Posted By: David_Trimble

bolting on a engine dolly- what am I doing wrong? - 11/14/10 12:31 AM

Hi-

A few years ago I bought a dolly off a board member, and up until this weekend it had sat in my garage gathering dust. Now I'd ask the member I bought it from this question, but being so long ago I lost all his contact information- but I think it's probably a easy answer to a stupid question....

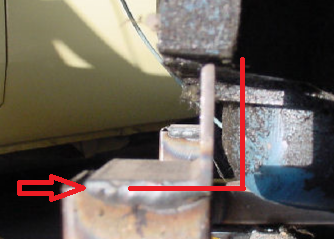

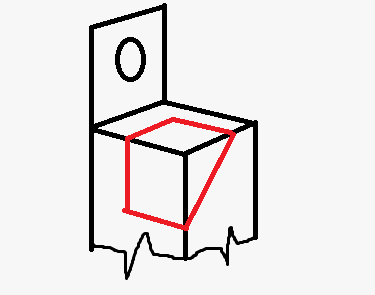

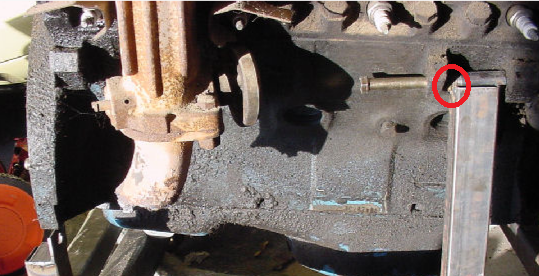

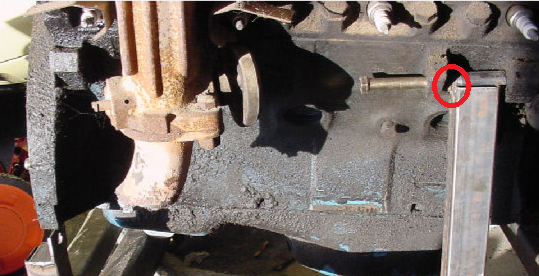

This weekend I got ahold of a engine hoist so I could lift the engine in question (a C-body 440) up so I could bolt the dolly on. While everything else looked good, I could not for the life of me get the rear brackets to line up with the back of the engine block. Now I'm assuming this bolts directly to the 'ears' on the engine block- or does it? I've included some pics to show the alignment.

Again- thanks for the input!

David

A few years ago I bought a dolly off a board member, and up until this weekend it had sat in my garage gathering dust. Now I'd ask the member I bought it from this question, but being so long ago I lost all his contact information- but I think it's probably a easy answer to a stupid question....

This weekend I got ahold of a engine hoist so I could lift the engine in question (a C-body 440) up so I could bolt the dolly on. While everything else looked good, I could not for the life of me get the rear brackets to line up with the back of the engine block. Now I'm assuming this bolts directly to the 'ears' on the engine block- or does it? I've included some pics to show the alignment.

Again- thanks for the input!

David

But I wasn't brave/stupid enuf to see if I could bend it back w/o snapping off that ear on the block. I understand that that mounting ear is not that difficult to break (especially the one on the starter side) so I didn't go too far trying that....

But I wasn't brave/stupid enuf to see if I could bend it back w/o snapping off that ear on the block. I understand that that mounting ear is not that difficult to break (especially the one on the starter side) so I didn't go too far trying that....