Moparts

Rocker arm geometry on a 440

Posted By: moparguy

Rocker arm geometry on a 440 - 04/03/13 02:32 AM

Posted By: rickraw

Re: Rocker arm geometry on a 440 - 04/03/13 02:38 AM

shim up the shaft. that will move the scrub pattern more towards the center.

Posted By: '72CudaRacer

Re: Rocker arm geometry on a 440 - 04/03/13 02:39 AM

Shim up the rocker arm shaft?

Brian

Posted By: moparguy

Re: Rocker arm geometry on a 440 - 04/03/13 02:57 AM

For some reason I was thinking backwards and thinking that if I shimmed it up it would get worse. Thanks guys!

Posted By: AAR-B4

Re: Rocker arm geometry on a 440 - 04/03/13 03:02 AM

You are right, shimming the shaft up will move the contact farther to the outside of the valve tip.

For me...........I'd leave alone, it will be ok.

Posted By: skrews

Re: Rocker arm geometry on a 440 - 04/03/13 03:16 AM

Shimming the shafts up will make the problem worse. Lash caps will improve the situation, but may not fit your retainer/keeper combo.

Posted By: StealthWedge67

Re: Rocker arm geometry on a 440 - 04/03/13 03:24 AM

Are the contact patterns shown in the pictures of a full sweep on the cam lobe?

Posted By: moparguy

Re: Rocker arm geometry on a 440 - 04/03/13 03:25 AM

Yes Stealthwedge, I marked it and turned the engine over 2 times to get a good rubbing.

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/03/13 03:44 AM

Add me to the shim up the shaft crowd.

How do those springs fit on those retainers , the retainers look a little small ??

Posted By: gregsdart

Re: Rocker arm geometry on a 440 - 04/03/13 04:41 AM

Quote:

shim up the shaft. that will move the scrub pattern more towards the center.

I don't agree with that. The rocker shaft bolt is not parallel with the intake valve, it is inclined towards it. The higher you move the rocker shaft, the closer the rocker and valve tip get, and the further out the scrub pattern will be, given you are going in the right direction to get the proper rocker arm to valve angle.

The first thing to do is to figure out at what angle the rocker is to the valve stem right now.

Posted By: Thumperdart

Re: Rocker arm geometry on a 440 - 04/03/13 05:18 AM

Quote:

shim up the shaft. that will move the scrub pattern more towards the center.

Ya. the shaft shimming doesn`t work here but lash caps may help and also spread the load.............that`s what I`ve done 4 years.

Posted By: big_wedge

Re: Rocker arm geometry on a 440 - 04/03/13 10:05 AM

those retainers look way to small for those springs... jus sayin

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/03/13 03:00 PM

Quote:

Quote:

shim up the shaft. that will move the scrub pattern more towards the center.

I don't agree with that. The rocker shaft bolt is not parallel with the intake valve, it is inclined towards it. The higher you move the rocker shaft, the closer the rocker and valve tip get, and the further out the scrub pattern will be, given you are going in the right direction to get the proper rocker arm to valve angle.

The first thing to do is to figure out at what angle the rocker is to the valve stem right now.

I never looked at the hold down bolt to valve angle relationship, if this is the case then shimming the shaft up would move the shaft towards the valve.

Lash caps would be the easier way to do do it , the OP will need to change his valve locks because those are the kind that accept lash caps. Otherwise it's machining off, or machining of, the stands .

Posted By: jlatessa

Re: Rocker arm geometry on a 440 - 04/03/13 04:48 PM

I'm not sure that shimming will make it worse,

take it to the extreme i.e. if you shimmed it an inch, the arc of the tip would be passing the valve on the inside, or is my reasoning wrong??

Joe

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/03/13 05:06 PM

Quote:

I'm not sure that shimming will make it worse,

take it to the extreme i.e. if you shimmed it an inch, the arc of the tip would be passing the valve on the inside, or is my reasoning wrong??

