Posted By: kentj340

Electrolytic Rust and Paint Removal - 09/23/16 06:08 AM

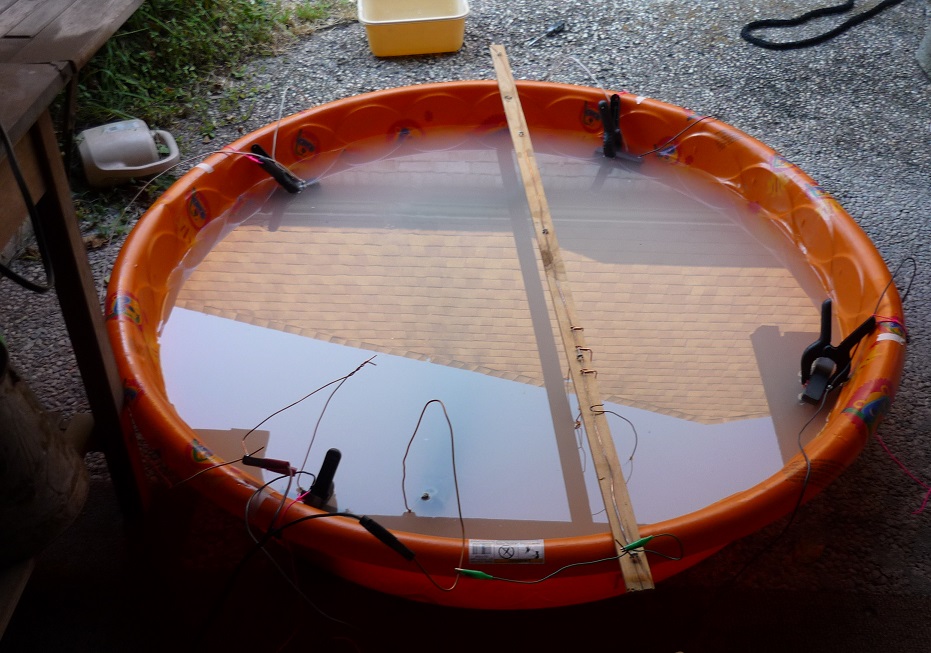

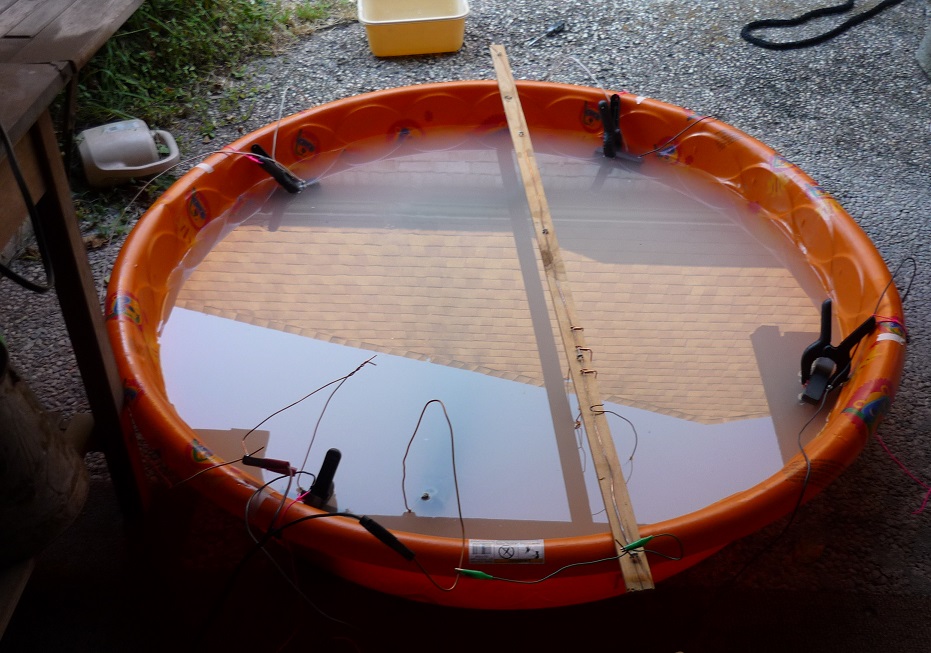

Top photo shows a milky solution of washing soda in water with a submerged tail pipe. I'm using a battery charger on low setting with 4 sacrificial graphite blocks. The tail pipe is bare steel - this process will remove the coating from any galvanized, aluminized, or painted parts and can harm non-iron/steel metal such as brass, babbitt, solder, etc.

