Moparts

400BB build up

Posted By: Volare4life

400BB build up - 08/14/14 03:32 AM

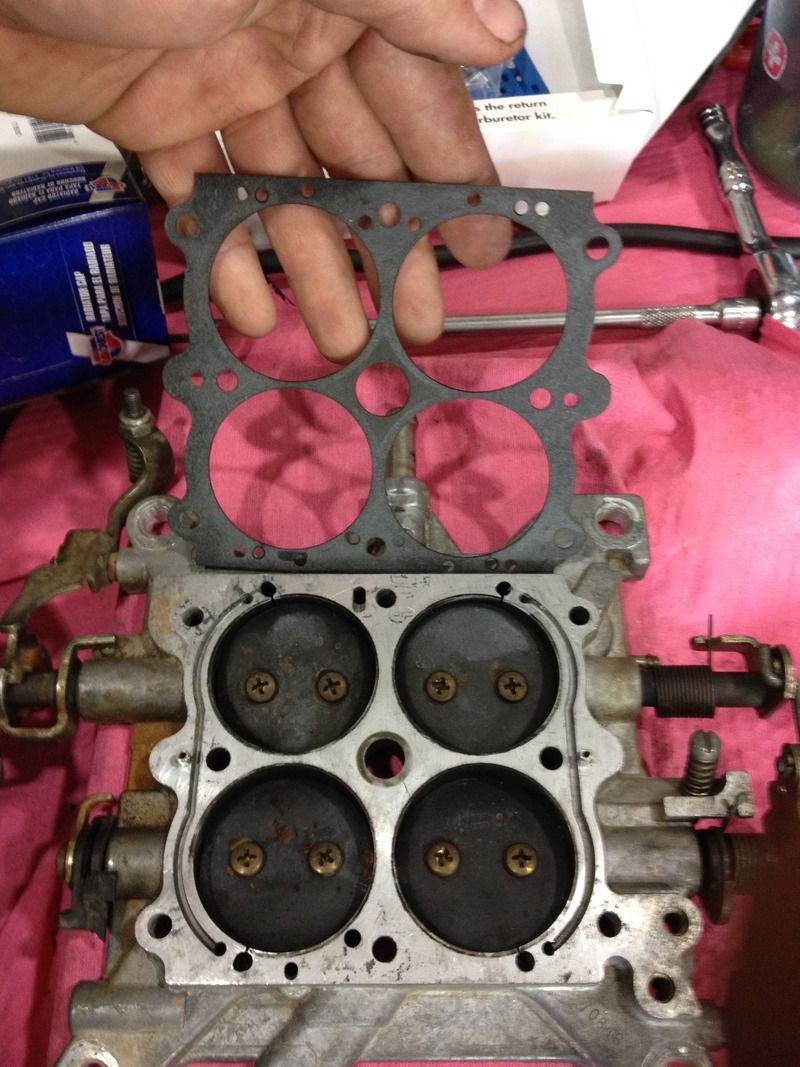

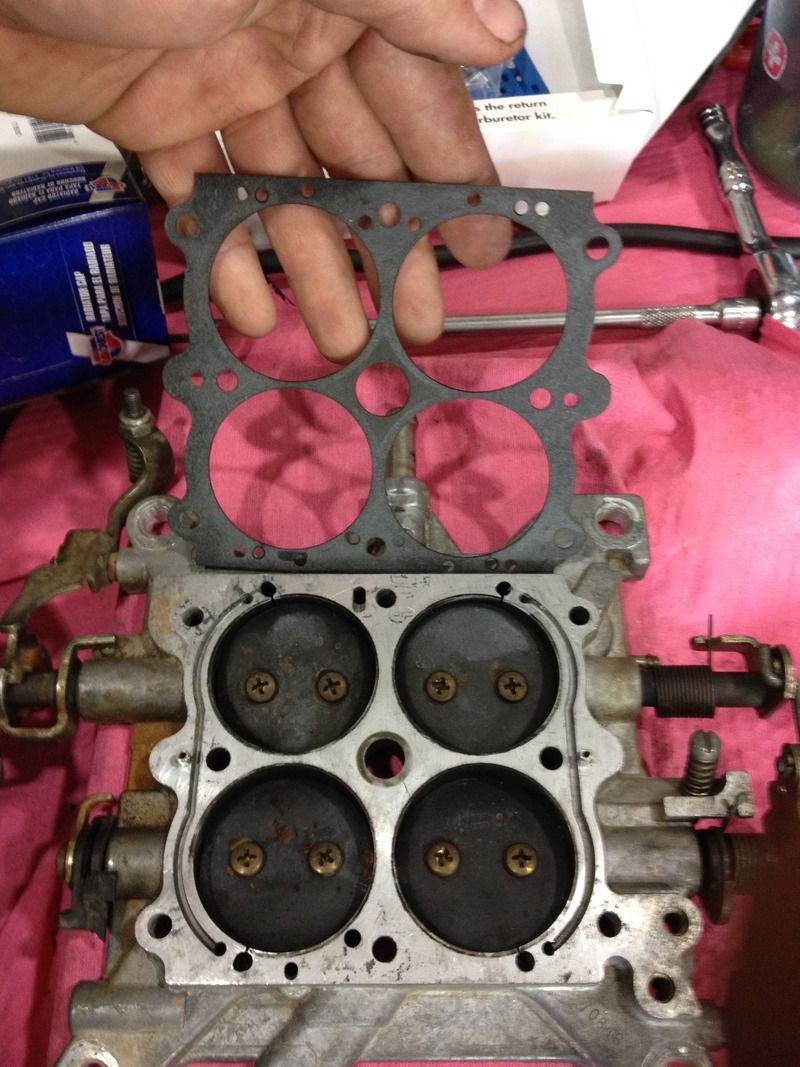

Hi guys, finally getting a chance to build up my 400BB that i have had forever, was foolish and young and listened to the advice of others and tore it down with no budget to rebuild it, now as it sits I have a 400BB , nothing real special just a '78 (date code 10-4-78) block stock bore

stock (to my knowledge) 906 heads

and i was told this is a forged steel 383 crank

the red stuff you see is HD bearing grease to protect the journals

can anyone confirm this is a forged steel crank ?

Also with this crank does my stock 400 rods and pistons have to get balanced as a whole ?

What kind of crank damper do i need to run ? one for internal balance or external ?

got a bone stock '67 727 that i am getting tomorrow from a guy here local, worked when pulled, I will still go through it before i bolt it all up together. What kind of flex plate should i use ? I can't imagine this thing making gobs enough torque to break a stock one in stock form, also does a slant flex plate fit a BB 6 bolt crank ?

I will need a cam for this and i plan on milling the heads to raise compression, is there any way to figure out how much to whack off to bring the CR up ?

I have been hearing good things about a few summit cams,

Summit Racing® Camshafts SUM-6400

Camshaft, 1-Bolt, Hydraulic Flat Tappet, Advertised Duration 288/298, Lift .444/.466,

and Summit Racing® Camshafts SUM-6401

Camshaft, 1-Bolt, Hydraulic Flat Tappet, Advertised Duration 298/303, Lift .466/.488

Any mopar cam recommendations for helping wake the 400 up ?

How much can i mill the heads before i need to worry about adjustable rockers ?

I know alot of questions, but i come from boosted slant land (max'ed at 18lbs of boost before i lost the head gasket all stock engine with a good tune on the carb) and really haven't dabbled to much in big blocks, i will eventually have an all forged as close to stock, (bore/stroke) and run a pair of holset hx-35 turbos, but for now i just need to get it running, so its gonna be bearings, rings and seals, but really looking at cam and head recommendations from those in the know

P.s

First: you're going to want to figure out exactly what the end game is here. Building a stock motor will not yield the same advice as building a twin hair-dryer big block.

Next:

If you don't already have a copy of Don Taylor's "How to Rebuild Big Block Mopars" book. go get one now

Assuming a stock (non-turbo) rebuild:

Yes, that is a forged crank

Yes, you'll want to balance the whole assembly

Stock 383 flex-plate should work and can be found cheaply.

The summit larger cam is generally spoken of as a pretty good stick for a street application.

Compression is what you'll want to focus on to wake up the 400. Milling the heads and / or decking the block will be in order to do that. You'll have to CC the heads in order to find out what they are now and where how far you'll want to cut them. keep in mind that cutting them enough to effect the compression will likely mean you'll have to also cut the intake to fit.

It won't take much work on those heads to get into the price range of a set of Stealth heads. And those would address the compression issue and offer a ton more potential.... just a thought.

BTW: I wouldn't mess with adjustable rockers. Just get new pushrods at the correct length. not too tought to figure out pushrod length, much cheaper and simpler. Adjustable rockers are not designed to make up for milling, and likely wouldn't fit correctly with the standard length pushrods anyway.

Again, if you want to keep playing with the turbo.... NONE OF THE ABOVE APPLIES.

Posted By: Hot 340

Re: 400BB build up - 08/14/14 04:26 AM

You GOTTA tell us about the slant build first. Waay more interesting.

Posted By: gregsdart

Re: 400BB build up - 08/14/14 01:45 PM

How much cylinder bore ridge at the top of ring travel is there? That needs to be removed. Also, not a good idea to try and rebuild a block with too much piston to wall clearance from wear. Go by the max bore wear in the factory manual, or very close. KB lists a piston that is hypereutectic (stronger than stock, and lighter) that will fit with your stock rods and give you 8.9 to 9.3 compression depending on head volume of the 906 heads. This is your cheapest route with an overbore. The motor will love the extra full point plus compression, and the pistons show big valve reliefs for all the cam you need. Depending on how much converter stall you will have (assuming automatic here) you can go pretty big on cam if you have a high stall ( 4000 or more) . I have run a 268 at .050 and .540 lift on stock rockers with a mild lobe that lived with the stock valve gear up to 6,000 rpm. Less stall will dictate staying pretty short on duration, go by cam manufacturer recommendations. Stock converters come in low stall or high stall, obviously you want the high stall if you want to go with a stock factory converter. Remanufactured converters can be had for around $120 in high stall. High stall will be somewhere between 2200 to 2600 rpm as a guess. Low stall is listed at 1800, real low end killer.