Joe

that was my thought , but that was ASSuMEing the rocker shaft holdown pedestals were parallel to the valve stems , they angle toward the valves it seems, I don't have a head handy to confirm this.

Posted By: jlatessa

Re: Rocker arm geometry on a 440 - 04/03/13 05:17 PM

I think what some are missing is that the tip of the rocker travels in an arc and the contact point has to move because of that...Hmmm

I have a head in the basement, I'll see if I can see some change.

Joe

Posted By: jlatessa

Re: Rocker arm geometry on a 440 - 04/03/13 05:33 PM

With the stamped rockers I have,

the contact point is not easily seen.

Joe

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/03/13 05:44 PM

I'll be interesting to see what the fix is , I have sharps going on 906's when I get my block back .

Posted By: tsanchez

Re: Rocker arm geometry on a 440 - 04/03/13 05:52 PM

The fulcrum point needs to be lowered to fix the geometry, by milling or removing shims if there is some. Raising will make it worse.

Posted By: AndyF

Re: Rocker arm geometry on a 440 - 04/03/13 07:48 PM

To make it perfect you need longer valves or you need to lower the rocker shaft. Neither of those fixes is very simple. Lash caps will help but they add another part to the mix and you will most likely need to change pushrods.

Setting up a BB Mopar to have "perfect" valvetrain geometry is no picnic.

Flip thru the valvetrain chapter in my big block book. I show a bunch of examples and some fixes.

The best fix is to buy rocker arms which are the correct length for the application. Some rocker arms are really short, others are too long.

Posted By: AndyF

Re: Rocker arm geometry on a 440 - 04/03/13 07:56 PM

Quote:

Quote:

I'm not sure that shimming will make it worse,

take it to the extreme i.e. if you shimmed it an inch, the arc of the tip would be passing the valve on the inside, or is my reasoning wrong??

Joe

that was my thought , but that was ASSuMEing the rocker shaft holdown pedestals were parallel to the valve stems , they angle toward the valves it seems, I don't have a head handy to confirm this.

15 degree valve angle which really messes up the geometry. As you raise the rocker shaft it gets closer to the valves.

I have a CAD drawing that details all of this out. It is kind of interesting to watch what happens with rocker arm scrub when you change the location of the shaft. Checking the scrub distance with a dial indicator is a good way to verify what is going on. Then you have an actual number that you can work with.

Sometimes the rocker shaft has to be moved a fair amount before the scrub distance is brought back in line. Ideally you want the minimum scrub distance as well as a centered pattern. That is tough to do with some of the rocker arms that are on the market.

Posted By: AAR-B4

Re: Rocker arm geometry on a 440 - 04/03/13 08:55 PM

What will you gain by centering the roller contact?

You have added the roller, that will greatly reduce the side-load on the valve stem and save the guide.

Put it together, race it and have fun.

Posted By: 70satelliteguy

Re: Rocker arm geometry on a 440 - 04/03/13 09:56 PM

Andy from the photo posted with that pattern would you run it that way?

Posted By: Stanton

Re: Rocker arm geometry on a 440 - 04/03/13 09:58 PM

Quote:

Quote:

I'm not sure that shimming will make it worse,

take it to the extreme i.e. if you shimmed it an inch, the arc of the tip would be passing the valve on the inside, or is my reasoning wrong??

Joe

Well that's just crazy logic. Theoretically if you lowered the shafts and inch it would accomplish the same thing! Think realistically and shimming the shafts does not solve the problem.

The solution is to run them as they are and don't worry about it. You have quality parts and a mild cam.

Posted By: tsanchez

Re: Rocker arm geometry on a 440 - 04/03/13 10:20 PM

For the amount of lift that is a crazy wide sweep pattern, not to mention it may not even get full lift because of the poor geometry.

My car the sweep is .055 across valve and thats with .800 lift.

But with lift that low and springs that are not real big it probably wont cause any real grief.

Posted By: polyspheric

Re: Rocker arm geometry on a 440 - 04/03/13 10:36 PM

If the valve-side lever length is wrong (more common than we would like) re-arranging the heights to cure it will make the geo worse.

