Moparts

Welder Purchase Advice

Posted By: QuickDodge

Welder Purchase Advice - 11/29/21 03:22 AM

I need some advice on purchasing a welder. I have some experience in ornamental iron work using electric arc welders. Unfortunately, no experience with a MIG or TIG welder.

In the near future, I would like to do some rust repair on my old truck and some other general repair work. I will typically be working with sheet metal up to 3/8 inch thick metal. Occasionally, there may be some projects with thicker metal, perhaps a 1/2 to 3/4 of an inch thick.

So, I have a few questions:

1. How important is the duty cycle of a MIG welder when welding sheet metal? I'm assuming that only short welds can be made on sheet metal anyway. (A long weld would cause the metal to warp.) If this is correct, would duty cycle be relatively unimportant when welding sheet metal?

2. How does the operating costs of a MIG welder compare with an arc welder?

My current thinking is to buy a lower priced brand name MIG welder and an arc welder. Not sure if this is the best plan though. Anyone have any advice?

I have a stick, Tig, and mig welder but I couldn’t run an aluminum spool gun on anything I owned so I just bought this on. I saved 100.00 joining the harbor freight club and another 10% getting their credit card. You can stick, mig, Tig, and run a spool gun with it.

https://www.harborfreight.com/unlim...ess-welder-with-120240v-input-64806.html

Posted By: Sunroofcuda

Re: Welder Purchase Advice - 11/29/21 06:00 AM

Hmmm - never heard of such a welder. Kinda cool. How does it work?

I have a Century MIG that I bought back in the early 90's. It uses shielding gas & has infinite wire speed & heat dials. The wire speed is VERY sensitive (which is good), vs cheaper welder click-click settings. Wire speed is CRITICAL for good non-spatter welds. There are a few great-looking MIGS out there for under $1,000. Look at Hobart & Miller brands.

Posted By: A12

Re: Welder Purchase Advice - 11/29/21 06:39 AM

There are a few videos here at the

EASTWOOD SITE CLICK HERE that may be of some help? I picked up a mig welder from them a few years ago and very happy with what I've been able to do not only for restoration but quick repairs like on the JD mower deck wheel support after hitting a hidden rock and welding a nut on a stripped and seized bolt etc.,

MIG welders

https://www.eastwood.com/welders/mig-welders.htmlTIG welders

https://www.eastwood.com/welders/tig-welders.htmlVIDEO LINK MIG welding basics:

https://www.eastwood.com/video-page-mig-welding-basicsVIDEO LING TIG welding basics:

https://www.eastwood.com/video-page-tig-welding-basicsMike

Posted By: A12

Re: Welder Purchase Advice - 11/29/21 08:22 AM

I'm lucky to have an Eastwood store only a 30 minute drive away and they have some very helpful and knowledgeable people that work there along with all of the AUTO/TRUCK restoration videos and products they specialize in it's a no brainer for me to buy somethings from them as they support the hobby. Then add in the image at the bottom of the page with the welding (and other) videos and it kind of seals the deal for me

(if I'm not mistaken that's not a Chevelle or a Nova is it

)

Mike

Posted By: Bad340fish

Re: Welder Purchase Advice - 11/29/21 10:46 AM

I can weld OK but I don't do it a ton. I mainly got a welder so I can have my friends that are good at welding weld things at my house lol. That being said I have become decent at it.

I have a Hobart 135 Mig. It is 110V but for a 110V machine it works very well, it has done some jobs beyond what is was rated for and done well. A friend was just asking me about it yesterday and I realized I have had it 12-14 years now. The biggest thing with a 110V machine is no extension cord and if you do have to have one it better be a good one or you can tell right away.

Posted By: Stanton

Re: Welder Purchase Advice - 11/29/21 01:46 PM

If all you're doing is sheet metal, the Eastwood welders are a good bang for the buck. I have a Miller 252 which is a very nice 220v welder and will weld just about anything BUT I do a lot of thicker welding and didn't want to have to switch wire, rollers and liner every time I do sheet metal. I bought an Eastwood 135 110v machine and it works beautifully. I use a mixed gas and .023 wire and follow the suggested settings on the welder.

In this day and age, unless you're building bridges or fixing tractors in the middle of a corn field, I don't know why you'd want an arc welder. If you want to do thicker metals, buy a bigger mig. These days a quality 220v mig will have the capability to weld everything from tin foil to 1/2" with a change of wire rollers and whip liner. Those accessories are fairly inexpensive.

Posted By: DAYCLONA

Re: Welder Purchase Advice - 11/29/21 02:19 PM

I always say "welders are like garages, never big enough nor equipped fully", do yourself a favor invest in a quality machine, 220V, spool gun, etc, etc....Miller or Hobart, .....I have both mfg's MiG machines (Miller 252 and a Hobart 185), zero issues, as well as an AC/DC Arc welder and Miller Syncrowave 250 TiG.....buy it once, buy it right, buying cheap and underrated you'll kick yourself in the [censored] down the road....

Posted By: 19swinger70

Re: Welder Purchase Advice - 11/29/21 02:58 PM

I have a Millermatic 251 I bought almost 20 years ago. Still going strong. Buy a good brand name, and get one with more capability than you currently need.

Posted By: TJP

Re: Welder Purchase Advice - 11/29/21 03:22 PM

Miller here, Lincoln and Hobart are good as well. My brother who is a retired union pipefitter always said pay once, or you can pay two, three or four times. He also said ask who is more likely going to be there should I you need parts in 5 10 or 20 years

Also, getting a machine to do 1/2" plate and sheetmetal is going to require a good 220V source.