Hear is a small stroker combo that yields 9.6 to 1 compression at 4.350 bore. 4.375 bore also available with these pistons.

Ross forged pistons, 99907 4.350 bore or

99906 4.375 bore. (max overbore for most 400s.

Chevy big block rods ,aftermarket 6.800 long

Offset grind the crank to 3.525 for a stroke increase of .150

This will produce a light rotating assembly that will make 418 cubes with 4.350 pistons, or 424 cubes at 4.375 bore

This is a cheap stroker combo for a 400 when you consider that you will need to rebuild the old rods, and buy pistons anyway, and possibly regrind the crank.

Posted By: Cab_Burge

Re: 400BB build up - 08/14/14 07:32 PM

Before you start this build make sure you know what you want IT to DO before starting

it is very easy to get the wrong parts and machine work when you start of wanting to make it run now as easy as possible but know that you want to add more power later, like your suggesting with the turbos

Stop, take a breath and think first before starting donwn the path to making this motor run

Posted By: Volare4life

Re: 400BB build up - 08/15/14 07:11 PM

I have the chuck senatore "BIG BLOCK MOPAR PERFORMANCE" book, its got a lot of good general build tips, but i feel it focuses more on stroker and all out race engines, I will have to check out that book. I would prefer just a piston change if i can help it. For right now this is a "lets get it running" build. so stock cast 4bbl manifold, was going to homeport it, block the heat crossover, 440 source heads would be nice but, not really in the budget now, being military, me and the family are getting ready to move down to keywest, and houses aren't cheap down there, and i prefer not to trailer her all that way.

Now why will the whole thing need to be balanced ? or is that just added insurance ?

what kind of crank damper do i need to run ?

do the SFI fluid damper's not care what crank they are on ?

I understand about the adjustable push rods, but even say i only knock .010 to clean up the heads, can stock pushrods still work effectively on a stock hyd flat tappet set up ?

Is there anyway to measure CC volume of the heads with out one of those fancy kits ? I mean its just a syringe and flat piece of glass with a tiny hole it right ?

I noticed on the rod oiling holes that well, they are not perfectly round, more like jagged holes, can they be rounded and counter sunk to help improve oil to the rods ?

speaking of mains and rods mains measure 2.622" using a brown & sharp 2"-3" micrometer

rods measure 2.344"

all measurements were taken in several spots at each main and rod journal.

which are .30 over(ish) size If i am correct, mains are stock,

I am going to have the oil holes chamfered and a micro polish on the crank, then get bearings after that, which bearing should choose for durability, clevite, dura-bond, etc

I haven't been able to find a domed KB piston, I did find the KB240KTM , they have a bunch of numbers listed below,

Compression Ratios

72-10.6

80-9.8

85-9.3

90-8.9

Is the first number added to the end of the part number to determine size ?

KB Pistons I found step pistons, would they be as effective ?

again I am just trying to keep machining cost down, that and I really have no way to transport a block.

If i remember right the slant and BB share a few things in common, i wonder if flexplates/flywheels are included in that as well ?

Posted By: Volare4life

Re: 400BB build up - 08/18/14 07:08 AM

bump

Posted By: gregsdart

Re: 400BB build up - 08/18/14 02:27 PM

The KB piston you listed is heavy, but if it is the same weight as a stock piston and pin you can skip balancing the motor. If it is not the same weight within a few grams, then balancing is a must to keep the motor from shaking badly. I would use this piston on a cheap rebuild, very mild performance build. The rings are 5/16 which will cost power compared to 1/16 rings used on most newer pistons.

A good quality stock replacement damper will work ok if you are staying under 6,000 rpm or so.

On the stock pushrods, they can work ok provided the rate of lift on the cam and spring rate aren't too high. They are on the weak side, and the stock rockers will not provide advertised lift because they aren't a true 1.5 rocker. There is enough travel in the lifters to handle more than .010 cut on the heads.

To measure head CCs a cheap syringe from a drug store, plastic plate and grease to seal it up and you are in business.

Posted By: Volare4life

Re: 400BB build up - 08/19/14 03:54 AM

Well i got the bearings and pushrods on order, should be here wednesday, sealed power/felpro gasket kit with blue perma-torques, not digging the cork op and valve cover gaskets, but i will work with what i got.

Thinking about using a summit damper, $100 stock replacement, seems like a good deal.

So how much can be whacked off the heads before the stock (8.55" 3/8 comp ball and ball ) pushrods need shortened ?

which would be better as far as cams go

Summit Racing Part Number:SUM-6400

Cam Style:Hydraulic flat tappet

Basic Operating RPM Range:1,500-5,000

Intake Duration at 050 inch Lift:214

Exhaust Duration at 050 inch Lift:224

Duration at 050 inch Lift:214 int./224 exh.

Advertised Intake Duration:288

Advertised Exhaust Duration:298

Advertised Duration:288 int./298 exh.

Intake Valve Lift with Factory Rocker Arm Ratio:0.446 in.

Exhaust Valve Lift with Factory Rocker Arm Ratio:0.466 in.

Valve Lift with Factory Rocker Arm Ratio:0.444 int./0.466 exh.

Lobe Separation (degrees):112

or

Summit Racing Part Number:SUM-6401

Cam Style:Hydraulic flat tappet

Basic Operating RPM Range:2,000-5,500

Intake Duration at 050 inch Lift:224

Exhaust Duration at 050 inch Lift:234

Duration at 050 inch Lift:224 int./234 exh.

Advertised Intake Duration:298

Advertised Exhaust Duration:303

Advertised Duration:298 int./303 exh.

Intake Valve Lift with Factory Rocker Arm Ratio:0.466 in.

Exhaust Valve Lift with Factory Rocker Arm Ratio:0.488 in.

Valve Lift with Factory Rocker Arm Ratio:0.466 int./0.488 exh.

Lobe Separation (degrees):114

I think the summit 6400 would be a better choice for a mostly stock motor,

-Mike

Posted By: ahy

Re: 400BB build up - 08/19/14 04:42 AM

Lots of good advice. Just a question and comment. To the best of my knowledge, all 400's were made with cast crank. I wonder how it got a forged 383 crank and still stock bore?

Also a comment. The 400 is often compression challenged. With lowish compression and 400 ci, the small Summit cam may make you happier in terms of low/mid range torque.

Posted By: 383man

Re: 400BB build up - 08/19/14 06:12 AM

This is a 400 we have in my boys Dart. We used the forged 383 crank and of course had it all balanced as it uses stock rods and KB pistons. Also use the internal crank balancer. It had Eddy RPM heads that were cut a bit for 10.6 comp. We use the MP .557 solid flat tappet cam and the RPM intake with a 750 DP. It has a 9.5 Dynamic converter and 3.91 gears. At 3550 lbs with him in it he has dipped in the 11.40's @ 117 and it is a driver street car and runs on pump. Course this build wont help you if you are going to go with the turbo. Ron

Posted By: Twostick

Re: 400BB build up - 08/19/14 02:12 PM

Quote:

Lots of good advice. Just a question and comment. To the best of my knowledge, all 400's were made with cast crank. I wonder how it got a forged 383 crank and still stock bore?

Also a comment. The 400 is often compression challenged. With lowish compression and 400 ci, the small Summit cam may make you happier in terms of low/mid range torque.

If the 400 came out of a manual trans vehicle, it will have a forged crank. No manuals with cast cranks in a BB.

Kevin

I think you would be wasting your money to mill the heads to try and gain compression when using stock pistons. The pistons are so far in the hole that the gains will probably not be worth the money spent. Those 400's are good engines...but they are advertised as 8.2:1 compression, but if they are like every BB Mopar I have dealt with, the compression is likely actually much less. I did some quick calcs and assuming the piston is .120 in the hole like a smogger 440 usually is, I get 7.58:1 compression with a .020 shim gasket. I get 8.17:1 compression by milling a typical 906

90cc chamber down to 80cc's.

If I'm wrong on this....someone please correct me though. If your set on using the stock pistons, that is ok...I would just use a stock shim style head gasket and not bother milling for compression. To mill enough to matter you would have to mill the intake side as well and this will all cost money. You could just spend a little more and buy some cheap ($350ish) KB hyper pistons like Greg suggested and get much more gain. But you will have to rebalance because KB's are lighter than stock pistons are.

Or just leave it all stock and live with the compression and use the smaller summit cam listed. It will still have good/ok power.

Posted By: Volare4life

Re: 400BB build up - 08/20/14 04:52 AM

@AHY I bought the crank from a guy here local thats into BB Dakota swaps, for dirt cheap, got a set of pistons with the deal( still for sale std bore if I remember right)

I have been talking with AllMotorDuster about getting his 2800 stall TCI converter, shes running a 2.94 sure grip rear, eventually getting a 4.10 ford 8.8, I figured a 2800 stall would be a good step in waking her up. I want to keep the compression between 8.0-8.5 to 1. especially when the hair dryers get bolted on.

Anyone know if these are any good dampers ?

ebay damper Talked to the seller they are made by a company called C.A.T Performance, are they any good ?

Now since I am using stock 400 pistons and rods, but a 383 forged crank, will i still need to get everything balanced, or get the crank polished, double/triple check the rod and main diameters and put it together as normal ?

-Mike

Posted By: dogdays

Re: 400BB build up - 08/20/14 05:45 PM

There were 383s with cast cranks

There were 383s with forged cranks.

There were 400s with cast cranks.

There were 400s with forged cranks.

Cast to cast, forged to forged, the cranks are the same. For all I know they are the same casting or forging number.

If you're using a forged crank with either 383 or 400 stock crank and rods, and neutral balance converter/harmonic damper, no need to balance.

If you're using a cast crank with either 383 or 400 stock rods and pistons, you will need the cast crank harmonic damper and converter. Then, no need to balance.

Of course, MOPAR balance jobs were the worst of the Big Three, so the stock balance jobs can definitely be improved. BUT, at this stage in your automotive development, you don't need to.

I'd pick the smaller camshaft. 383s and 400s are very easy to overcam.

R.