The "scrub path" length and behavior on the stem is far more important.

The best path is the shortest, and begins at 0% lift (valve closed) with the roller tip closest to the rocker shaft, and to the stemís near edge (not the center).

As the valve opens, the roller walks toward the stem center, is centered in its own path (which may not be the stem tipís center) at 25% lift.

It reaches its farthest point away from the rocker shaft at 50% lift, then reverses direction.

The roller walks back, reaching its path center again at 75% lift.

Full lift is, again, at the closest point to the shaft and its original resting place.

Posted By: AndyF

Re: Rocker arm geometry on a 440 - 04/04/13 12:42 AM

You can also design a valve train to minimize the product of scrubbing and load. That is, the arc is offset so that as the valve opens the travel across the tip is reduced.

It requires some advanced math to design it that way. I've never figured out the math but I can simulate it on a CAD system. The bottom line is that if you have the rocker arm 90 degrees to the valve at 2/3 lift. When you do it this way you have extra travel across the valve tip at low load, but reduced travel at high loads.

Some engine builders do it this way when running monster valve springs.

Posted By: Stanton

Re: Rocker arm geometry on a 440 - 04/04/13 03:35 AM

Quote:

If the valve-side lever length is wrong (more common than we would like) re-arranging the heights to cure it will make the geo worse.

The "scrub path" length and behavior on the stem is far more important.

The best path is the shortest, and begins at 0% lift (valve closed) with the roller tip closest to the rocker shaft, and to the stemís near edge (not the center).

As the valve opens, the roller walks toward the stem center, is centered in its own path (which may not be the stem tipís center) at 25% lift.

It reaches its farthest point away from the rocker shaft at 50% lift, then reverses direction.

The roller walks back, reaching its path center again at 75% lift.

Full lift is, again, at the closest point to the shaft and its original resting place.

But this will only happen on a specific lift. For example all the ideal roller/tip positions may occur on a .600 lift cam but on an cam with more or less lift these points will be off. Ideally you need to match the cam to the rocker or vice versa. I hate to say it but there are advantages to the "stud" system.

Posted By: AndyF

Re: Rocker arm geometry on a 440 - 04/04/13 05:28 PM

Yes, that is also a very good point. The factory rocker arm geometry is designed for valve lift of roughly 0.400 inches. Which is exactly what you would expect since that is what the lift was when those heads were designed in the late 50's.

To keep the geometry correct, you have to lower the rocker shaft into the head 50% of the additional lift. So if you go from 0.400 lift to 0.600 lift, the rocker shaft should be lowered 0.100.

The only reason to use shims if if you are running less lift than the original design of 0.400. Most people don't do that.

The problem is that if you lower the rocker shaft it moves away from the valve so then you need a longer rocker arm. Best fix for stock heads is to mill off the pads and use offset blocks like the factory designed for the W2. Then you can lower the shaft and move it into position. But then you need to modify the pushrod holes and all of that jazz.

I think the serious class racers used to do all of this stuff years ago. Not sure if anyone still does it anymore. They probably just send their heads to Jesel for modification if Jesel valve gear is allowed in the class rules.

I wrote up all of this information years ago in a magazine article and then covered it again in my big block book. Not sure why I'm bothering to type it in again here.

Posted By: dogdays

Re: Rocker arm geometry on a 440 - 04/04/13 05:33 PM

To add another factor, where the arm begins and ends its path also has an effect on the actual valve opening curve. It is possible to have the valve come off the seat faster with the same ratio by chainging the heightt of the rocker shaft and rocker cup with respect to the top of the closed valve's stem.

There are some interesting Websites devoted to this issue.

R.

Posted By: CSK

Re: Rocker arm geometry on a 440 - 04/04/13 06:57 PM

Quote:

Yes, that is also a very good point. The factory rocker arm geometry is designed for valve lift of roughly 0.400 inches. Which is exactly what you would expect since that is what the lift was when those heads were designed in the late 50's.