Posted By: IMGTX

Re: Welder Purchase Advice - 11/29/21 06:10 PM

I am with Dayclona and 19Swinger70, buy for a bigger job than you will think you will do.

I bought a Century (rebranded by Sears to be Craftsman) for sheet metal because that is all I wanted to do at the time. It is OK for sheet metal but I now frequently hit it's duty cycle when doing stuff like exhaust or brackets.

My next one will be more than I need for now and name brand, American made.

I buy tools for a long term investment and have run into numerous problems with HB and other chain store brands not having parts available even a couple years (even months) down the road.

You may say I am being picky when I say American made but I have reasons.

I had to repair a refrigerant pump with a cracked valve. It was on a chinese assembly and was made in 3 pieces. Nobody made the replacement part because it was metric on one end, SAE on the other and the internal threads were British Whitworth. So I had to have a new part made. The money the company saved by buying a chinese device that didn't adhere to any manufacturing standards was more than lost when the pump had to be serviced, which was often.

It taught me not to skimp and by asian junk when I can avoid it.

Posted By: A12

Re: Welder Purchase Advice - 11/29/21 11:50 PM

120v or 240v?

Some have both capabilities but if you don't have a good 240v source at the moment your possibilities are narrowed.

Posted By: J_BODY

Re: Welder Purchase Advice - 11/30/21 01:05 AM

After missing a couple “deals” on Craigslist I ended up at a local welding shop and bought a Millermatic 211 as well as a tank of argon. Was way over my “budget” and skill level but it’s certainly come in handy. Various brackets on the racecar. Broken latch on one of our gates into the yard. …. and the biggest task so far was repairing my 28’ enclosed trailer after finding the spring mounts broken. That job required the 220 setting so I bought a 50ft cord and rigged up a power outlet off our main home panel. Saved my butt big time on that one!

Posted By: poorboy

Re: Welder Purchase Advice - 11/30/21 04:30 AM

I bought my Miller 252 30 years ago. Other then the whip, which has been changed 3 times, the machine is all original. I opened a one man welding shop about a year after I bought my Miller. It has been welding stuff together daily, Mon-Fri until I retired 32 years ago, Now it only gets used occasionally.

About 20 years ago I bought a Miller 210 because I needed a spool gun for welding aluminum, my 252 didn't have a spool gun attachment, and buying the 210 was about the same cost as having my 252 upgraded to accept the spool gun. When I retired, I sold the 210, and got all of my investment back + free use for 15 years.

Duty cycle isn't as important welding sheet metal as it is when you start welding 1/8" thick metal, but eventually exceeding the duty cycle with sheet metal will still kill the machine. My buddy bought one of those HF welders because he was only going to weld sheet metal. He had to replace that original HF welder after the 1st year. The next HF welder he bought was their top of the line 220v welder. Its about a year and a half old and is also starting to fail. Yes, he has exceeded the 60% duty cycle on it as well. At this point he has spent as much money as it would have cost him to buy a good Miller 220v with a 100% duty cycle.

Buy a good American built welder with a 100% duty cycle. Miller blue would be my choice. Gene

Posted By: PhillyRag

Re: Welder Purchase Advice - 11/30/21 05:19 AM

I bought am HTP mig some 20+ years back. At the time a package deal was lower then other more commonly discussed brands.

Then they were USA made with a good copper core x-former.

They weren't advertised to a broad market at that time, but don't know about today.

Machine never needed any repairs/work since.

They also sold other metal working tools/equipment.

Worth at least a look into.

Posted By: Stanton

Re: Welder Purchase Advice - 11/30/21 02:03 PM

How could you possibly exceed any duty cycle welding sheet metal ?!?!? It would really have to be a POS welder !

Posted By: 6PakBee

Re: Welder Purchase Advice - 11/30/21 02:31 PM

Only two comments, Miller and Auto-Set. I have one and it makes this hack look like I know what I'm doing.

Posted By: jcc

Re: Welder Purchase Advice - 11/30/21 06:04 PM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much, and forget anything flux core

I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Posted By: Jeremiah

Re: Welder Purchase Advice - 11/30/21 06:23 PM

A Miller 211 will run on 110 or 220 and can operate a spool gun. The only thing that will hold you back is duty cycle if you are welding 3/16" for a while. Anything bigger than that and you will be looking at a Miller 252 or will go 1/2" however it is 220V only and no Autoset feature which comes in handy. Essentially Autoset allows you to flip a switch and the dial indicating material thickness and proportionately follows the voltage/wire speed table. In my experience it is pretty darn close for most projects if the metal is clean, etc. As with everything the prep and skill of the operator will make or break the performance of the machine.

Posted By: 6PakBee

Re: Welder Purchase Advice - 11/30/21 06:37 PM

A Miller 211 will run on 110 or 220 and can operate a spool gun. The only thing that will hold you back is duty cycle if you are welding 3/16" for a while. Anything bigger than that and you will be looking at a Miller 252 or will go 1/2" however it is 220V only and no Autoset feature which comes in handy. Essentially Autoset allows you to flip a switch and the dial indicating material thickness and proportionately follows the voltage/wire speed table. In my experience it is pretty darn close for most projects if the metal is clean, etc. As with everything the prep and skill of the operator will make or break the performance of the machine.