Posted By: Volare4life

Re: 400BB build up - 08/21/14 04:55 AM

right on Dogdays, I appreciate the info, got more parts ordered tonight, can't wait to get'em

-Mike

Posted By: Volare4life

Re: 400BB build up - 08/22/14 01:44 AM

well scored a nice TM-6 with a holley 2bbl on it for $80 locally,, gonna clean up and sell the holley and recoup at least some beer money lol

Posted By: Volare4life

Re: 400BB build up - 09/26/14 06:26 PM

so got the block spotless, and guess what a few of the cylinders got some deep pitting, its bad enough after running a "dingle-berry" hone to knock off the varnish i could clearly see the pitting. Oh damn now i have to bore it out, So what do you guys recommend for a really good forged piston ?

Also how much HP/TQ can stock 400 rods take ?

I think it would be a good time to upgrade the rods to h-beams, any good brands out there that can take a bunch of abuse ? looking to make around 400+ crank HP, and going either blown or boosted, but i want to build a stout forged bottom end.

Speaking of bottom ends, already drilled out the pick up to 1/npt, suction side of the block, blended and smoothed the OP suction and discharge sides, drilled out the discharge with a 9/16 till about 3/16 from the oring.

I won't know the overbore for a few days, but I want to build this right the first time, and yes I will be keeping the iron heads for now. which i know even with porting and maybe another round of decking (had the shop just machine them enough to clean them up).

While we are at it, I am returning the cardone reman dizzy, thing is a real piece of work, it needs its mag pickup replaced because it is not only almost flush with the tanish rubber insulator, but is angled and is smacking the reluctor, I do have a few slant dizzy's lying about i was gonna take a pick up off of one of them and just install it, but aside from MSD what is a quality dizzy for a low deck, and i already know to avoid that procomp crap,

And i was thinking magnecor wires for it as well,But i am open to suggestions, already have the GM HEI up grade as well,

-Mike

Posted By: 80fbody

Re: 400BB build up - 09/26/14 06:46 PM

Time to build a simple badazz 451 out of that block. Probably get 500hp even with the stock 906 heads.

Old school and pretty easy. New pistons, 440 crank turned down, 440 rods & a balance.

Will last forever if put together right & good heads with net you 600hp in the future.

Posted By: GTS340

Re: 400BB build up - 09/26/14 06:50 PM

Quote:

There were 383s with cast cranks

There were 383s with forged cranks.

There were 400s with cast cranks.

There were 400s with forged cranks.

Cast to cast, forged to forged, the cranks are the same. For all I know they are the same casting or forging number.

If you're using a forged crank with either 383 or 400 stock crank and rods, and neutral balance converter/harmonic damper, no need to balance.

If you're using a cast crank with either 383 or 400 stock rods and pistons, you will need the cast crank harmonic damper and converter. Then, no need to balance.

Of course, MOPAR balance jobs were the worst of the Big Three, so the stock balance jobs can definitely be improved. BUT, at this stage in your automotive development, you don't need to.

I'd pick the smaller camshaft. 383s and 400s are very easy to overcam.

R.

Forged 400 cranks? What year and what applications were forged cranks used in 400s?

The rods should be good for your application but looking at your build it is very mild and all the stock components should be fine.

Both the cams you are looking at are mild and should work. I would not mill the head, I would pick up a cheap set of closed chamer heads instead like some 516's.

These are plentiful and cheap. I would run the .022" steel shim gaskets to keep the compression up and just surface the heads and block to make them true.

Quote:

Quote:

There were 383s with cast cranks

There were 383s with forged cranks.

There were 400s with cast cranks.

There were 400s with forged cranks.

Cast to cast, forged to forged, the cranks are the same. For all I know they are the same casting or forging number.

If you're using a forged crank with either 383 or 400 stock crank and rods, and neutral balance converter/harmonic damper, no need to balance.

If you're using a cast crank with either 383 or 400 stock rods and pistons, you will need the cast crank harmonic damper and converter. Then, no need to balance.

Of course, MOPAR balance jobs were the worst of the Big Three, so the stock balance jobs can definitely be improved. BUT, at this stage in your automotive development, you don't need to.

I'd pick the smaller camshaft. 383s and 400s are very easy to overcam.

R.

Forged 400 cranks? What year and what applications were forged cranks used in 400s?

I never saw a forged 400 crank in a stock engine but I've only seen about 200 so who knows?

Posted By: dogdays

Re: 400BB build up - 09/26/14 08:23 PM

Some early 4-speed cars and trucks had forged cranks in 400s. It's been discussed here before.

R.

Posted By: Volare4life

Re: 400BB build up - 09/26/14 10:49 PM

I said the crank was a forged unit from a 383, I wanted to keep a stock displacement, but up compression with pistons to a solid 8-8.5, so its a better setup for boost by blower or turbos.

Posted By: 80fbody

Re: 400BB build up - 09/27/14 12:40 AM

I would drop the crank back in with a couple bearings (1,3,5) & install a couple pistons to check your deck height. I have a few 400 blocks and the pistons are WAY down in the hole. Also make cc kit and assemble one chamber on the head and check the cc's. These two measurements will allow you to accurately understand & set your compression the 1st time.

Posted By: Volare4life

Re: 400BB build up - 09/28/14 06:36 AM

can't really do that, block is already at the machine shop. Just waiting to hear back from them to see how much they are boring it over, they want the pistons,rods, full set of rings for one piston, flex plate, and balancer so they can weigh and balance the whole set up and fit the pistons, know i know forged pistons expand more than the hyper's from what i am reading so how much piston to cylinder wall gap should i run ?

What about a quality forged piston ? Icon, CP are names i keep seeing but haven't heard much about anyone running them ??

I saw these Wiseco Pro Tru Pistons PT108A55, its listed for a BB chebby,4.375 bore, flat top with 4 valve reliefs, has a Compression Distance (in):1.250 in. Piston Head Volume +10.00cc, and of course a .990 pin and the more desirable 1/16x1/16x3/16 ring pack and for about $530 not a bad deal

Posted By: EchoSixMike

Re: 400BB build up - 09/28/14 11:27 AM

Those Wiseco pistons are for a 3.75 stroke low deck with a 6.800 chevy rod. S/F.....Ken M

Posted By: Volare4life

Re: 400BB build up - 10/03/14 12:52 AM

So I am looking at either the

KB240

Bore (in):4.382 in.

Bore (mm):111.303mm

Piston Style:Flat top, with a trough

Piston Material:Hypereutectic aluminum

Compression Distance (in):1.908 in.

Piston Head Volume (cc):-5.00cc

Wrist Pin Style:Press-fit or floating

Pin Diameter (in):1.094 in.

Piston Ring Thickness:5/64 in. x 5/64 in. x 3/16 in.

or the KB280

Bore (in):4.382 in.

Bore (mm):111.303mm

Piston Style:Step head, with two valve reliefs

Piston Material:Hypereutectic aluminum

Compression Distance (in):1.327 in.

Dome Height (in):0.155 in.

Piston Head Volume (cc):0.00cc

Wrist Pin Style:Press-fit or floating

Pin Diameter (in):1.094 in.

Piston Ring Thickness:5/64 in. x 5/64 in. x 3/16 in.

I am confused as to which with help with the compression bump, oh and I have to go 40 over, already magna fluxed and sonic checked to make sure and they said it could 60 over with no worries. So which pistons should i go with ? and these will be going on stock length rods

THanks,

-Mike

Posted By: Volare4life

Re: 400BB build up - 10/04/14 12:55 AM

Bump for info on pistons

Posted By: 80fbody

Re: 400BB build up - 10/04/14 02:43 AM

KB240 is the one. The KB280 is for the 451 stroke setup. That's why the comp distance is so much smaller. Do look into Probe, Icon, etc forged pistons. They're not typically much more than those KB hypers and much stronger. Oh and Icon is KB's forged line. You also can get 1/16" rings with forged pistons which make more power and give more options than the old style 5/64" rings that the hypers use.

This guy has some pretty good piston prices usually.

http://www.cnc-motorsports.com/pistons-1.html

Posted By: cudadoug

Re: 400BB build up - 10/04/14 07:17 AM

Quote:

This is a 400 we have in my boys Dart. We used the forged 383 crank and of course had it all balanced as it uses stock rods and KB pistons. Also use the internal crank balancer. It had Eddy RPM heads that were cut a bit for 10.6 comp. We use the MP .557 solid flat tappet cam and the RPM intake with a 750 DP. It has a 9.5 Dynamic converter and 3.91 gears. At 3550 lbs with him in it he has dipped in the 11.40's @ 117 and it is a driver street car and runs on pump. Course this build wont help you if you are going to go with the turbo. Ron

Not to hijack but Ron...do you realize that with light race wheels and a glass hood/sealed scoop your sons Dart is knocking on the 10 secon door? Holy smokes!

Posted By: Volare4life

Re: 400BB build up - 10/04/14 07:43 AM

I appreciate the info and link 80fbody,

-Mike

Posted By: Volare4life

Re: 400BB build up - 10/08/14 04:03 PM

got a set of eagle H-beams with arp 8740 bolts, and kb240's .040 over ordered up through cnc-motorsports, great guys to deal with and great prices too. Now I am looking at what dizzy to get, I have heard great things about both firecore and MSD, I want vacuum advance, and currently have an HEI setup on the car, just wondering which dizzy is easier to tune, also looking at some magnecor wires, I used them on my boosted slant and loved them, but I am open to suggestions as to what people have used and liked.

-Mike

Posted By: 80fbody

Re: 400BB build up - 10/08/14 06:31 PM

I went with the Firecore as it clears pretty most all BB aluminum heads & I got a great deal on a new in box one. That said, MSD truly has the market cornered on the these. Quality product with plenty & plenty of guys run them on here so there's no shortage on help available.

Posted By: Volare4life

Re: 400BB build up - 10/09/14 01:23 AM

Very true, but for the price you can't beat a firecore vacuum dizzy, and i hear its a lot easier to recurve it vs losing your mind breaking a MSD down lol Are you running firecore wires as well ? I was thinking about going with magnecor wires, but i don't know how they compare to firecore

-Mike

Posted By: 383man

Re: 400BB build up - 10/09/14 05:56 AM

Quote:

Quote:

This is a 400 we have in my boys Dart. We used the forged 383 crank and of course had it all balanced as it uses stock rods and KB pistons. Also use the internal crank balancer. It had Eddy RPM heads that were cut a bit for 10.6 comp. We use the MP .557 solid flat tappet cam and the RPM intake with a 750 DP. It has a 9.5 Dynamic converter and 3.91 gears. At 3550 lbs with him in it he has dipped in the 11.40's @ 117 and it is a driver street car and runs on pump. Course this build wont help you if you are going to go with the turbo. Ron

Not to hijack but Ron...do you realize that with light race wheels and a glass hood/sealed scoop your sons Dart is knocking on the 10 secon door? Holy smokes!

