01/06/15 01:36 AM

My race car had a ground to frame and the previous 3 engines (6 cyl, Sml block, Big Block) were all fine. Forth engine (500ci BB on alcohol had an ever so slight miss. Grounded heads and block to separate cable back to battery and ran clean as after that.

I didn't believe it to start with, but I do now.

Posted By: dogdays

Re: Grounding for battery in the trunck? - 01/06/15 02:08 AM

I was imagining a solid copper bus bar from front bumper to rear.

The statement that current runs on the outside of the conductor is partially true, the least true for DC. When the current starts to alternate it moves to the outside of the conductor, the faster the current alternates the more it bunches up at the outside. It's called the "skin effect".

R.

Posted By: CHAPPER

Re: Grounding for battery in the trunck? - 01/06/15 02:50 AM

Quote:

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Lets look at a new Charger or Challenger. Battery in the trunk, tons of components that are Can Bus based. Cars are even sent to the lab to check for radio and magnetic interference. Guess where the ground connects? Frame rail next to the battery. What do you think?

Doug

Frame has high copper content.

Posted By: Cab_Burge

Re: Grounding for battery in the trunck? - 01/06/15 03:41 AM

Quote:

Quote:

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Lets look at a new Charger or Challenger. Battery in the trunk, tons of components that are Can Bus based. Cars are even sent to the lab to check for radio and magnetic interference. Guess where the ground connects? Frame rail next to the battery. What do you think?

Doug

Frame has high copper content.

Posted By: Sport440

Re: Grounding for battery in the trunck? - 01/06/15 04:21 AM

Quote:

Quote:

Quote:

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Lets look at a new Charger or Challenger. Battery in the trunk, tons of components that are Can Bus based. Cars are even sent to the lab to check for radio and magnetic interference. Guess where the ground connects? Frame rail next to the battery. What do you think?

Doug

Frame has high copper content.

Along with some silver and gold I heard.

Posted By: Sport440

Re: Grounding for battery in the trunck? - 01/06/15 05:52 AM

Quote:

I have had great success running a rear battery and using the cage for a ground for the most part. I ground the heads AND block to the frame, use two 3/8 bolts welded to the frame, one for the electronics and one for the starter circuit.

My question is, for my street dart there is no cage, and I am moving the battery to the back. I am looking for a good way to ground the battery and thought that the same system would work, provided the ground connections are big enough (bolt welded all around the head?)to not create resistance at those points. I would drill a hole in the floor at the subframe area and weld it to the sub. The car has frame connectors. Input?

IMO, the way you suggested is Fine and maybe overkill.

IMO, where people go wrong is when they bolt a battery end against a painted surface#1 Number#2, they don't make sure they have good grounds from the engine to the body.

IMO, the unibody works fine as a ground circuit as long as every ground connection is clean and solid.

That's where the problem lies with some that have had problems. Bolt the neg to a painted surface and don't bother to check the quality of the engine ground to the body. Problems!!

I run two separate neg grounds to the engine from the body. I run the bat neg to a quality ground to the factory multi welded trunk brace. Never a problem. Greg, your methods will work fine.

Posted By: Stanton

Re: Grounding for battery in the trunck? - 01/07/15 12:23 AM

A lot of electronics like a dedicated ground cable to the battery. The ground ensures they don't get nuisance calls on the tech line because of bad grounds. Who can blame them. On the flip side, the starter draws more current than ANY other component - and its grounded through the casing/block/chassis.

Posted By: gregsdart

Re: Grounding for battery in the trunck? - 01/07/15 02:51 AM

One thing we can agree on, there needs to be good grounds from the heads and block to where ever the main ground is. I also like to use a ground right to a starter mounting bolt. The heads and block ground can be much smaller if you are using a big ground independently for the starter.

Posted By: 383man

Re: Grounding for battery in the trunck? - 01/07/15 03:23 AM

I ground my trunk mounted battery to the body in the trunk. But I have a few extra grounds from the frame to the unibody and an extra one from the eng to the body. Working for a Dodge dealer for 24 years I would see some strange ground problems over the years like the one that causes the trans bearing to have problems or seeing sparks from a throttle cable because the body to eng ground is bad. So in my opinion if your not sure put another ground on it as you can not have to many grounds. Ron

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/07/15 04:08 AM

Soooo, what's everyone's opinion on running static straps for them highly sensitive electronics?

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/07/15 05:16 PM

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/07/15 05:48 PM

Quote:

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

"properly sized" - would a frame be big enough?

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/07/15 05:58 PM

A ground is NOT a ground so to speak. Lot to be said for "clean" grounds and "noisy" grounds. Something like a starter, doesn't NEED a clean ground.......ANYTHING electronic DOES. You want to use the chassis as one big ground conductor, that's fine, many do, but it is NOT the best way to do it. I prefer to do it right and prevent any future issues. Seen too many problems too many times that drove guys crazy, that was fixed with a proper ground system.

I used to ground stuff like everybody else, to the chassis, until I learned better. Just because it is the way you have ALWAYS done something doesn't mean its the BEST way. You would like to think you do something long enough, that you find BETTER ways to do it........not the same old same oh.

Monte

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/07/15 06:33 PM

Quote:

A ground is NOT a ground so to speak. Lot to be said for "clean" grounds and "noisy" grounds. Something like a starter, doesn't NEED a clean ground.......ANYTHING electronic DOES. You want to use the chassis as one big ground conductor, that's fine, many do, but it is NOT the best way to do it. I prefer to do it right and prevent any future issues. Seen too many problems too many times that drove guys crazy, that was fixed with a proper ground system.

I used to ground stuff like everybody else, to the chassis, until I learned better. Just because it is the way you have ALWAYS done something doesn't mean its the BEST way. You would like to think you do something long enough, that you find BETTER ways to do it........not the same old same oh.

Monte

While this is true, I've seen that more wires CAN

create more issues... like is it REALLY grounded after

its been on there a while

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/07/15 08:43 PM

Quote:

A ground is NOT a ground so to speak. Lot to be said for "clean" grounds and "noisy" grounds. Something like a starter, doesn't NEED a clean ground.......ANYTHING electronic DOES. You want to use the chassis as one big ground conductor, that's fine, many do, but it is NOT the best way to do it. I prefer to do it right and prevent any future issues. Seen too many problems too many times that drove guys crazy, that was fixed with a proper ground system.