To keep the geometry correct, you have to lower the rocker shaft into the head 50% of the additional lift. So if you go from 0.400 lift to 0.600 lift, the rocker shaft should be lowered 0.100.

The only reason to use shims if if you are running less lift than the original design of 0.400. Most people don't do that.

The problem is that if you lower the rocker shaft it moves away from the valve so then you need a longer rocker arm. Best fix for stock heads is to mill off the pads and use offset blocks like the factory designed for the W2. Then you can lower the shaft and move it into position. But then you need to modify the pushrod holes and all of that jazz.

I think the serious class racers used to do all of this stuff years ago. Not sure if anyone still does it anymore. They probably just send their heads to Jesel for modification if Jesel valve gear is allowed in the class rules.

I wrote up all of this information years ago in a magazine article and then covered it again in my big block book. Not sure why I'm bothering to type it in again here.

so why not just use a longer valve ?

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/04/13 08:03 PM

Quote:

Quote:

Yes, that is also a very good point. The factory rocker arm geometry is designed for valve lift of roughly 0.400 inches. Which is exactly what you would expect since that is what the lift was when those heads were designed in the late 50's.

To keep the geometry correct, you have to lower the rocker shaft into the head 50% of the additional lift. So if you go from 0.400 lift to 0.600 lift, the rocker shaft should be lowered 0.100.

The only reason to use shims if if you are running less lift than the original design of 0.400. Most people don't do that.

The problem is that if you lower the rocker shaft it moves away from the valve so then you need a longer rocker arm. Best fix for stock heads is to mill off the pads and use offset blocks like the factory designed for the W2. Then you can lower the shaft and move it into position. But then you need to modify the pushrod holes and all of that jazz.

I think the serious class racers used to do all of this stuff years ago. Not sure if anyone still does it anymore. They probably just send their heads to Jesel for modification if Jesel valve gear is allowed in the class rules.

I wrote up all of this information years ago in a magazine article and then covered it again in my big block book. Not sure why I'm bothering to type it in again here.

so why not just use a longer valve ?

One could , finding the right length will be the fun part , that's why a lash cap would be one alternative.

Posted By: AndyF

Re: Rocker arm geometry on a 440 - 04/04/13 09:37 PM

A longer valve is an option. Another benefit of a longer valve is that you can then use a taller valve spring which is also probably a good thing.

But a longer valve means that you might need a shorter rocker arm.

Posted By: shoebox

Re: Rocker arm geometry on a 440 - 04/07/13 03:21 AM

I wrote up all of this information years ago in a magazine article and then covered it again in my big block book. Not sure why I'm bothering to type it in again here.

Why would you say it all again? Don't get involved with lil guy questions

Let him buy your book and figure it out

You can stay " up here"

And we'll be "down here" helping each other because were mopar

Brothers

Posted By: 70satelliteguy

Re: Rocker arm geometry on a 440 - 04/07/13 02:25 PM

"Why would you say it all again? Don't get involved with lil guy questions

Let him buy your book and figure it out

You can stay " up here" "

"

And we'll be "down here" helping each other because were mopar"

You got something against Andy trying to help someone out!

Posted By: gregsdart

Re: Rocker arm geometry on a 440 - 04/07/13 02:39 PM

Quote:

"Why would you say it all again? Don't get involved with lil guy questions

Let him buy your book and figure it out

You can stay " up here" "

"

And we'll be "down here" helping each other because were mopar"

You got something against Andy trying to help someone out!