He is actually in the process of getting a glass hood with the 6 pk scoop so he can run a taller intake if he wants to try some other intakes also. He has not had it out or driven it much in the last 2 years as he got married and his wife had my grandson about 3 months ago so he has been very busy. But he plans to get more serious with the Dart some day soon. Thanks , Ron

Posted By: Volare4life

Re: 400BB build up - 10/17/14 01:07 AM

got everything but the torque converter, flex plate, just real quick I am looking at roughly 9.5:1 compression with my build, what would everyones recommendation be for a DP carb and would a 2400 stall be a enough to help motivate my 3400lb 2dr volare with a 2.94 rear gear ? or should i be looking for a higher stall ?

-Mike

Posted By: Thumperdart

Re: 400BB build up - 10/17/14 02:18 AM

Quote:

got everything but the torque converter, flex plate, just real quick I am looking at roughly 9.5:1 compression with my build, what would everyones recommendation be for a DP carb and would a 2400 stall be a enough to help motivate my 3400lb 2dr volare with a 2.94 rear gear ? or should i be looking for a higher stall ?

-Mike

Looks pretty good but why r u stuck on a DP carb? Also, there`s a fine line in my opinion w/verts and gearing especially n/a and that`s a TALL gear..............

Posted By: Volare4life

Re: 400BB build up - 10/17/14 04:21 AM

never could get vac secondary carbs to run right, and always had good success with DP carbs, and I just want lower rpms while cruising, might step up to 3.23, but its still a daily driver for now

Posted By: GTX MATT

Re: 400BB build up - 10/17/14 05:02 AM

750 for the double pumper, and I'd go with 3.55s. 2.94s just suck, especially with a tall tire.

Did you pick a cam?

Posted By: 80fbody

Re: 400BB build up - 10/17/14 04:24 PM

I'd also go 750dp,3:55 gears & a 3000 rpm converter.

Posted By: Thumperdart

Re: 400BB build up - 10/17/14 05:04 PM

Quote:

750 for the double pumper, and I'd go with 3.55s. 2.94s just suck, especially with a tall tire.

Did you pick a cam?

Agreed.............and the carb needs to be "THUMPAFIED" ......

Posted By: Volare4life

Re: 400BB build up - 10/17/14 06:30 PM

Gtx Matt, see above for cam specs. What do you mean by thumpafied ?

Posted By: Thumperdart

Re: 400BB build up - 10/17/14 06:39 PM

Quote:

Gtx Matt, see above for cam specs. What do you mean by thumpafied ?

Hi, I`m Thumper and I`m a carboholic............get it? Thumpafied...........

Posted By: GTX MATT

Re: 400BB build up - 10/17/14 08:23 PM

Quote:

Gtx Matt, see above for cam specs. What do you mean by thumpafied ?

Did you pick the 6400 or 6401 though? I read through I never saw the final choice.

Posted By: Volare4life

Re: 400BB build up - 10/17/14 09:46 PM

6400, and I am still not getting what your putting down thumper lol, are you talking about what mods you do to carbs ? Also are 2" headers to 3.5" collectors too big for the current build ?

Posted By: forphorty

Re: 400BB build up - 10/18/14 03:46 AM

Quote:

6400, and I am still not getting what your putting down thumper lol, are you talking about what mods you do to carbs ? Also are 2" headers to 3.5" collectors too big for the current build ?

Yes, much.

Posted By: Thumperdart

Re: 400BB build up *DELETED* - 10/18/14 03:49 AM

Post deleted by Thumperdart

Posted By: forphorty

Re: 400BB build up - 10/18/14 04:03 AM

Quote:

Quote:

Quote:

6400, and I am still not getting what your putting down thumper lol, are you talking about what mods you do to carbs ? Also are 2" headers to 3.5" collectors too big for the current build ?

Yes, much.

Yes sir...........Unless DP does the things others and myself do, I guarantee I can make it cleaner and better............GUARANTEED!

To clarify, I meant, yes, I believe a 2x3.5 header is much too big for the current build. Something more like 13/4 x3 would probably be better.

To clarify, I meant, yes, I believe a 2x3.5 header is much too big for the current build. Something more like 13/4 x3 would probably be better.

Posted By: Thumperdart

Re: 400BB build up - 10/18/14 04:21 AM

My bad, I clicked on your name.............

Posted By: Volare4life

Re: 400BB build up - 10/22/14 09:57 PM

*bump for GTX MATT* opinions on my cam choice 6400 summit ? or would the tried and true .509 be a better option ? cam recommendations are always welcome

-Mike

I've recently wrenched together a bone stock 400 as a simple cruiser engine.

Didn't change much on the stock internals, except for a slightly larger than stock cam and new cambearings.

I did use 0.020" steel headgaskets and lightly milled a set of 915-heads to up the CR a bit but I didn't cc or measure anything to find out where I was at.

Used an Offenhauser dualport intake. It was the only 4-bbl intake I had.

Needed to enlarge the intake boltholes slightly because of the headmilling.

Engine vacuum is fairly low still so I suspect the piston rings have seen better days.

Recently recurved the ignition which woke it up nicely.

Before After

After

So you might have some idea what the 6400 cam will do..........

Just built a .030 over 400 using the 6400 camshaft. Used the 346 heads with some minor porting so they flowed 250 cfm @ .500" lift. The engine was 7.515:1 compression and with the factory 2bbl carb and the factory 2bbl cast iron intake and dyno headers it made 371 lb-ft and 285 horsepower.

Went to the shelf and grabbed a 383 Street Dominator intake and the old reliable 950 Quick Fuel and it made 397 lb-ft and 361 horsepower.

Posted By: 72N96RR

Re: 400BB build up - 10/22/14 11:09 PM

Quote:

so got the block spotless, and guess what a few of the cylinders got some deep pitting, its bad enough after running a "dingle-berry" hone to knock off the varnish i could clearly see the pitting. Oh damn now i have to bore it out, So what do you guys recommend for a really good forged piston ?

Also how much HP/TQ can stock 400 rods take ?

I think it would be a good time to upgrade the rods to h-beams, any good brands out there that can take a bunch of abuse ? looking to make around 400+ crank HP, and going either blown or boosted, but i want to build a stout forged bottom end.

Speaking of bottom ends, already drilled out the pick up to 1/npt, suction side of the block, blended and smoothed the OP suction and discharge sides, drilled out the discharge with a 9/16 till about 3/16 from the oring.

I won't know the overbore for a few days, but I want to build this right the first time, and yes I will be keeping the iron heads for now. which i know even with porting and maybe another round of decking (had the shop just machine them enough to clean them up).

While we are at it, I am returning the cardone reman dizzy, thing is a real piece of work, it needs its mag pickup replaced because it is not only almost flush with the tanish rubber insulator, but is angled and is smacking the reluctor, I do have a few slant dizzy's lying about i was gonna take a pick up off of one of them and just install it, but aside from MSD what is a quality dizzy for a low deck, and i already know to avoid that procomp crap,

And i was thinking magnecor wires for it as well,But i am open to suggestions, already have the GM HEI up grade as well,

-Mike

Diamond custom dish piston 18cc..10.95 to 1 with 75cc head...

4.250 low deck stroker crank

6.535 big chevy H beam rods

Posted By: GTX MATT

Re: 400BB build up - 10/22/14 11:26 PM

Quote:

*bump for GTX MATT* opinions on my cam choice 6400 summit ? or would the tried and true .509 be a better option ? cam recommendations are always welcome

-Mike

How racy/radical do you want it to be? At this point you're upping the compression, you're going to give it good induction and exhaust, pretty much everything it needs with the exception of gear. If you want it to run harder NA I would go with the 6401. I'd stay smaller than the 509 unless you plan to go to 3.91s or more eventually though.

IMO the 6401 isn't too radical, and with your converter and decent compression you're not losing anything to the 6400 really. The 6400 is really basically a stock HP cam, or what people call and RV/Towing cam. I think with the 6401 it would be a 400-425 horse engine

Posted By: mopar400

Re: 400BB build up - 10/23/14 02:28 AM

Here is a free Desktop Dyno you can download to get an idea of what you're working with. To get more accurate you can google your head flow and enter that in too. Old school program but works.

http://www.colorado4x4.org/vbb/showthrea...o-Free-Download

http://www.colorado4x4.org/vbb/showthrea...o-Free-Download

Posted By: Volare4life

Re: 400BB build up - 10/23/14 05:02 AM

Appreciate the dyno software MOPAR400.

Laroy those are pretty decent numbers considering the compression, I will be about 9.3/9.5-1 according to eagles calculator.

72N96RR, i already have KB240's and eagle H beams (6.358, but thank you for the recommendation.

GTX MATT I plan on running a 3000-3200 stall, just realised Turbo Action is literally 30mins from my house here in jacksonville fl. Gonna give them a call, they seem to get good reviews on there converters.

Unfortunately my order that was supposed to be here today, but fedex yet again has let me down and my order is still in georgia !! So one more day before I can get the rotating assembly balanced.

Posted By: mopar400

Re: 400BB build up - 10/23/14 04:13 PM

Quote:

Quote:

*bump for GTX MATT* opinions on my cam choice 6400 summit ? or would the tried and true .509 be a better option ? cam recommendations are always welcome

-Mike

How racy/radical do you want it to be? At this point you're upping the compression, you're going to give it good induction and exhaust, pretty much everything it needs with the exception of gear. If you want it to run harder NA I would go with the 6401. I'd stay smaller than the 509 unless you plan to go to 3.91s or more eventually though.

