Moparts

Small Block Rocker Arm Oiling

Posted By: MisterBee

Small Block Rocker Arm Oiling - 02/28/11 09:37 AM

Hi All,

I have a query on my mate's 360 I hope you can answer.

Specs;

Stock stroke,

Approx 12:1,

.650 lift cam, duration is 270 @ 50.

W2 Heads

The issue is that the rocker arm for the #3 intake is dry (i.e. no oil) all others seem to be well lubricated. In particular the area where the pushrod and adjusting nut come together.

All rocker arms are adjusted pretty much the same however this arm has a bit more thread showing than the others. They are either crane or mopar aluminium anodized rockers(cant remember right now).

He's just had it apart and checked alignment of oil holes etc, no blockages etc, but still that particular arm has no oil.

He's using Penrite HPR 30 oil and has about 70 psi hot at idle (~1100rpm).

There is a restrictor tube in the rhs lifter gallery.

Any ideas/suggestions???

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 02/28/11 01:57 PM

Aye mate. Check if that rocker arm has any squirt holes that might be blocked/not drilled/angled properly. Check shaft/rocker clearance. might open up the small oiling hole on the shaft at that rocker arm, might take off the valve cover w it idling & see what you observe, it'd b messy but something might b apparent. Holler what it turns out being

Posted By: 5spdcuda

Re: Small Block Rocker Arm Oiling - 02/28/11 04:57 PM

The left [ drivers ] side on pre-magnum small blocks oils the rockers from the # 2 rocker shaft support. Consequently the # 1 & 3 intake rockers are first in line to get oiled. If all the other rockers on that side are getting oil it almost has to be some sort of blockage either in the oil hole in the shaft for the # 3 intake or in the rocker arm itself. The fact that there are more threads showing on that rocker may indicate some other problem. Usually all the adjusters will show similar thread exposure. A different style rocker or a short pushrod could cause this. Or possibly a cam lobe / lifter going away. Hope that's not it. Good luck.

Posted By: Supercuda

Re: Small Block Rocker Arm Oiling - 03/01/11 12:10 AM

Might consider banana grooves if it turns out to not be a blockage.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/01/11 10:25 AM

He has a set of banana grooves so that's probably worth a try.

Definately not blocked, shaft or rocker itself.

The thread difference is very minor between this rocker and the others.

Does anyone have a comment about the oil? - from their website "Penrite HPR 30 is a premium mineral SAE 20W-60 non-friction modified petrol engine oil". He's concerned about excessive oil pressure. and has read somewhere that Mopar small blocks should only run about 40psi at idle. I can understand that for a stock (ish) engine but this one idles quite fast and I would have though 70 psi is up there but still ok.

I'll pop over there at some stage and try and get some photo's

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/01/11 11:51 AM

Update...just been over to my mate's house and a couple of other bits of information.

1 - Banana Grooved shafts are already fitted.

2 - The shafts are off a std set of heads and the hold down bolt holes have been "ovalled out" on a mill to fit the offset of the W2 rocker stands.

3 - The oil on most rockers "dribbles" out as opposed to "squirting". I'm not sure what the normal flow out of these would be but I would think that there should be some velocity so the oil reaches the ball and cup.

4 - Rocker gear is the blue anodised Mopar gear. Interestingly, even though it was purchased as a set, there is a distinct colour difference between the intake and exhaust rockers. Not sure whether this is normal or not, but cant see it being a huge problem.

I took a couple of photo's on my phone but dont have the cable to download at the moment. will do tomorrow (AU time).

Thanks for your comments so far!

Posted By: The_Mean_Machine

Re: Small Block Rocker Arm Oiling - 03/01/11 02:59 PM

70psi oil pressure @ idle seems way high to me.

Are the rock shafts mounted in the correct orientation (oil holes down towards the rocker stands)?

Are the hold downs covering the 'ovaled' holes? If not, you may loose all the oil pressure before it gets to the rocker and rocker tip...

Posted By: Supercuda

Re: Small Block Rocker Arm Oiling - 03/02/11 12:53 AM

70 PSI is way too high, the pressure relief valve in the oil pump will open, or should, well before that. 20w60 is pretty thick, too thick for most cases, imo.

The factory minimum for warm idle oil pressure is something like 12 psi. Idle oiling requirements are fairly low, that might be why you aren't seeing oil at that rocker.