I used to ground stuff like everybody else, to the chassis, until I learned better. Just because it is the way you have ALWAYS done something doesn't mean its the BEST way. You would like to think you do something long enough, that you find BETTER ways to do it........not the same old same oh.

Monte

I agreed with your post - in principal, but you gotta look at the bigger picture some times. For instance, is the added weight of having to run a ground cable from a rear mounted battery to the front of the car off set by the better conductivity of the cable over the frame? Doubt if you could measure the difference. The reason that it is still done the way it was done 30 years ago is because nothing "practically" better has come along. Change for the sake of change is not better. Who ever coined the phrase "change is good" must be in sales.  Who ever invented "scotch-locks" should be shot.

Who ever invented "scotch-locks" should be shot.  Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/07/15 08:55 PM

Quote:

Quote:

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

"properly sized" - would a frame be big enough?

Yes, most definitely but may not be properly electrically connected, circumventing the benefits of being properly sized. In my previous reply example I intended the "properly sized" to more refer to any of the wiring size that is being used to connect to the battery Negative. The chassis is just a multi sheet metal steel welded sometimes questionable conductor in that goal.

Posted By: Cab_Burge

Re: Grounding for battery in the trunck? - 01/07/15 10:32 PM

Years ago, 1976 to 1990, the telephone industry went from old analog mechanical equiptment to digiatl computer to do the calling, billing and offer a lot of features we now know as standards. The conversion process and the debugging took a lot of work and energy as well as dicovering some new ways to get the job done without problems, grounding being a big factor in noise and problem prevention. All the phone companys I know of use banks of batterys to power the equiptment offices, we used commercial power ran through inverters to charge the batterys but all the equiptment drew its power from the battery banks. The reason I'm clarifying this is all power, voltage and amperage, comes out of ALL batterys from the negatve battery post and travels through the circuit and returns back to the positive post

My main point is we had to convert our grounding(positive side) in the offices from conventional to perephial grounding, we had copper buss bars aroud two to three inches tall by 1/4 inch thick, depending on the office size and the power used, running all the way around the equiptment in the offices with multiple 000 or larger ground wires hook to them

We lived in the Mojave Desert in SO CA and the summer thunderstorms could wreak havoc with the digital offices through the air and telephone lines

Noise can be induced from many sources into digital devices is my message. You can never have to good of a ground on any thing using electrical power to run digital devices

IHTHs someone

Posted By: Plumb Wired

Re: Grounding for battery in the trunck? - 01/07/15 11:22 PM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

I agree 100%, this is the ONLY way I will wire a car!

Mike Gray

Plumb Wired

Posted By: LAD 524

Re: Grounding for battery in the trunck? - 01/08/15 12:05 AM

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

Monte, I assume you run the MAIN -ve batt cable to the bus bar under the dash so that the bus bar gets is grounding from the batt cable itself, and NOT the body ? Or in other words, the bus bar is NOT grounded to the body/mounted on isolators/non conductive mounts....right?

That would be a decent gauge cable if thats the case - do you run it inside the car ?

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/08/15 12:13 AM

If anything is grounded to the chassis, and he said the lights are, this floating ground buss bar, must also have a connection to the chassis someplace, or no lights. This is the best in our situations, and most complex(?) solution, and a bad ground is a lot easier to trouble shoot, and all grounds are very close to the same resistance.

Posted By: Dean_Kuzluzski

Re: Grounding for battery in the trunck? - 01/08/15 12:46 AM

The "bussbar" would be for electronic devices that NEED a "clean" ground free from noise. And that same bussbar would have its own dedicated cable to the battery. The whole idea is to separate/isolate the high tech digital devices away from the old school analog devices like alternators, wiper motors, headlights and such. Motors and alternators create electromagnetic fields that cause noise.

When it comes to the starter motor......it is the highest current drawing device in the vehicle. Of course it needs just as high current carrying a path as the positive cable that feeds the starter (A basic law of DC voltage). One little ground strap is not going to do it. If the motor is solid mounted, it should be fine.

High current devices like, headlights, starter motors, wiper motors, when poorly connected will seek the path of least resistance creating a "groundshift" or a voltage drop that causes more problems for sophisticated devices like electronic modules.

Bottomline.......run a separate ground for your ignition modules/boxes and otherwise the use of the rollcage is perfectly acceptable for the rest of the old school automotive circuits.

And the electron flow is within the metal of the wire (copper being best) but the electromagnetic field travels along its outer layer.

Posted By: dvw

Re: Grounding for battery in the trunck? - 01/08/15 01:29 AM

No one has answered how production cars with numerous electronic devices rely on the "terrible" floor pan/unibody to attach ALL the grounds in the entire vehicle. This remains the same regardless of where the battery is located. There is a heck a lot of surface area in a unibody. I do agree if the car is a rust bucket the unibody spot welds could possibly be an issue. If its so bad that the majority of the spot welds are suspect there is a way bigger issue than the ground path. When my car was completed I voltage drop tested my ground side under load. There was .2 volts drop at 28 amp draw from the center ground post of the battery to the ground wire of the dual cooling fans. The battery is grounded to a 3/8" stud welded to the cage with 1awg cable. The block/trans is also grounded with 1awg cable.

Doug

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/08/15 02:59 AM

Quote:

Quote:

A ground is NOT a ground so to speak. Lot to be said for "clean" grounds and "noisy" grounds. Something like a starter, doesn't NEED a clean ground.......ANYTHING electronic DOES. You want to use the chassis as one big ground conductor, that's fine, many do, but it is NOT the best way to do it. I prefer to do it right and prevent any future issues. Seen too many problems too many times that drove guys crazy, that was fixed with a proper ground system.

I used to ground stuff like everybody else, to the chassis, until I learned better. Just because it is the way you have ALWAYS done something doesn't mean its the BEST way. You would like to think you do something long enough, that you find BETTER ways to do it........not the same old same oh.

Monte

I agreed with your post - in principal, but you gotta look at the bigger picture some times. For instance, is the added weight of having to run a ground cable from a rear mounted battery to the front of the car off set by the better conductivity of the cable over the frame? Doubt if you could measure the difference. The reason that it is still done the way it was done 30 years ago is because nothing "practically" better has come along. Change for the sake of change is not better. Who ever coined the phrase "change is good" must be in sales.  Who ever invented "scotch-locks" should be shot.