IMO the 6401 isn't too radical, and with your converter and decent compression you're not losing anything to the 6400 really. The 6400 is really basically a stock HP cam, or what people call and RV/Towing cam. I think with the 6401 it would be a 400-425 horse engine

I ran a 400 for years with the .484 and .509 cam later on. I think the .484 was a lot better fit for my combo (only 8-8.5:1). I'd go with the 6401. Should run strong.

I ran a 400 for years with the .484 and .509 cam later on. I think the .484 was a lot better fit for my combo (only 8-8.5:1). I'd go with the 6401. Should run strong.

Posted By: Volare4life

Re: 400BB build up - 11/02/14 07:58 PM

Well got the old summit cam all packaged up ready to ship back, I am just hoping that the 6401 cam will pull to redline (5,500 RPM)like advertised, Like i said I am open to other suggestions anything to anything bigger,also wondering if stock springs would be ok to reuse with the 6401 cam, I have cut the valve stem guides to .530 with teflon seals, remember it should be around 9.5:1 compression on a set of lightly decked 906 heads with KB hyper pistons, ferrea SS valves, and eagle H-beam rods, still need to get over to turbo action, but I need to finish the engine and get it to the dyno to figure out which converter to mate to it,gonna give my engine machine shop a call monday and see how things are going,

-Mike

Posted By: Volare4life

Re: 400BB build up - 12/03/14 08:08 AM

so got everything back from the machine shop, getting ready to assemble the engine, I do have a few questions before I fire it up, and I have killed the search button, but there are just so many different ways to cut the cake, it gets a bit confusing, and looking for clarity so i do it right, since this is my first real (mild) performance build.

I have read that you can run just straight water, then once its broke in drain and fill with anti-freeze, which makes sense especially if (knock on wood) you have leaks, but any truth to running it with no t-stat for break in ?

I also remembering hearing when breaking in a fresh motor, that you should run exhaust manifolds vs headers, any truth to that ?

Is the general rule of thumb to start it and set timing then bringing it up to the varied 1800-2000/2500rpms or start it bring it up to the varied rpm for break in, then bring it to idle and set the timing ?

What is the go to oil for break in, straight 30W, any 30W with a ZDDP additive ? conventional dino, semi or full syn ? I have also heard "break it in with what you plan on running in it" ?

How soon to change it after the break in is complete ? I have heard right after, 200-500 miles of mild driving, so ??

And I know this topic has been beaten worse then a tough chunk of meat, BUT who uses normal dino oil with an additive vs say brad penn/gibbs/VR1 etc ? I don't mind paying extra for quality, but if you get the same results at the end of the day and can save a bit, hey its a good day.

How much ZDDP is too much ? in a diesel vs reg/semi syn/full syn,I know that the higher zinc is good, higher phosphorus is bad.

Thanks as always,

-Mike

Quote:

Appreciate the dyno software MOPAR400.

Laroy those are pretty decent numbers considering the compression, I will be about 9.3/9.5-1 according to eagles calculator.

72N96RR, i already have KB240's and eagle H beams (6.358, but thank you for the recommendation.

GTX MATT I plan on running a 3000-3200 stall, just realised Turbo Action is literally 30mins from my house here in jacksonville fl. Gonna give them a call, they seem to get good reviews on there converters.

Unfortunately my order that was supposed to be here today, but fedex yet again has let me down and my order is still in georgia !! So one more day before I can get the rotating assembly balanced.

i put a 400 in my duster my "stage 1" engine lol. i spent about 5500 kb 240 pistons, zero deck 400 stock crank, eddy rpm heads had to be milled slightly, 10:1 eddy rpm inake, eddy cam that came with the kit 750dp carb

the lil 400 got 460hp peak on the dyno at 6100

stage 2 i might get some nice heads either full ported or maybe some stage v's or something. stroker kit etc. and efi.

or i may choose to put in a gen3 i havent decided yet. my tubular k frame will take sb/bb/gen2/gen3 so i have many options lol

Quote:

so got everything back from the machine shop, getting ready to assemble the engine, I do have a few questions before I fire it up, and I have killed the search button, but there are just so many different ways to cut the cake, it gets a bit confusing, and looking for clarity so i do it right, since this is my first real (mild) performance build.

I have read that you can run just straight water, then once its broke in drain and fill with anti-freeze, which makes sense especially if (knock on wood) you have leaks, but any truth to running it with no t-stat for break in ?

>>> most shops with a dyno run with no t-stat and straight water for 25 min at 2000 rpms.

I also remembering hearing when breaking in a fresh motor, that you should run exhaust manifolds vs headers, any truth to that ?

>>> yes because the headers can get red hot/ so use the dyno headers or some old manifolds. not new shiney headers definitely

Is the general rule of thumb to start it and set timing then bringing it up to the varied 1800-2000/2500rpms or start it bring it up to the varied rpm for break in, then bring it to idle and set the timing ?

What is the go to oil for break in, straight 30W, any 30W with a ZDDP additive ? conventional dino, semi or full syn ? I have also heard "break it in with what you plan on running in it" ?

>>> Brad Penn 20w50 or some other racing oil not straight weight not rotella fleet oil or some cheap stuff. run the good stuff.

How soon to change it after the break in is complete ? I have heard right after, 200-500 miles of mild driving, so ??

>>>first 500 miles vary the speeds dont drive at a constant 55 or something. continued high rpms can damage bearings and lots of jack rabbit starts before it's broke in can damage the rings. depends on your setup and how well everything is clearanced and built though. if everything is perfect it will take a lot of abuse. change oil at 500 or 1000 ... a good idea

And I know this topic has been beaten worse then a tough chunk of meat, BUT who uses normal dino oil with an additive vs say brad penn/gibbs/VR1 etc ? I don't mind paying extra for quality, but if you get the same results at the end of the day and can save a bit, hey its a good day.

How much ZDDP is too much ? in a diesel vs reg/semi syn/full syn,I know that the higher zinc is good, higher phosphorus is bad.

>>>just use Brad Penn, it's good stuff. you can order it off summit. valvoline has a racing oil as well. there are a few others but why experiment

Thanks as always,

-Mike

Posted By: GTX MATT

Re: 400BB build up - 12/03/14 09:00 PM

To answer your questions on valve springs no, do not run stock springs. Comp 911s or something similar. Take off springs from Stealth or Eddy heads would work fine too.

For break in what kind of distributor are you running? If its points get it pointed to number 1 and turn it until the points just start to open. If electronic get it pointing to number 1 and advance it a little, 10 degrees or so. Then snug it leaving it loose enough to turn if you need to. Plug in the vacuum advance.

Use a real break in oil, 30W is good. I used the Comp Cams break in oil. Dump it after break in. If you want to take a ride around the block before dumping it you won't hurt anything, but the sooner the better. After you dump it refill with oil with another bottle of break in additive. I would do this for the first 2 oil changes. 500 miles on the second batch of oil after break in, and you can increase the second oil change if you want. I change my oil often, cleaner oil is better.

Once you're done with break in VR1 or Brad Penn, either is fine. I used VR1 for my first few oil changes with a bottle of the comp cams additive. I put the Brad Penn in last time with the additive. Both of these oils have enough zinc and in a 20W50 both of these oils are extremely sticky and will keep your cam lubed when your engine sits so it wont be starting dry. I'm probably overdoing it adding the break in bottle to either, but I've got a 9 quart pan and rather be safe than sorry (too much zinc is not really good though, over 2000 PPM).

No truth to manifolds vs headers IMO, maybe they think the back pressure will help seat the rings? I say old wives tale. If its because of glowing headers they aren't running enough timing, which brings me to:

Pre-fill your carb bowls. If its a Holley remove the sight plugs. Pour some fuel in a dry water bottle and get a clean cap from a gear lube bottle. Trim it so it fits in the vent tube. Now fill the bowls until the fuel is at the sight plug bottom, just like setting the floats. Put the sight plugs back in.

Hook up your choke if you have it. Turn the curb idle screw in far.

If you've got the timing close it will fire up immediately. HAVE A HELPER. Hold the RPM above 2000 if the curb idle screw isn't enough. Have your helper adjust it until it is. If that isn't enough adjust the throttle cable to hold it.

Now check your timing. This depends on how your dizzy is curved, but shoot for 40-45 degrees with the vacuum advance for now while running at 2000-2500 RPM. This is conservative but should be enough to keep your headers from glowing/EGTs being high. When you're done you can get it dialed up perfect. Come back for tuning advice if you need it.

You can run water, no problem. Just make sure the engine will be out of close to freezing temps before you dump it. No thermostat? Might ask for trouble but should be fine. I'd put a 180 stat in it. If you run hot you have cooling or tune issues. If you can run half 110 leaded and half 93 pump for a break in on a street engine. The lead helps the engine run cooler.

Vary the timing. 2000 minimum, so have it set to run there or slightly over. Get behind the wheel and bring it up to 2500 and hold it every few minutes. I like to wack it up to 3K or so a few times in between it running at 2000 and holding it at 2500.

Once done get your timing set right. Then dump the oil and refill. With that cam shoot for a baseline of 15 initial, 34 total mechanical all in by 2500 or so, then find what the engine really prefers. I would run vacuum advance as well. Then take it out and put it under a load. Mat the pedal in high gear a few times, bringing the revs up higher each time (try to avoid a kickdown though, IDK if you have a MVB). Start 2K to 3K, back off. Let the engine slow down don't hit the brakes. Then 2K to 4K, etc.

Then go burn some rubber

Posted By: MR_P_BODY

Re: 400BB build up - 12/03/14 11:51 PM

Depending on the dist you can set the damper at about

30* BTDC then set the rotor to just point at the #1

tower and thats gonna be close(if you run a vac and

mech dist

set the dammper at 18* then set the rotor at #1... if

the exhaust turns red during break in ADVANCE the dist

more(you will hear the revs come up)... the above data

is on the compression stoke(both valves closed)

Posted By: Volare4life

Re: 400BB build up - 12/04/14 06:51 AM

There is a guy on here that is hooking me up with a new set of springs and retainers off a set of stealth heads, I am going to be using a firecore vacuum dizzy and their pro-fit wires, msd blaster 2 coil, with the HEI upgrade for the ignition system. Getting a good deal on a case of brad penn 10w-30 right at $60 for a 12pk, the break in oil I am sure is gonna be cheaper still, and also have a case of wix filters standing by, I am going to be running an external pickup and I am concerned about the size difference in the HV vs external milodon pump covers, should I worry about enlarging the holes at all ?

so your saying to use an additive for the break in, and first 2 oil changes ? I thought that the BP had high enough ZDDP to not need anything else ?