That all said, I think maybe your problem is the wrong shafts. I cannot remember if the W2 rockers have the oiling holes relocated for the offset that W2 rockers have. I suspect that is your problem.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/02/11 11:41 AM

Is the only difference between the W2 shafts and the stock version the location of the bolt hole or is there more to it than that?

On the oil pressure, another mate has a 408 w/- approx 540hp which runs about the same pressure at idle, but when hot goes down to ~40 psi. That one is still running in though, and still has the running in oil in it (ULX-110).

Took some photos last night but they didn't turn out very well.

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 03/02/11 09:15 PM

Quote:

He's just had it apart and checked alignment of oil holes etc, no blockages etc, but still that particular arm has no oil.

from the beginning you'd (1) want to align the cam bearing & w the rocker shaft assy off (cover #2 pedestal w a no lint rag & preoil it w the drill to see if you have psi then (2) button it up & run it w that valve cover off & see if your getting enough flow from the timed passages in use & you said the rest are good ex for #3. So if the shaft is being fed plenty w the ovalled out shaft hole at the 2nd from the front feed pedestal (for driver side bank) & the mini oiling holes ended up being aligned good w this mod then the only other thing I can think of is some debris from the drilling didn't get cleared out but I'm suspicious of that & yes I think your pics will tell the story & we're missing something right in front of us.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 04:40 AM

OK just went around there again this morning.

The rocker gear has been removed now and there is a quite big difference in the oiling arrangements between the W2's and the stock arrangement.

Fundamentally, on the std heads, at the top of the rocker stand is a recess around the bolt to provide oil to the shaft. This recess intersects with the oil gallery coming up through the head.

On the other hand the W2's have a VERY small (say 1-2mm) gap on the lower side of the stand (maybe 4mm wide - the bolt hole basically covers the passage for oil to the rocker shafts. Forgive my ignorance, but is this "normal" it appears to cause a massive restriction in the oil system.

I'll try and post some photo's shortly.

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 03/05/11 04:52 AM

from what you're seeing does it look like a smaller shank bolt at the bolt head or opening the shaft hole or?? will let it flow more

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 05:01 AM

The W2 hold down bolts are a larger diameter than the std type but the principle remains.

We have thought about turning down the W2 bolts on a lathe, but not sure if that will weaken them too much.

Just trying to work out how to add photo's...I know there's a thread around here somewhere about it....

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 05:09 AM

OK here we go... stock first.

Note the gap between the bolt and the head casting.

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 03/05/11 05:10 AM

click edit then put a checkmark in the lower of the (3) boxes & click "change this post" then click on "browse" & select the pic out of your file where they are stored & click on that pic & it's address/name will load into the vacant white rectangular address bar. Not sure what your dimentions are but opening the shaft bolt hole dia or a smaller bolt just as long as the psi is contained from leaking out plus not restricted to flow into the shaft or at least the restriction opened up enough to get the flow you need.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 05:17 AM

Working on a convoluted way of adding the photo's one down another to go!

Here's the W2 version quite obviously an issue getting oil to the rocker shafts with this arrangement.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 05:25 AM

Side view of the W2

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 05:29 AM

Ok, last one, back to stock now.

Note the thread for the rocker shaft bolt only starts about 1/4" down the bore.

On the W2, the threads go right up to the top of the stand

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 03/05/11 05:29 AM

I'm thinking if you drilled a hole down alongside the threads for the oil to get past the bolt threads but 1st not being familiar w W2's that is a pedestal just like LA's (it's shallow in the pic & hard to tell) & the only diff (as far as valvetrain is the offset rockers right? or are the stands offset also?). What I'm missing is what bolt do the stock w2's use that lets the oil flow past it? EDIT just saw your latest pics. I'd drill the notch in the W2's & unless I am missing something I think that'd b a simple fix. You'd lose a little bit of thread engagement but that wont hurt you. W care you could temporarily plug below your drilling to keep shavings out.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 06:09 AM

I think there's three options - all have issues as my mate is reluctant to take the head(s) off.

1 - Over size the top portion of the rocker pedestal thus creating an area around the bolt that oil can flow through (per std arrangement).

Issue - Need to somehow prevent getting filings everywhere, incl down the oil gallery.

2 - Machine the Bolt Down on a lathe in the area where the oil flows out of the pedestal.

Issue - Need to ensure bolt retains enough strength to effectively hold rocker shaft.

3 - file back the oil gallery so oil flows straight into the rocker shaft.

