that would be a really interesting topic !

when that becomes a reality, i'm sure there will be a super version of 3D printing, as well as ways to make whatever parts the computers needed for that flight would require.

the material needed for such repair parts, which i'm sure would include some exotic materials not yet thought of yet, would require some thought as to the variety and amount to carry as well.

as the machining industry is constantly evolving with new, more powerful machines able to do amazing things with a single setup, weight is drastically increasing as a byproduct.

old manually operated machines that are very precise are very heavy as well, because the weight is used to keep the machine extremely ridged, which absorbs vibrations and any shock loads that may be imparted during the process, thus allowing repeated, precisely made items to be produced.

although spacecraft are not lightweight vehicles, component weight is still a huge concern.

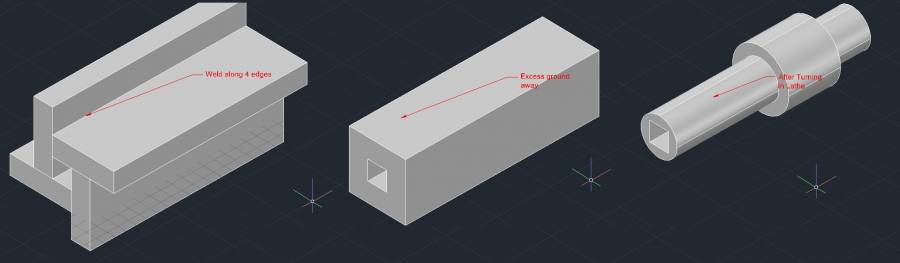

as an old [not much hair left on the top of my head] machinist with lots of experience with the CNC machines of my time, it is pretty neat what a person can do with just a basic drill press, small lathe, a bridgeport mill, and a few measuring tools.