I think, THINK, Autoset must be more than that. If I manually set the voltage and wire speed, with clean metal I get an acceptable weld. If I go to Autoset, I get a great weld. I have the feeling, FEELING, that Autoset is always varying something while you are welding, wire speed or voltage or both, to obtain the best weld possible.

Or I could be full of it.

Posted By: nutso suave

Re: Welder Purchase Advice - 11/30/21 06:40 PM

After missing a couple “deals” on Craigslist I ended up at a local welding shop and bought a Millermatic 211 as well as a tank of argon. Was way over my “budget” and skill level but it’s certainly come in handy. Various brackets on the racecar. Broken latch on one of our gates into the yard. …. and the biggest task so far was repairing my 28’ enclosed trailer after finding the spring mounts broken. That job required the 220 setting so I bought a 50ft cord and rigged up a power outlet off our main home panel. Saved my butt big time on that one!

I inherited the same welder and it is awesome. The next model up allows you to stick weld as well, which is nice. I agree with previous posters that buying more than you think you need is a good idea.

Posted By: justinp61

Re: Welder Purchase Advice - 11/30/21 07:15 PM

I have two Millers, a Millermatic 210 with a spool gun and a Syncrowave 250DX and both have been flawless. Welders are like air compressors IMO, buy once cry once.

Here are my other two welders, both Lincoln’s. Like I said my reason for buying the Titanium welder from harbor freight was so I could hook it up to an aluminum spool gun. My Lincoln was a pain in the butt to convert the liner on to run aluminum and aluminum being so soft didn’t run very good. I lucked out on my Tig welder as I bought it from a shop that builds trailers and they wanted to go bigger. When I took night classes for Tig welding I trained on the exact same machine

Posted By: Sniper

Re: Welder Purchase Advice - 11/30/21 08:33 PM

Some of the recommendations strike me as being told that you should buy out the contents of the Snap-on catalog if you are planning to put together a Power Wheels for Christmas.

If I weld, and I don't, I am the kind of welder that epitomizes the bigger the blob the better the job type. All these fancy machines would be a gigantic waste of money for me with my skill set. A cheapo HF one that would allow me to glob on more weld, or maybe actually learn to weld with, would be my starting point. This way if it turns out I an congenitally incapable learning to weld, or I actually learn to weld and decide to spend money of a welder my skills are worthy of, I won't have spent much on that cheapo one to begin with.

Posted By: jcc

Re: Welder Purchase Advice - 11/30/21 08:54 PM

Two counterpoints, before 2008?, any quality welder could be resold used for what it was purchased new for, and a better welder is easier to learn on and weld with than a cheap piece of junk, especially when operating near its limits. In 35 years I have upgraded 3 times with miller tig welders, and have never regretted upgrading.

Posted By: DrCharles

Re: Welder Purchase Advice - 11/30/21 10:44 PM

A cheapo HF one that would allow me to glob on more weld, or maybe actually learn to weld with, would be my starting point. This way if it turns out I an congenitally incapable learning to weld, or I actually learn to weld and decide to spend money of a welder my skills are worthy of, I won't have spent much on that cheapo one to begin with.

I used to think that way, and wondered why I couldn't learn to weld... then I bought a decent Hobart Handler 140 MIG and suddenly I could actually make steel stick to other steel

If you get a cheapo, it won't feed worth a crap, the duty cycle will be very limited, and your welds will always look like hemorrhoids.

Posted By: Sniper

Re: Welder Purchase Advice - 12/01/21 12:09 AM

Trust me, I have used good welders and it didn't turn my welds into anything good.

I have an old, got it used from a rental place in 1991, Lincoln stick welder. Nothing magical about it. Tried a good mig welder at work, did nothing magical either.

Now I can solder, I can silver solder, I can braze, but not weld.

Sometimes it’s like mechanics thinking Snap On tools make them a better mechanic. All it makes you is more broke. Lol

Posted By: poorboy

Re: Welder Purchase Advice - 12/01/21 12:51 AM

Trust me, I have used good welders and it didn't turn my welds into anything good.

I have an old, got it used from a rental place in 1991, Lincoln stick welder. Nothing magical about it. Tried a good mig welder at work, did nothing magical either.

Now I can solder, I can silver solder, I can braze, but not weld.

Mig and stick welding use a pretty similar process to stick two pieces of metal together. If you don't understand the process, a welder you will never be.

If you can braze good (good is the important word, does the braze hold together every time?) Have you tried to use steel filler rod using the same process you use to braze? If you can braze, you should be able to replace the brass rod with a steel rod and do the same thing. If you can steel weld, you probably would learn to use a tig much easier because both of those use a similar process.

If when your welding what you see is a big blob, you need a better helmet, clean lenses, or better eye glasses. You should be able to see both edges of the metal you are welding together and the weld puddle melting between the two pieces of metal. A blob just tells me you are melting the filler (solder or brazing rod) on top of the metal and not getting the metal hot enough for the filler to bite.

Posted By: Michael Ecks

Re: Welder Purchase Advice - 12/01/21 12:58 AM

I have the same HF Titanium 200 multi-process dual voltage welder. I took welding classes 20 years ago, and it only took 3 or 4 practice welds to get a decent looking weld trying to relearn how to do it. So far I have only used flux core for some small projects, but I went with the 200 to give myself some room to grow with it and try other processes. It seems to be capable of more than I will ever do with it. Keeping usage in mind (they aren't constant use professional models) I don't think I've seen a single bad review of any of their Titanium welder line.