Issue - Unclear whether this will provide sufficient oil.

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 03/05/11 06:18 AM

I think you can get it WO taking the heads off. Plug the hole below where you are drilling/coat the bit w grease/duct tape etc to collect errant shavings & if you turn the bolt you can use a higher grade one. EDIT turn the drill slower to keep shavings from being flung out

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 03/05/11 11:02 PM

I dawned on me yesterday as to why these W2's have this problem. I reckon the rocker stands were delivered per the standard configuration and have been subsequently milled down flat for the W2 rocker stands (aluminium blocks). This would have effectively removed the area for oil to reach the stands in question.

Anyway, he has now oversized the hole around the base of the bolt and widened out the area where the oil gallery comes up through the head. Hopefully this will provide sufficient room for oil to pass through the head into the rocker shafts.

Will fire it up later today and report back. Still have to do the other side, assuming it has the same issue.

Posted By: CKessel

Re: Small Block Rocker Arm Oiling - 03/06/11 06:18 AM

Back in the early 80's when I did a W2 motor, I fried some arms and pushrods from lack of oiling. I had used the bushed arms from D/C and also the shafts plus the semi-finished pushrods. I did some checking and it turned out that even though the shafts were from D/C for the W2 application, not the regular heads, the oil holes were miss drilled 90*. The arms would have had to be straight up and down with the rocker tip pointing at the crank to get oil. By chance I had contact with one of the gents who designed the heads for Ma Mopar, Lee Muir at Chryslers west coast skunk works Shadow Racing, and he told me that Mopar made a bunch of these shafts with this screwup and did nothing to remedy it. I ended up replacing some arms, both shafts, some pushrods and ground in some light grooves into the shafts for oiling. With the heads assembled, stick a wire into the oil hole that squirts the valve, when the valve is closed, and see if the arm and shaft holes line up. If they don't, bingo! Just because D/C makes the stuff, it doesn't mean its going to work properly. Lee Muir developed these heads with the King, #43, and it was a MAJOR HONOR to meet this guy who did all this neat stuff way back in the Can-Am, Formula 5000 and REAL NASCAR days. This was the engine that was originally in Diego Teds, my old, Duster.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 10/12/14 07:49 AM

Hi All,

Sorry to exhume an old thread but my mate has come back to me with some issues.

Easy question I hope - does the hole in the shaft need to intersect with the hole in the rocker through some part of its travel to get a squirt of oil to the top of the pushrod, or is there (or should there be) sufficient pressure there to provide oil to that area. I suspect the answer is the holes need to align but I'd like some clarification.

Thanks

Shannon

Posted By: MoparforLife

Re: Small Block Rocker Arm Oiling - 10/12/14 10:49 AM

I did not go back through this string but if you make sure to have the notch in the rocker shaft end down and forward on the left (drivers side) and down to the rear on the right (passenger side) side of the engine all will be well. If you don't have oil to the top then you have a misaligned cam bearing or oil galley plug missing. Remember that the engine only oils to the top in certain positions of engine rotation and then to alternate heads. Both do not oil at once.

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 10/12/14 11:22 AM

Howdy, thanks for that.

Yep all of that seems to be correct and we definitely have oil in the shafts, but there's a couple of rockers that appear to be dry(er) than the others. However the notch is more of a grind mark than a notch (Mopar shafts).

In particular it appears that the offset (intake) rockers are more affected than the straight ones.

There's a long and painful back story to this regarding using econo rocker shafts and having to oval them out to fit race W2 arrangements etc. etc etc so my question really is as simple as;

Does the hole on the rocker arm, have to come into alignment with the hole in the shaft, for it to oil the pushrod?

Posted By: MoparforLife

Re: Small Block Rocker Arm Oiling - 10/12/14 03:48 PM

On mopar engines big or small block the stamped rockers are all offset one way or the other. Put the left hand rocker in left hand right in tight hand and work your way around the vehicle. I always start on the drivers (left) side. Left towards front on left side and to rear on pass side.

