Posted By: T-Fish

CNC porting - 11/06/13 01:46 AM

Who do you guys trust to do CNC porting on your cylinder heads?

Quote:I just trusted Hughes.

Who do you guys trust to do CNC porting on your cylinder heads?

Quote:I've had Modern Cylinder Heads,586-468-7914, do three different types of BB Mopar heads,Eddy RPM, B1-BS and two sets of 440-1

Who do you guys trust to do CNC porting on your cylinder heads?

They all made great power on the dyno and went fast at the track, faster than some others on here I believe

They all made great power on the dyno and went fast at the track, faster than some others on here I believe

Quote:

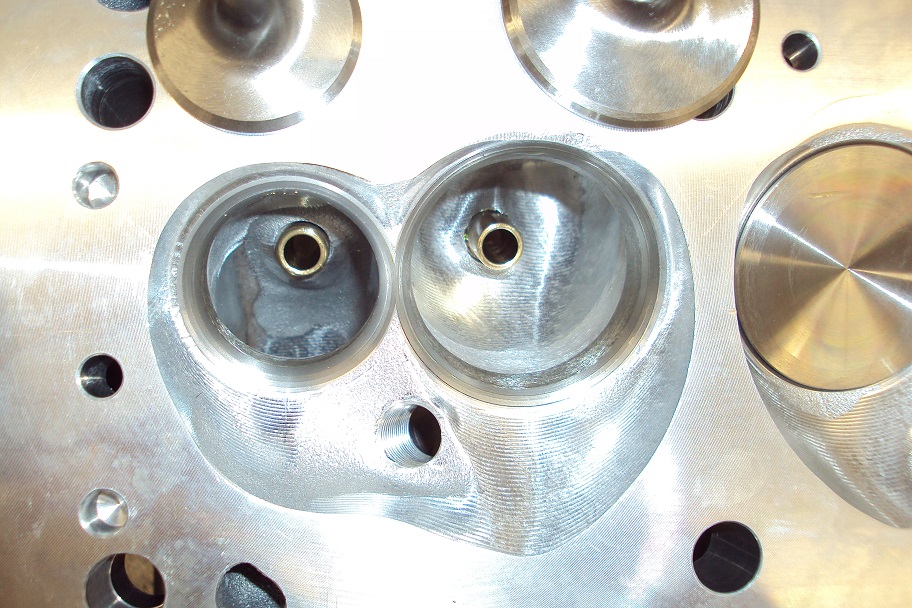

And what head is that with no pushrod bulge?

Nice!

Joe

Quote:

Eddy Victors.

Quote:

Why is the port divider wall so narrow?

Quote:

Why is the port divider wall so narrow?

Do you have a measurement you can share on the width of that?

Quote:Quote:

Eddy Victors.

Standard-size port or Max Wedge?

Quote:

I though the same thing,thin divider wall.Not only do you have to be carefull with the gasket fit but manifold match also.Keeping that alignment you may find it nescessary to add alignment dowels to the head and manifold to make sure it it returned to that precise position when it is removed and replaced.Why not start with heads that are cast for large ports to begin with?

Quote:Quote:Quote:

Eddy Victors.

Standard-size port or Max Wedge?

They are the standard ports. One of the ports has been opened up to Max Wedge size so the rest will need to be done.

Quote:

I don't see how that is possible considering the Eddy's are two seperate castings with the pushrod hole machined in a different position. This is probably why your center divider is thin-because they are std. port Victors. J.Rob

Quote:

All I can add is that T&D now specifies two different part #s for Victor heads depending on MW vs. standard, and the MW version uses an intake rocker w/ more offset.

Quote:Quote:Quote:Quote:

Eddy Victors.

Standard-size port or Max Wedge?

They are the standard ports. One of the ports has been opened up to Max Wedge size so the rest will need to be done.

Combination details? I'm asking because I did some research into what CNC offerings are out there for Victors (not many) and what I did find was predominantly for MW-sized ports anyway.

Some seemed focused more on big high-lift #s (e.g. Speier Racing Heads), whereas the Hughes program seems more oriented to more moderate lift requirements.

Quote:I have both sets of heads in this picture, CNC ported 440-1 and a stock unported set of Victor M.W.

I don't see how that is possible considering the Eddy's are two seperate castings with the pushrod hole machined in a different position. This is probably why your center divider is thin-because they are std. port Victors. J.Rob