Posted By: DrCharles

Re: Welder Purchase Advice - 12/01/21 01:05 AM

Sometimes it’s like mechanics thinking Snap On tools make them a better mechanic. All it makes you is more broke. Lol

The Cult of Snap-On is a whole different issue. Their tools are nice... but not THAT nice.

My Dayton Electric welder had problems with the feed that I never could completely get rid of with adjustments, feed wheels, lubrication, new gun liners, tips, etc. Without a steady wire feed there is no way to maintain a stable arc and bead. The guy who sold it to me also admitted he'd never learned to weld.

The Handler doesn't have that problem and it "just works". Not that expensive either. Your experience may be different

Posted By: 6PakBee

Re: Welder Purchase Advice - 12/01/21 01:10 AM

Sometimes it’s like mechanics thinking Snap On tools make them a better mechanic. All it makes you is more broke. Lol

I have to disagree a bit here. A talented person can do good work with crap tools. A hack (like me) needs all the help he can get.

Posted By: Sniper

Re: Welder Purchase Advice - 12/01/21 01:20 AM

Trust me, I have used good welders and it didn't turn my welds into anything good.

I have an old, got it used from a rental place in 1991, Lincoln stick welder. Nothing magical about it. Tried a good mig welder at work, did nothing magical either.

Now I can solder, I can silver solder, I can braze, but not weld.

Mig and stick welding use a pretty similar process to stick two pieces of metal together. If you don't understand the process, a welder you will never be.

If you can braze good (good is the important word, does the braze hold together every time?) Have you tried to use steel filler rod using the same process you use to braze? If you can braze, you should be able to replace the brass rod with a steel rod and do the same thing. If you can steel weld, you probably would learn to use a tig much easier because both of those use a similar process.

If when your welding what you see is a big blob, you need a better helmet, clean lenses, or better eye glasses. You should be able to see both edges of the metal you are welding together and the weld puddle melting between the two pieces of metal. A blob just tells me you are melting the filler (solder or brazing rod) on top of the metal and not getting the metal hot enough for the filler to bite.

Brazing is more similar to soldering, insomuch as that the filler material melts at a lower temp than the two pieces you are sticking together. When I try using a steel rod instead, I have, I end up with melted blobs of rod and material. I don't have a problem brazing, it flows nicely and doesn't blob up on me, unlike when I weld. Of course I was taught how to solder and those skills transfer to brazing, I was never taught to weld and my soldering/brazing skills don't seem to transfer.

I loved it in the mill when they said we had to learn how to weld and get certified on one inch plate on both mig and stick. The teachers laughed when instead of grabbing one inch of rods my buddy’s and I each grabbed a whole box of rods. We had a blast.

Posted By: PhillyRag

Re: Welder Purchase Advice - 12/01/21 02:12 AM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much,

and forget anything flux core I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Has it's uses outdoors where maintaining shielding gas could be an issue.

Posted By: justinp61

Re: Welder Purchase Advice - 12/01/21 02:59 AM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much,

and forget anything flux core I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Has it's uses outdoors where maintaining shielding gas could be an issue.

Yes flux core has many uses. Some even use flux core with gas, if makes for good penetration and nice looking beads. I have used flux core in my spool gun outside on dirty/rusty steel.

Posted By: Stanton

Re: Welder Purchase Advice - 12/01/21 03:47 AM

I am the kind of welder that epitomizes the bigger the blob the better the job type. All these fancy machines would be a gigantic waste of money for me with my skill set. A cheapo HF one that would allow me to glob on more weld, or maybe actually learn to weld with, would be my starting point.

Total mistake

First of all, "the bigger the blob ... the WEAKER the job" is more like it. In welding, more is only better if each pass is done properly. You need penetration INTO the base metal - anything above the base metal is of little use.

Second, a cheapo welder will have you chasing your tail. A good welder will give you accurate setting recommendations, taking the guesswork out of that. Thus, you can focus on your technique without debating if the settings are at fault.

And there are also some VERY IMPORTANT things to keep in mind to create good welds. In no particular order

Good eyesight within about 18" of what you're welding.

A good mask that fits under your helmet - you won't believe the amount of sh!t welding generates

A mixed gas for mig - straight CO2 is fine but generates a lot of spatter. With a mixed gas (CO2/Argon) you will achieve very clean welds once you develop your technique.

Clean wire - if you don't weld for extended periods, take your wire out of the welder and store it in a baggie. The amount of rust needed to degrade a weld is almost invisible on the wire. Also, the rust will clog the feed rollers as well as the whip liner and degrade the electrical contact.

Weld clean metal - rust, paint and mill scale will contaminate a weld.

Get comfortable before doing your weld. If running a bead, go through the motion first to ensure you'll be comfortable through the entire length.

Use two hands - one operating the gun, the other providing support. One-handed welding takes a LOT of practice - don't waste your time trying one-handed welding until you master welding with two hands.

Posted By: 330Scott

Re: Welder Purchase Advice - 12/01/21 05:08 AM

Excellent suggestions, Stanton. You've spent time with your hood down.

If I may offer another suggestion: Try to not to position yourself, and especially your hands, over what you just welded. You don't want the distraction and discomfort of the heat from your previous welds and the hot metal. I always try to start my welds with those welds that are the furthest away and work toward myself. Did what I said make sense in a sort of convoluted way?

Spend the money for a good hood. I own a 3M Speedglas 9100 which is a pretty expensive hood, but I only have one set of eyes. I used a 3M PAPR unit when I welded at Deere and it was the cat's pajamas.