This is what got his attention

"Not sure why I'm bothering to type it in again here. "

Posted By: 1_WILD_RT

Re: Rocker arm geometry on a 440 - 04/07/13 07:49 PM

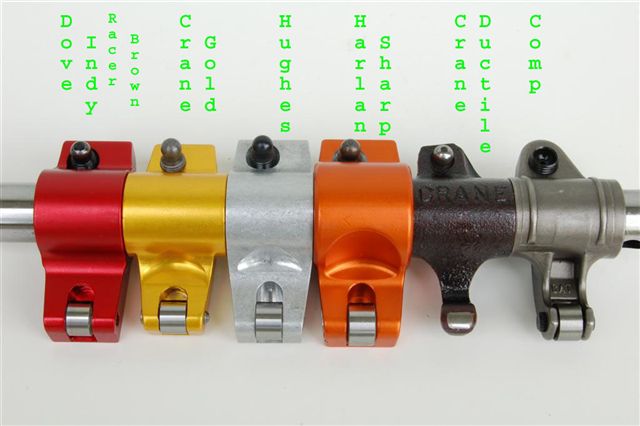

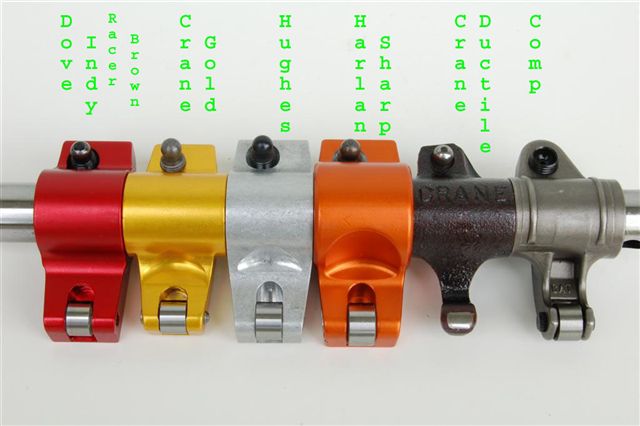

I've saved a few pictures from threads about rocker geometry in the past... First the rocker arm length that Andy mentioned... It would be nice it the rocker brands were mentioned ....

Posted By: 1_WILD_RT

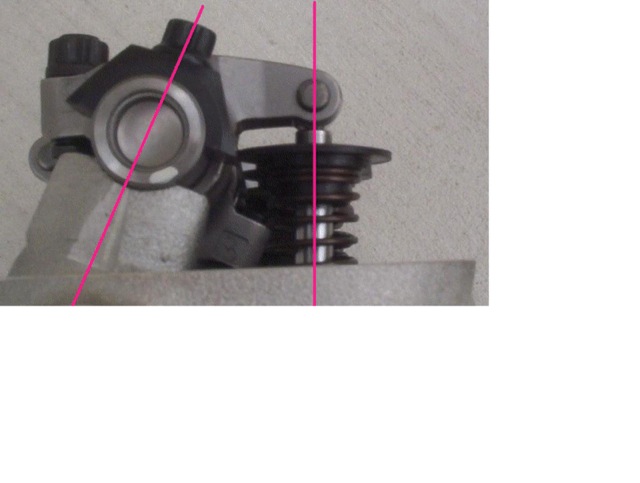

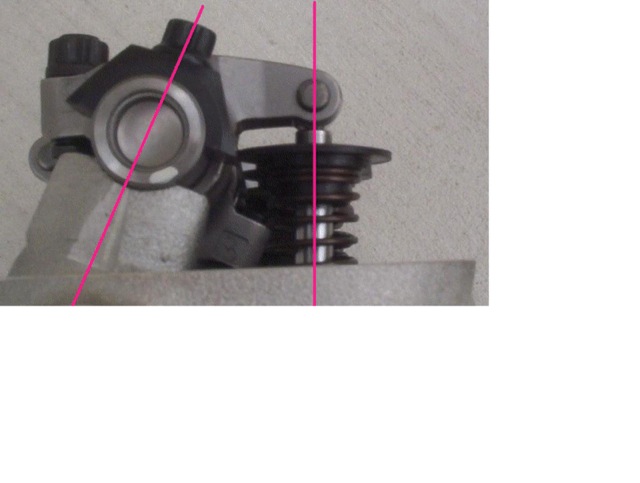

Re: Rocker arm geometry on a 440 - 04/07/13 07:55 PM

And second the hold down bolt vs valve stem angle..