Who ever invented "scotch-locks" should be shot.  Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Wire a few EFI cars.....chase your ass for weeks with EMI "noise" and get back to me on if its "worth" it

Monte

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/08/15 03:41 AM

"copper being best"

Not busting your chops, but Audi uses pure silver for wiring on its Kerv racing cars, being slightly better then copper for the task.

Posted By: Duner

Re: Grounding for battery in the trunck? - 01/08/15 04:48 AM

Quote:

Wire a few EFI cars.....chase your ass for weeks with EMI "noise" and get back to me on if its "worth" it

Monte

Hahaha.... I've been chasing my tail trying to get rid of noise on my TPS signal forever.... and I haven't even moved my battery yet. Who knows, bigger cable and better grounds might just fix it yet!

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/08/15 04:58 AM

Quote:

Quote:

Quote:

A ground is NOT a ground so to speak. Lot to be said for "clean" grounds and "noisy" grounds. Something like a starter, doesn't NEED a clean ground.......ANYTHING electronic DOES. You want to use the chassis as one big ground conductor, that's fine, many do, but it is NOT the best way to do it. I prefer to do it right and prevent any future issues. Seen too many problems too many times that drove guys crazy, that was fixed with a proper ground system.

I used to ground stuff like everybody else, to the chassis, until I learned better. Just because it is the way you have ALWAYS done something doesn't mean its the BEST way. You would like to think you do something long enough, that you find BETTER ways to do it........not the same old same oh.

Monte

I agreed with your post - in principal, but you gotta look at the bigger picture some times. For instance, is the added weight of having to run a ground cable from a rear mounted battery to the front of the car off set by the better conductivity of the cable over the frame? Doubt if you could measure the difference. The reason that it is still done the way it was done 30 years ago is because nothing "practically" better has come along. Change for the sake of change is not better. Who ever coined the phrase "change is good" must be in sales.  Who ever invented "scotch-locks" should be shot.

Who ever invented "scotch-locks" should be shot.  Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Minimum wiring, minimum ( and clean ) connections, still the best bet IMO.

Wire a few EFI cars.....chase your ass for weeks with EMI "noise" and get back to me on if its "worth" it

Monte

Ok

Posted By: Cab_Burge

Re: Grounding for battery in the trunck? - 01/08/15 05:28 AM

Quote:

"copper being best"

Not busting your chops, but Audi uses pure silver for wiring on its Kerv racing cars, being slightly better then copper for the task.

Silver is NOT the best conductor of electricity, gold is

I think copper is number four and I can't remember if silver is number two or three

I think copper is number four and I can't remember if silver is number two or three  I believe aluminum is number 7 or lower. Tin and silver plated copper holds up well to corrosion, but gold is the hot setup for the least resistance, best against corrosion and the best conducting

I believe aluminum is number 7 or lower. Tin and silver plated copper holds up well to corrosion, but gold is the hot setup for the least resistance, best against corrosion and the best conducting

Posted By: 383man

Re: Grounding for battery in the trunck? - 01/08/15 05:41 AM

Quote:

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

My point was not to have a bunch of undersize grounds. My point was its nothing wrong with adding a ground of the correct size even if you already have a ground of the correct size in whatever circuit you are working with. Hence the saying .....you can never have to many grounds. Ron

Posted By: RobX4406

Re: Grounding for battery in the trunck? - 01/08/15 06:13 AM

Quote:

The most electrically conductive element is silver, followed by copper and gold. Silver also has the highest thermal conductivity of any element and the highest light reflectance. Although it is the best conductor, copper and gold are used more often in electrical applications because copper is less expensive and gold has a much higher corrosion resistance.

http://chemistry.about.com/od/elements/f/What-Is-The-Most-Conductive-Element.htm

I run my cars much like Monty suggest. I ground the frame and run a dedicated ground circuit for sensitive electronic/ignition.

One thing to watch for on cars is ground looping. It may create static and noise.

Posted By: FastmOp

Re: Grounding for battery in the trunck? - 01/08/15 07:28 AM

Posted By: dvw

Re: Grounding for battery in the trunck? - 01/08/15 01:30 PM

I run a twisted pair with shielding and a shielding ground wire from the MSD box to both the coil and the crank trigger. However the box is grounded to the cage like everything else.

Doug

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/08/15 06:14 PM

Quote:

No one has answered how production cars with numerous electronic devices rely on the "terrible" floor pan/unibody to attach ALL the grounds in the entire vehicle. This remains the same regardless of where the battery is located. There is a heck a lot of surface area in a unibody. I do agree if the car is a rust bucket the unibody spot welds could possibly be an issue. If its so bad that the majority of the spot welds are suspect there is a way bigger issue than the ground path. When my car was completed I voltage drop tested my ground side under load. There was .2 volts drop at 28 amp draw from the center ground post of the battery to the ground wire of the dual cooling fans. The battery is grounded to a 3/8" stud welded to the cage with 1awg cable. The block/trans is also grounded with 1awg cable Doug

I think you are missing the point on race cars, it's not a voltage drop issue. it is a noise issue and old analog ignitions may never have a problem. but with new digital race ignitions it is an issue.

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/08/15 06:28 PM

Quote:

Quote:

No one has answered how production cars with numerous electronic devices rely on the "terrible" floor pan/unibody to attach ALL the grounds in the entire vehicle. This remains the same regardless of where the battery is located. There is a heck a lot of surface area in a unibody. I do agree if the car is a rust bucket the unibody spot welds could possibly be an issue. If its so bad that the majority of the spot welds are suspect there is a way bigger issue than the ground path. When my car was completed I voltage drop tested my ground side under load. There was .2 volts drop at 28 amp draw from the center ground post of the battery to the ground wire of the dual cooling fans. The battery is grounded to a 3/8" stud welded to the cage with 1awg cable. The block/trans is also grounded with 1awg cable Doug

I think you are missing the point on race cars, it's not a voltage drop issue. it is a noise issue and old analog ignitions may never have a problem. but with new digital race ignitions it is an issue.