Wish it would have followed me out the door when I retired from that place.

Posted By: TJP

Re: Welder Purchase Advice - 12/01/21 03:35 PM

The biggest issue I have always had is being able to actually see the tip of the wire / arc and the material being joined through the hood lens. I have a Jackson helmet which is a few years old but fully adjustable tint wise etc. It's almost as though the ambient light is coming through the backside of the hood affecting my ability to see the material. I can see the arc but not the material / puddle. I've tried adjusting lighter and darker on the lens and will say the lighter setting seems to help but I still have trouble seeing the material / puddle. I thought maybe oneof the more experienced welders might have a suggestion other than turning the lights out

Taping a bifocal lens to my helmet was a big help at my age. They are available at your local welding supply shops.

Posted By: 330Scott

Re: Welder Purchase Advice - 12/01/21 05:47 PM

The biggest issue I have always had is being able to actually see the tip of the wire / arc and the material being joined through the hood lens. I have a Jackson helmet which is a few years old but fully adjustable tint wise etc. It's almost as though the ambient light is coming through the backside of the hood affecting my ability to see the material. I can see the arc but not the material / puddle. I've tried adjusting lighter and darker on the lens and will say the lighter setting seems to help but I still have trouble seeing the material / puddle. I thought maybe oneof the more experienced welders might have a suggestion other than turning the lights out

Try a cheater lens like Little John suggested. I remember playing around with magnified hood lenses when I first started production welding, but eventually went with lined bifocal lenses in my prescription safety glasses. I did have the line raised a little bit so that it was easier on my neck. Maybe 1/4" or 3/8"? And I have seen guys who put their up-close correction not only on the bottom of their lenses, but also at the top. I liked the concept but never tried it.

Ambient lighting is a biggie, for sure. Some lighting there is little to no ability to control, but as you said, it may be coming in from the backside of your hood. And possibly from down around your chin area. Check to see if there are cloth extended coverage options specific to your hood or you might have to go with generic.

The biggest issue I have always had is being able to actually see the tip of the wire / arc and the material being joined through the hood lens. I have a Jackson helmet which is a few years old but fully adjustable tint wise etc. It's almost as though the ambient light is coming through the backside of the hood affecting my ability to see the material. I can see the arc but not the material / puddle. I've tried adjusting lighter and darker on the lens and will say the lighter setting seems to help but I still have trouble seeing the material / puddle. I thought maybe oneof the more experienced welders might have a suggestion other than turning the lights out

Try a cheater lens like Little John suggested. I remember playing around with magnified hood lenses when I first started production welding, but eventually went with lined bifocal lenses in my prescription safety glasses. I did have the line raised a little bit so that it was easier on my neck. Maybe 1/4" or 3/8"? And I have seen guys who put their up-close correction not only on the bottom of their lenses, but also at the top. I liked the concept but never tried it.

Ambient lighting is a biggie, for sure. Some lighting there is little to no ability to control, but as you said, it may be coming in from the backside of your hood. And possibly from down around your chin area. Check to see if there are cloth extended coverage options specific to your hood or you might have to go with generic.

I see on Facebook they are advertising bifocals on top for guys shooting pistols. Interesting but they are out of my price range.

Posted By: Stanton

Re: Welder Purchase Advice - 12/01/21 06:39 PM

I wear glasses but my prescription is such that I can't buy off the shelf reading glasses or a cheater lens. I weld enough that I bought a pair of prescribed glasses specifically for welding. Can't see sh!t more than six feet away but I see up close really well !!

I generally have my Lincoln helmet set at 9.5 - 10 and I weld mostly 3/16" material in a well lit shop. I have no trouble seeing the weld. Almost all my welding is done right to left with the torch close to vertical to the weld - this means I'm welding towards me, not away - so the weld puddle is always visible. However, once you develop your technique, speed, etc you will pretty much be able to produce welds blindfolded. Really, as long as you have the tip at the right height, the proper angle and your speed is correct and consistent, you only need to worry about where to start and stop - the weld will be fine.

But back to the lighting issue ..

So I sometimes have a problem with spatter flying over my helmet and into my hair and sometimes getting very close to my eyes. To solve this I took an welding jacket and just made a simple hood that I tape to the top of my helmet. So the besides keeping the spatter off my head it also block any light from above or behind.

Posted By: jcc

Re: Welder Purchase Advice - 12/01/21 09:40 PM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much,

and forget anything flux core I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Has it's uses outdoors where maintaining shielding gas could be an issue.

Yes flux core has many uses. Some even use flux core with gas, if makes for good penetration and nice looking beads. I have used flux core in my spool gun outside on dirty/rusty steel.

I

Who is welding here outside and windy and/or on rusty metal that wants a quality finished weld enough that they are here asking for advice?

You left out one other use of a flux core only machine, they are usually the cheapest machines.

