Posted By: '84 D150 Shorty

318crank and heads - 03/11/10 07:20 PM

couple of questions for you guys:

i have 318 out of an 86 diplomat that was hooked up to an automatic, but i am going to use my manual tranny. i have heard sometimes the crank isnt machined for the pilot bushing if it was an automatic. mine looks like it is machined for it, but how can i tell for sure? perhaps someone has pics of a machine versus non-machined crank?

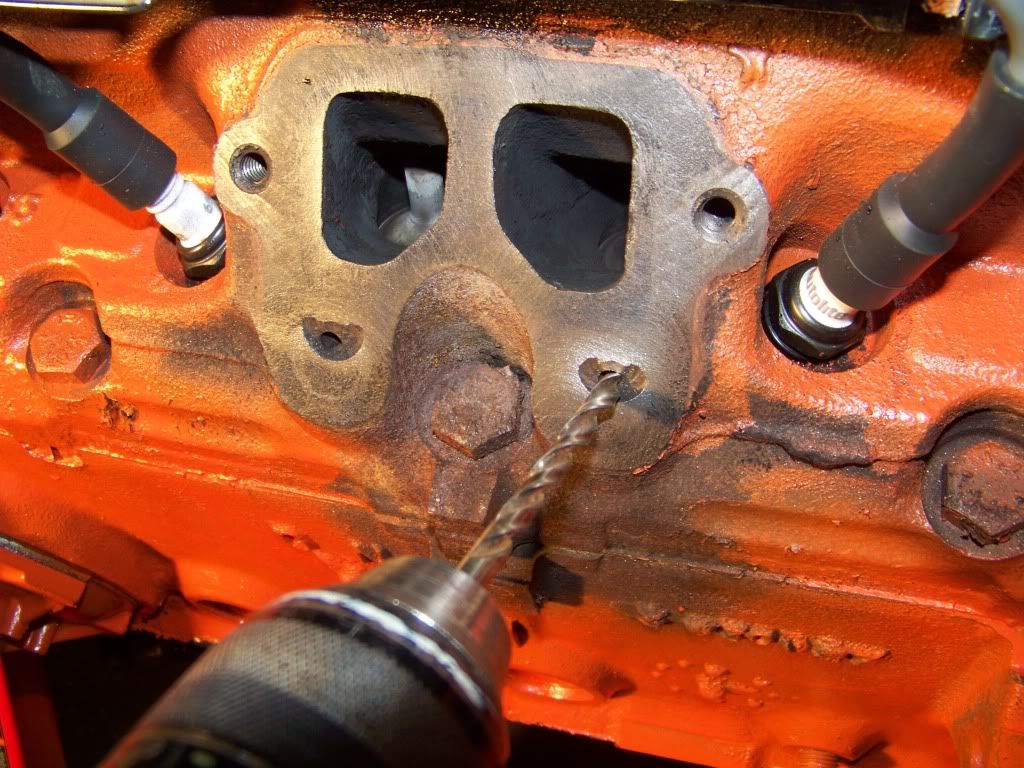

second, i want to put headers on it, and i noticed the heads have these small holes below the ports that were for some sort of smog tubes. do i have to weld these shut, or will the headers cover those?

thanks for any help guys!

i have 318 out of an 86 diplomat that was hooked up to an automatic, but i am going to use my manual tranny. i have heard sometimes the crank isnt machined for the pilot bushing if it was an automatic. mine looks like it is machined for it, but how can i tell for sure? perhaps someone has pics of a machine versus non-machined crank?

second, i want to put headers on it, and i noticed the heads have these small holes below the ports that were for some sort of smog tubes. do i have to weld these shut, or will the headers cover those?

thanks for any help guys!

I checked my crank; seems it IS machined as described above, the hole for the converter is there of course, and then there is a smaller hole much deeper in the crank. I am going to try to get pics of this as well to illustrate for someone in the future

I checked my crank; seems it IS machined as described above, the hole for the converter is there of course, and then there is a smaller hole much deeper in the crank. I am going to try to get pics of this as well to illustrate for someone in the future