There are on board computers on all the new cars..

multiple ones in some cases... they are really touchy

with noise

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/08/15 06:33 PM

Quote:

Quote:

Quote:

No one has answered how production cars with numerous electronic devices rely on the "terrible" floor pan/unibody to attach ALL the grounds in the entire vehicle. This remains the same regardless of where the battery is located. There is a heck a lot of surface area in a unibody. I do agree if the car is a rust bucket the unibody spot welds could possibly be an issue. If its so bad that the majority of the spot welds are suspect there is a way bigger issue than the ground path. When my car was completed I voltage drop tested my ground side under load. There was .2 volts drop at 28 amp draw from the center ground post of the battery to the ground wire of the dual cooling fans. The battery is grounded to a 3/8" stud welded to the cage with 1awg cable. The block/trans is also grounded with 1awg cable Doug

I think you are missing the point on race cars, it's not a voltage drop issue. it is a noise issue and old analog ignitions may never have a problem. but with new digital race ignitions it is an issue.

There are on board computers on all the new cars..

multiple ones in some cases... they are really touchy

with noise

i bet they are not anywhere as sensitive as race ignitions. and how many different filters are they using? how confined are they?

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/08/15 06:38 PM

Quote:

Quote:

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

My point was not to have a bunch of undersize grounds. My point was its nothing wrong with adding a ground of the correct size even if you already have a ground of the correct size in whatever circuit you are working with. Hence the saying .....you can never have to many grounds. Ron

I believe I understand your overall point, but the problem I see is when one has multiple grounds, often for extra assurance/back-up/whatever, unless they are all sized for the largest possible current demand, when one of the redundant grounds becomes less effective (corrosion, intermittent, loose, disconnected in error, etc), the current will then seek another ground with less resistance, and IF that ground is undersize, issues arise. Therefore My concept is just to have a single "great" ground path, and if a problem with that ground arises, the effect is immediate and maybe very obvious, and likely in a single location. That's why having a "lot" of grounds is not a goal for me.

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/08/15 06:41 PM

bet they are not anywhere as sensitive as race ignitions. and how many different filters are they using? how confined are they?

I dont know about the filters but its the low voltage

stuff that your trying to protect.. your dealing

with 0-5 volts or even 0-2 volts and the auto companies

run the grounds as said above... are they keeping it

clean with filters or not.. I dont know... I know

I had to deal with millivolt stuff on the fuel tank

(mainly the filler tube when it was plastic)

Posted By: Quicktree

Re: Grounding for battery in the trunck? - 01/08/15 06:45 PM

Quote:

bet they are not anywhere as sensitive as race ignitions. and how many different filters are they using? how confined are they?

I dont know about the filters but its the low voltage

stuff that your trying to protect.. your dealing

with 0-5 volts or even 0-2 volts and the auto companies

run the grounds as said above... are they keeping it

clean with filters or not.. I dont know... I know

I had to deal with millivolt stuff on the fuel tank

(mainly the filler tube when it was plastic)

there you have it, that why you can't compare a pass vehicle with a race car.

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/08/15 08:01 PM

Noise can be a problem on any EFI car, but you add noise to the incredible cylinder pressure that you have in some of these cars that make 3000+ HP and you have a SERIOUS issue.

This is a typical thing we see, especially on THIS site. Guys have always done things a certain way, it works OK and when something different is suggested, they attempt to shoot that theory full of holes. Just because you have always done something a certain way, does not make it the right way for EVERY car out there.

I changed the way I wired cars, because I DID have issues on some high HP EFI cars with intermittent noise. So common sense tells you that if the changes were BETTER for EFI cars, they were better in general. At least that's how I looked at it, plus to me the "floating ground" deal is clean and easy. So what you have to string a couple extra wires. It makes trouble shooting SO much easier, because things are contained in a specific area.

As far as factory cars........who cares......I don't, because we are not talking about factory cars. Plus, when I worked for Dodge, I know our ECUs were directly battery grounded. Are they still??.........don't know, don't care.

So, you want to ground your whole car through the chassis or sheetmetal...........fine, no problem, but no need to try and prove it's the ONLY way or best way to do it

Oh yeah, forgot something and this is FACT not here say. The Holley Dominator ECU is capable of running factory LS coils. Millions of cars out there with LS coils. However, in a HIGH hp application, with high cylinder pressures, the "flyback" voltage from the LS coild was horrendous. Bad enough in fact, that we had to put a stupid amount of filtering in our boxes to keep the junky coils from smoking our boxes. So the point......what the factory cars have don't mean squat in a race car

Monte

Posted By: gregsdart

Re: Grounding for battery in the trunck? - 01/08/15 08:19 PM

Monte, thanks for making those points. It occurred to me that if I don't want to run a huge ground all the way to the battery in the trunk, then I should at least ground the critical components on their own circuit all the way to the battery with a properly sized ground wire for the load, and totally isolated from the starter.

Posted By: Cab_Burge

Re: Grounding for battery in the trunck? - 01/08/15 08:25 PM

Quote:

Quote:

The most electrically conductive element is silver, followed by copper and gold. Silver also has the highest thermal conductivity of any element and the highest light reflectance. Although it is the best conductor, copper and gold are used more often in electrical applications because copper is less expensive and gold has a much higher corrosion resistance.

http://chemistry.about.com/od/elements/f/What-Is-The-Most-Conductive-Element.htm

.

I wonder where this Professor got or decided to make this statemnet, I was taught in the 1970s/1980 in basic elctricity and electronic college classes that gold was best for conductivity and silver and copper where down the ladder 3 or 4 from gold

I wonder what changed

I wonder what changed

Not trying to hijack, clarification sometimes helps, sometimes hinders

My main message is the path of electron flow from the battery is out the negative side of the battery so that side, path, is really important to get right

Posted By: Thumperdart

Re: Grounding for battery in the trunck? - 01/08/15 08:33 PM

Just had a thought.............What if I ran a smaller gauge wire directly from my trunk mounted batts along the frame w/the fuel line for example BUT like factory cars, had it attached along the frame say every 2' or so............

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/08/15 08:53 PM

Quote:

Just had a thought.............What if I ran a smaller gauge wire directly from my trunk mounted batts along the frame w/the fuel line for example BUT like factory cars, had it attached along the frame say every 2' or so............