Posted By: Mr T2U

Re: Welder Purchase Advice - 12/02/21 12:23 AM

It's almost as though the ambient light is coming through the backside of the hood affecting my ability to see the material. I can see the arc but not the material / puddle. I've tried adjusting lighter and darker on the lens and will say the lighter setting seems to help but I still have trouble seeing the material / puddle. I thought maybe oneof the more experienced welders might have a suggestion other than turning the lights out

i have this problem occasionally. i tape a shop rag to the top of the welding helmet and let it hang down to the middle of my head. this removes any light from behind hitting the view window.

to help see the weld puddle get your head on a right angle to the weld torch and actual weld area. then pull the weld torch towards you. this will help you see the puddle and the weld joint you are welding. it also gives you a good view of the amount of stick out you have when welding. more, to much, stick out = less penetration and power into the weld making poor welds.

i also like to steady the weld torch with my free hand when welding. this will help from wandering off the weld joint and maintain proper stick out when welding.

i remember my welding class when i went to votech college for autobody classes. the teacher took 2 pieces of thick steel at right angles to each other. he set the welder to get minimal penetration. them we had to lay a 2" bead on the joint. the teacher put the 2 pieces in a vice and snapped the 2 pieces apart by hitting with a hammer on the opposite side of the weld. because there was low power you only got a little penetration.if there was penetration it would remove a nugget of steel from the bottom plate. you can also see the amount of weld penetration on the other piece when you look at the weld nugget. if you were off the joint slightly you wouldn't get any penetration on both pieces of metal and it would be easily seen if you looked at the snapped joint. you couldn't weave between the 2 metal pieces it had to be a single bead straight weld.

to pass the class you had to have 1 3/4" of perfect penetration of the 2" weld. it took me a while to accomplish this task.

this is a good exercise to improve your welding skills and help you see the weld puddle when welding.

Posted By: poorboy

Re: Welder Purchase Advice - 12/02/21 12:38 AM

I solved the problem of seeing the weld puddle by using a drop light in front of the helmet, pointing at the weld area. With the auto darkening lens set @ 10, and with a "tru-color" helmet, I can clearly see the weld area. My current helmet is a $129 Hobart true color auto darkening helmet (often on sale for $99), it is about 2 years old now, and has replaceable round batteries. Adding that light above the work area sure helped as well (been doing that for 10 years or more). I'm 65 and have been welding full time for over 30 years.

One more thing I've noticed, my prescription glasses have the sun darkening lenses, sometimes they will darken if I'm doing a lot of welding in a short time. I've noticed sometimes they are about 2 shades darker when I lift the helmet. Gene

Posted By: Mr T2U

Re: Welder Purchase Advice - 12/02/21 12:42 AM

if you want use a proper light use one of these. they work great.

https://www.amazon.com/Steck-23240-Mig-light/dp/B002YKIM6S

I like that and think it would really come in handy under the race car. Should be here Saturday. Thanks.

Posted By: Mr T2U

Re: Welder Purchase Advice - 12/02/21 01:03 AM

your welcome.

for clarification i have never used one. i have heard from several people i have talked to at body shop training classes they work pretty good.

your welcome.

for clarification i have never used one. i have heard from several people i have talked to at body shop training classes they work pretty good.

I’ll find out soon.