I should use 20W-50 in a freshly rebuilt motor ? I figured 10W-30 would be plenty thick.

I run an aeromotive 340 stealth intank pump, so the bowls should fill quickly lol

I appreciate clearing up on the header vs manifold issue as well,

Thanks as always guys,

-Mike

Posted By: Volare4life

Re: 400BB build up - 12/04/14 06:59 AM

Also no mufflers on the break in correct ? And 30mins is still the time to shoot for yea ?( my neighbors hate me anyway, good thing I am moving soon lol)

-Mike

Posted By: GTX MATT

Re: 400BB build up - 12/04/14 07:08 AM

I would run mufflers for sure so I could hear the engine, I don't think there is any advantage there to not running them.

You should choose your oil weight based on your main and rod bearing clearances. 10W30 in general is good. But that 20W50 BP and VR1 is stickier. It gives me a warm fuzzy feeling when the car has been sitting for weeks so I run it.

And yeah I'd run boosted zinc levels in the first oil change or two after break in. It may be overkill but better to be safe than sorry.

Posted By: MR_P_BODY

Re: 400BB build up - 12/04/14 07:08 AM

Quote:

Also no mufflers on the break in correct ? And 30mins is still the time to shoot for yea ?( my neighbors hate me anyway, good thing I am moving soon lol)

-Mike

Muffs or not.. no matter... your playing at about 2000

rpm and fluctuate the rpm up to about 2500 rpm

EDIT

have you assembled this yet... I think you MIGHT have

screwed up buying your push rods so early... normally

you test the PR length when you mock up AFTER all

the machine work is done.. if the block is decked or

the heads are cut or you change head gasket thickness

any or all of these factors will change the PR length..

I hope your OK

Posted By: Volare4life

Re: 400BB build up - 01/10/15 06:19 AM

well sorry for bringing this thing back from the dead, in a unrelated note I ended up replacing the frame rails in my volare while waiting for parts from here or there, and it sucks, every single thing about it sucked, from cleaning up and fully welding the crappy factory spot and 1" weld beads, to boxing in and eliminating the factory jig holes, except painting them, that I enjoyed

from this

to this

ALL FAITH AND MEASURED 50+ times

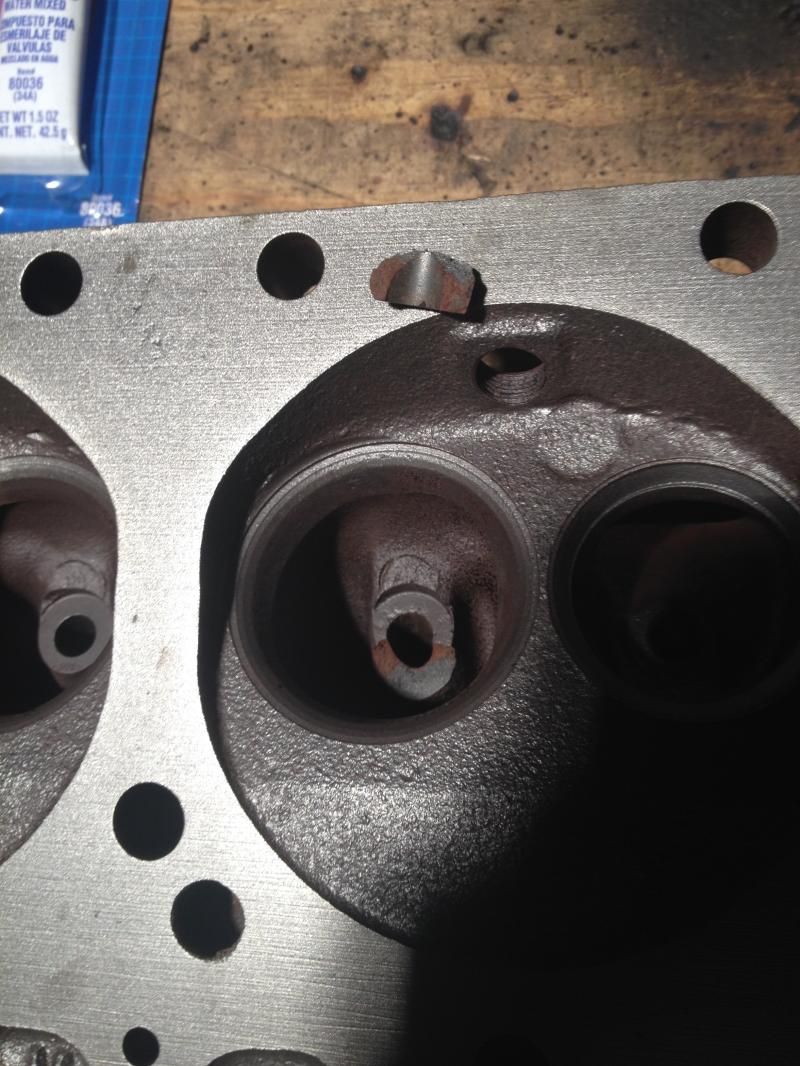

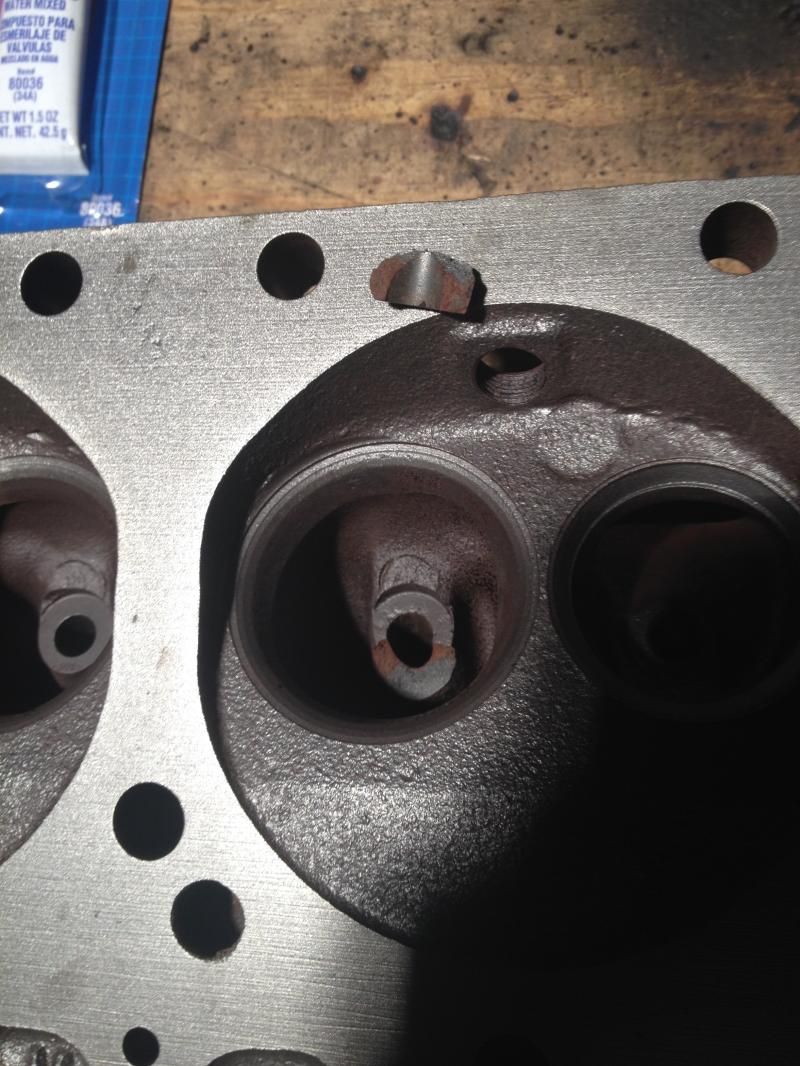

got this built up after several federal mogul bearing issues.....

and then i sent the heads out to get a good cleaning which worked great except I found 2 tiny cracks in a valve guide boss....

and this happened

better here on the bench the at 6,500 through the first shift

So the heads are going back to the shop monday for a set of guides, and probably gonna do hardened seats at the same time, not unless I can blend this out without needing to replace the guide, anyone in FL got a spare 906 head ?? sometimes I swear its like its not meant to be, that Gods saying hey dumb a$$ should have stuck with the slant.....

Posted By: gch

Re: 400BB build up - 01/10/15 07:36 PM

Buy some heads

Posted By: Skeptic

Re: 400BB build up - 01/10/15 09:52 PM

Good work, I like the wheels

This one has a stock stroke 400 as well.

Posted By: Skeptic

Re: 400BB build up - 01/10/15 09:57 PM

Here's a pic with the new bullet.

Posted By: Volare4life

Re: 400BB build up - 01/11/15 02:52 AM

Sick fish bro, anyone have any opinion on the jacked up intake guide ? Do they even make a sleeve thick enough to make up the difference of the chunk missing ? I am strongly thinking about blending it in smooth and sharp edge free to prevent future cracks, and at the spring pressures I am running I think it will be ok

Posted By: Skeptic

Re: 400BB build up - 01/11/15 05:29 AM

Quote:

Sick fish bro, anyone have any opinion on the jacked up intake guide ? Do they even make a sleeve thick enough to make up the difference of the chunk missing ? I am strongly thinking about blending it in smooth and sharp edge free to prevent future cracks, and at the spring pressures I am running I think it will be ok

Thanks, I'd just have bronze guide(s) installed. Should be fine.

Posted By: Volare4life

Re: 400BB build up - 01/18/15 05:57 AM

well heads are at the shop, should have them back Monday/Tuesday, and the motor running by next weekend, pretty excited !!

Posted By: Volare4life

Re: 400BB build up - 02/11/15 06:55 PM

Posted By: Cab_Burge

Re: 400BB build up - 02/11/15 09:41 PM

Posted By: Volare4life

Re: 400BB build up - 02/13/15 03:33 PM

I would but, #1 its a mild setup for now, #2 I haven't found a decent set of iron adjustable rocker's ( not real trust worthy of aluminium, and the ones that are high quality are just as much as if not more than a set of iron adjustable rockers.