Monte is talking about ISOLATED ground.. totally separate

from the main ground... the ONLY place that they are

common is at the battery itself... the battery acts

as a filter and takes spikes and what not out of it

Posted By: RobX4406

Re: Grounding for battery in the trunck? - 01/08/15 09:15 PM

Quote:

Quote:

Quote:

The most electrically conductive element is silver, followed by copper and gold. Silver also has the highest thermal conductivity of any element and the highest light reflectance. Although it is the best conductor, copper and gold are used more often in electrical applications because copper is less expensive and gold has a much higher corrosion resistance.

http://chemistry.about.com/od/elements/f/What-Is-The-Most-Conductive-Element.htm

.

I wonder where this Professor got or decided to make this statemnet, I was taught in the 1970s/1980 in basic elctricity and electronic college classes that gold was best for conductivity and silver and copper where down the ladder 3 or 4 from gold

I wonder what changed

I wonder what changed

Not trying to hijack, clarification sometimes helps, sometimes hinders

My main message is the path of electron flow from the battery is out the negative side of the battery so that side, path, is really important to get right

Another from a manufacturer

http://www.tibtech.com/conductivity.php

Posted By: Duner

Re: Grounding for battery in the trunck? - 01/08/15 09:20 PM

So if I am running an isolated/floating ground for the EFI portion - I'd imagine that the wire size vs load requirement would be downsized quite a bit when compared to the wire size / load requirement for the starter, lights, pumps and fans.

I'm thinking I could get by with a #6 wire for the isolated/floating ground portion, then go with an 00 run up to the starter/chassis itself. All sensors and the standalone computer get their own dedicated grounds running to the bus bar isolated/floating ground.

Does that sound right?

The only place I see a conflict is with the crank and cam sensors. Won't they see both grounds just thru contact? And can that negate the "floating" part anyway?

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/08/15 09:31 PM

Quote:

So if I am running an isolated/floating ground for the EFI portion - I'd imagine that the wire size vs load requirement would be downsized quite a bit when compared to the wire size / load requirement for the starter, lights, pumps and fans.

I'm thinking I could get by with a #6 wire for the isolated/floating ground portion, then go with an 00 run up to the starter/chassis itself. All sensors and the standalone computer get their own dedicated grounds running to the bus bar isolated/floating ground.

Does that sound right?

The only place I see a conflict is with the crank and cam sensors. Won't they see both grounds just thru contact? And can that negate the "floating" part anyway?

I would think your right with the wire size.. as

for the crank and cam I dont know.. maybe Monte will

tell you

Posted By: jcc

Re: Grounding for battery in the trunck? - 01/08/15 09:34 PM

Are sensors powered hall effect, or two wire, or?

Posted By: FastmOp

Re: Grounding for battery in the trunck? - 01/08/15 09:35 PM

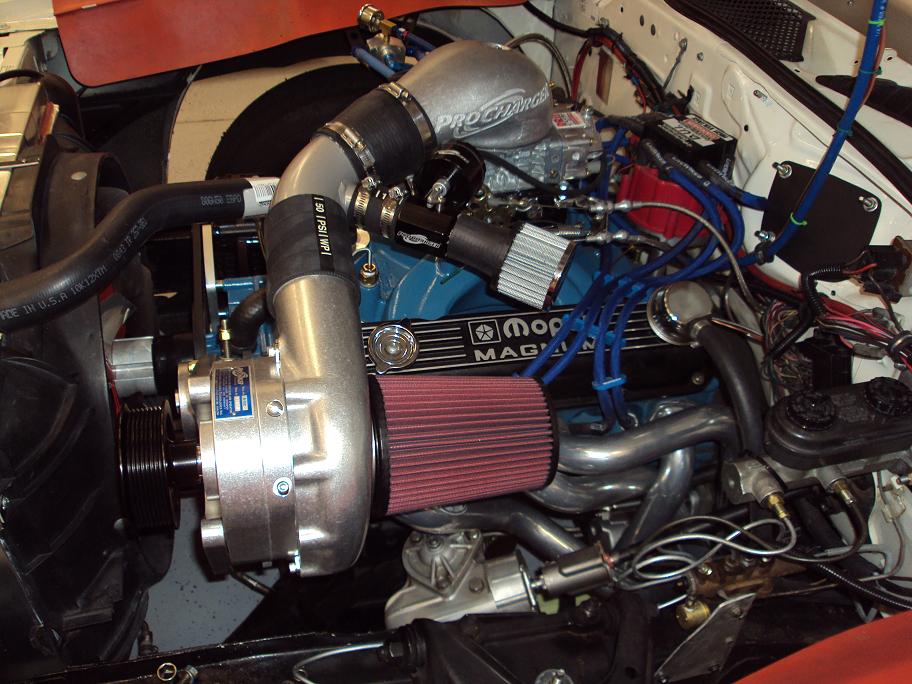

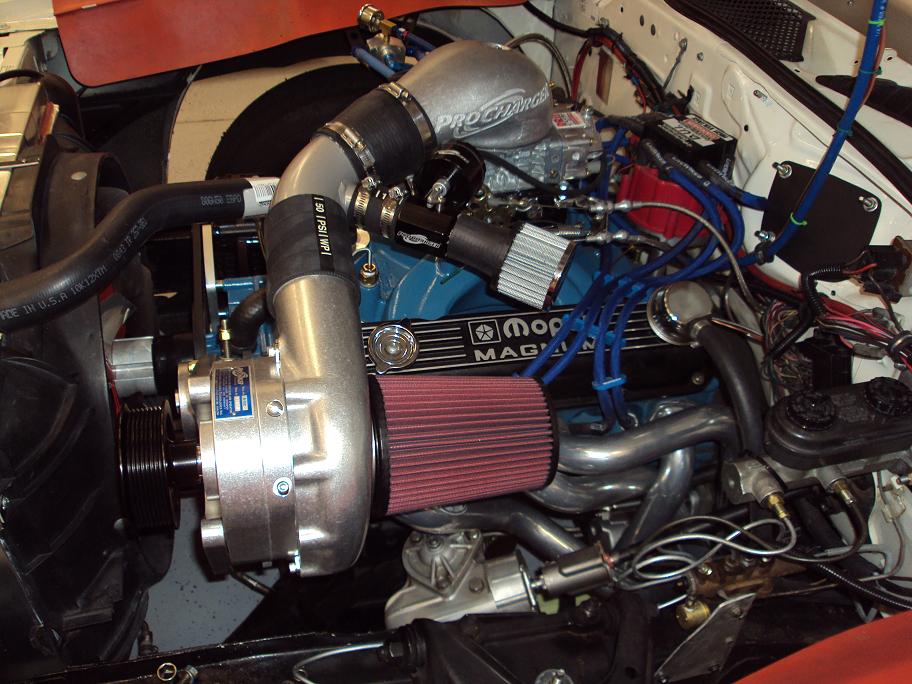

I have been fighting issues like Monty talks about. My stuff is grounded to the battery and I still fight it.