Posted By: TJP

Re: Welder Purchase Advice - 12/02/21 02:03 AM

Posted By: PhillyRag

Re: Welder Purchase Advice - 12/02/21 03:43 AM

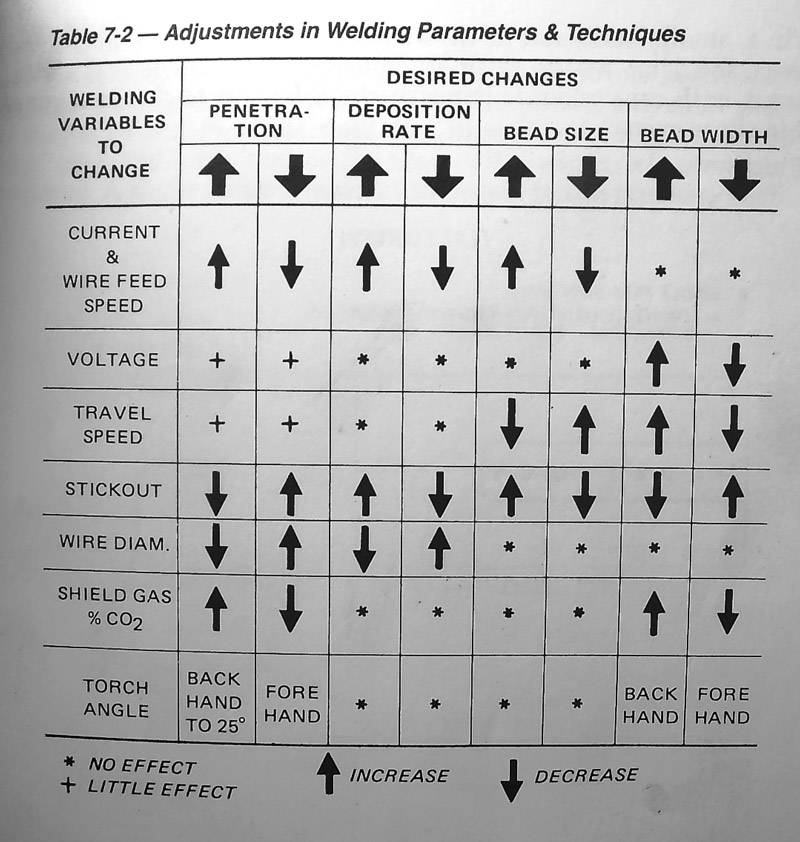

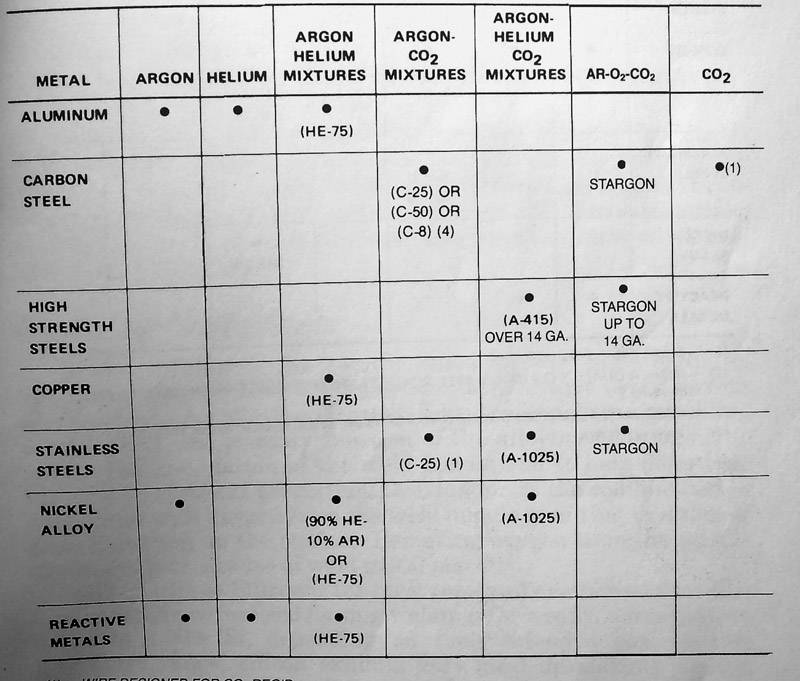

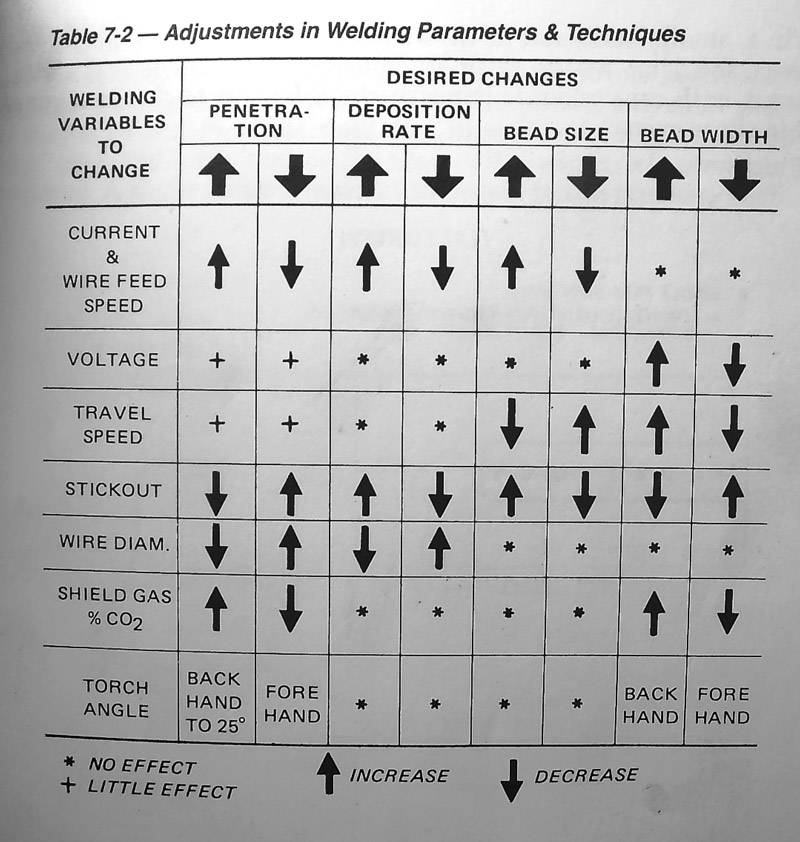

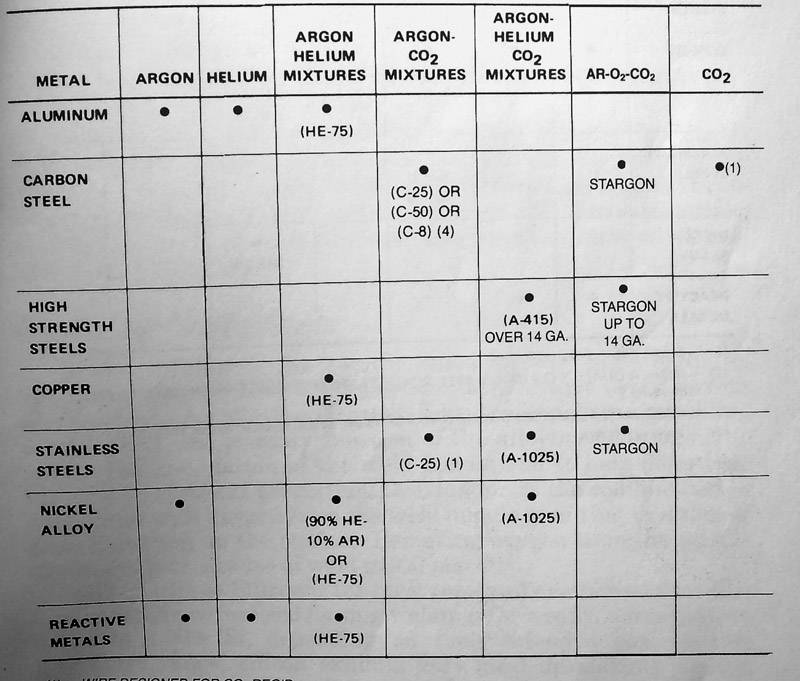

Two handy charts from a Linde manual that I've kept taped to welder.

