Posted By: cermac

727 front bushing - 05/26/12 07:34 PM

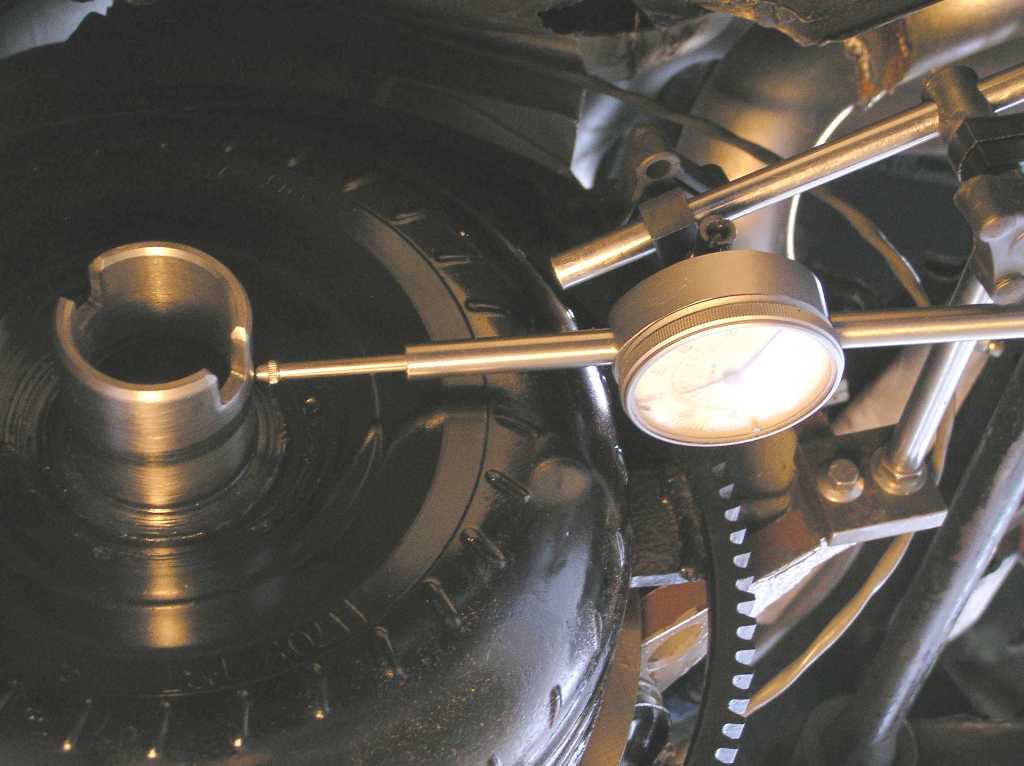

This is 2nd new bushing And it's worn again. Trans leaking from front pump. New ATI 8" treemaster hooked to 416 ci with 620 hp and 550 fpt. Motor line bored and built 2yrs ago. Same tranny housing with block on new build. Only diff was old Lupo 9.5 " converter. Just switched to ATI, 7 passes, leak! Pressure tested converter. Ok! Tranny rebuilt this past winter. Put back together and bushing worn again and leaking. Are there manuals to show how to align housing with crank or any other suggestions. Thanks. Ps want to get to track!!! BSD in Pa

with mr.p, i made my own dowel pins using a 1/2 bolt shank. mine are sticking through the trans case about 1/16". also use the trans case u are indicating to the crank.

with mr.p, i made my own dowel pins using a 1/2 bolt shank. mine are sticking through the trans case about 1/16". also use the trans case u are indicating to the crank.