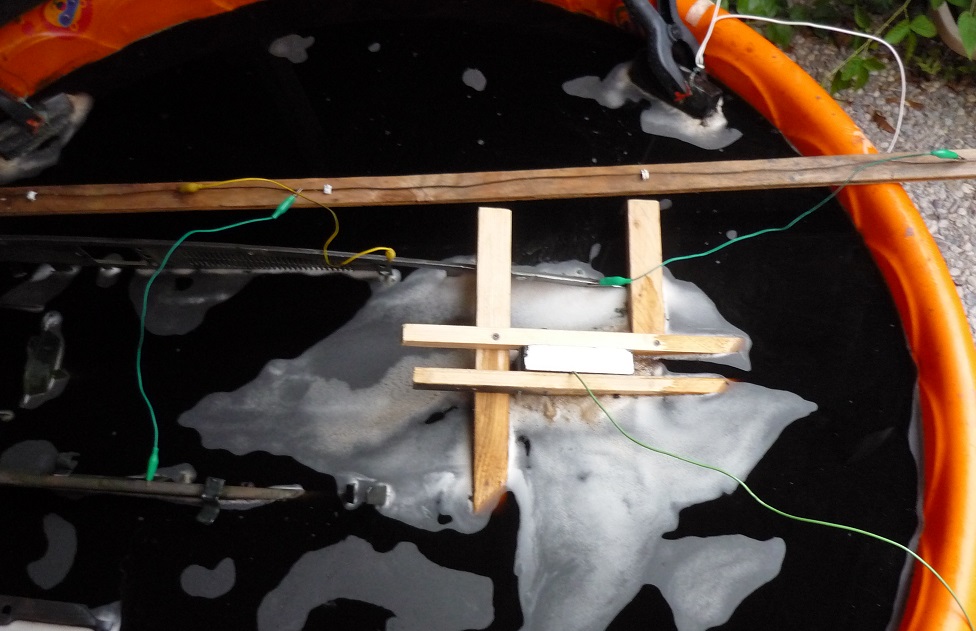

The solution turned black from the graphite. This is the other tailpipe with more bends that wouldn't fit in the pool except by double dipping. I used the tail pipes just to test the process and get it started.

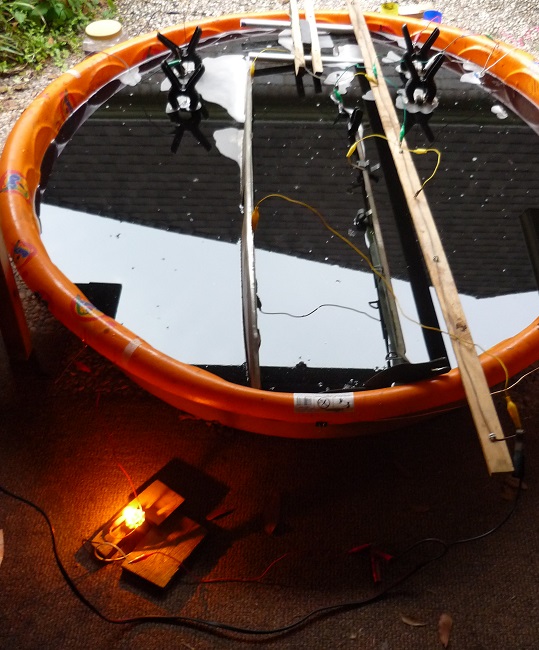

Bottom photo is a K-frame, also double dipped. I'm very pleased with how the tail pipes and the K-frame turned out after electrolysis.

The solution turned black from the graphite. This is the other tailpipe with more bends that wouldn't fit in the pool except by double dipping. I used the tail pipes just to test the process and get it started.

Bottom photo is a K-frame, also double dipped. I'm very pleased with how the tail pipes and the K-frame turned out after electrolysis.