Once you get agressive with the tune (over 20 psi of boost in my case) the plugs are hard to light. And that energy will go somewhere when the plug stops firing.

I'm still trying to figure it out lol

Posted By: MR_P_BODY

Re: Grounding for battery in the trunck? - 01/08/15 09:52 PM

Quote:

Are sensors powered hall effect, or two wire, or?

One thing I dont know is... since the battery is a

filter... the flow goes from neg to pos and we are

trying to isolate the neg... HOW far up the neg is

the battery still acting as a filter... maybe this

is what our issue is.. just guessing.. I dont know

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/08/15 10:04 PM

Quote:

I have been fighting issues like Monty talks about. My stuff is grounded to the battery and I still fight it.

Once you get agressive with the tune (over 20 psi of boost in my case) the plugs are hard to light. And that energy will go somewhere when the plug stops firing.

I'm still trying to figure it out lol

What plug wires do you have?

Monte

Posted By: 383man

Re: Grounding for battery in the trunck? - 01/08/15 10:34 PM

Quote:

Quote:

Quote:

I am not sure I agree, I would rather have one reliable, properly sized, tested/measured ground, then, unless in an in an emergency, a random selection of undersized, maybe good grounds, and let the electrical devices figure which one is best. IE, if a ground is thought to be not correct, then any additional backup grounds have to all be the same proper size, thinking you can "share" or combine grounds is unwise and asking for future problems.

"static straps", are primarily for grounding static charges, not grounds.

My point was not to have a bunch of undersize grounds. My point was its nothing wrong with adding a ground of the correct size even if you already have a ground of the correct size in whatever circuit you are working with. Hence the saying .....you can never have to many grounds. Ron

I believe I understand your overall point, but the problem I see is when one has multiple grounds, often for extra assurance/back-up/whatever, unless they are all sized for the largest possible current demand, when one of the redundant grounds becomes less effective (corrosion, intermittent, loose, disconnected in error, etc), the current will then seek another ground with less resistance, and IF that ground is undersize, issues arise. Therefore My concept is just to have a single "great" ground path, and if a problem with that ground arises, the effect is immediate and maybe very obvious, and likely in a single location. That's why having a "lot" of grounds is not a goal for me.

I understand your point also. I guess what I like about having a second proper ground is I kinda look at it like back-up. Like an eng to body ground. If for some reason one is left unhooked or the bolts left loose then with a back-up ground everything will still work. And if both are done right and working with good clean connections even better. Not saying do it as a bandaid just that it cant hurt. I dealt with alot of body ground problems over the years working at the Dodge dealer where even with a good looking tight connection you could only find the problem doing a voltage drop test. We had problems with Dodge Vans doing some weird things and finding grounds through the strange places causing some trans and wheel bearing problems so I always made an additional ground and put it on them myself after cleaning the factory ground. Ron

Posted By: 383man

Re: Grounding for battery in the trunck? - 01/08/15 10:40 PM

You know with the digital race ignitions and all the electronics on race cars its easy to understand about having good proper grounds.

I would say its why MSD tells you to ground the ground and put the red power wires on their units right to the battery. I see alot where guys dont do that and some get away with it but there is a reason they want the main ground and power wires put right to the battery. Ron

Posted By: Airwoofer

Re: Grounding for battery in the trunck? - 01/08/15 10:49 PM

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

So Monte, are you saying that the only stuff that is critical to have the floating ground is the electronic stuff and not necessarily the rest of the analog stuff like starter, lights, fan, water pump, etc...? That's a whole lot easier to swallow than a complete rewire of a car to add EFI. Them wires under the dash are hard to get to on my junk, and the dash isn't coming out without cutting bars.

Posted By: FastmOp

Re: Grounding for battery in the trunck? - 01/09/15 02:41 AM

Quote:

Quote:

I have been fighting issues like Monty talks about. My stuff is grounded to the battery and I still fight it.

Once you get agressive with the tune (over 20 psi of boost in my case) the plugs are hard to light. And that energy will go somewhere when the plug stops firing.

I'm still trying to figure it out lol

What plug wires do you have?

Monte

The 409 Taylor's. Plan on switching to fire core this spring.

I was running Autolites and new plugs helped some. So now I have NGK plugs but waiting on March to see if there a little better.

Posted By: slammedR/T

Re: Grounding for battery in the trunck? - 01/09/15 04:25 AM

Mont is right, in factory efi vehicles the modules all have a seperate ground going to the battery. They are joined to gether with a splice comb. the body/frame is grounded and the starter and engine and fan motors, etc.. use frame/body grounds. On computer data lines they are ALL twisted pair and on the newer CAN bus sytems the ecm and bcm(some times the ebcm) will have a 120 ohm resistor in both modules, these resistors make the the data lines have even less noise. Also a sensor ground is not a standard ground, it will have an inline transistor to remove noise and it is a "higher ground threshhold" than a normal ground. Then when you get into 5v referenced systems and double redundant 5v reference systems your head starts to spin LOL!

Posted By: Duner

Re: Grounding for battery in the trunck? - 01/09/15 04:36 AM

I'm sharing my 5v referenced sensors with both the factory PCM and the MS3X - with power and grounds supplied by MS3X. I'm betting my noisy TPS signal is from the sharing somehow. How the heck do I clear it up?

Posted By: slammedR/T

Re: Grounding for battery in the trunck? - 01/09/15 04:46 AM

Quote:

I'm sharing my 5v referenced sensors with both the factory PCM and the MS3X - with power and grounds supplied by MS3X. I'm betting my noisy TPS signal is from the sharing somehow. How the heck do I clear it up?

