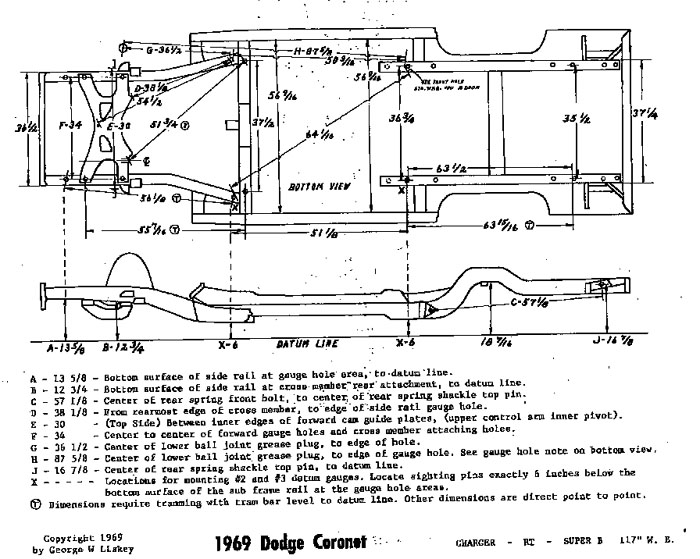

Looks like most of the info is right there, plus a straight unibody.

Build the base to size, then slap it under a straight unibody and fab up to the frame rails, spring and K member points and maybe even the door hinge points.

You could probably make the frame supports on a complete car except the areas above the rear springs, but could still take measurements.

If the drain holes are standard (they should be, they are used in the alignment drawings), you can put tapered pins on the tops so they self-align.

Firuge out what hard points are important and build removable arms to define them.

The alignment specs for the unibody should be available from a good collision shop.

Here's another

http://www.moparmusclemagazine.com/proje...g/photo_10.html