Well since I haven't received any input on OP choices, I will go with my original plan, ported HV pump and cover and 1/2" internal pickup, slightly baffled pan and windage tray with extra louvers and a stepped center section, time to get fabbing,

-Mike

Posted By: Cab_Burge

Re: 400BB build up - 02/13/15 09:25 PM

Quote:

I would but, #1 its a mild setup for now, #2 I haven't found a decent set of iron adjustable rocker's ( not real trust worthy of aluminium, and the ones that are high quality are just as much as if not more than a set of iron adjustable rockers.

Well since I haven't received any input on OP choices, I will go with my original plan, ported HV pump and cover and 1/2" internal pickup, slightly baffled pan and windage tray with extra louvers and a stepped center section, time to get fabbing,

-Mike

If you haven't already opened up the block for the 1/2 inch oil pickup you really don't need to do that, it is overkill for most motors  I used the stock 3/8 oil pickup and stock Mopar 6 quart 1970/1971 Street Hemi and 440 6 pak oil pan in my 518 C.I. low deck pump gas stroker motor for year and years of abuse

I used the stock 3/8 oil pickup and stock Mopar 6 quart 1970/1971 Street Hemi and 440 6 pak oil pan in my 518 C.I. low deck pump gas stroker motor for year and years of abuse  I did use the Federal Mogul full narrow groove truck main bearings and there HP rod bearings, both clearances where above .0030

I did use the Federal Mogul full narrow groove truck main bearings and there HP rod bearings, both clearances where above .0030  I used Valvoline 5W20WT oil in that motor from day one, never a oiling issue as long as I kept the oil level above the add oil line on the calibrated dipstick

I used Valvoline 5W20WT oil in that motor from day one, never a oiling issue as long as I kept the oil level above the add oil line on the calibrated dipstick

BTW, that motor ran 9.99 ET motor only in my 3450 Lb duster through the complete exhaust system on Oregon 91 octane pump swill

BTW, that motor ran 9.99 ET motor only in my 3450 Lb duster through the complete exhaust system on Oregon 91 octane pump swill

My main message is there is a lot of misinformation out there on Mopar oiling systems, get it(the motor) ALL right and the stock stuff works fine

My main message is there is a lot of misinformation out there on Mopar oiling systems, get it(the motor) ALL right and the stock stuff works fine  I have and do use the Milidon oiling parts on some of my race motors, not all of them though

I have and do use the Milidon oiling parts on some of my race motors, not all of them though  If your planning on shifting the motor below 7000 RPM and not having it revved past 7000 RPM at the finish line you really don't need those expensive racing oil system parts

If your planning on shifting the motor below 7000 RPM and not having it revved past 7000 RPM at the finish line you really don't need those expensive racing oil system parts

I use the high volume Mellings and Speed Pro oil pumps in all my builds, I cut the bypass spring so I have 10 lbs of pressure per 1000 RPM of intended use, that is with hot thin oil

I use the high volume Mellings and Speed Pro oil pumps in all my builds, I cut the bypass spring so I have 10 lbs of pressure per 1000 RPM of intended use, that is with hot thin oil  The 518 motor had 18 to 20 lbs idling at 850 RPM with 180 + F oil temps, it would have 35 lbs at 1200 RPM and 65 lbs at or above 5500 RPM withthe 3/8 pick up and high volume Mellings oil pump with the spring cut back a coil or two

The 518 motor had 18 to 20 lbs idling at 850 RPM with 180 + F oil temps, it would have 35 lbs at 1200 RPM and 65 lbs at or above 5500 RPM withthe 3/8 pick up and high volume Mellings oil pump with the spring cut back a coil or two IHTHs

IHTHs

Posted By: Volare4life

Re: 400BB build up - 02/14/15 04:11 AM

I will have the melling HV pump, block has already been opened up for 1/2" and smoothed, just going to run the deep pan, I just wanted to make sure i was going to have zero oiling issues, i know i know, as long as the pick up remains covered I am good, but whats an extra $350 for the oil pump and dizzy drive when you have $3k in the motor ? I do want to push this car and see if a Silver state challenge 200mph+ is possible, motor has full groove bearings on the mains, so the added psi shouldn't be an issue, I was planning on running 10w-30, I mean we are in floridas winter month and a half right now so it is a bit brisk out, but I don't think it should be an issue for the other 10 1/2 months lol, especially in all the damn stop and go here in jacksonville,

-Mike

Posted By: Streetwize

Re: 400BB build up - 02/15/15 07:35 PM

Having built Many of these, my .02 is not to Over-think these things. for a high torque 550-670'is horse motor theyt can't be beat. Find a good solid block like this one 71 230 but not a cold weather uber-thick main and drop in a 4.15 to 4.30" crankwith a decent st of 280-320 CFM heads with a streetable 250-265 ish @.050 cam and let it go; there's really not much point making more top end power if you can't make the torque you already have hook up. The best, most reliable motors are the ones that keep the torque peak in the 3800-4400 RPM range, when you really turn up the wick with big 360-380 cfm Max Wedge heads they can make 675-725+ HP but it requires a lot more spring/cooling/converter and tire to really make it pay off and 90% of people won't even know the difference between a 620HP and 720HP motor below ~5000 RPM anyway. Torque is what sets you back in the seat and as strong as B/RB blocks are they are (after all) 2 bolt main motors designed for modest RPM torque peaks... If you think about it....there's a reason Hemi's had/have cross bolted Mains....durability.

I'm not saying you can't build a reliable 700 hp motor and drive it on the street, it';s just that it generally costs a lot more to achieve a powerband improvement that is usually only appreciated above an RPM you (for most people) seldom get to use outside of a drag strip.

Again, don't over-think things, build it the way you want it, this is the Race forum so (although well-intentioned) a lot of what you'll hear on this forum will lean toward "super-sizing" the build. You can, but don't feel you need to. MHO only

Posted By: Volare4life

Re: 400BB build up - 04/17/15 09:24 AM

so after having several issues with timing, running the coyles "tru roller" double roller timing set up. and changing out to a msd blaster 3, she fired right up. And all was right with the world, until it started bubbling and geysering water from the radiator. immediately shut it down, had no clue what could have caused it. oh joy time to trouble shoot, so here we go down the rabbit hole;

So the radiator is a thicker 2 core out of a 80's ramcharger with ac, copper/brass, capped it put a gallon of distilled vinegar and topped it with distilled water, gave it a 5-10 minute shakey shake, let it sit for an hour vertically so all the crap would settle at the cap, did that for about 4 hours, got it nice and clean before the install.

****TSTAT WAS OUT THE WHOLE TIME OF BREAK IN******plugged the lower rad hose and filled up the block with garden hose water, once full popped the plug and continued to flush block the best I could to get all the crap out.

best thing I can figure is the arp head studs need a retorque, and the main reason I went with studs instead of bolts is a better clamp load, and yes I cleaned, cleaned cleaned the crap out of the bolt holes, bottom tapped them, arp lubed them.

Once I get off watch I am going home, tearing it down to get to the studs, torque checking them and if any turn break them all loose and retorque them, put back together and fire it up......again and pray it fixed the exhaust in the coolant, weird thing was car didn't miss a beat, no knock or ping, nothing, hell we'll see. still need to get the wide band hooked up ( weld the bung in place ) and get my tune on

and as always thank you everyone for the continued help with this project

-Mike

Posted By: Cab_Burge

Re: 400BB build up - 04/17/15 07:39 PM

How long and what RPM did you run it at before the troubles started?

Posted By: Volare4life

Re: 400BB build up - 04/18/15 01:22 AM

only about 5 mins, just set timing at 2,500rpm 34deg vac plugged on carb and dizzy ( fire core vac dizzy not the RTR), thought it could have been a hella air bubble trying to burp out, but it didn't seem right so i shut it down and it kept spewing brown *EXTREMELY HOT WATER* every where, I just finished retorquing the head studs to 80 ft/lbs per ARP instructions, all but 2 moved, started it back up same issue, belt not hooked up and still puking fluid out of the rad fill hole, so heads are coming off, off to the shop for a magnaflux and pressure check, i may say f it and quite wasting money on these iron heads and go with some 440 source heads,

-Mike

Posted By: davenc

Re: 400BB build up - 04/18/15 03:33 AM

Before you pull the heads, you could connect an air line to each cylinder, with the piston at TDC, and look for bubbles in the radiator. It may help you find which cylinder is leaking into a coolant passage. It might just be a gasket problem.

I have a radiator pressure/coolant system tester tool I could loan out, it may help and im here in Jax. Also, i've had water puke out forever on a dry engine until all the air is purged... but im always using a t-stat in mine so that could be why.

Posted By: Volare4life

Re: 400BB build up - 04/19/15 10:58 PM

Dustmite it would be appreciated, but I plan on ripping it down tonight to get the heads ready for turn in tomorrow, I thought it might have been a wicked air bubble as well, but with the water pump/ alternator belt off it still gurgles and pukes from the rad. Dave I hope its just a gasket problem, other wise it might be time to pull the trigger on a set of 440source heads, already have about $400 in the iron heads

-Mike

Posted By: Volare4life

Re: 400BB build up - 04/23/15 11:03 PM

so they magnafluxed the heads again, and still good, double checked the flatness, still good, so i got another set of felpro blues, lets see if if this works, thinking about making sure the studs are a bit more then hand tight this time, and running a torque check at least twice before i fire it up again, trying what the shop suggested and sprayed them with copper coat, lets hope all is right this time. also I noticed the cooling holes in the gasket are just tiny slots, should i use a hole punch and atleast punch them out round to max coolant flow through the heads ?

Posted By: Cab_Burge

Re: 400BB build up - 04/24/15 09:04 AM

Posted By: JeffL

Re: 400BB build up - 05/21/15 05:09 AM

How's the Volare coming? I just got my 440 back in my Volare last weekend.