I would do a ground bus, with the bus ground feed striaght to the bettery. Only have sensors grounded on the bus.

Posted By: Duner

Re: Grounding for battery in the trunck? - 01/09/15 04:55 AM

Quote:

Quote:

I'm sharing my 5v referenced sensors with both the factory PCM and the MS3X - with power and grounds supplied by MS3X. I'm betting my noisy TPS signal is from the sharing somehow. How the heck do I clear it up?

I would do a ground bus, with the bus ground feed striaght to the bettery. Only have sensors grounded on the bus.

I will be switching to rear mount battery this weekend. Simple enough to just run a #4 lead for the sensor grounds.

Posted By: dvw

Re: Grounding for battery in the trunck? - 01/09/15 05:19 AM

Quote:

Noise can be a problem on any EFI car, but you add noise to the incredible cylinder pressure that you have in some of these cars that make 3000+ HP and you have a SERIOUS issue.

This is a typical thing we see, especially on THIS site. Guys have always done things a certain way, it works OK and when something different is suggested, they attempt to shoot that theory full of holes. Just because you have always done something a certain way, does not make it the right way for EVERY car out there.

I changed the way I wired cars, because I DID have issues on some high HP EFI cars with intermittent noise. So common sense tells you that if the changes were BETTER for EFI cars, they were better in general. At least that's how I looked at it, plus to me the "floating ground" deal is clean and easy. So what you have to string a couple extra wires. It makes trouble shooting SO much easier, because things are contained in a specific area.

As far as factory cars........who cares......I don't, because we are not talking about factory cars. Plus, when I worked for Dodge, I know our ECUs were directly battery grounded. Are they still??.........don't know, don't care.

So, you want to ground your whole car through the chassis or sheetmetal...........fine, no problem, but no need to try and prove it's the ONLY way or best way to do it

Oh yeah, forgot something and this is FACT not here say. The Holley Dominator ECU is capable of running factory LS coils. Millions of cars out there with LS coils. However, in a HIGH hp application, with high cylinder pressures, the "flyback" voltage from the LS coild was horrendous. Bad enough in fact, that we had to put a stupid amount of filtering in our boxes to keep the junky coils from smoking our boxes. So the point......what the factory cars have don't mean squat in a race car

Monte

Monte as much as I respect your knowledge sometimes I have to disagree. So the fact that a race car has more cylinder pressure make the injectors need a floating ground? Really? I agree that cylinder pressure could be an issue with spark. But what in the heck does cylinder pressure have to do with injector firing or coil triggering? Nothing that I can think of. I will go tomorrow and get some straight facts and report back. If I'm incorrect I will post that as well. The bottom line is that every electrical circuit needs correct sizing. Clean tight connections. And correct routing . We fight noise issues all the time. Fixes involve different routing, shielding and yes moving the feed or ground circuit to a different power or ground location. But saying "grounding at the frame/cage" (which was the original question in this post) won't work is a catch all, and I believe incorrect.

Doug

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/09/15 05:22 AM

Quote:

Quote:

Quote:

Directly to the frame is ALWAYS your best bet - for grounding everything. Least # of attaching points for the starter / alternator. Next best is something that is welded to the frame. Worst is something that is bolted to the frame. Doing voltage drop tests are always in order when doing / checking grounds.

Not close to correct...........in fact that is the WORST way to wire a ground system. Just because people do it all the time and it is passable, does not make it right. Work with a lot of EFI cars as I do and you will quickly find the flaws in this type system. Your frame or sheetmetal is a TERRIBLE conductor.

What I do on all the EFI and actually everything I wire now, is a "floating" ground system. I attach a copper bus bar on rubber isolators under the dash. I run the cable from battery to bus bar and run all high draw grounds to this bar, such as ignition, pumps, fans, etc. I also tie both heads together and run a ground wire to bus bar as well. The ONLY thing I ground to the actual chassis or sheetmetal is the lights

Monte

So Monte, are you saying that the only stuff that is critical to have the floating ground is the electronic stuff and not necessarily the rest of the analog stuff like starter, lights, fan, water pump, etc...? That's a whole lot easier to swallow than a complete rewire of a car to add EFI. Them wires under the dash are hard to get to on my junk, and the dash isn't coming out without cutting bars.

You are asking for a MAJOR headache with what you want to do...........and if I recall correctly, is the EXACT reason that I am not wiring your car for you. I told that I WOULD NOT do it, unless you let me rip all that stock crap out and wire the car RIGHT and you were NOT on board with that. You are asking for a MAJOR headache. Been there, done that and won't do it again. We have HAD this conversation standing in my shop. I refuse to chase gremlins on a car with a modern EFI and 40 year old factory wiring. Not worth it

Monte

Posted By: fourgearsavoy

Re: Grounding for battery in the trunck? - 01/09/15 05:23 AM

Quote:

bet they are not anywhere as sensitive as race ignitions. and how many different filters are they using? how confined are they?

I dont know about the filters but its the low voltage

stuff that your trying to protect.. your dealing

with 0-5 volts or even 0-2 volts and the auto companies

run the grounds as said above... are they keeping it

clean with filters or not.. I dont know... I know

I had to deal with millivolt stuff on the fuel tank

(mainly the filler tube when it was plastic)

That is the way Toyota/Lexus vehicles get away with grounding most of their 20-30 separate ECU's to the sheet metal. Most of the sensing circuits operate on a 5 volt reference signal so a sheet metal body ground on even the most sensitive systems is adequate. I'm kinda ground crazy on all my components on the Savoy  I run ground points all over and most all of them can be traced back to my ground strap from the battery.

I run ground points all over and most all of them can be traced back to my ground strap from the battery.

All that being said I still ground my battery to the bar in the trunk

Gus

Posted By: Monte_Smith

Re: Grounding for battery in the trunck? - 01/09/15 05:26 AM

Quote:

Quote:

Quote:

I have been fighting issues like Monty talks about. My stuff is grounded to the battery and I still fight it.

Once you get agressive with the tune (over 20 psi of boost in my case) the plugs are hard to light. And that energy will go somewhere when the plug stops firing.

I'm still trying to figure it out lol

What plug wires do you have?

Monte

The 409 Taylor's. Plan on switching to fire core this spring.