Posted By: PhillyRag

Re: Welder Purchase Advice - 12/02/21 03:48 AM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much,

and forget anything flux core I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Has it's uses outdoors where maintaining shielding gas could be an issue.

Yes flux core has many uses. Some even use flux core with gas, if makes for good penetration and nice looking beads. I have used flux core in my spool gun outside on dirty/rusty steel.

I

Who is welding here outside and windy and/or on rusty metal that wants a quality finished weld enough that they are here asking for advice?

You left out one other use of a flux core only machine, they are usually the cheapest machines.

Just saying that flux-cored has a purpose.'

A MIG is basically a flux-core machine with gas components added.

Posted By: 340SIX

Re: Welder Purchase Advice - 12/02/21 05:43 AM

I had at the time the best 110 Lincoln mig they sold I used it a few times on sheet metal and I do ok. My friend says I am better than I think but tgats not saying much.

A storm hit and wiped my friends large body shop out. He moved to a small 2 garage door tgst held 6 cars and a large enough outside yard. Lost every thing large Lincoln 220 on a nice cart everything gone.

He calls me and says can I borrow the small 110 mig to do some sheet metal and weld up gates to secure the yard.

He needed to get a few jobs under his belt to get back on his feet

I told him keep it he needed it more than me.

That was 8-10 years ago and the Lincoln is still going but looks like hell after body shop has dirty use.

He did have to change the gun as the trigger wore out.

He welds basic sheet metal to the deck on his mower to cut the grass there.

He proberly needs a bigger one but says he will get one when that one dies.

Posted By: TJP

Re: Welder Purchase Advice - 12/02/21 03:32 PM

Two handy charts from a Linde manual that I've kept taped to welder.

Handy charts

Posted By: justinp61

Re: Welder Purchase Advice - 12/02/21 05:33 PM

IMO, buy the most powerful machine you can afford, I can't see as a hobbyist that duty cycle matters much,

and forget anything flux core I have a hobart 140amp 120V mig (for 20+ years, and exceed the duty cycle all the time)

With the cars, I find myself using the Hobart the most often.

Has it's uses outdoors where maintaining shielding gas could be an issue.

Yes flux core has many uses. Some even use flux core with gas, if makes for good penetration and nice looking beads. I have used flux core in my spool gun outside on dirty/rusty steel.

I

Who is welding here outside and windy and/or on rusty metal that wants a quality finished weld enough that they are here asking for advice?

You left out one other use of a flux core only machine, they are usually the cheapest machines.

Yes, flux core has its place. Sometime you have to weld outside, not everything can be brought in to the bench.

Must have never worked in a steel mill. 90% of our welding was stick welding. 6010 and 7018.

Posted By: justinp61

Re: Welder Purchase Advice - 12/03/21 02:16 PM

Must have never worked in a steel mill. 90% of our welding was stick welding. 6010 and 7018.

No I've never worked in a steel mill, but yes I've burned a bunch of 6010 and 7018's. The OP asked about welding sheet metal, not many people stick weld body panels.

Posted By: moparx

Re: Welder Purchase Advice - 12/03/21 04:58 PM

i have an old 1972 AirCo "Dipstick" [name fits me perfectly.

] mig, tig, stick welder i bought back in 1996. it's 200 amps on tig and stick, and something above 160 on mig. [the adjustment crank goes about 1/2" above the 160 amp mark]

it has either .030 or .035 wire in it all the time, and the only service i have done is replace the liner twice, and the usual tips and gun barrels.

that thing is HUGE, and is on wheels. it has a lifting ring on the top, and it took my engine crane to unload it.

i have a new tig torch setup still in the box i have been going to try for years now, but i never get around to it.

for exhaust work or body panels, i have a century 110v that has .023 wire in it.

for big stuff, i have a 1970 lincoln "tombstone" i bought new. there has been many 6010, 6011, 7018, jet rod, and others burnt through that thing over the years, and i'm glad i kept it all this time. i have had to do nothing to it service wise.

my one peeve is guys throwing an arc on the ground clamp before they start. why do guys do that ?

that sure dicks up the clamp !

if i need to do a test, i have lots of scrap to use for that. boneheads !

for a lid, i started out with an HTP Stryker. that thing worked great for many years, but as my old eyeballs got some mileage on them, i bought a lid [i can't remember the name or model] that had a JUMBO viewing screen. that is larger than the common BIG screen. it also has a knob on the outside left side that can fine tune the lens color number.

if i need extra light to see the weld joint when using the mig, i tape on one of those small, round Hobo Fright "freeby" flashlights to the mig torch.

Posted By: Uberpube

Re: Welder Purchase Advice - 12/05/21 03:44 AM

I always say "welders are like garages, never big enough nor equipped fully", do yourself a favor invest in a quality machine, 220V, spool gun, etc, etc....Miller or Hobart, .....I have both mfg's MiG machines (Miller 252 and a Hobart 185), zero issues, as well as an AC/DC Arc welder and Miller Syncrowave 250 TiG.....buy it once, buy it right, buying cheap and underrated you'll kick yourself in the [censored] down the road....

I have a Miller 350p. Sometimes I hate it and wish I still had my Hobart 140 handler.

Posted By: TJP

Re: Welder Purchase Advice - 12/05/21 03:29 PM

A lot of good helpful ideas, thanks again