Posted By: Volare4life

Re: 400BB build up - 05/22/15 01:49 AM

its coming, had issues with the rag joint and 1 7/8" hooker headers, that's a post in and of its self, just been working alot more than normal ( thanks navy training squadron), but I am shooting to have it up and running this weekend, and hopefully fixed its coolant demon

Posted By: Volare4life

Re: 400BB build up - 05/22/15 01:51 AM

btw thats a really good looking car, very clean install

Posted By: MarkZ

Re: 400BB build up - 05/22/15 07:27 PM

Sorry to hijack...

Jeff, what headers are those? I'm stuffing a BB into my M body and the engine compartment is exactly the same as an F. Are those shorties?

Very clean install!

Thanks...

Posted By: Volare4life

Re: 400BB build up - 06/16/15 12:15 AM

well I am stuck like chuck, the rusty color all over everything is from the radiator and block flush/ first explosion of water. So I have kept having problems with what i assume is head gasket issues, but now i am thinking more head issues, and not willing to go aluminium just yet ($1,000 is a big chunk just to throw at something for trouble shooting) but if thats what will fix it, heres the story in the short,

-73 vintage block .040 over

-906 heads decked to clean up

-block decked to clean up

-calculated comp is right around 9.8-1

-stock length eagle h-beams

-KB 240 hyper pistons

-383 forged crank cleaned up stock specs

- felpro gasket kit (felpro blue gaskets)

-GMB aluminium WP

-440source aluminium pass side water pump housing

-ARP bolts for mains

-ARP head studs

- firecore dizzy and wires

first issues with was on first start, brought up rpms for break in, then water puked from the rad filler neck, I just figured huge air bubble, shut it down to cool continued to try and burp it, nothing was working.

disconnected wp/alt belt and it still was puking from the rad filler neck, not good, pulled off the valve train and retorqued the head gaskets ( installed finger tight with the arp lube, on re torque #3 i broke them all loose snugged them down with an allen key, then retorqued them) and still same issue.

ripped the heads back off the motor, took them back to the machine shop, had them go through them again, re magna flu them, and still all checks good. put it all back together, except this time copper spray the gaskets, and now all seemed right with the world.

except now it still does this......

[video:youtube]

https://youtu.be/GO94yMbJUiU[/video]

and the [censored] is driving me insane, and no i broke the mic on my iphone so no sound, but still shows how even theres no belt it still bubbles and gurggles, also once shut it down, refilled it with water, put the radiator cap on, drove it around the front yard, parked it and shut it down, i could hear an audible hiss from the passenger side right around the 4-6 cylinder region, which has me thinking i have a crack in a water jacket, but......

no water in oil

no oil in water

no visible water leaks

no "white smoke" or any smoke/water vapor from either muffler

I am really getting irritated with this, like to the point of selling it and going back to the boosted slant, kinda pissed... but jesus i have so much $$$$$$ into the build, and so much $$$ into the iron heads,

I need help guys, and if your in the local jacksonville, fl area feel free to come by, i have a beer fridge in the garage lol

-Mike

Posted By: GTX MATT

Re: 400BB build up - 06/16/15 05:32 AM

Is there a thermostat in it? What kind of radiator?

Are you running it with the cap on it first? And it starts to overflow? Or?

Posted By: EchoSixMike

Re: 400BB build up - 06/16/15 03:27 PM

When the shop "checked the heads out" did they pressure test the effing things? S/F....Ken M

Posted By: WO23Coronet

Re: 400BB build up - 06/16/15 04:07 PM

So it looks like its pushing compression/exhaust out by the heat crossover on the driver side, I agree to double check with your shop to see if they pressure testing them. You could also fill the cylinders in the trouble spot yourself with compressed air and see what happens, maybe the heat cross over is cracked?

Posted By: GTX MATT

Re: 400BB build up - 06/16/15 05:48 PM

Hmmmm missed the part with the heat crossover. It would seem that its cracked where the heat crossover is. If you were close I'd lend you a set of stock heads to bolt on and see if they work.

Posted By: 340man4ever

Re: 400BB build up - 06/16/15 06:18 PM

I had a similar experience with a 360...heads were milled.......decks milled......ended up the intake needed corrected for proper fitment......

acted and sounded just like you are describing

Posted By: GTX MATT

Re: 400BB build up - 06/16/15 06:59 PM

I had a similar experience with a 360...heads were milled.......decks milled......ended up the intake needed corrected for proper fitment......

acted and sounded just like you are describing

On a small block it would make sense, but remember, big block's don't flow coolant through the crossover

Posted By: WO23Coronet

Re: 400BB build up - 06/16/15 07:46 PM

It shows it on the video, u can see coolant bubbling by the heat cross over

Posted By: Volare4life

Re: 400BB build up - 06/16/15 11:34 PM

the coolant you see bubbling in the video is just excess water from when i was rinsing the motor down from its first explosion of water from the radiator neck.

@EchoSixMike, no they didn't pressure test them, just a magnaflux twice

@GTXMatt no tstat, just finished the break in process and was still having this coolant issue, the radiator is a 18" high by 24" wide HD 2 core from a ramcharger, and no i didn't have the cap on when it first puked, wp/alt belt on, tried it again the first time before pulling the heads with cap on and it pissed out the over flow tube hook up, gonna go try another new rad cap and see if the china/mexico junk motorad one was just a turd,

-Mike

Posted By: davenc

Re: 400BB build up - 06/17/15 04:46 AM

Have you tried putting air pressure into one cylinder at a time and look for bubbling in the radiator? It would be good to try to narrow down where the leak is. If you end up with the heads off again, use a straight edge on the block around all sides of each cylinder to make sure there isn't anything funny on that surface. Given that you have tried two gaskets, it must be something either in the head or head surface or block surface.

Posted By: EchoSixMike

Re: 400BB build up - 06/17/15 07:39 AM

Well, magnaflux is fine if you're looking for cracks in the valve seats and the like, but if you have some problems in the coolant passages etc, pressure testing is the only choice AFAIK. I sorta thought it was fundamental when checking if heads were worth spit, but I see I'm hopelessly optimistic. S/F....Ken M

Posted By: WO23Coronet

Re: 400BB build up - 06/17/15 03:36 PM

Pressurize each cylinder as a start and see what happens, if nothing then take the heads back off and get them pressure tested

Posted By: Volare4life

Re: 400BB build up - 06/17/15 10:26 PM

Yea i know, and i even asked before in sunk in almost $450 in parts and labor to them, should have not been cheap and got source heads, going to pressure check the cylinders and look for bubbles......at this point i hope something either positive or negative happens, getting real sick of tearing apart and putting back together,

-Mike

Posted By: dmking

Re: 400BB build up - 06/17/15 11:11 PM

you could pull one plug out at a time and run it. even wire off plug should make a cylinder pressure difference.

Posted By: Volare4life

Re: 400BB build up - 06/17/15 11:53 PM

I figured it might even be a good idea to re torque check the heads since i did have issues with them "sealing?" the first time, so i will pull the valve train and plugs and pressurize the cylinders one at a miserable time, what kind of psi should i pressurize them too ??

-Mike

Posted By: davenc

Re: 400BB build up - 06/18/15 03:53 AM

Put the cylinder on top dead center (approximately) and use 70-80 PSI. The piston might move a little but that shouldn't be an issue. Leave the cap off the radiator and look for bubbles.

Posted By: GTX MATT

Re: 400BB build up - 06/18/15 04:18 AM

I dont know if this is going to find anything. IMO you've probably got a crack between a waterjacket and the exhaust crossover passages, you need need to feed pressure with the #3 or #5 exhaust valve open somehow. Not sure how you'd really do that. I think you need to pressurize the coolant system.

Posted By: Volare4life

Re: 400BB build up - 06/19/15 05:05 PM

I really don't know what to do then, they put in new guides and valve seats, and I am not sure if either of those things had anything to do with it, hell at this point I think i am gonna buy a set of stealth heads off my buddy and call it a day,

-Mike

Posted By: WO23Coronet

Re: 400BB build up - 06/19/15 05:35 PM

It's probably still worth a try, the OP said that the bubbling by the heat cross over was some water that splashed onto that area and was boiling off. To get that much pressure into the water jacket I'd guess it's probably in the combustion chamber? Not sure how much pressure is in the exhaust port but it's still worth a try

Posted By: Volare4life

Re: 400BB build up - 06/20/15 03:07 AM

well earlier in the thread ( and the reason for the valve guides) was because once i got the heads back from the machine shop for being surfaced and cleaned,I noticed one of the guides was cracked on the intake side, so back they went for a set of guides, seals, hardened seats etc between parts and labor about $450 later on a set of iron heads..... yea i know that was stupid to do, but again the goal was to get it running, now hindsight being what it is I plan on tearing the motor out of the car through the bottom rolling it in the garage, check it, and when it fails testing, i have a nice set of aluminium heads I plan on picking up from Chris2342 tomorrow evening.

Now with aluminium heads that are out of the box new, and a set of felpro 8519 pt-1's, do i need to worry about copper spraying them as well ? I figured new gaskets would be cheap insurance, rather then trying to reuse a set that are barely broke in, or could i reuse them ?

its gonna be a long night tonight.......

-Mike

Posted By: Volare4life

Re: 400BB build up - 06/23/15 12:06 AM

so motor, trans and front k-frame are all out, not fun by yourself btw

pulled the intake, and pulled all the plugs out, hooked up the compression checker hose ( pulled the valve core out) made sure it was a tight seal, pulled the rocker gear so i would have to keep rolling the motor over for tdc, put 110psi to it and i heard ait hiss from all eight cylinders, but no bubbles...........not a single damn bubble, I am thinking about putting a thermostat in it and running it on the "factory motor stand" and run it, other wise i pull the heads take them to the machine shop tomorrow, have them pressure check, hopefully at no cost to me since they have told me with 2 magnafluxs that they are good and then I dumped soo much $$$ into iron.... frustrating, I am open to any ideas and suggestions guys,

-Mike

Posted By: TRENDZ

Re: 400BB build up - 06/23/15 01:14 AM

Its likely that there is nothing wrong. With no water pump running, and no pressure in the system, you are boiling the water in the heads.

Reading through this thread... It seems you never gave the engine a chance to burb out the air without jumping to conclusions.

Posted By: 1969RR

Re: 400BB build up - 06/23/15 07:56 PM