Posted By: JohnRR

Re: Rocker arm geometry on a 440 - 04/08/13 03:25 PM

Quote:

And second the hold down bolt vs valve stem angle..

Good picture , now I see why going up with the shaft will make it worse. Looks like I may have to shelve the HS rockers and go for something else on my 906's

Posted By: Jerry

Re: Rocker arm geometry on a 440 - 04/08/13 03:34 PM

Quote:

I've saved a few pictures from threads about rocker geometry in the past... First the rocker arm length that Andy mentioned... It would be nice it the rocker brands were mentioned ....

in the pic it looks like the

don't know; crane roller rocker; don't know; harland sharp; crane ductile iron ; comp stainless steel rocker

this is my guess at looking at the various pics. hopefully this is a little help full.

Posted By: VernMotor

Re: Rocker arm geometry on a 440 - 04/08/13 03:46 PM

That's what I thought Jerry

Posted By: BradH

Re: Rocker arm geometry on a 440 - 04/08/13 04:43 PM

Quote:

I've saved a few pictures from threads about rocker geometry in the past... First the rocker arm length that Andy mentioned... It would be nice it the rocker brands were mentioned ....

Dove / Indy / Racer Brown; Crane Gold; Hughes; Harland Sharp, Crane iron, either Comp Pro Magnum or C.A.T. ripoffs of same.

Posted By: Stanton

Re: Rocker arm geometry on a 440 - 04/08/13 06:53 PM

The harland sharps should work fine on stock heads - they're an ancient design from when there were no aftermarket heads. The geometry isn't that great on stuff like Indy's, etc.

Posted By: 1_WILD_RT

Re: Rocker arm geometry on a 440 - 04/09/13 04:25 AM

Quote:

Quote:

I've saved a few pictures from threads about rocker geometry in the past... First the rocker arm length that Andy mentioned... It would be nice it the rocker brands were mentioned ....

Dove / Indy / Racer Brown; Crane Gold; Hughes; Harland Sharp, Crane iron, either Comp Pro Magnum or C.A.T. ripoffs of same.

And from that we get...  BTW Thank You..

BTW Thank You..

Posted By: 1KoolBee

Re: Rocker arm geometry on a 440 - 06/09/13 12:55 AM

Quote:

What will you gain by centering the roller contact?

You have added the roller, that will greatly reduce the side-load on the valve stem and save the guide.

Put it together, race it and have fun.

I agree, especially given the extra large roller on the HS rockers.

I just ran into the exact same issue with my HS rockers on my Edelbrock heads, although mine seem to be slightly closer to center

But even if you went with lash caps, the recessed valve locks and lash caps would run about $80 plus pushrods, which is a lot less than a new set of good rockers.

Posted By: polyspheric

Re: Rocker arm geometry on a 440 - 06/09/13 10:34 PM

In general, I agree that if the scrub path is small and a safe distance away from the stem tip's edge I'd leave it alone.

The roller diameter is a bit of a design puzzle. Most mfg. have settled on a 3/8" OD roller as a reasonable compromise between 2 extremes:

1. A really small roller (like 1/4") punishes the stem tip, and has very few needle bearings actually loaded = early failure. Only a few needles at the top of the roller take the entire load, and they don't actually rotate - they oscillate a few degrees.

2. A really big roller (like 1/2") lives longer, loads many more needles, and locally depresses the stem less in psi (yes, I know in theory it's only line contact!), but that's the worst possible place to add both weight and inertial resistance - the roller must reverse rotation instantly or it scuffs across the stem.

Roller tips effectively increase the stem height (compared to pallet ends, as far as geometry is concerned) by their radius, since the axle is the "end" of the stem.

When you run a big roller, the rocker doesn't change (as to geo), but now the valve is too long.

Warren Johnson played with geo on his "stock" Olds 350 motors 100 years ago.

Posted By: moparguy

Re: Rocker arm geometry on a 440 - 06/10/13 03:38 AM

after talking with you guys, and also with Harland Sharp, I put it together and ran it. works perfectly so far.