Posted By: IMGTX

Wood working guys, Table Saw Questions. - 08/09/22 10:07 PM

I had to buy a table saw for a kitchen remodel project.

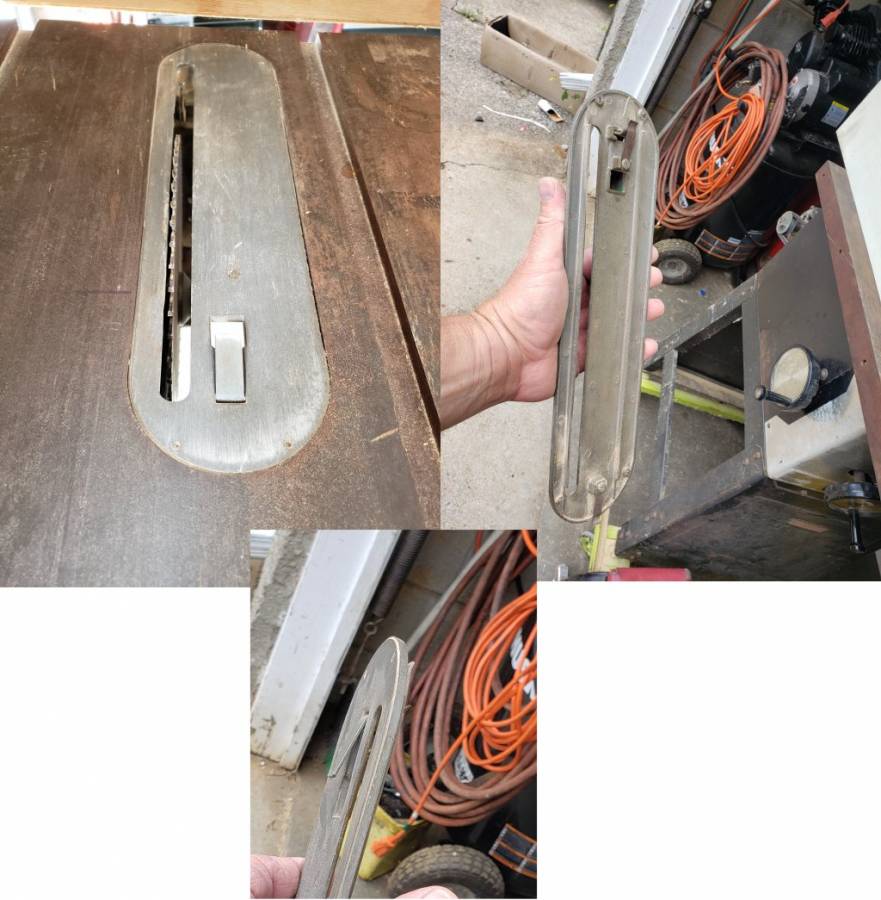

There is a tab in the "guide plate"? that helps hold the plate to the table top.

It sticks up and when cutting it often lifts the wood, especially thin sheets. Is this normal or can I bend it down?

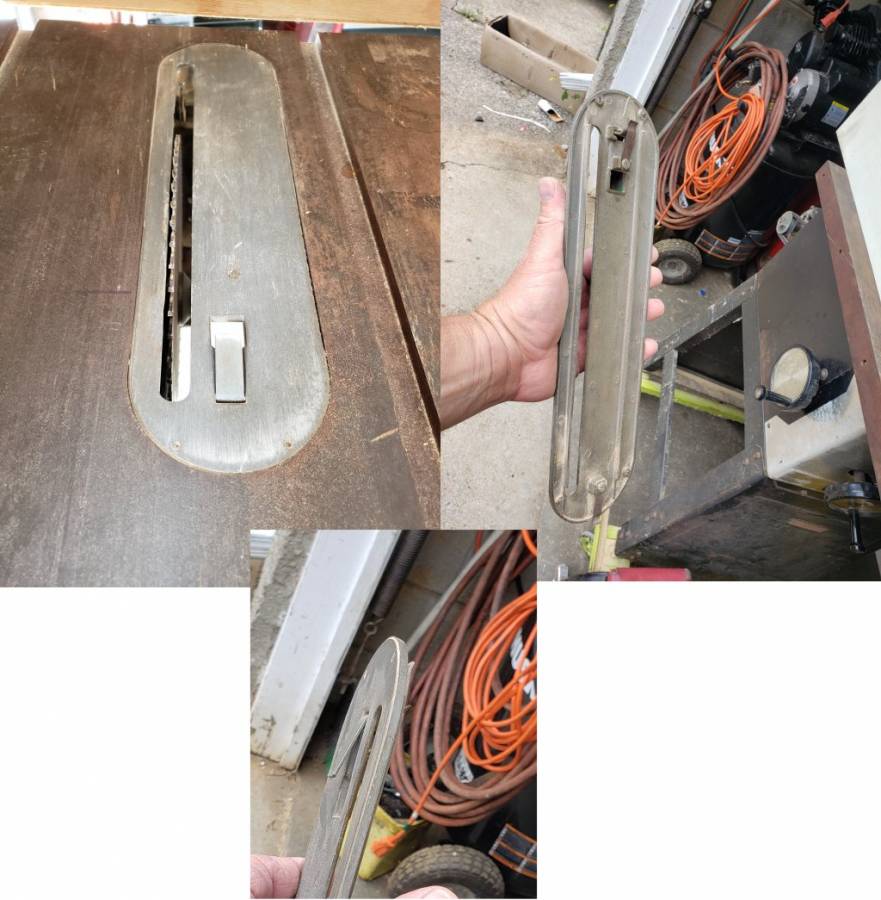

Also what is the bracket with the vertical hole in it on the back of the assembly? Is it for a guard that I do not have?

Thanks

There is a tab in the "guide plate"? that helps hold the plate to the table top.

It sticks up and when cutting it often lifts the wood, especially thin sheets. Is this normal or can I bend it down?

Also what is the bracket with the vertical hole in it on the back of the assembly? Is it for a guard that I do not have?

Thanks