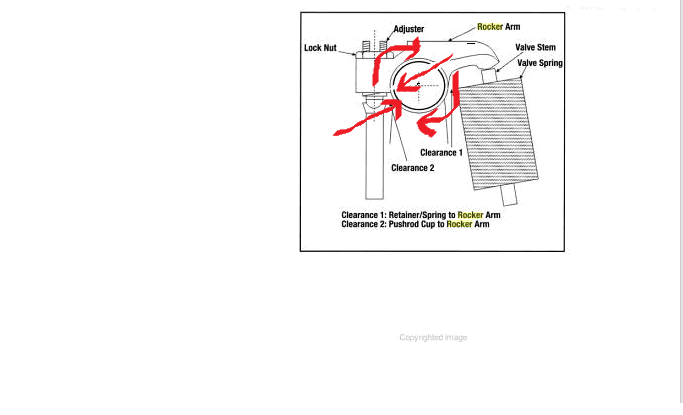

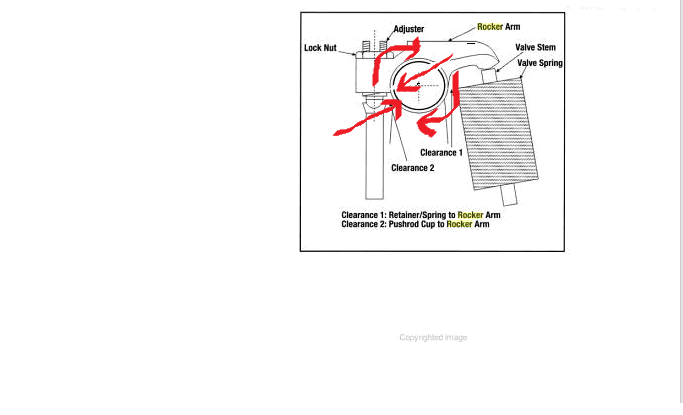

Pictured is small block:

Posted By: MisterBee

Re: Small Block Rocker Arm Oiling - 10/12/14 11:50 PM

Yep got all that, we're OK with that.

It just appears to us that a misalignment of the two holes in the rocker and the shaft isn't allowing the oil to escape to oil the top of the pushrod. There appears to be oil everywhere except at the top of the pushrod.

I've attached a picture to try and explain what im on about!

Shannon

Posted By: RapidRobert

Re: Small Block Rocker Arm Oiling - 10/13/14 12:15 AM

Oh OK I see what you are sayin. The hole(s) could very well have been drilled wrong. I would check another set of rockers to confirm & you may need to redrill em at the right clocking. On a side note iirc the DC manuals want the ball to be 9/32" below the rocker tip for the oil stream to be aimed correct and a straight line from the hole like a laser beam in a bullet hole goes right alongside/touching the surface of the rocker arm pad that contacts the valve stem and Hughes engines has an informative orange sheet on pushrod length/alignment etc. That's all I know. Post how it goes. EDIT The small holes in the bottom side of the shaft(s) you have them offset slightly (15 deg) toward the valve side correct? and the only other holes in the shaft are the (5) top/bottom large holes for the mounting bolts. post where the (2) holes in the rocker arm are (the (1) on one side for the pushrod cup and the (1) on the other side for the valve stem tip)

Posted By: MoparforLife

Re: Small Block Rocker Arm Oiling - 10/13/14 03:18 PM

Quote:

Oh OK I see what you are sayin. The hole(s) could very well have been drilled wrong. I would check another set of rockers to confirm & you may need to redrill em at the right clocking. On a side note iirc the DC manuals want the ball to be 9/32" below the rocker tip for the oil stream to be aimed correct and a straight line from the hole like a laser beam in a bullet hole goes right alongside/touching the surface of the rocker arm pad that contacts the valve stem and Hughes engines has an informative orange sheet on pushrod length/alignment etc. That's all I know. Post how it goes. EDIT The small holes in the bottom side of the shaft(s) you have them offset slightly (15 deg) toward the valve side correct? and the only other holes in the shaft are the (5) top/bottom large holes for the mounting bolts. post where the (2) holes in the rocker arm are (the (1) on one side for the pushrod cup and the (1) on the other side for the valve stem tip)

If you are not having a noise issue and there is oil there I probably wouldn't worry too much about it. On a normal Mopar engine there is an over abundance of oil to the top end any way.

If you are not having a noise issue and there is oil there I probably wouldn't worry too much about it. On a normal Mopar engine there is an over abundance of oil to the top end any way.

If you are not having a noise issue and there is oil there I probably wouldn't worry too much about it. On a normal Mopar engine there is an over abundance of oil to the top end any way.

If you are not having a noise issue and there is oil there I probably wouldn't worry too much about it. On a normal Mopar engine there is an over abundance of oil to the top end any way.