I was running Autolites and new plugs helped some. So now I have NGK plugs but waiting on March to see if there a little better.

The Taylors and the Moroso blue wires are notoriously bad for EMI noise. The Firecores are an excellent choice for an EFI car. I seldom "drink the koolaid" on that type stuff........but they flat work.......period.

Monte

Posted By: FastmOp

Re: Grounding for battery in the trunck? - 01/09/15 07:45 AM

Thanks for the help!

Posted By: dvw

Re: Grounding for battery in the trunck? - 01/10/15 03:38 AM

I said I would report back what I found out about grounds. First I will say that I have NO experience in running cars anywhere near the power level of Montes stuff. I will also admit I'm not a degreed electrical engineer. I do work with car electrics on prototype and production vehicles everyday. I sought out 3 very knowledgeable electrical engineers that design and work on modern electrical vehicle systems. These guys are not racers but are extremely knowledgeable if the field of electronics. Two of them of the saw absolutely no need for a separate ground cable from the battery to a forward location in the car. The third saw the only possible advantage would be to run a separate cable from the battery to the cylinder heads themselves. His theory was that enough current was being sent through a "race type coil" that it was possible that the spark plug current might possibly corrupt the ground side. Though he thought the possibility was very slight. He also stated that any possible advantage would be lost unless this cable was routed and used for cylinder head grounding (and obviously the starter) only. Everyone agreed on a few things.

#1 Grounds should be as close as short as possible.

#2 Grounds should not be stacked more than a few. But should all be as close together as possible. Such as having multiple ground studs with-in a small area.

#3 The mass of the uni-body/roll cage is more than adequate as a ground plane.

#4 The use of a thermal grease such as Alonox on connections, especially where wiring is bolted to aluminum. This will reduce the likelihood of fretting and heat damage due to thermal expansion and contraction of aluminum.

#5 That cylinder head grounding to the chassis may have the most potential of anything that has been discussed here. The possibility of plating on head studs/bolts may inhibit good grounding of the spark plug, though they have yet to see it in the field.

#6 Do not run any high current cables near sensor or pickup wiring.

Make sure sensor wiring pairs are twisted to cancel magnetic field effects in the harness. A shielded wire as part of that harness with a foil covering grounded at the module end only will act as a capacitor helping disperse noise.

Finally everyone agreed that testing voltage drop on individual circuits under loaded conditions will tell the story if the ground is adequate. Although this could be accurately done with an Oscilloscope acceptable results could be taken with a Fluke meter. The min/max selection will take samples of voltage drop at .01 second while recording.

I hope everyone can gain some insight from this. While I don't think a dedicated ground would hurt, I don't think it is necessary either. In my world budget is paramount. With 25' of #1 cable going for close to $100 that is an area where my dollars might be spent wisely elsewhere.

Doug

Posted By: fourgearsavoy

Re: Grounding for battery in the trunck? - 01/10/15 03:51 AM

Wow! Thanks for the research Doug

Gus

Posted By: slammedR/T

Re: Grounding for battery in the trunck? - 01/10/15 04:58 AM

Posted By: Crizila

Re: Grounding for battery in the trunck? - 01/10/15 05:05 AM

Quote:

I said I would report back what I found out about grounds. First I will say that I have NO experience in running cars anywhere near the power level of Montes stuff. I will also admit I'm not a degreed electrical engineer. I do work with car electrics on prototype and production vehicles everyday. I sought out 3 very knowledgeable electrical engineers that design and work on modern electrical vehicle systems. These guys are not racers but are extremely knowledgeable if the field of electronics. Two of them of the saw absolutely no need for a separate ground cable from the battery to a forward location in the car. The third saw the only possible advantage would be to run a separate cable from the battery to the cylinder heads themselves. His theory was that enough current was being sent through a "race type coil" that it was possible that the spark plug current might possibly corrupt the ground side. Though he thought the possibility was very slight. He also stated that any possible advantage would be lost unless this cable was routed and used for cylinder head grounding (and obviously the starter) only. Everyone agreed on a few things.

#1 Grounds should be as close as short as possible.

#2 Grounds should not be stacked more than a few. But should all be as close together as possible. Such as having multiple ground studs with-in a small area.

#3 The mass of the uni-body/roll cage is more than adequate as a ground plane.

#4 The use of a thermal grease such as Alonox on connections, especially where wiring is bolted to aluminum. This will reduce the likelihood of fretting and heat damage due to thermal expansion and contraction of aluminum.

#5 That cylinder head grounding to the chassis may have the most potential of anything that has been discussed here. The possibility of plating on head studs/bolts may inhibit good grounding of the spark plug, though they have yet to see it in the field.

#6 Do not run any high current cables near sensor or pickup wiring.

Make sure sensor wiring pairs are twisted to cancel magnetic field effects in the harness. A shielded wire as part of that harness with a foil covering grounded at the module end only will act as a capacitor helping disperse noise.

Finally everyone agreed that testing voltage drop on individual circuits under loaded conditions will tell the story if the ground is adequate. Although this could be accurately done with an Oscilloscope acceptable results could be taken with a Fluke meter. The min/max selection will take samples of voltage drop at .01 second while recording.

I hope everyone can gain some insight from this. While I don't think a dedicated ground would hurt, I don't think it is necessary either. In my world budget is paramount. With 25' of #1 cable going for close to $100 that is an area where my dollars might be spent wisely elsewhere.

Doug

Talked to a close friend of mine today ( Dick Headman - Headman headers ) who does a lot of EFI work worth "Fast Systems" and he echoed this thread. "Biggest problem is dirty connections and bundled wires". He recommends welding a ground stud (s) to the frame in a convenient area. He also mentioned grounding the rad ( especially aluminum radiators ) and individual aluminum head grounds. Alonox was also mentioned.

Posted By: DusterDave

Re: Grounding for battery in the trunck? - 01/10/15 05:12 AM

I'm thinking this thread should go into the Tech Archives at some point.

Posted By: RobX4406

Re: Grounding for battery in the trunck? - 01/10/15 05:13 AM

#1 at $4/ft?

Find a new supplier. There are plenty of places to get #1 battery cable for under $2/ft. Welding cable will come in at $3/ft or less.

I bought 2/0 battery cable for under $3/ft

Posted By: dvw